Fab Academy 2014 - FabLab Manchester

Fab Academy 2014 - FabLab Manchester

Week 5 - 3D Scanning and Printing, Group Work by

James Fletcher, Micheal Walsh and Annie Lynwood

3D Scanning with the Roland Modela MX-20 - Write up

by James Fletcher

In order to investigate as many 3D scanning methods as possible we

decided to work on some of them as a group and then take one each to

write up.

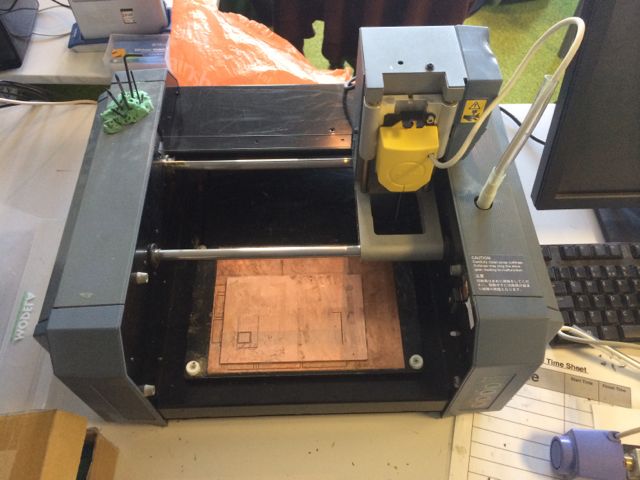

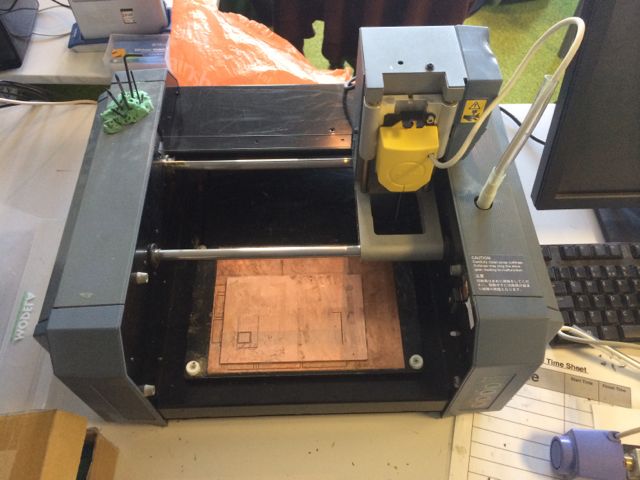

The Roland MDX-20 can be used for 'Tactile Scanning' of objects as

well as milling. The process essentially involves delicately

moving a long needle tip around over the model and prodding it to

work out where the surface is at any point.

1. What Object to Scan?

We decided to try and find an object that we would be able to scan

with as many methods as possible. This proved quite awkward as

the different methods we planned on trying all work best with

different scales of object. We settled on a pencil sharpener

as it's quite an interesting shape, has some surface detail, has a

flat bottom surface so that it's easy to stick down and has a chance

of producing a scan with the Modela, 123D Catch and FabScan.

2. Modela Setup

The machine requires a small amount of setup, basically the milling

head needs to be replaced with the scanning head. The heads

are only held in place by 2 'alan' screws so this is a fairly quick

process.

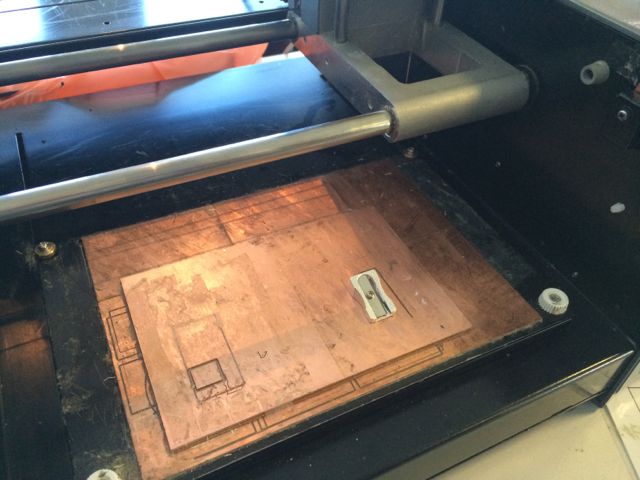

Once the machine was setup we stuck our object down on a flat part

of the Modela bed with double sided tape.

