****************************************************************************************************************

ASSIGNMENT: PROPOSE A FINAL PROJECT THAT INTEGRATES THE RANGE OF UNITS COVERED

PROJECT:PHOTOGRAMMETRIC FAB SCANNER

NOTE: FINAL PROJECT HOMPAGE

****************************************************************************************************************

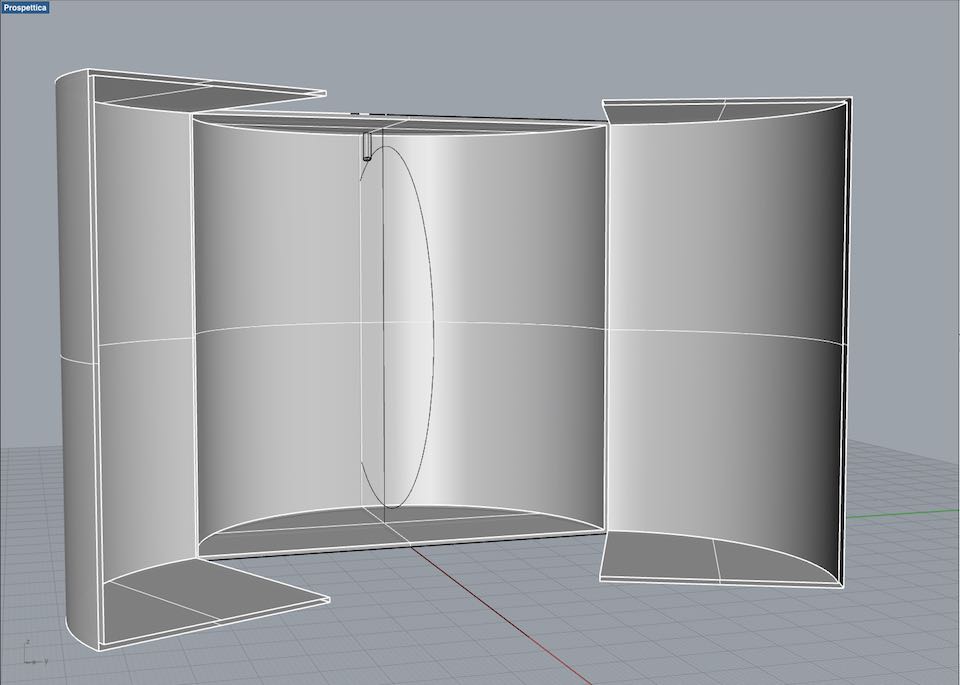

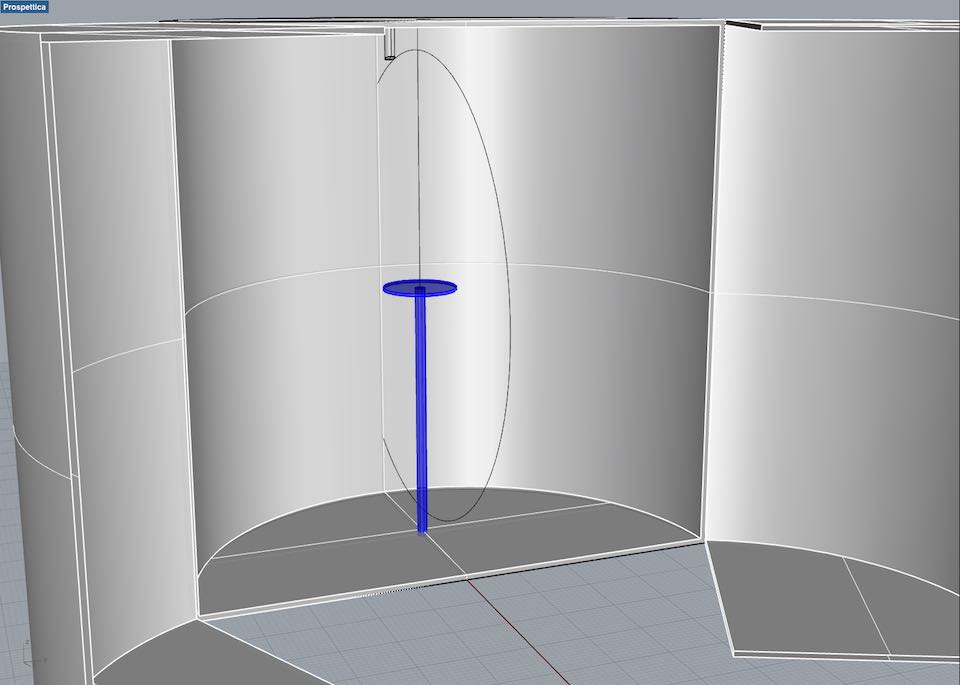

The Photogrammetric Fab-Scanner is a cylindrical box of diameter 50 cm

It consists of 3 different parts that work in a direct relationship:

