The brief for this weeks

assignment was to design something small that would be

difficult to machine any other way (using subtractive

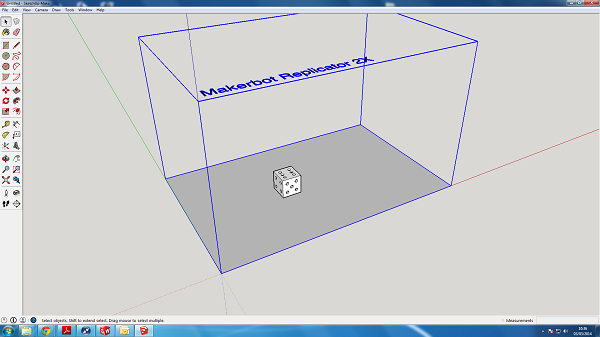

manufacturing methods) that can be 3D printed. I chose to do a

simple design of a dice using Google Sketch-Up. I have been 3D

modelling for many years now and I am trained in Catia and

Solidworks but this was a nice way of making a commonly

recognisable part using freeware software.

The design itself (although simple) does use many of the

common design features that Sketch-Up offers including

push-pull, dimensioning, creating pattern features, scaling,

and accurate positioning using guides. I have used this

exercise in the past with inexperienced 3D modellers and it is

a good way to get to grips with the way that Sketch-up works,

and how to use shortcuts to model efficiently. In short there

are many different ways that you can arrive at a resultant

object using 3D modelling, and some are more efficient than

others. The key is to experiment and learn the best practice

for modelling objects. When considering best practice it is

often necessary to use a more advanced program that has

hierarchical and parametric deign capabilities that Sketch-Up

does not have but for this exercise Sketch-up worked very

well.

Here is the model I created.

Although it would be possible to machine this part from a

block it would require either a multi-axis machine to be able

to complete the part in 1/2 toolpaths which are not available

in most Fab Lab's s or alternatively you would need to create

a jig (to anchor and keep relative dimensions) and accurately

rotate the part and machine each side individually. For this

reason I think the design fits the brief quite well.

3D

Printing - UltiMaker 1

At Fab Lab Manchester we have access to two 3D printers, so to

make the most of the assignment I thought it would be a good

idea to print the same part on both printers and compare the

results. This is an interesting comparison as the UltiMaker 1

costs 1/30th the price of the Stratysis Dimension 1200es and

on paper has 5 X the layer resolution of the more expensive

machine. Both use FDM

(fuse-deposition-modelling) technology to extrude plastic

filament and build parts in stacks of cross-sectional layers

but the obvious main differences are that the Stratysis has

dual extrusion and uses a soluble support material to help

build more complex shaped parts and even assemblies of parts

printed all in one go (ready assembled).

The second main difference is that the Stratysis has a

patented closed and heated building environment. This extra

control of the rate of cooling in the material should allow

for a more consistent and repeatable build quality of parts.

The last difference in the test to be aware of is that the

UltiMakr can extrude PLA

(poly-lactic acid) a plastic with green credentials which is

made up of plant/vegetable protein or ABS, a substantially

less green plastic which is not bio-degradable and has

structural properties more akin to an injection moulded part.

In this test the UltiMakr used 2.85mm PLA Filament which costs

aprox £30 per kiogram. Whereas the Stratysis extruded ABS+

plastic at a cost of £160 per kilo (through a company that has

reverse engineered the material called Bolson Materials.

Cartridges direct from the seller cost £250 ex vat and come

equipped with a micro-chip that makes it very difficult to

hack the cartridges to accept refills of cheaper fialment

material- although

it is possible.

