Stage 1

ECG

My final project will collect data from different sensors and will show

the data on a special suit. These are the main features:

1.- All the data will be captured by Arduino sensors.

2.- The data will be: Heart Rate, Body temperature, Stress (measured

by heart rate variability), speed, Anaerobic threshold, Sweet, and so on.

3.- All these data will have a color code and the suit will change

the color because of the data acquired.

With this suit, you will see how the t-shirt change its color due

to hear rate, or how fast your friend ski.

After some electronic assignments and check the time it take in each,

now I realize that my project can not be carried out in few weeks. For

that reason I decided o simplify it.

Here it is my project updated:

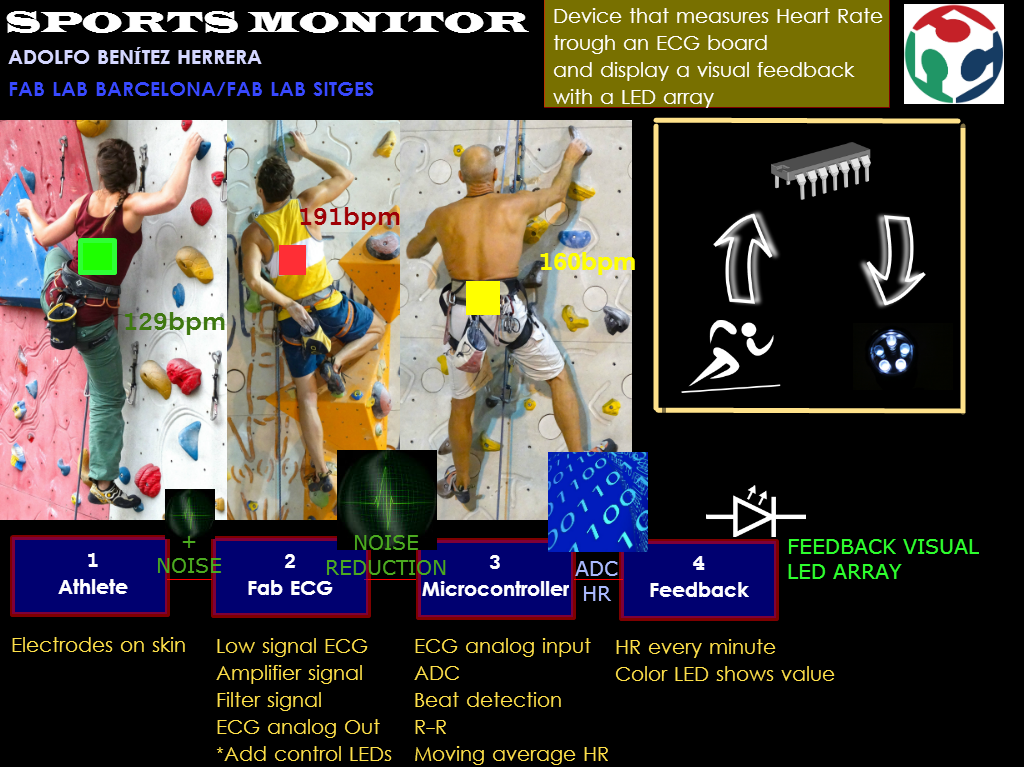

This is the new proposal. Just one measurement and just one visual feedback. Here it is the presentation.png, scroll down for further information.

What will it do?

It's a weareable that could be attached on any t-shirt or cap. It will

collect the values of Heart Rate (HR) and change the color of an LED array

by value.

Who's done what beforehand?

There are three main part in my project:

1 Data acquisition

2 Data processing

3 Data Visual feedback

Let's talk one by one:

1 Data acquisition.

After some internet research and many DIY proposals, I decided to start

from Adam Marblestone FabECG. I think his work is easy to undestand

because is well documented.

At the moment of write this, I see some important changes that need to

be done: First the three low pass filters. I seems to be designed for 60Hz

US electrical power noise. Second some feedback LED. And third, a battery

suply.

In this stage, it will be acquired a 1mV ECG signal with electrical noise

and it will be sent a 1V ECG with noise reduction.

