Computer Controlled Machining

ASSIGNMENT UPDATE - 25th of May 2015

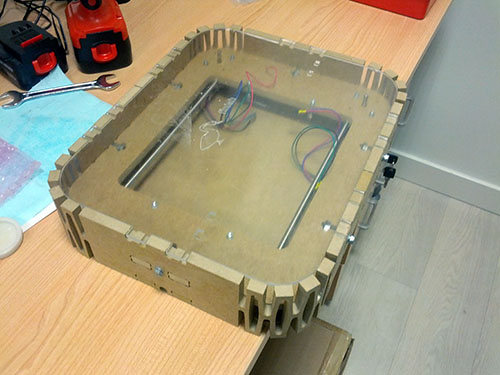

As mentioned in my last update I had to return to the CNC machine to fabricate the box for my final project: the interactive goose game. I have integrated flexures and joints in the design and the result came out beautifully. I have used 10mm MDF and as the image shows the pieces are fitting together just perfectly. So far so good: the project is on the right track and everything is coming together as planned.

As for tooling I have used a 6mm diameter flat end mill using conventional cutting strategy. The cut depth I have lowered to 5mm (less than the end mill diameter) and with the machine default's RPM for the 6mm diameter end mill. As for the profiling strategy I have used all 3 possible strategies (inside, outside and over). For the side of the game I have used the over strategy: the end mill goes on the center of the drawn line. And for the other 3 parts (middle, bottom and X carriage) I have used outside or inside strategy depending which part I needed to "eliminate".

More details can be found in the final project section.

ASSIGNMENT UPDATE - 3d of April 2015

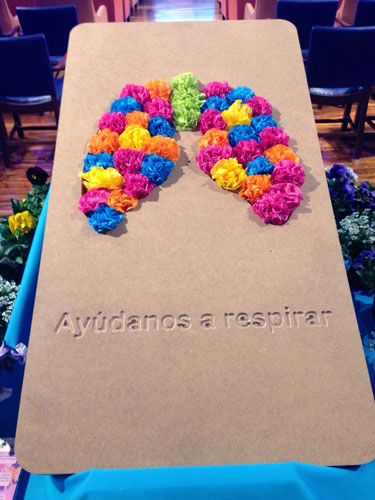

As promised, I will write an update on the poster. Surprisingly the delivered flowers for this project where way off from the expected ones (communication issues). I was expecting small flowers to plant them on the lung shape and the delivered flowers where roses and quite ugly. Because the lack of time I had to improvise and place something on the lung shape. The idea was to have a living poster and lasting for a long time. Following this idea, from colored napkins, I made some flowers and glued them on the poster. The poster came out quite nicely, but wasn't the final product what I had in mind when I started with the project.

For my final project I will have to return to the CNC machine and mill the box of the interactive goose game. I would like to draw this box using living hinges in the corners because of design and functionality point of view, and with that completing the assignment.

ASSIGNMENT - 18th of March 2015

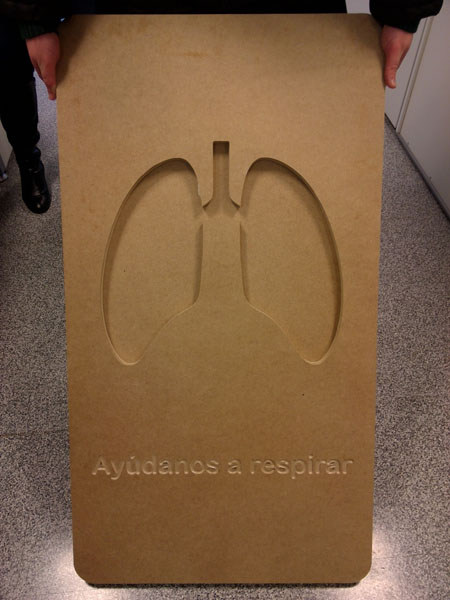

Make something big was this week's assignment. At the University we are having an anti-tobacco event this week and I thought I could make a really nice poster using the fablab resources and all the gained experience. My idea was to design a living poster, to be descriptive enough for the upcoming event and to be big enough for the assignment.

Firstly, I had to find the perfect idea on what I can start with. This idea came from the actual event: no tobacco event. Lungs, smoke, health, pure and flowers where the key words to implement graphically in the poster. From all these words occurred an idea: cut a lung design in couple of MDF sheets, glue them together and in the cavity plant flowers to replicate a healthy lung.

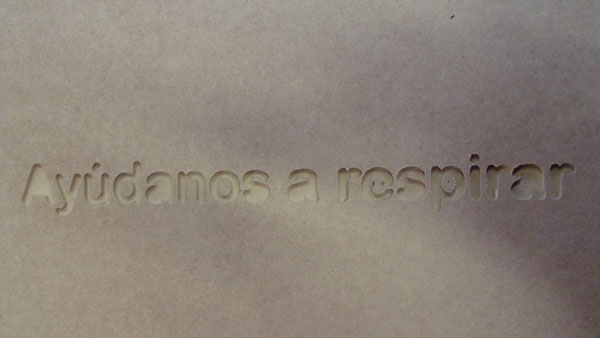

The design was pretty straight forward and easy to realize, but had to be more careful with the added text dimensions. For this, I had to be sure that the end mill diameter would pass nicely between all the letters and won't skip details. I was using a 10 mm MDF sheet and a 6 mm end mill for this project. I have loaded the *.dxf format into the Aspire software, set up the MDF sheet dimensions, the passes, inside and outside cut, medium cut for the letters and generated the *.tap file formats. After all the set up I had 3 files: one for the outside cut, one for the inside cut and one for the letters cut.

After having all the necessary files generated I had to set up the x, y points of the milling machine and define the z depth. Surely, the right end mill had to be fixed correctly before moving the points on the machine. IMPORTANT to remember and to follow: the end mill have to be tightened well in the CNC collet and on the right height. After all this preparation I have launched the file containing the letters and checked if the machine was working accordingly. The milling machine was doing his job quite nicely, respecting the outlines and all the generated lead-in. After finishing and vacuuming the generated chips, I had realized some small imperfections with the text: because of the rotational speed and "small" dimensions the insides of some letters where cut out.

I was confident that I'll be able to find a solution for it and just continued with the cutting, secondly with the lung cut and finally with the board outline. Since I had all the necessary files I only had to move the x, y points to keep going with the project. After moving the x, y points the second cut came out nicely and for the third layer I had to cut out only the outline in a new x, y location. Having the 3 layers of MDF cut out it was time to glue them together.

After the gluing workout I was thinking to place acryl letters on top of the milled holes. Didn't really had any color acryl on hand and decided to cut out transparent letters. Had to modify the letters by 0,1 mm to press-fit inside the holes and not to fall out, but everything went as expected: the letters where fitting perfectly and the poster had an overall outstanding beauty.

The next step would be the flowers, but since the event we have it only on Thursday I decided to plant them on Wednesday and, of course, because I don't have the flowers delivered yet. I will have to make an update next week with the finished poster.

Overall, I had a really cool experience and used all the gained experience to overcome the different emerging issues. Had really fun and learned a lot!