3. Software Setup

We had been using Fab Modules in Ubuntu for all the milling work

with the Modela, unfortunately scanning with the Modela is currently

only supported by the official Roland software called 'Dr PICZA'

which only runs under Windows.

Dr PICZA proved to be quite intuitive to use and after 10 minutes

fiddling around with it, investigating, we were happy we knew how it

worked.

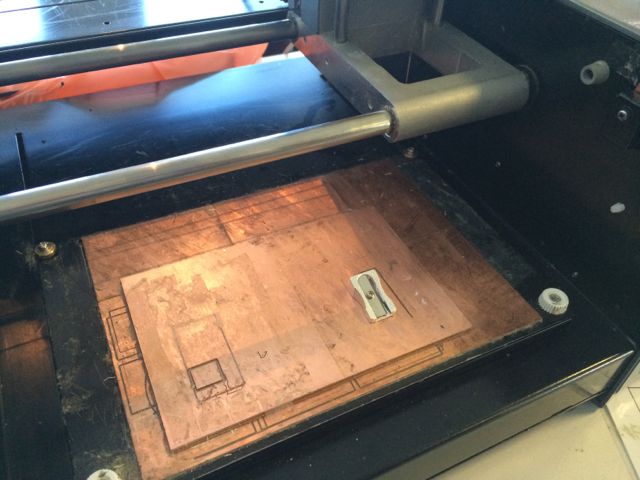

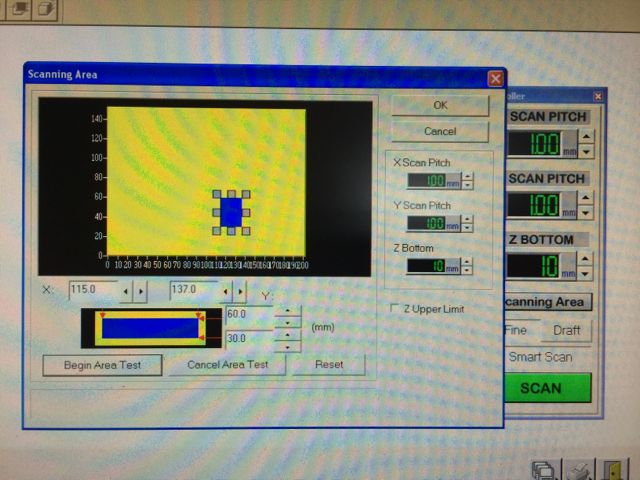

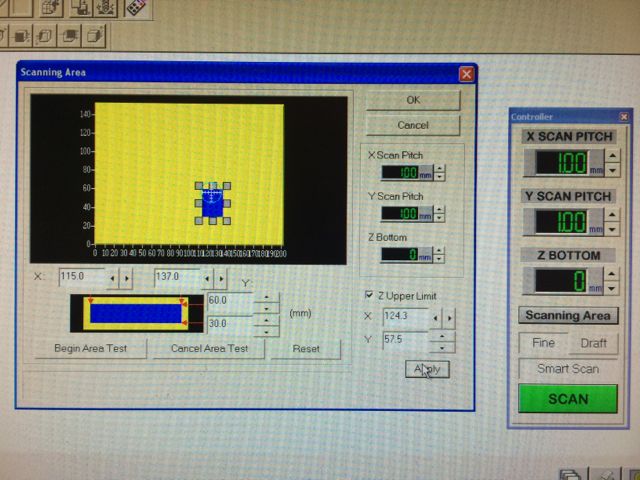

3.1. Setting Scan Area

First thing to do is tell the Modela the area of the bed that

requires scanning. Getting this as close as possible to the

boundaries of the object will reduce the scanning time. Our

initial estimate was by measuring from the lower left corner of the

Modela bed. We put these measured numbers for x-min, x-max,

y-min and y-max into the scan area dialog and then used the 'Begin

Area Test' button to check them. The software gives you a

visual representation of the scan area with drag handles that can be

used to adjust it. This gives a quick initial visual check of

the area to be scanned.

For the 'area test' the Modela moves around the boundary of scan

area lifting the needle up as far as it will go and dropping it at

each of the corners and mid points of the of the boundary in turn

(these are the same points as shown by the drag handles on the

image).

