This

week we have tried 3D scanning in a variety of ways. We have

all made our own scans but because of the number of different

methods available we have decided to work together as a group

to explore using 123D Catch, Fabscan, the Modela,

I

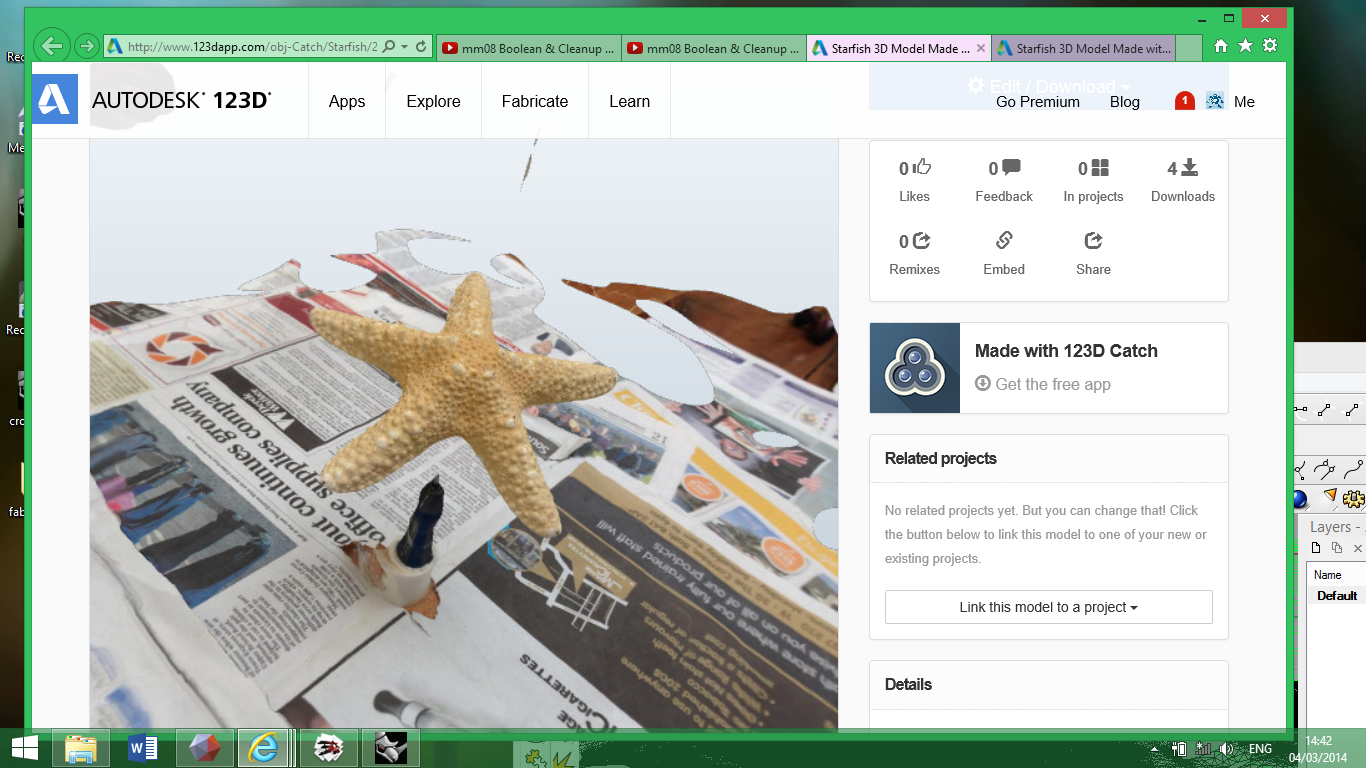

started with 123D Catch using my ipad and iphone ( you can

also use a camera) I captured images from several objects

around the house. This was the fun part and surprisingly

simple as long as you follow the advice offered.

·

Newspaper

provides useful, busy and varied background

·

Don’t

use flash, have consistent lighting

·

The

object must stay still, only you move

·

No

transparent, shiny or glossy surfaces

·

Plan

your shoot carefully at 5 to 10 degree intervals

I

then emailed my catches to myself and downloaded them into

123D Catch software on my computer to tidy up the model and

things slowed down quite a bit!