2 Data processing.

At this stage, I need to detect Heart Rate (HR) from 1V ECG signal. For

this purpose, I will introduce a microcontroller into the FabECG that do

the analog to digital convertion and detect the HR.

Many options to detect HR from an ECG: Voltage threshold, Fourier Transform,

correlation with the essential ECG graph, wave lets, and so on... Voltage

threshold seems to be the easy one, but any electrical noise or ectopic

beat could send an error. About Fourier Transform, I would use Fast Fourier

Transform (FFT) that is an algorithm to compute the Discrete Fourier Transform

(DFT). DFT converts a finite list os equally spaced samples in time domain

function to a finite list of coefficients combination of complex sinoids

in frequency domain. FFT option seems to be better, but we will see if

it's possible to compute it in few days.

I have found some nice tutorials about FFT and attiny:

http://shin-ajaran.blogspot.sg/

http://www.arduinoos.com/2010/10/fast-fourier-transform-fft-cont-6/

In order to avoid aliasing, it's needed to apply the Nyquist-Shannon sampling

theorem, that set the minimun sample rate which permits a discrete sequence

of samples to capture all the information from a continuous time signal

of finite bandwith (it means that no actual information is lost in the

sampling process). At arduinoos part 6 there are some important advices.

3 Data Visual Feedback

The visual feedback have to be easy to see and understand, so an LED array

with 3 colors could be a very nice option. In order to keep it simply,

I would do it with Carlieplexing method, that allow to manage several LED

with few microcontroller pins. The ecuation between pins and LEDs is:

L leds can be driven by=(1+sqr(1+4L))/2

So 4 pins can drive12 LEDs and 5 pins can drive 20 LEDs.

What materials and components will be required?

Let's talk one by one

1 Data acquisition

(First process iteration). I will order an digital potentiometer to try

autoadjustment second amplifier.

2 Data processing

3 Data Visual feedback

4 Connections

5 Packaging

Where will they come from?

The electronic stuff from digikey

Vinyl and Methacrylate from local distributors

Other stuff from corner shops

How much will it cost?

Between 30 and 40 €

What parts and systems will be made?

All the electronics and packaging. The electrodes, battery cage will be used commercial ones.

What processes will be used?

3 iterations. First iteration will be do everything as simple as possible, compying all that parts that already works. Second iterations will be change one by one those parts that could be improved. Third iteration will be redisign everything to set the final version of all parts.

What tasks need to be completed?

Redisign the FabECG in order to: 1st, change de cutout frequency to avoid

50Hz eurpean power energy (instead of 60Hz american one). 2nd, do a autoadjustable

potentiometer.

Redisign the array LED to set 6 row leds driven by 5 pins

Recode the charlieplexing code to manage the LED array

Code o adapt code for a FFT of ECG signal, in order to detect the Heart

Rate

Design the package

Design how to attach it to a athlete.

What questions need to be answered?

Is possible to do a FFT with 8 bits microcontroller (ATtiny44)?

What is the schedule?

Hopefully 1 iteration per week.

How will it be evaluated?

Detect the Heart Beat or the Heart Rate, is the main point. If is possible

to do it, is possible to finish the project.

Other parts, seem to be able to resolve.

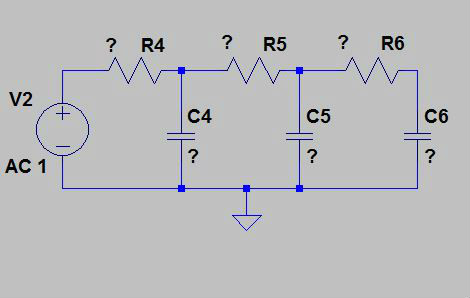

Removing 60Hz noise

Nowadays, coexist two configurations of voltage and frequency worldwide

to transmit the electric power:

230V with 50Hz and 110 V with 60Hz. There is no technical reason

to prefer one over the other.

At US is used 110V and 60Hz configuration, at Europe is used 230V

with 50Hz configuration.

