- Logged in as: fablabtaipei (fablabtaipei)

- Recent changes

- Media Manager

- Sitemap

- Admin

- User page

- Update Profile

- Logout

User Tools

- Logged in as: fablabtaipei (fablabtaipei)

- Admin

- User page

- Update Profile

- Logout

Site Tools

Table of Contents

Composites

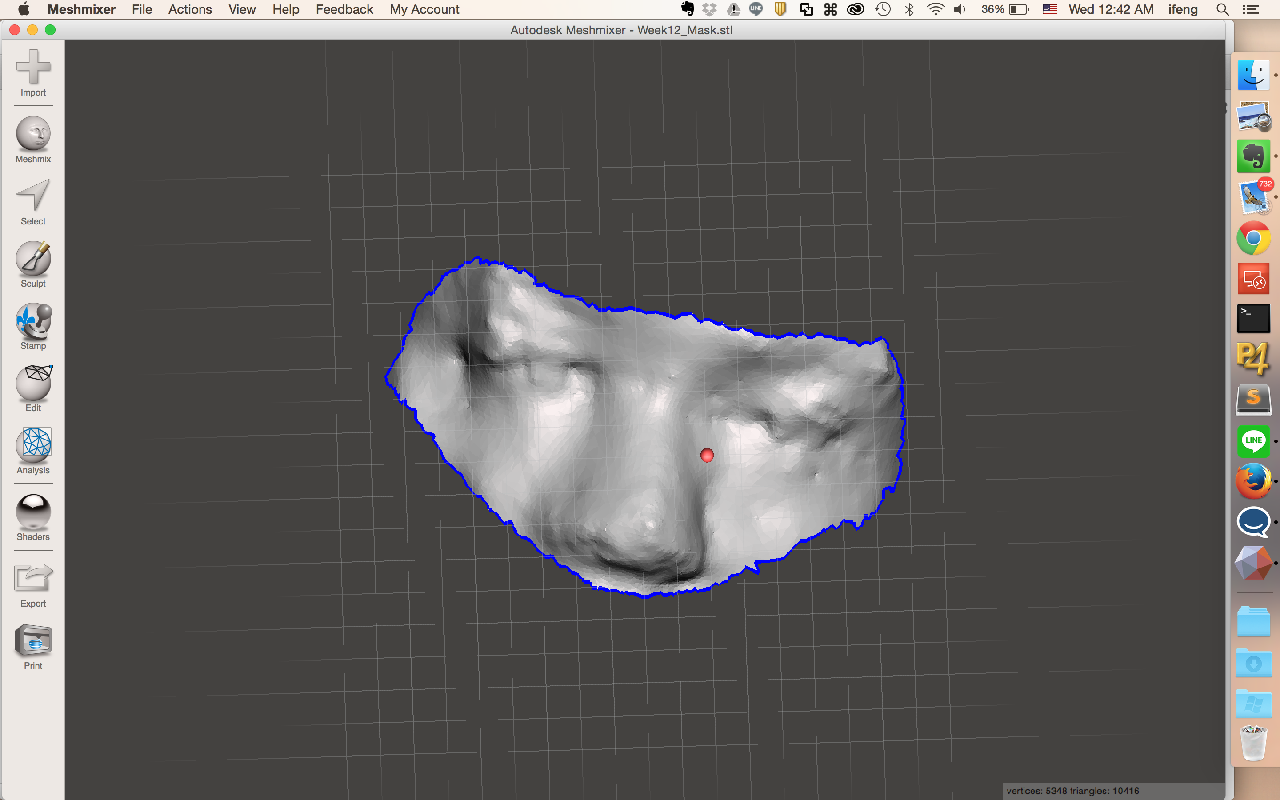

Model

At first I planned to make a mask and therefore I made a model with 123D Catch. Then I processed it with MeshMixer.

