Week 14: Mechanical Design Machine Design

In the week of the mechanical design we have created a group project. Me and our team we decided to build a hot wire cutter. We split the tasks to speed up the realization of the project Alessandro and Sergio took care of the programming part of the machine. I and Tommaso instead we took care of part of design and realization of the structure. Tommaso has design the files to cut with the Solidworks program while I was in charge of the cutting and assembly of the machine. We used plywood as material for the structure, easily available in Rome and much cheaper than the cardboard.

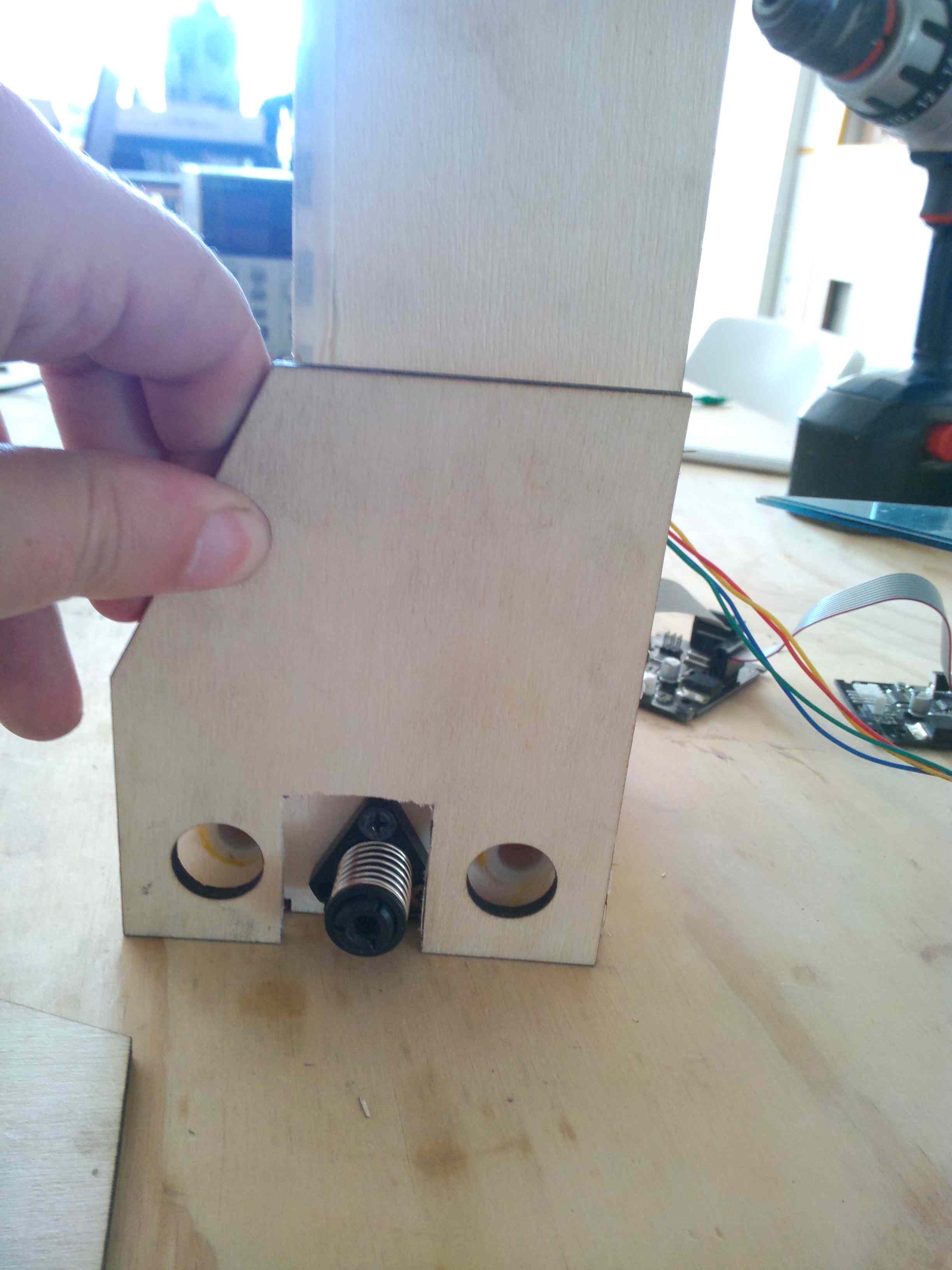

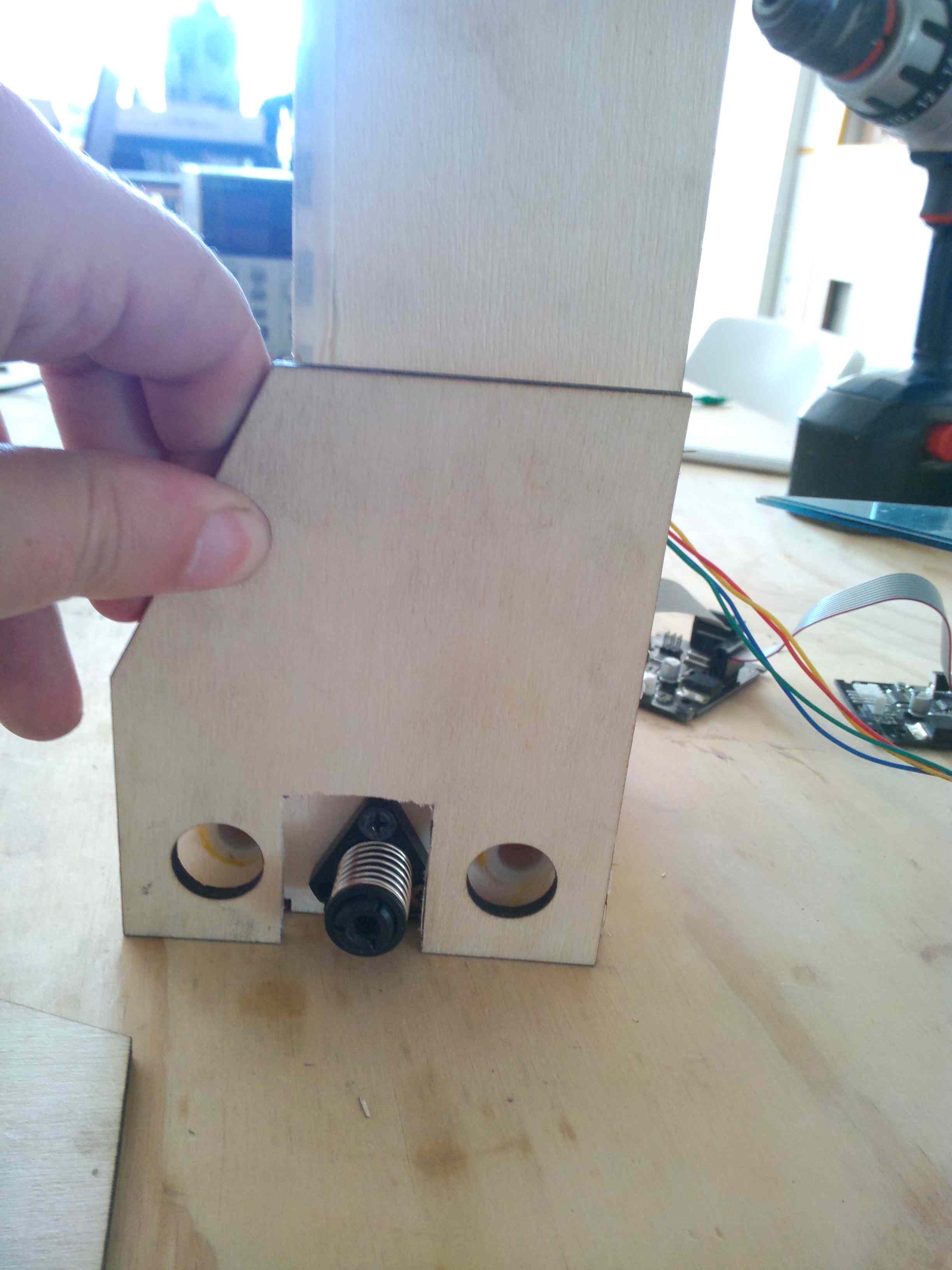

We used the columns for both the two vertical axes and are for the two axes horizontal. Inside the columns there were two bars with a diameter of 20 mm which functioned as rails to slide engines and threaded screw that moved axes.