This test allows us to refine the scan area from our initial

measurements, moving the boundary in closer to the object so that

the modela has less area to sample. We iterated this scan /

refine boundary a few times until we were happy that we weren't

scanning a large area of the flat bed but our scan was still well

clear of the edges of the object.

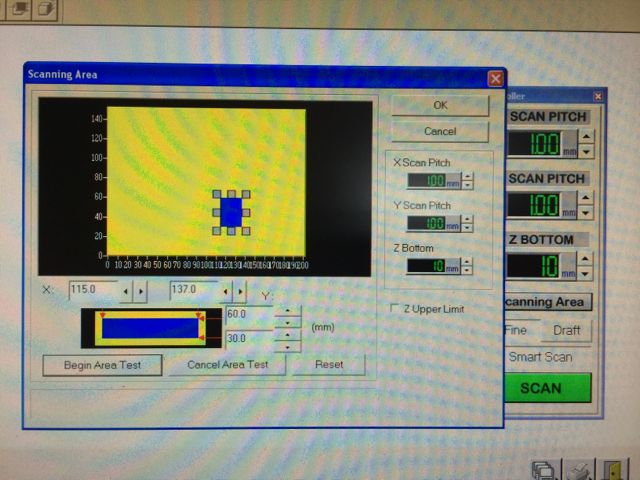

3.2. Z Upper Limit

One thing that was obvious to us from watching the 'Test Area'

process was that it takes an appreciable amount of time (around 15

seconds per cycle) for the Modela to lift the test needle as high as

it will go and then rop it back down again. Obviously with no

other information about the object being scanned the software has no

choice but to do this. We realised that if we use the 'Z Upper

Limit' function we could tell the Modela the upper extent of the

object on the Z axis and it would know that it only needed to lift

that far to clear the object as it moved around.

Setting the x, y position of the highest part of the object and

clicking 'Apply' causes the Modela to move the needle to this

position and drop it down to test the actual height at this

point. By watching closely as it did this we could refine the

x, y co-ordinates to get an accurate measure of the maximum

height. hopefullyy this would save some time in the scan

process as the Modela wouldn't need to lift the needle the whole way

up as it moved it around. Watching the Modela actually perform

a scan later showed us that even without this info it seems to be

slightly more intelligent than this.

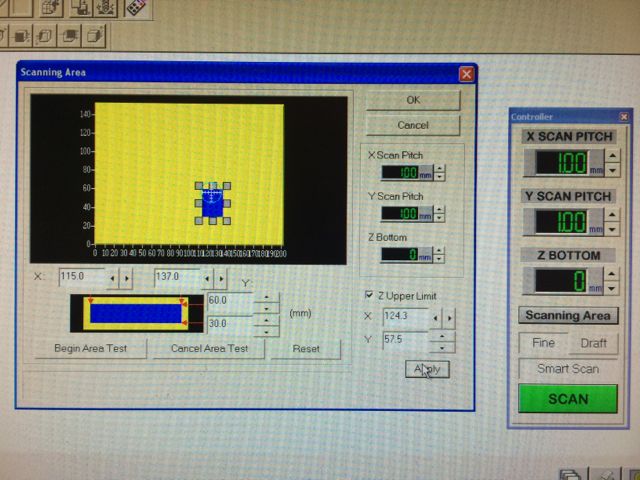

4. Scanning

Once the scan area had been set up we set the x, y scan pitch and

clicked scan. The software defaulted to 1.00mm for the x, y

pitch when we launched it, so even though this didn't sound like it

would give us a very accurate scan we decided to start with this to

watch how the machine worked and then refine it later.