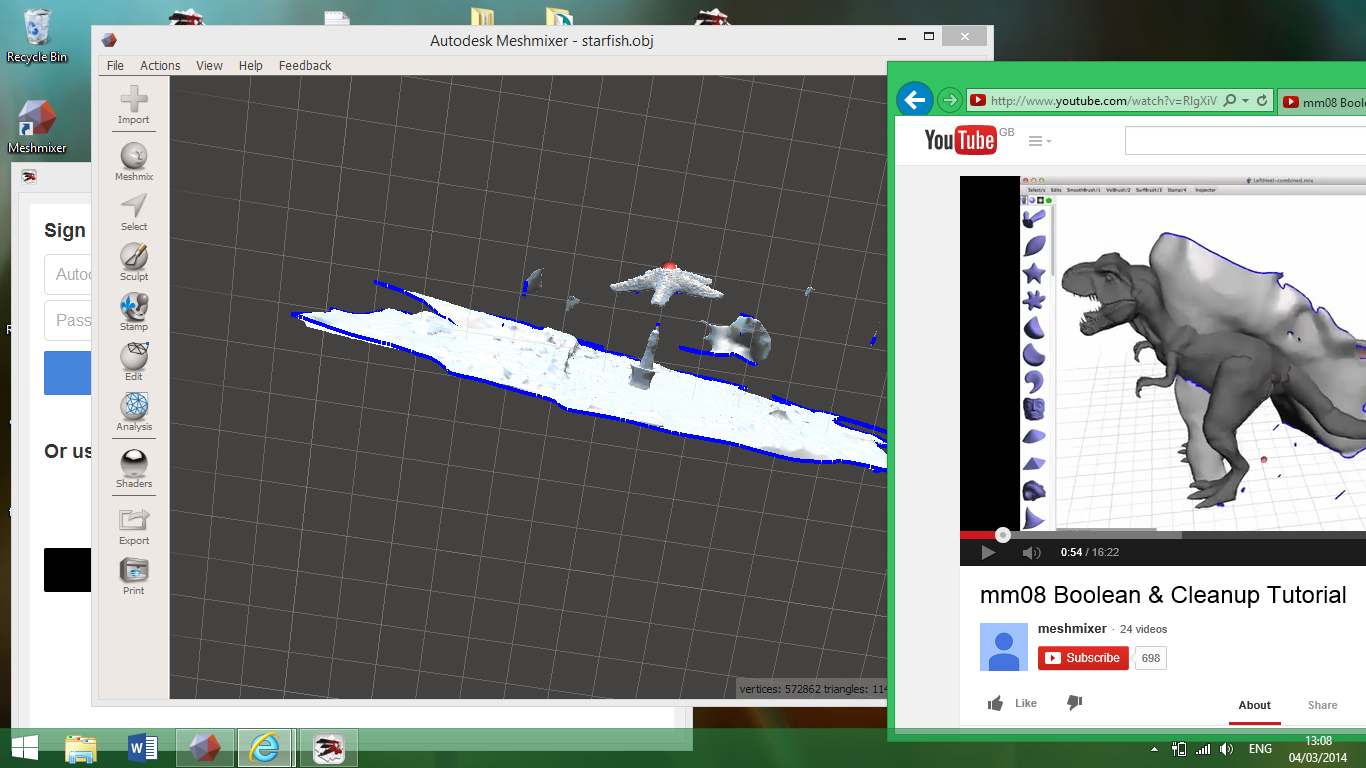

It was frustratingly slow trying to edit the catches

and clean off the background shell. Next I saved the model as

an obj and imported it into Meshmaker, used the auto repair

function to repair holes in the mesh, smooth the surface,

scale the model and save as an stl file ready for printing. I

did not manage to get a good enough image for printing but

have spent some time following the meshmixer tutorial. I

found several useful links for 123 Catch and Meshmixer on

utube. Other software you can use for tidying up the images

are Netfabb and Meshlab. I have also had a go at editing the

mesh in Rhino but found it quite tricky as I'm new to Rhino.

Group scanning projects

Scanning with the Modela -

link to group file week

5 group modela scan

photo above showing the sharpener we scanned using the

modella and the resulting 3D prints in 2 sizes

NEXT

3D

Printing

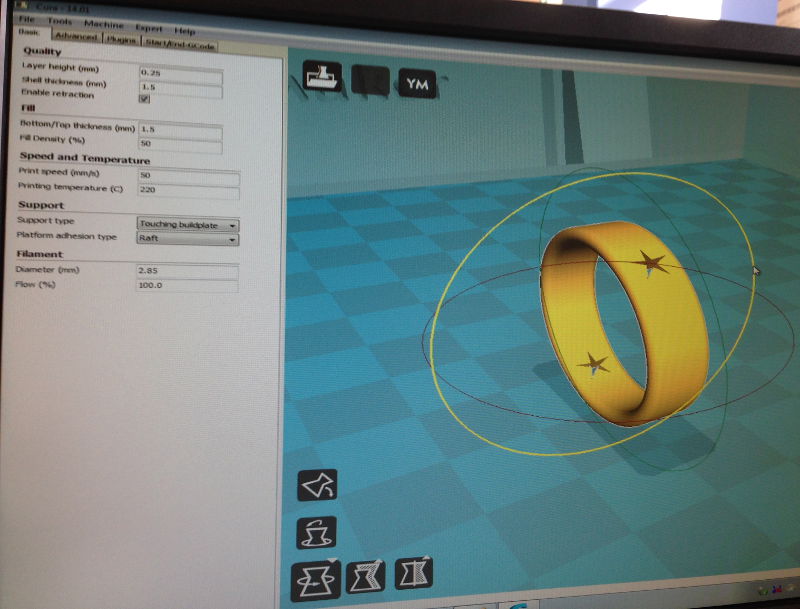

I

drew my design for a decorative ring using Rhino, ( I also

took this opportunity to practice my Rhino skills) saved it as

a STL file, downloaded Curo the software for Ultimaker and

imported my STL file then set up the printer as follows.

