Week 8: Computer controlled machining

For me, this week was very important in view of the final project. I realized in fact the four hexagons that make up my Hubdesk. I used the files modeled with Solidworks that have a peculiarity, they are double-side. Hubdesk 3D file

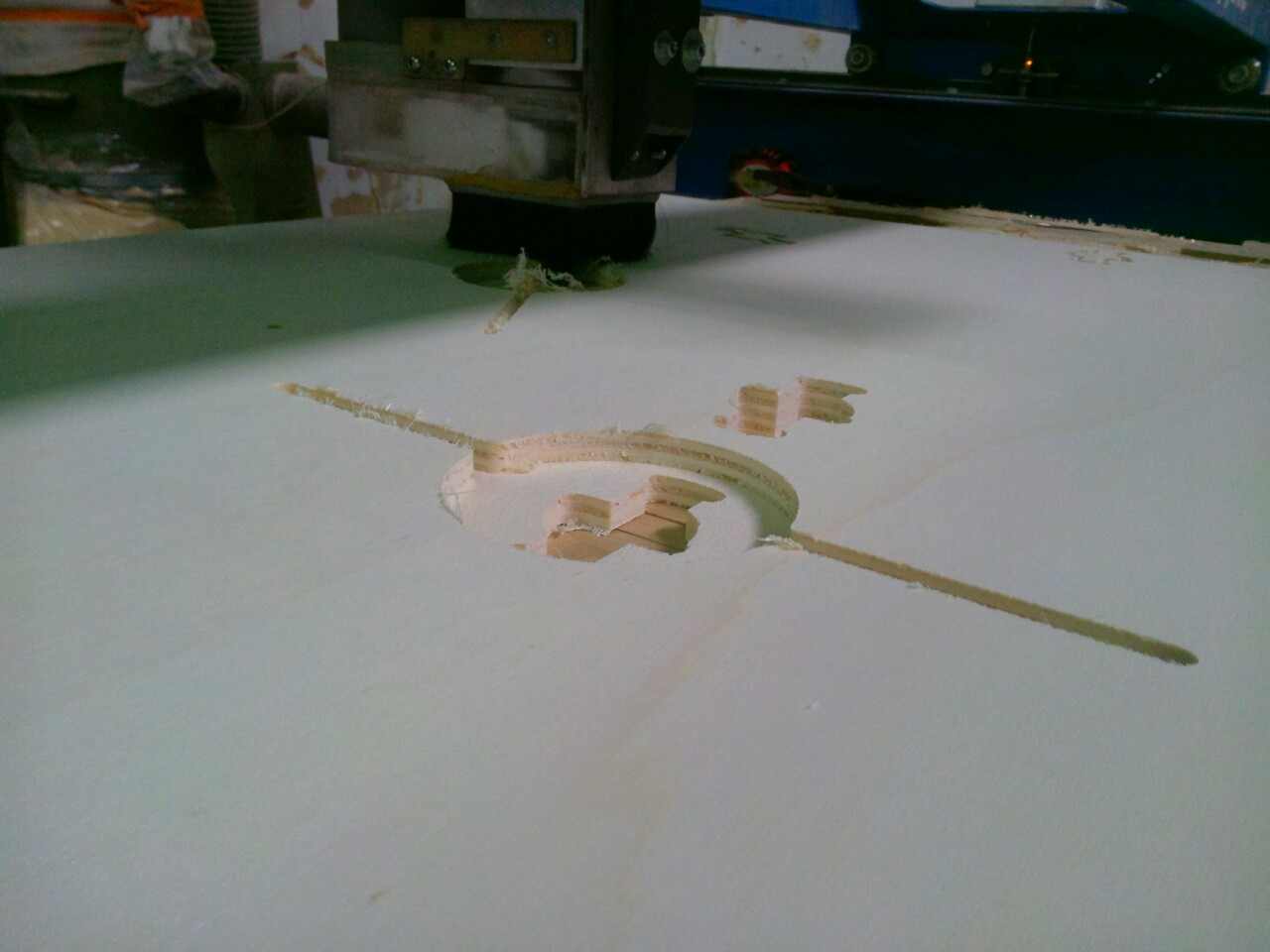

I use the Mech Mate for mill my panel and choosed an economic 20mm poplar plywood, cutted with a 6mm upcut 1 flute end mill tool with a speed of 3600mm/min and 7mm depht of cut.

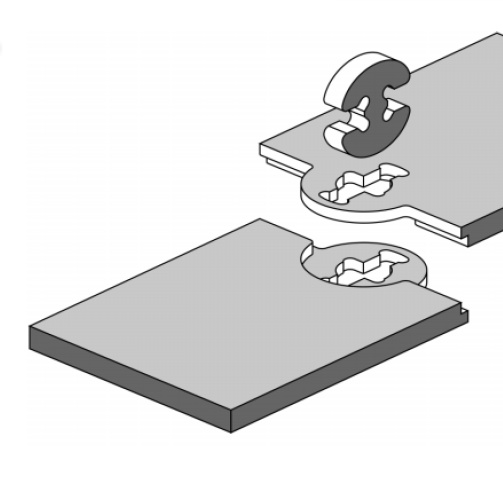

The closure system of the hexagons using a double face method where one side cutting arrives at a depth of 1 cm, while from the opposite side 2 cm, alternating of hole in hole thus creating a system of joints staggered.

To do this operation I had, with the help of Sergio, going to take the zero fix the panel at certain points to the wooden base of the Mach Mate with screws for the first milling. The second step was to flip the wood panel and screw it in precisely the same point in order to be precise to the maximum and not lose the zero point.

By the same panel of wood I also obtained all the keys of wood that I need to join the hexagons.

Saving costs !