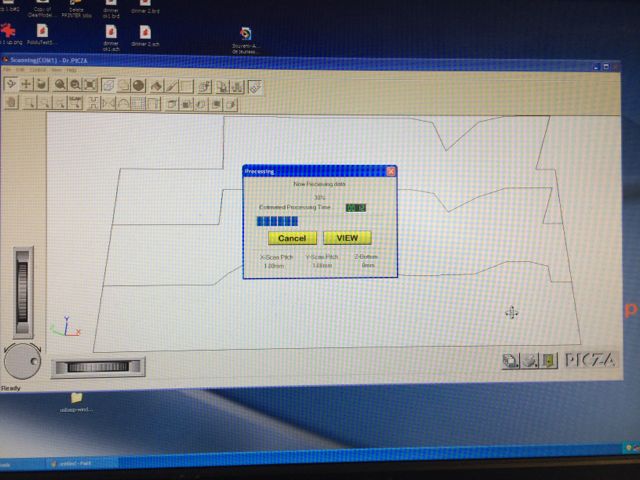

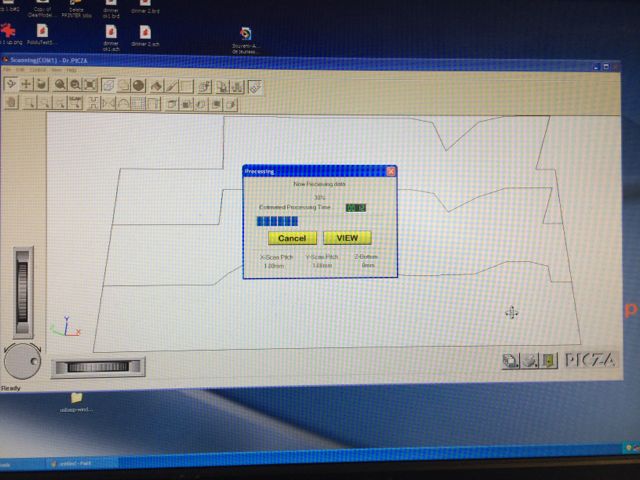

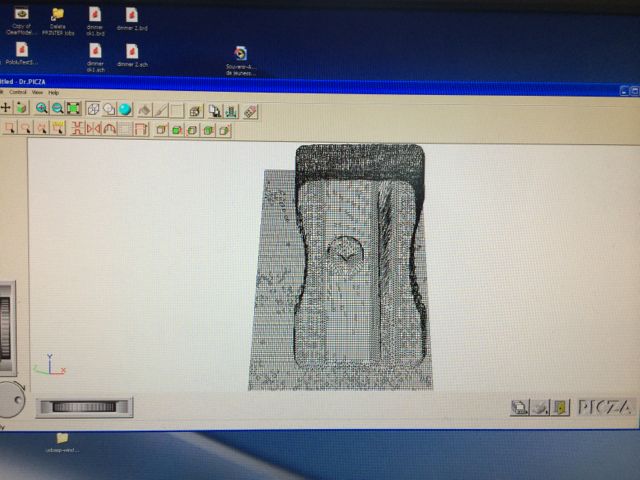

The image below shows the scan in progress.

You can see from the image above that this scan is about a 3rd of

the way through and still has about 12 minutes remaining until it is

complete, so a total scan time of about 15 minutes. Our scan

area was 22mm by 30mm, at 1.0mm pitch this is approximately 713

points including the boundaries. At 15 seconds per point

samlpe this is around 180 minutes. So it looks like setting

the z upper limit has had a significant effect (Or maybe the machine

is cleverer than we think!).