Now, if you read the Fab ECG tutorial, it has a bank of three low-pass

filters after amplification to remove additional 60Hz noise. In Europe,

the electric power noise is at 50Hz, so I decided to recalculate the bank

of three low pass filter to remove that noise.

One RC low pass filter configuration is a passive filter with cutoff frequency

fc = 1 / ( 2piRC ) . If multiple filters are chained much more selective

filter is achieved.

We can see a simulation of these bank of Low Pass Filters in the next

picture. We can see that:

- Between 50Hz and 60Hz there are -2.5dB.

- At 60Hz there are -26.12dB and at 50Hz there are -26.1dB.

So, I will redesign the filter to obtain -26dB at 50Hz.

In order to make a Low Pass Filter, we can use any pair RC values they

meet the equation:

fc=1/(2piRC)

Where:

fc: Cutoff frequency

R: Resistor value

C: Capacitor value

Considerations:

1.- The cutoff frequency (fc) occurs at resonance circuit RC , or what

is the same, the values of resistance (R) and capacitive (Xc) reactance

are equal.

R=Xc

And Xc=1/(2pifC), Xc value depends on frequency.

2.- Capacitor should not be polarized or high value, as they often have

higher internal losses and tolerances capacity that subsequently result

in a lack of accuracy during operation. For this reason, capacitors are

typically used by the nanofarad between 1nF and 680nF have a fairly wide

selection margin . Note that these filters often work in low frequency

between 20Hz and 20KHz.

Non- electrolytic capacitors have better performance in high frequency

than electrolytic capacitors.

3.- To minimal electrical losses, the output impedance of the signal should

be insinificant in comparison to the imput impedance (voltage bridging).

Zin>>Zout. So we need to know the Zin of next stage to be accurate.

That's because we could work in two situations:

a) We wish to to transfer maximum power and minimize power

losses by reflections from the load, if both sides are linear we

have to match impedance: Zin=Zout. (No, this is not our case)

b) We wish to transfer maximum voltage, instead of power,

then Zin>>Zout. (Yes, this is our case!)

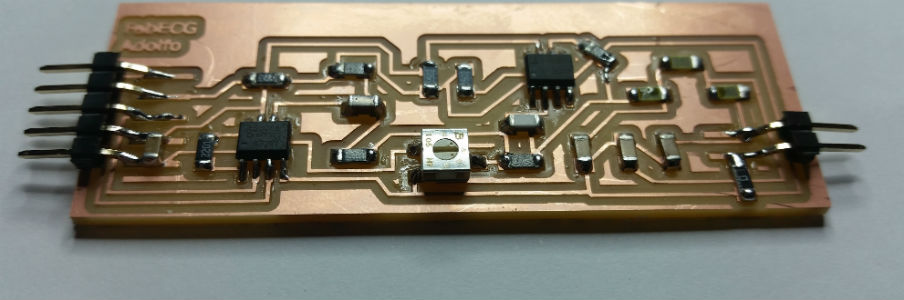

Charles Fracchia and Adam Marblestone FabECG Week4 Fab Academy 2012

Charles Fracchia and Adam H Marblestone, have made an Open Source ECG

as a part of a collaborative effort between MIT and Harvard Medical School.

I have followed the tutorial of Adam Marblestone week5.

First I got all the documents:

