Assignment Week16

Mechanical Design, Machine Design

This week’s assignment is group assignment.

" make a machine, including the end effector

build the passive parts and operate it manually

document the group project and your individual contribution”.

In FAB LAB HAMAMATSU, I'm only student.

So, I try most task of this assignment.

But, my instructor TAKE has helped me a little tasks.

What we make?

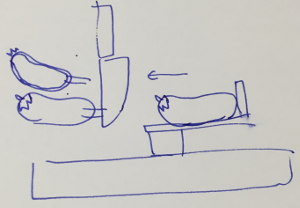

We decided to make vegetable cut machine.

We were inspired from "firewood chopping machine".

This is my lab's machine. Very interesting!

So I sketched the Rough picture.

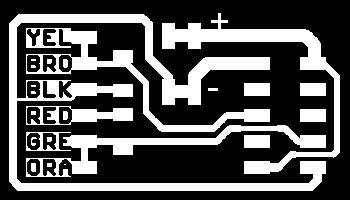

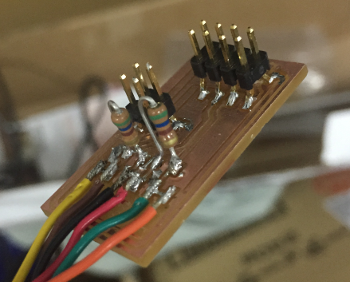

Making Fabnet PCB

First we made Fabnet PCB.

It is used for communicate between PC and Gestalt note.

I selected board data. I choice Bas's design.

But we didn't have 600 ohm resisters.

So TAKE made this board using 560 ohm lead resistance.

Next, I connect PC, Fabnet PCB, one Gestalt nodes, and AVR ISPMk-2.

Start Fuse setting of ATMEGA328 that is on Gestalt note. Following this tutorial.

Download Gestalt library from GitHub.

Unzip this file, move to it's folder and type "make program-avrisp2-fuses" and "make program-avrisp2" in terminal.

Fuse setup has done.

pyGestalt

Next, setup pyGestalt following this tutorial.I had olready setuped FTDI driver. So only check my USB serial adress.

And execute python code"single-node.py"

...But This program can't find my Gestalt node. Appeared communication errer.

I did't understand why is it happened.

Then I try to execute using Python Launcher using GUI and right-crick menu. So Connection is success.

I think, because of errer is Python version of my PC is old or new.

wxGestalt

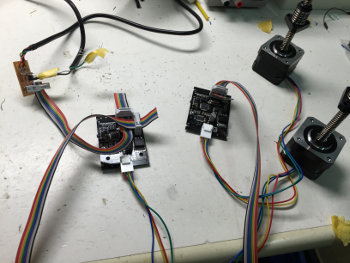

I connected PC and two Gestalt nodes and two stepper motors.And, try to install wxGestalt following this tutorial.

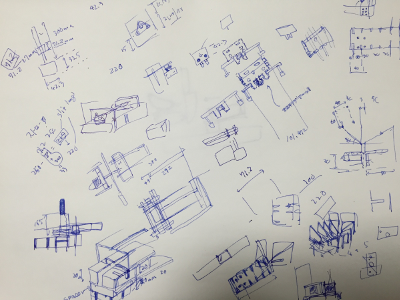

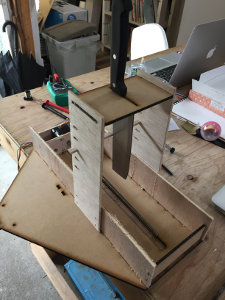

Mechanical Design

I want to make it using Lasr cutter.

So, I used DraftSight, and send dxf data to PC for manipulating Laser cutter.

Mechanical parts data is here.

But, we had hace the problem. Laser cutter was broken. Mirror part was melted.OMG!!

I re-layout design data for CNC and T4-plywood board. Size is 1820 x 920.

Milling!!

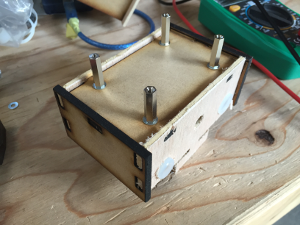

Construct and DEMO

At last, I constructed milled parts.

I bought two knives, and setting with it.

DEMO

wxGestalt movement program is here.

This code is changed move distance of 2 axis case from sample code.

This assignment is introduced in FABLAB HAMAMATSU's Fab Academy website