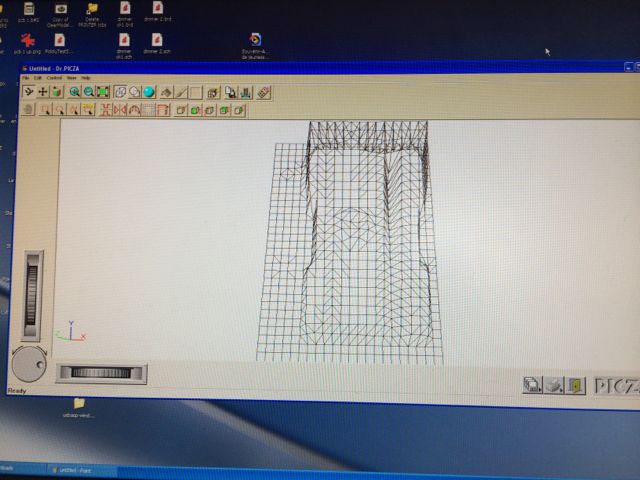

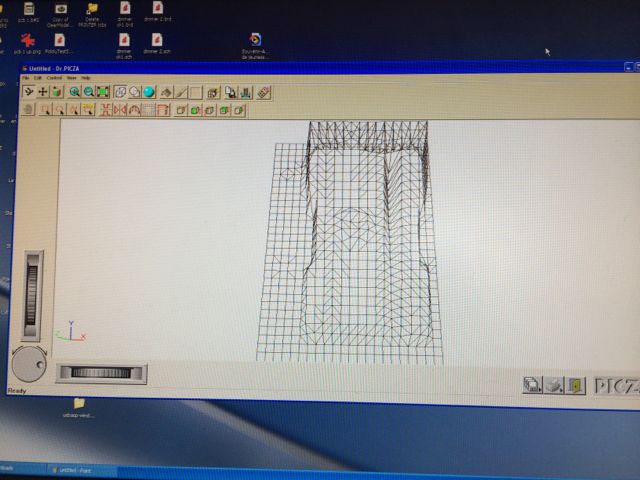

And finally the mesh generated with our initial 1.0mm pitch scan.

You can see from this that even though the pitch was only 1.0mm, the

scanned object is still clearly identifiable. However it's

missing all of the finer detail such as the ridges on the finger

indentations and the texture on the upper surface.

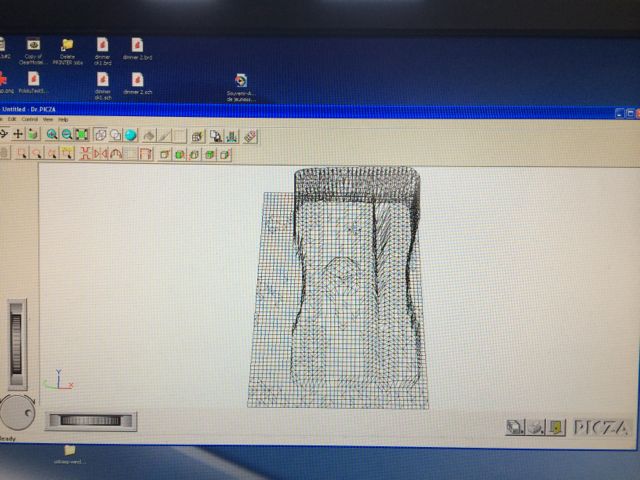

So we decided to refine the scan pitch and see how the detail

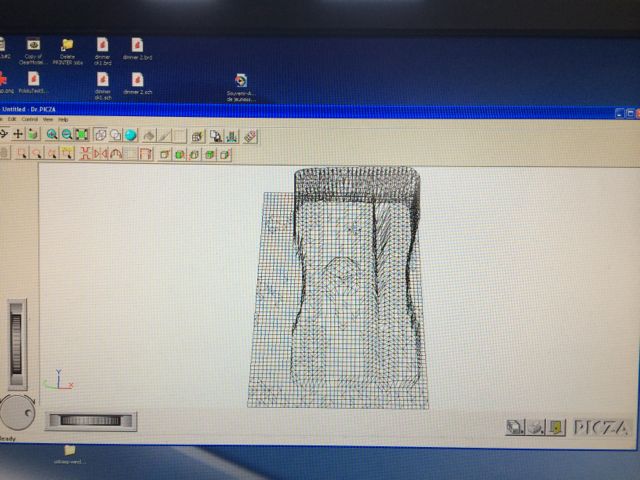

changed. Below is the final mesh at 0.5mm pitch.

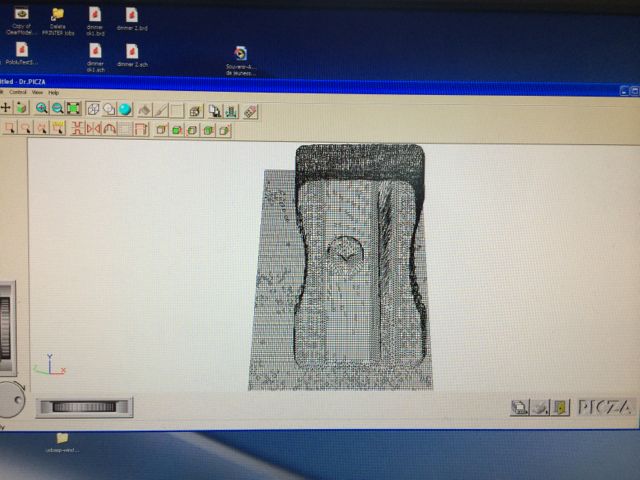

And this one below at 0.25mm scan pitch, this took around 2 hours to

complete the scan.