· Check surface of print table is flat pick position on the table

·

Open

file in Curo

·

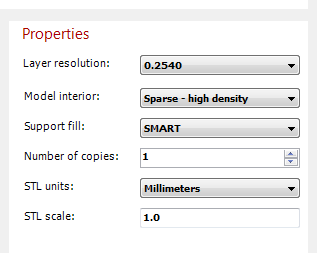

Input

settings, see below

I

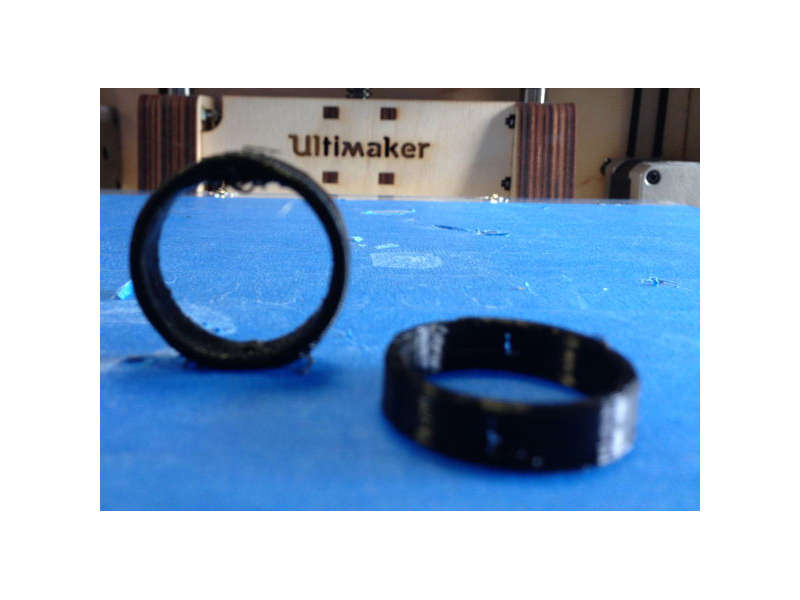

found it is important to consider the orientation of your 3D

printed object as it can effect the quality of your print. The

rings were printed upright and flat and there was a

considerable difference in the quality of the finished

product. See below

I

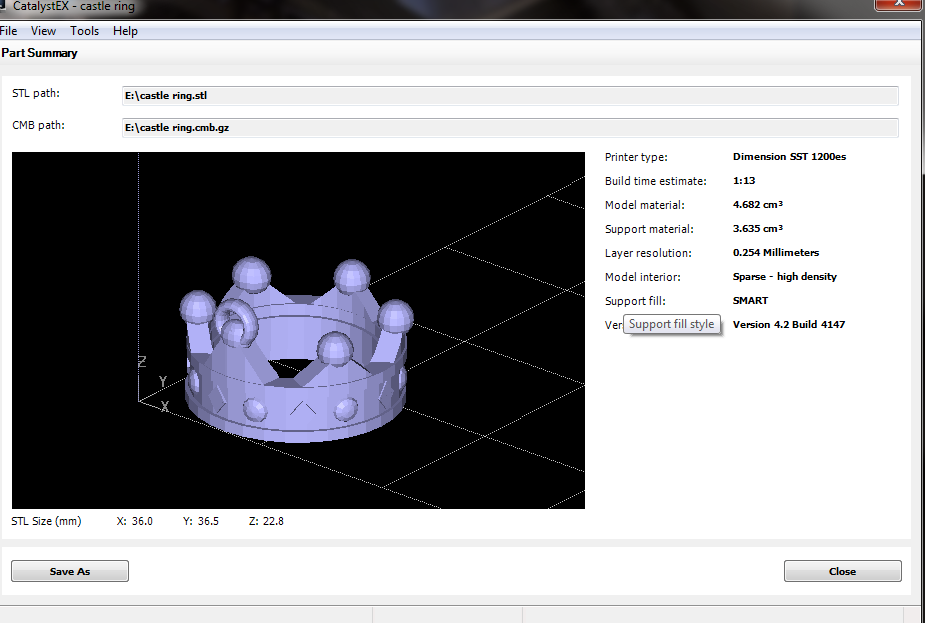

also printed another ring using the Dimension 3D printer to

compare the quality and learn how to use it.

Using a new design and the settings below

the crown ring printed successfully

the crown ring printed successfully