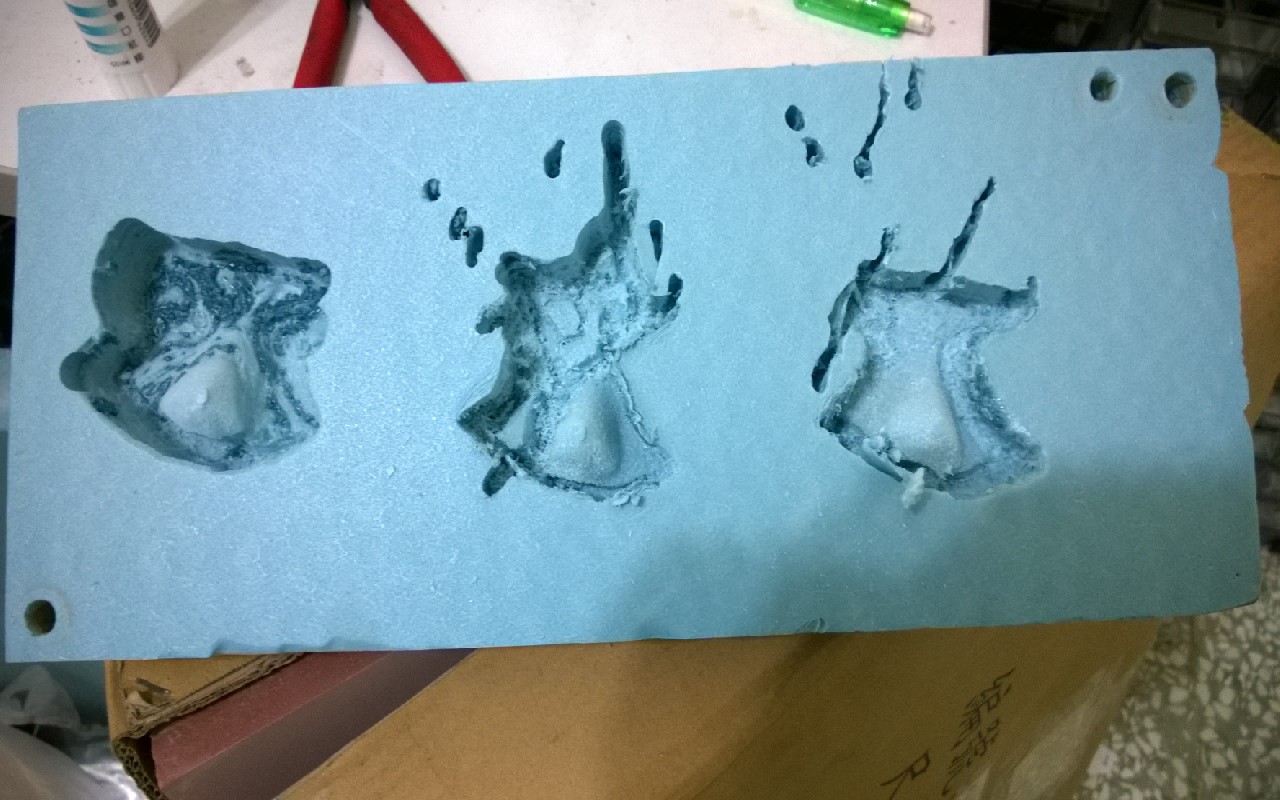

During production, however, CNC did not work well with my model. The material I used was Polystyrene. Since a mask was small, I used attached a slight piece of it onto CNC and fixed it with screws. Polystyrene was very fragile and the piece was too small. Therefore the screws failed to fix it at sever shaking made by spinning blade. I tried three times and all failed.

You may download the stl model file: mask.stl, and the processed file mask.mix

I turned to bigger stuff ( and more applicable with composites) and decided to make a shield for my robot in Project Proposal. I used cupboard to make a cylinder. I put three spheres of wood which were byproducts in Computer-Controlled Cutting week (fortunately I kept them.) and they were meant to be the perfect size for the outfit of the robot.