- A - The Light Box

- B - The Motorized Stepper Dish

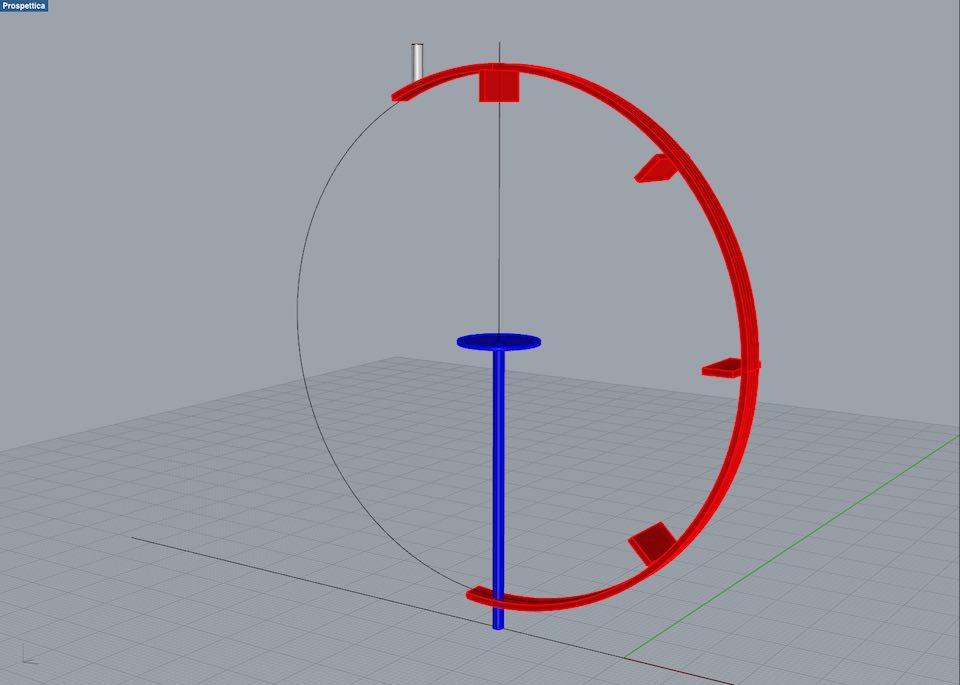

- C - The Motorized Camera Curved Rail

When the box is closed, the process starts: the photographic camera will take a picture every time the dish rotates through a preset angle, until the completion of 360° full circle.

This process will be repeated in 4 different positions (-45°; 0°; +45°; +90°) thanks to the radial movement of the camera on the circular rail.

At the end of the process, we will have an appropriate number of aligned pictures to allow us to create a 3D Photogrammetric Mesh

Until now I have not found an project similar to the one I'm trying to develop.

It’s no secret that I would be really delighted to find something that would have a similar concept for completing the photogrammetric scan process.

A number of really powerful set-ups already exist but they multiply the number cameras and this obviously increases the costs.

What I feel may be useful in my proposal final-project is to use only one camera; combined with the rotation of the object to be scanned, it allows the realization of a series of aligned photos. This automated process drastically reduces the costs of the photogrammetric scan

At this stage of development, there are a number of other issues to be sorted out.

--> What I am certain of is that

- the external structure will be made from 5mm Plywood. And I will probably need:

2 X 1m2 of 5mm plywood for the light box

PRICE: 30 euro

1 X Nema 17 Stepper Motors to move the camera support along the Curved Rail

PRICE: 20 euro

1 X Nema 8 Stepper Motors for the Rotatif Object System Part

PRICE: 20 euro

2 X 1m2 of White LED Strips for illuminating the inside of the box

PRICE: 20 euro

1 X Micro-Controller to control the devices: MODIFIED SATSHAKIT

PRICE: 10 euro

1 X 12V Power Supply Trasformer

PRICE: 20 euro

20 X Ball Bearings for the mobile part of rail, camera and LED support

PRICE: 25 euro

--> What I need to understand is:

* whether the mechanical design of The Motorized Camera Curved Rail will be made in PMMA 5mm

* This choice of the photographic instrument will definitely determine the final cost of the project.

I have identified different possibilities that over the cost, force the type of management of the totality of the system.

It is essential that the photographic instrument satisfies some characteristics:

1 - High resolution of the sensor

2 - Redoubt focal distortion

3 - Possibility of changing the focal distance

4 - Easy alignment of the focal point and the object

* 1st possibility ---> Use a cell phone

This is certainly the most economic solution and would ensure that the project would really be Fab Lab diffused.

A mobile phone is a complete and very powerful tool: the resolution and the quality of the camera is often excellent. The images are recorded on the device, allowing the scanner to operate autonomously from a computer.

* 2nd possibility ---> Use Raspberry pi + Camera Module

(cost : 35euro Rasberry pi + Camera Module 20 euro + 6 euro micro sd card -->TOT: 61 euro)

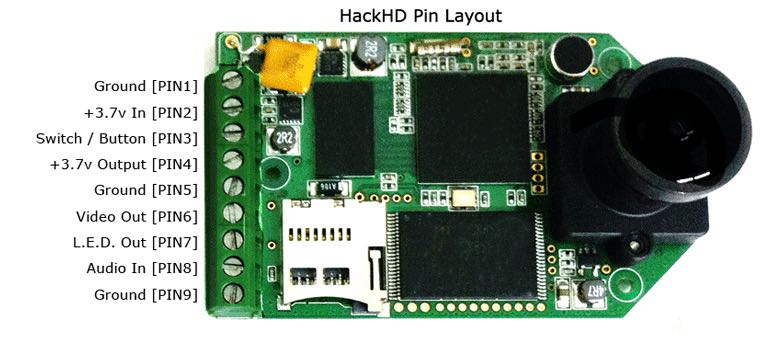

* 3rd possibility ---> HACKHD CAMERA

( 164 euro + micro sd card 6 euro --> TOT: 170 euro)

The idea is to use components and materials that are easily sourced easy to find. Wood and Plexiglas can be purchased from local stores (Italy - Milan). Electronic components can be bought on the Internet in an attempt to purchase them at more competitive prices. Every component can be sourced from local specialized retailers.

The cost depends on the option of development selected.

For the construction, I will try to use the possibilities offered by a Fab Lab

- The box and the structural support --> CNC Milling Machine

- The curved rail system portion and elements of the gear system--> Laser Cutter Machine

- The rotating support dish and engine gears support --> 3D Print Machine