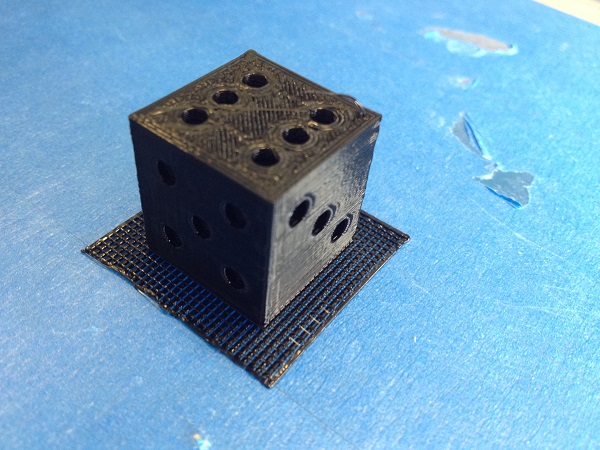

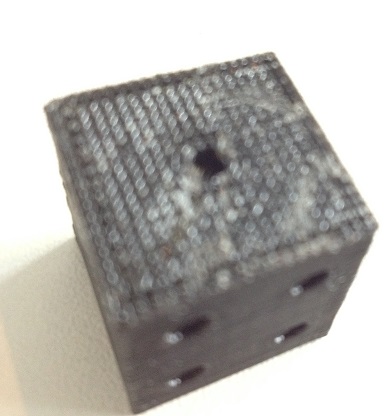

Results

- Ultimaker 1

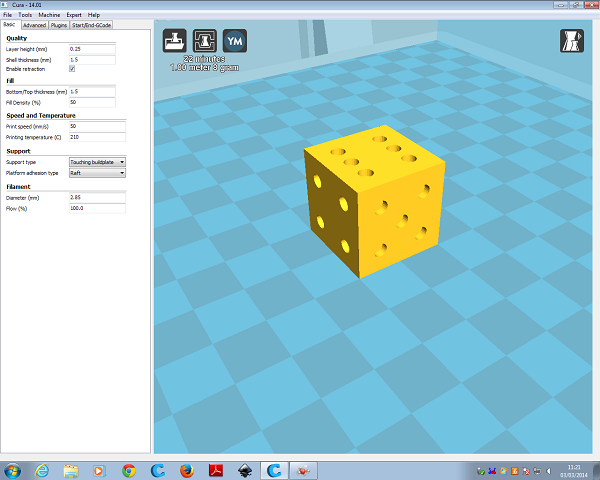

Print time: 22 mins

Layer Resolution: 0.25mm (this is the

lowest layer resolution available and was chosen to match

the stratysis)

Support Material method: Buildplate support

Fill density -

50%

Build Accuracy: 19.78 mm from a 20mm Dice = 98.9%

Observations

- Ultimaker 1

Surface finish - Good on all sides apart from the bottom

of the dice (buildplate side).

Support Areas - When creating the recess for each number on

the side there are strands of support material which need

removing. As s tehsupport is built using the same material

there is strong adhesion to the model and it is necessary to

cut away these areas with sharp snips as oppose to trying to

break away the support.If you try to pull away the support

sections they often damage the model section.

Layer resolution / texture - It appears to have quiet a finely

packed layer resolution with no major defects.

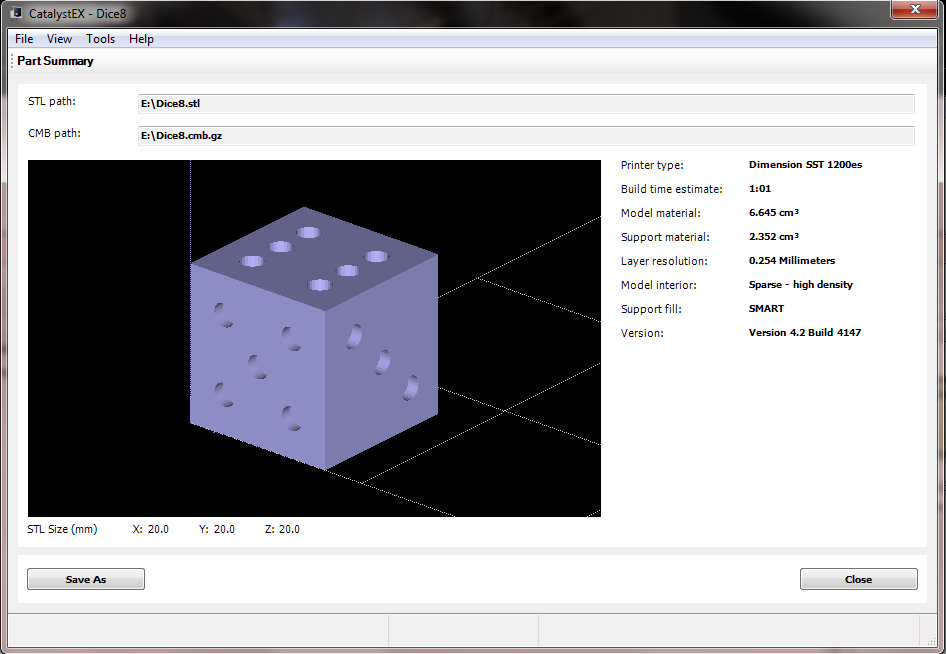

Results

- Stratysis 1200es

Print time: 1h 14 mins

Layer Resolution: 0.25mm (this is the

highest layer resolution available)