You may download the dxf file: week8_circle.dxf

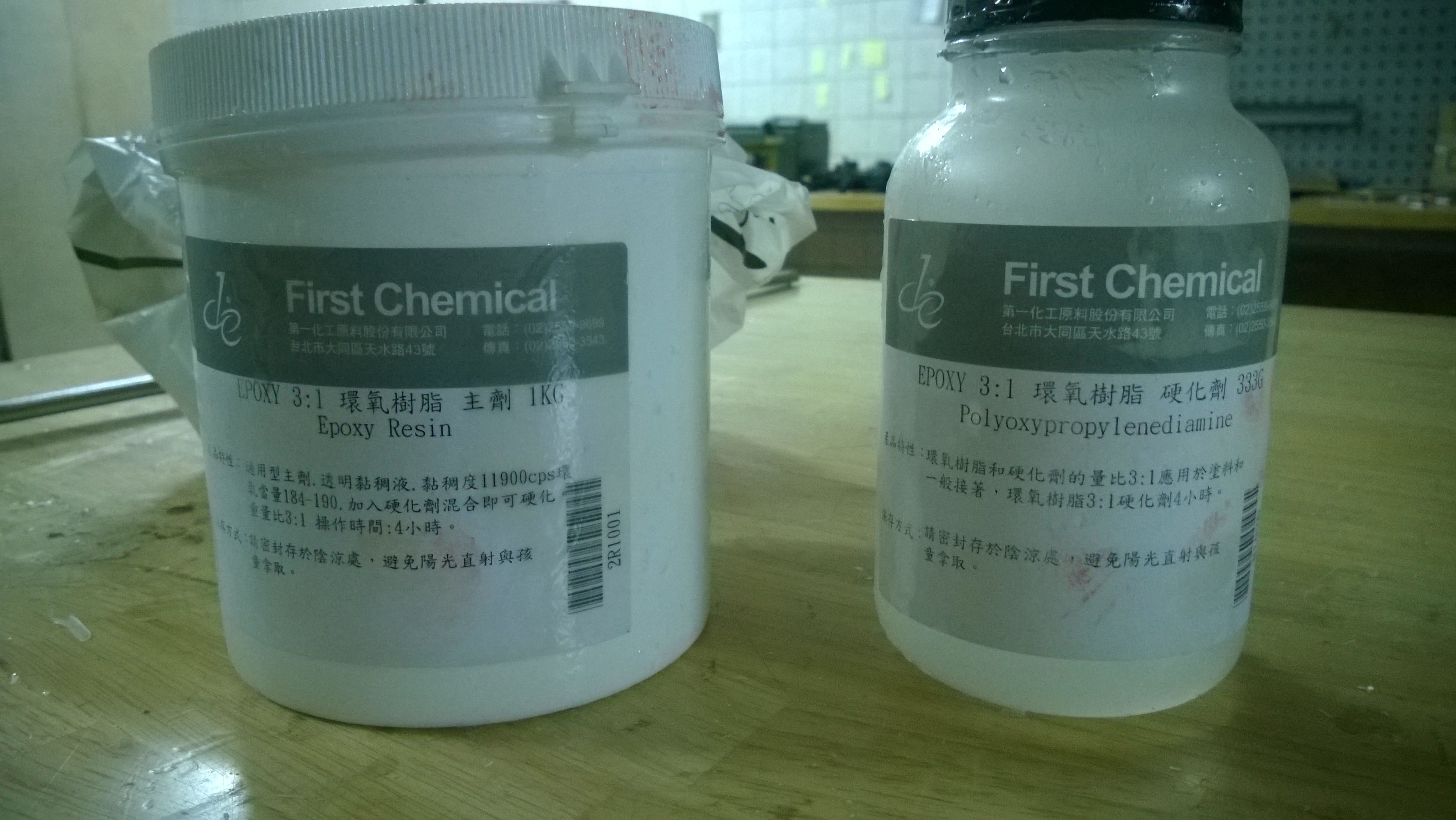

Resin

This was an exhausting job. I mixed the liquids (proportion 1:3) and stirred them hard. I used roughly 130g in total. Then I put many layers of net onto the cylinder and spread the resin onto it. It did not seem easy to make a full cylinder at one time and therefore I decided to make a surface of half cylinder instead. It was a mess in the end. Fortunately I wear gloves and mask for safety (it's a must.)