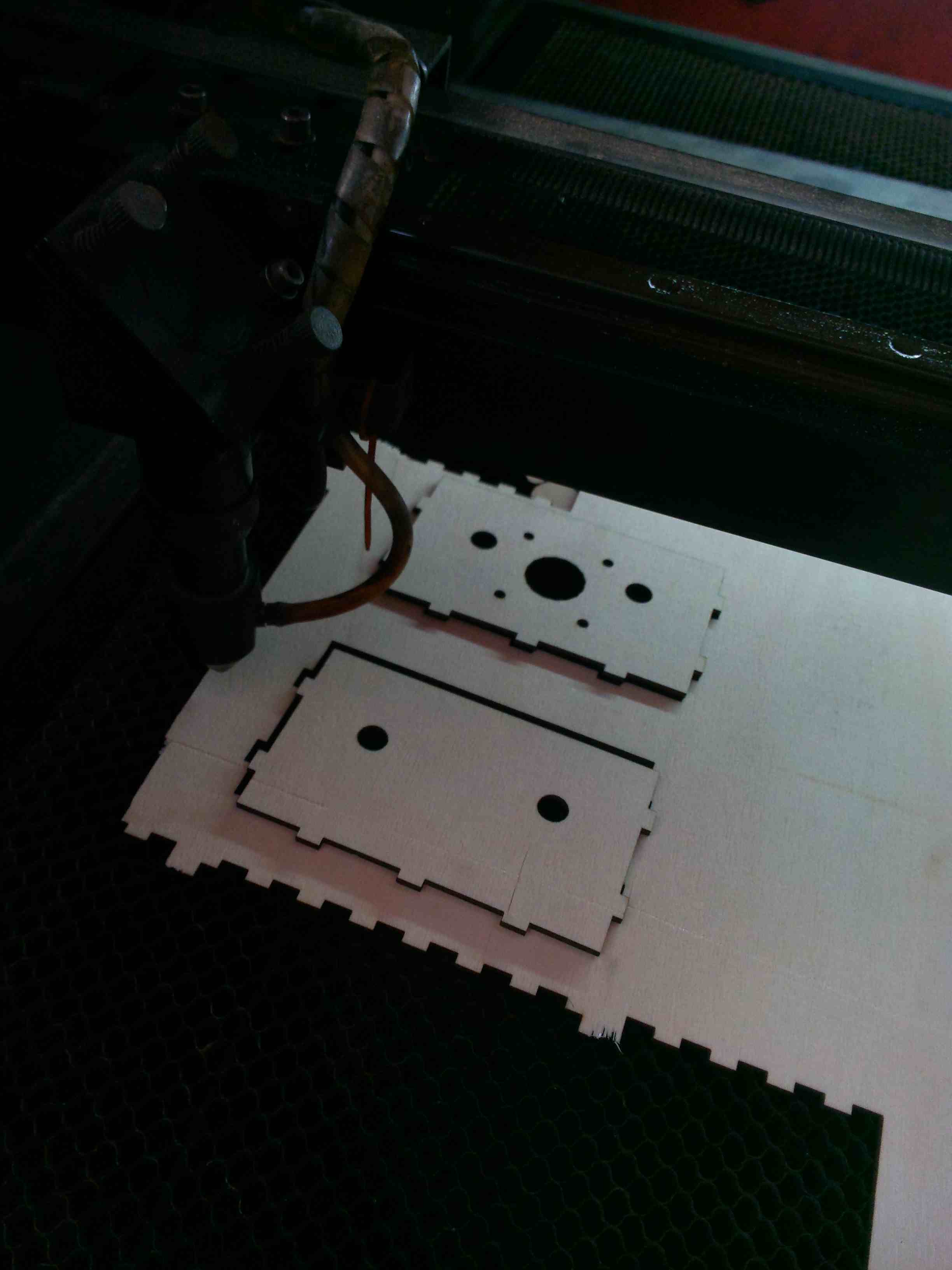

The settings for cutting our laser cut were power 70 speed 10.

We also used several panels waste of Fablab.

Obviously everything was not perfect and I had to resort to eletric hacksaw in some cases. For axis bases we forgot to make two holes for the engines :)

The final work was really great, i also retrieved the wire nickel chrome to cut your car polystyrene as butter.

This is the video of the machine at work! Wow!!