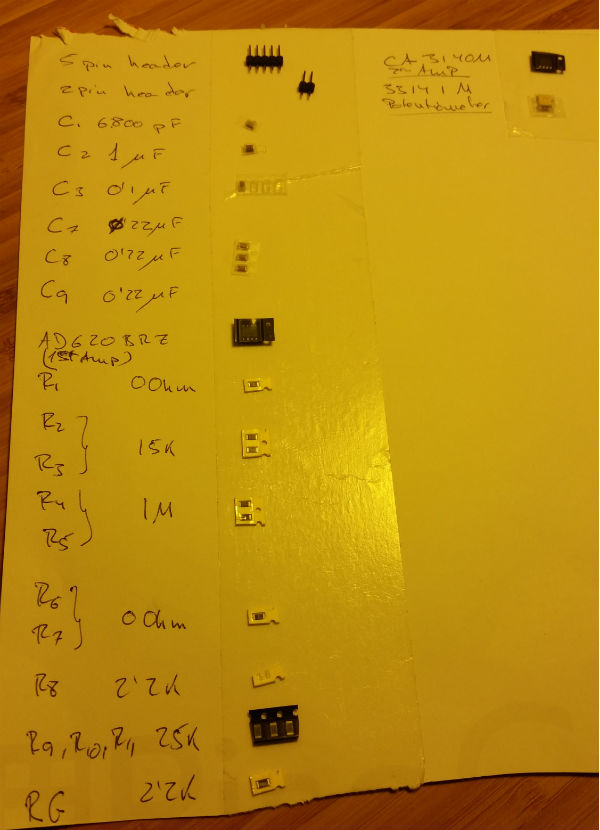

Components List

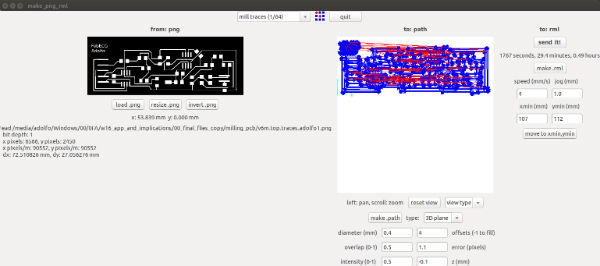

To see how to use Modela and Fab Modules, visit my

week4 Electronic production.

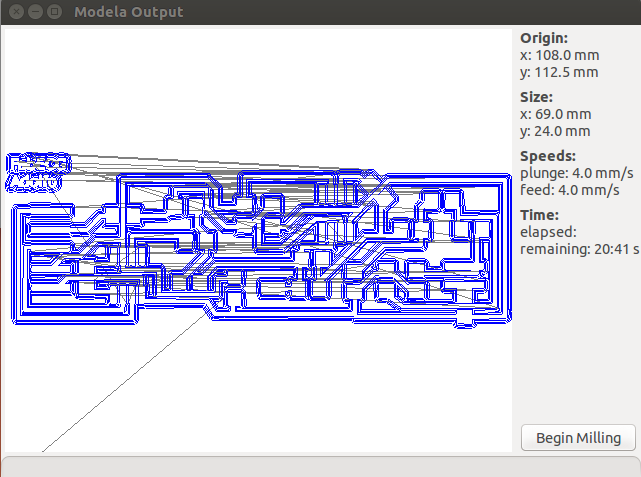

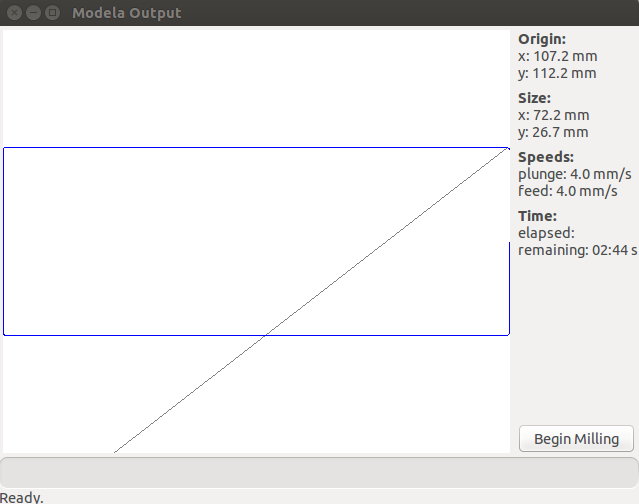

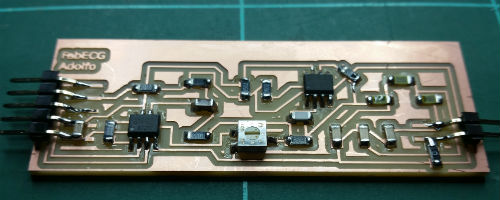

20mins 41 seconds for milling the PCB traces and less than 3 min to cut

out it.

After milling, still in the modella.