Support Material method: SMART support

Fill density -

High density

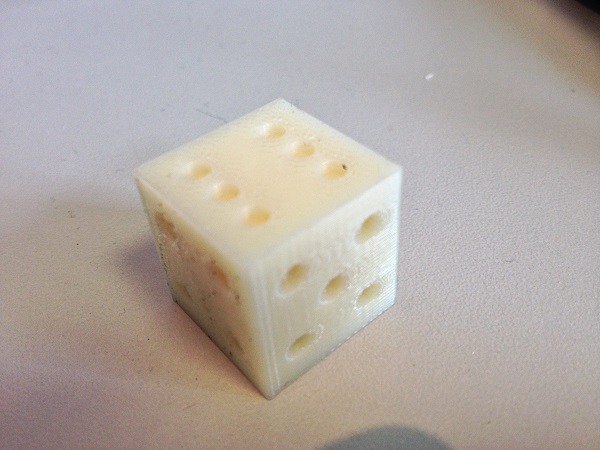

Build Accuracy: 20.20 mm from a 20mm Dice = 99.0%

Observations

- Stratysis 1200es

Surface finish - Uniform

on all sides.

Support Areas - Support material was calculated using the

Catalyst 4.2 software suite which is supplied with the

printer. SMART support is the most used of all 4 types of

selectable support and this was used for this model. SMART

allows the software to decide where t is necessary to build

support for the best part in the defined orientation. It is

possible to choose Basic/Breakaway support options but this

was not chosen for this experiment.

Support encased approx 50% of the model and therefore it was

necessary to dissolve the material in the bath of heavily

diluted sodium hydrozide solution which is heated to 70

degrees C and pumped around inside the tank. This process took

over-night to completely remove the support material from the

dice (although using a fresher solution, it would be closer to

3-4 hours).

Layer resolution /

texture - The dice from the stratysis appears to have a very

neat finish. The texture looks uniform throught the model

and at the edges (seams) there is a sharp clean edge.

Conclusion

When looking at the results the two machines performed very

well and also very similarly in terms of build accuracy on

the overall size measurement, in fact it could be said they

performed exactly as expected. The Ultimaker was quite easy

to set up using Cura and it was easy to find/change all

necessary parameters before sending the job to the printer.

But the machine itself did need a few more checks to ensure

proper extrusion was occuring before printing the part. It

quickly produced a dice to a good standard and although the

removal of buildplate support left a poor underside finish

it still made for a very usable part. On the other hand the

Stratysis had a full automated software setup which requires

no machine checks/calibration (in between 3 monthly checks

and maintenance). The software is clear and easy to use. The

printer takes it's time to print the dice in 1 h 14 mins,

and a lot of this time is due to the use of support material

on the build. The dual nozzled head has to clean off and

select the new nozzle drive at least once for each layer,

this explains the big difference in time. Despite the time

(we all know 3d printing is a slow process) the part was

built very successfully and with the use of soluble support

I was able to get an excellent surface finish on each side

of the part.

I was surprised when I took the measurements of the dice and

found they were almost exactly the same level of accuracy.

As I have worked in the lab for a few years now I am aware

of the strengths of each machine and I think that the test

didn't accurately show these. From experience I know that

the stratysis (although expensive, and slow) produces

consistent parts time after time and when used for

prototyping 2 interacting parts I know that in the design

process if i leave 0.5mm difference between the interacting

sections it will fit together correctly almost every time.

In contrast to that when I have designed parts for the

Ultimaker i have often had to open out holes by as much as

1.5mm to make them fit on a particular tool/part and the

offset value has never really been constant. It is with this

experience that I think if I were to print 10 dice and

compare each one that the Stratysis' quality would show

through. Also I were to set-up a pack of dice in different

bed locations that would move the printer around more than a

20mm X 20mm square I suspect that the errors would start to

mount up on the Ultimaker.

3D

Scanning

Due to time constraints we decided as a group to work

through each scanning method available as a team and then

each write up a different process.

Modella

After working through using the Modella tactile scanning

feature with the Dr Picza software James

wrote up that method of scanning. For me it seemed

that the Modella although outdated in its tactile scanning

system and without the option of getting a fully 3D scan (as

it does not get overhang data and it does not map any data

for the bottom face/s of the model) on the plus side it does

very good resolution and with the use of the high resolution

3 axis movement it does make for a very detailed and

accurate point cloud.