At 0.25mm detail in the object is becoming clearly visible.

You can see the following features:

- Dimpled texture on the upper surface of the sharpener body.

- Cross head screw holding blade in place.

- Difference in height of blade and body.

- Cutting edge of blade.

- Knurls on finger grips at side of body.

We did set off an overnight maximum resolution scan at 0.01mm pitch

that estimated 12 hours to complete. However when we came back

in the next morning the PC had crashed and our scan had

failed. Given time we may attempt this again as we would like

to see what this machine is capable of.

STL Files for the 3 scans that worked are here, here and here.

5. How does it Scan?

The simplistic way to scan would be to step across the scan area in

pitch step increments completely raising the scanning tip each time

and then dropping it back down again. Based on our quick time

to scan estimate earlier on vs. the actual time it took to do a scan

and on observations of the machine scanning the process appears to

be much more intelligent than that.

The first thing to note is that t needle doesn't operated a simple

switch when it drops down and touches the object. It is

actually a piezoelectric sensor. This means that it will

resond to deflections in the x and y directions as well as the

z. With this the machine appears to sweep the tip across the

object at a constant low height until it touches an edge. When

it touches it lifts up until it clears and then continues it's

sweep. with this information it can work out a better

approximation of the boundary of the object than that provided by

our simple scan area estimates and z upper limit. With this

better boundary information it returns and performs a high

resolution scan of the object only just lifting the scanning tip

just enough to clear the object and saving a lot of time moving the

head on the z axis.

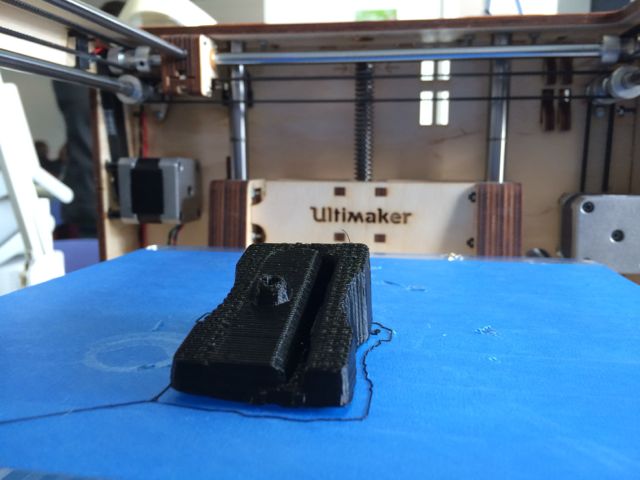

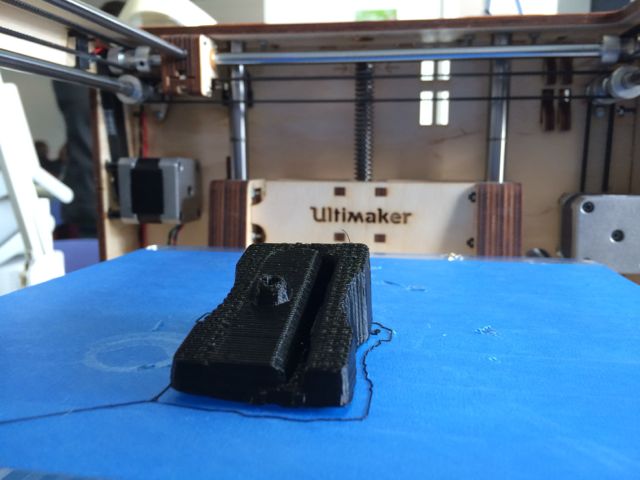

6. Printing our Scans

Having scanned our pencil sharpener we decided to try and print a

copy and see how close to the original it looked. Our original

print was at 1:1 scale, but at this resolution the printer (our in

lab Ultimaker) wasn't capable of reproducing some of the detail that

was visible in the mesh, so we decided to scale the print up to

2.5:1 to see how much detail had actually been captured. The

original and both models are shown together in the image below.

Close up of the largest 2.5:1 print.

Fab Academy 2014 - FabLab Manchester

Fab Academy 2014 - FabLab Manchester Fab Academy 2014 - FabLab Manchester

Fab Academy 2014 - FabLab Manchester