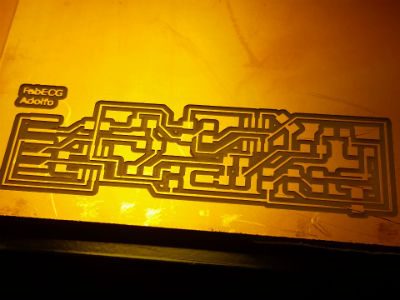

This is the second try, the first try there were many traces not

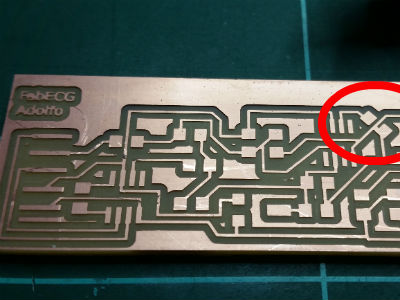

milled, probably because the board wasn't flat enough.

I checked all traces and I discovered two traces not well milled. It have

to be repaired with a cutter. Let's do it!

This is the microscope view after reparing the traces. It seems to be

ok, now.

I'm used to make a list of all components in a piece of paper and with

double side tape, attach all components prior to start soldering.

This is a good trick from Ferdi (BCN Fab Lab at 2015)

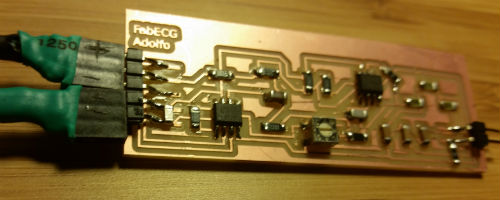

This is the final PCB soldered with all components on it. It looks nice...

There are many connections to do:

Clips for the electrodes (I will use commercial electrodes because according

to Neil, could be a nightmare project if I try to make my own electrodes.

ECG signal is 1mV signal, so any noise on electrodes will cover the signal.)

Cable electrodes to FabECG.

Connections to FabECG.

Battery case. I will supply with 5v battery case.

The Electrodes will need a female header for connect with FabECG

After solder the 3 pin connectios, seems to be too close to each others.

So I will cover the central pin to avoid short circuits

A little piece of plastic tube to cover the central connection

To make a protection for the central pin I have used:

Tools:

Plier

Hair dryer (electronics especific)

Tweezers

Material:

Plastic tube

I opened the plastic tube, cover the central pin, and finally hot air

from the hair dryer to adjust the plastic connector.

This is a commercial electrode for ECG. I got many of them from many different

brands.

All of them have a "clip" connection. So, next step is to make a clip

connection between electrodes and FabECG.

From a corner shop, I got some clothes clip and solder them to the electrodes

cable.

To adjust the clip to the electrode, a little piece of metal have to be

free in order to make the "clip" action. Many times, when I used tin to

solder, it solder this piece of metal, doing impossible to do the "clip"

action.

I had to make several attempts in each clip until welding wire firmly

and free clip.

FabECG connected to battery case cable and electrodes cable

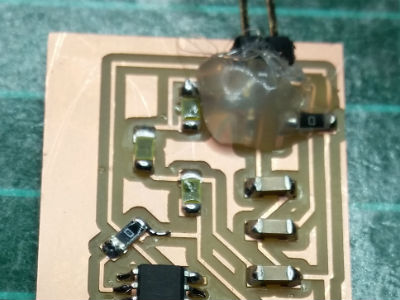

After some test, the FabECG has need some reparations on headers. That's

because the FabECG it will be portable and those connections are not prepared

for movement.

Yes, I know... You don't need to say to me.

It's a shame!. It was very nice the FabECG before putting silicone,

but I need further testing without having to continually repairing.

It doesn't work yet... may be is the moisture of human sking under my t-shirt?? Mmm, may be.

Yesssssssssss,... It's getting worse, isn't it?. Why that? Well,

I decided to destroy the nice image of my old "nice FabECG" because is

in continuous contact with human skin and may be this make some unwanted

connections. Hopefully, my final project will have a better case look.

Lol!

Adolfo is alive, it works!