This was an exhausting job. I mixed the liquids (proportion 1:3) and stirred them hard. I used roughly 130g in total. Then I put many layers of net onto the cylinder and spread the resin onto it. It did not seem easy to make a full cylinder at one time and therefore I decided to make a surface of half cylinder instead. It was a mess in the end. Fortunately I wear gloves and mask for safety (it's a must.)

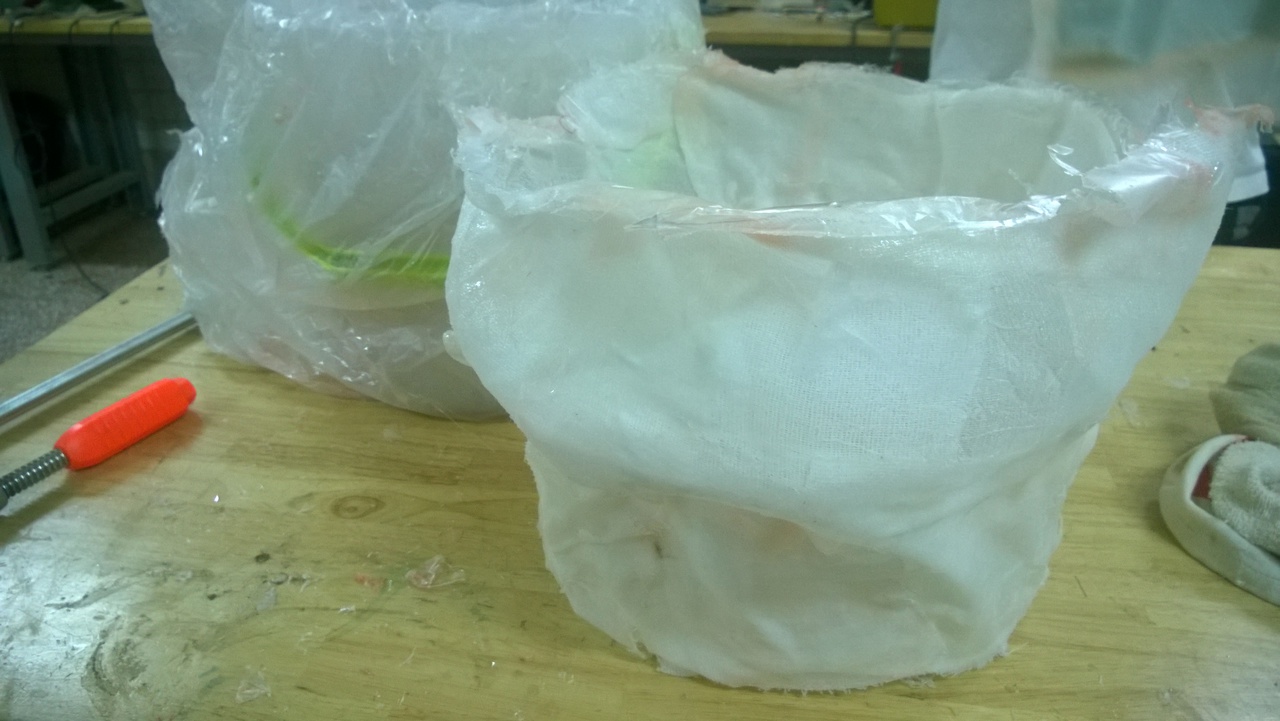

Vacuum

Then I put it into a vacuum bag and vacuumed it. The pressure made by vacuum was too strong and the cylinder collapsed!! It seemed meant to happen because I only put three cylinders in the tube even without fixing them. It was too late to modify the design so I just went with it.