123D Catch

Having used this method before in the past with quite

poor results I was keen to improve on them and see how other

people obtain good scans using this system. After doing some

research I found that the important parts of getting a

good scan were to:

- Take at least 40

photos showing top bottom and side viewpoints

- Use a detailed

background such as a newspaper page that has different

data points to help the software stitch together the

photos correctly

- Take photos from

the same distance away from the model each time and

don't use a flash as shadows will be included in the

resulting mesh.

- Don't use

auto-focus feature on a camera as this can blur

important data in the image and skew the resulting scan.

It occurred to me that a jig could be constructed to try and

keep constant the viewpoint and field of vision and could

work with a controllable turntable to get the best results.

This may be something I look to construct in machine week.

As a team Annie

chose to write up this scanning method. Annie

investigated this method but it seems to me that it can be

reasonably successful when scanning larger objects but

smaller objects with finer detail seem harder to scan and

more prone to error.

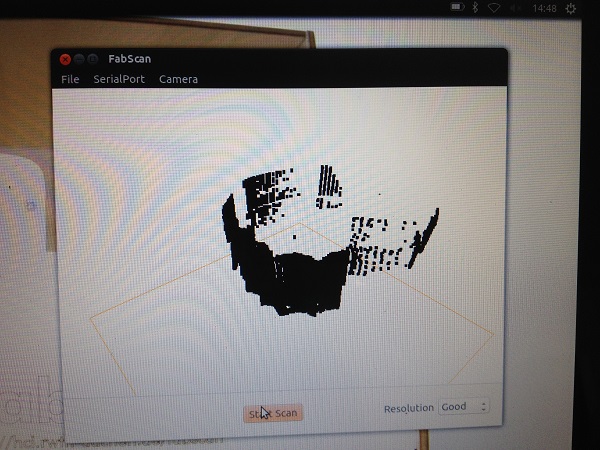

FabScan

FabScan is an open-source, do it yourself 3D laser scanner

which started out as a bachelor's thesis by Francis

Engelmann, supervised by Rene Bohne.

David

our mentor at the lab has put this machine together as part

of his coursework when completing the academy in a previous

year and it has been tinkered with recently

and is now scanning data.

To use

the machine we installed fabscan control software on David's

mac connected up the webcam and Arduino controlled

turntable.

My first

thought was to try and use this machine to scan the dice I

had printed on the Ultimaker (as the Stratysis model was

still dissolving at the time) and then I could compare the

scanned data to the original design. Unfortunately after

configuring the scanner which involves adjusting the field

of vision of the webcam and ensuring that the laser projects

a vertical line across the centre of the turntable and does

not light up the front face of the turntable or the ceiling

of the FabScan box, it became clear that scanning a black

plastic dice in a dark box was not going to give good scan

data.

As this

wasn't proving successful I then tried to scan the same

object that we used for the Modella scanning - a metal

pencil sharpener. After setting up and starting the scan it

again became obvious that the scan was not producing good

data. A reason for this could be the reflective surface of

the object diverting the laser and not being picked up

accurately by the webcam.

In an effort to get a good

scan from the FabScan I choose to scan a larger less

reflective object - a red chocolate box. When setting up the

FabScan there is the option to use poor/normal/best scanning

options. These options seem to vary the amount of points of

data scanned by modifying the amount of degrees turned at

each scan point. I chose best and scanned the chocolate box

and got this result.

This data shows an error that was soon explained when i

heard a thud and lifted off teh cardboard to reveal

this....

The lesson here is to make sure your object is held

down securely to teh turntable. So after some searching aroung

teh lab and trying out some tape i desided more Blutack was

the way to go.

The next scan was

successful and the data was exported as an .stl and a .pcd.

This is where another error was made. After trying to open the

stl file it is obvious that The stl export has not been

successfull as the file does not open in any program without

returning an error and after looking at the size of the file

it is only 27 bytes. This being

the case I next tried to find a file that opens or converts

.pcd files which is where I came up short. It seems that

MeshLab will open .pcl files which are an export option but

did not save from my scan. Therefore it seems I need to rescan

and re-export that data to analyse it with MeshLab. This was

not possible in the time for this week and I will re-visit

when possible in the next week.

Downloadable

Files

Sketch Up model - Dice

Scan Data -

chocolate box.pcd