Unpacking

This is what I got. I needed a knife to do it.

What to improve

There are a few fatal mistakes that made my work not what I expected:

- When doing CNC, always fix the material as secure as possible.

- Make the cylinder solid, not hollow. Another approach is to use the insider of the cylinder. Press the material onto inner surface of the cylinder with air pressure.

- When vacuuming, Don't put the sponge on the material you want; put it on somewhere you don't need.

Second Trial

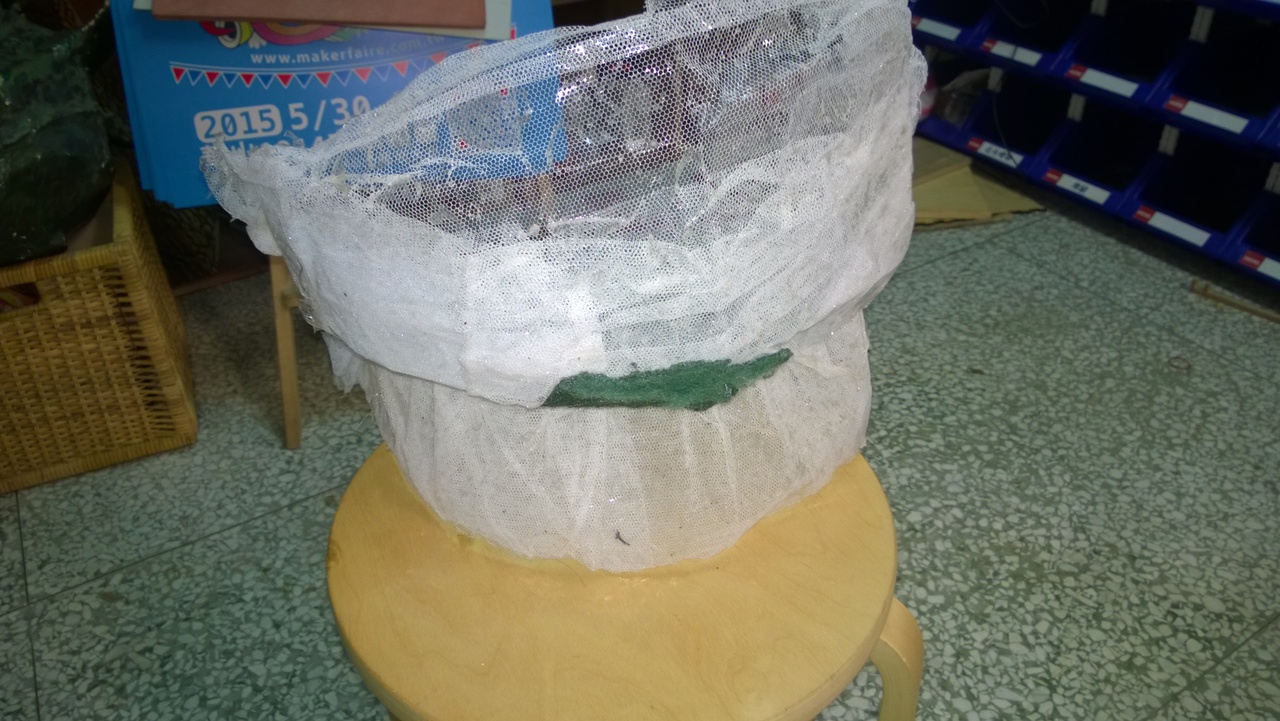

I decided that to make a second attempt. This time I used a solid wanter tank as my model. Also I used more rasem (about 270g). Because the pieces were well attached, I did not use a vacuum bag this time and just put in on the ground for one night.

I checked my result the next day and the result was not bad. It was rough and craggy but very hard. The layers of clothes created beauty of randomness.

I checked my result the next day and the result was not bad. It was rough and craggy but very hard. The layers of clothes created beauty of randomness.