CCC (Computer Controlled Cutting)

This weeks Assignment is to design and fabricate a press fit construction kit, A kit of parts design to attach together with no glue or fasteners held together with only Friction to make multiple shapes it easy to think about hard to design but i will give it a shoot, My inspiration came to me as i was thinking about my final project i needed a good way to prototype and build the endoskeleton so i was looking at 80/20 aluminum extrusion but i found it to be a bit expensive to buy or ship in Egypt and thus i thought of it as the perfect project for this week so i started researching all different types of aluminum extrusion and there hardware and started designing

Tutorials and Helpful sites:

- You tube

- http://makezine.com/2012/04/13/cnc-panel-joinery-notebook/

- http://makezine.com/magazine/tutorial-laser-cutting-techniques-and-projects/

- http://www.inkscape.org/en/learn/tutorials/

Software Used:

- Inkscape

- AutoDesk Inventor 2012

- OpenSCAD

Project: A-Tech Structure Rapid building blocks

Goal: Build a kit to quickly prototype structures

Files For this Assignment can be found here

Let The Dance Begin

Starting at Inkscape to design the parts of the beams in 2D so learning Inkscape as you go is kind of difficult but learning with a goal makes it a lot easier

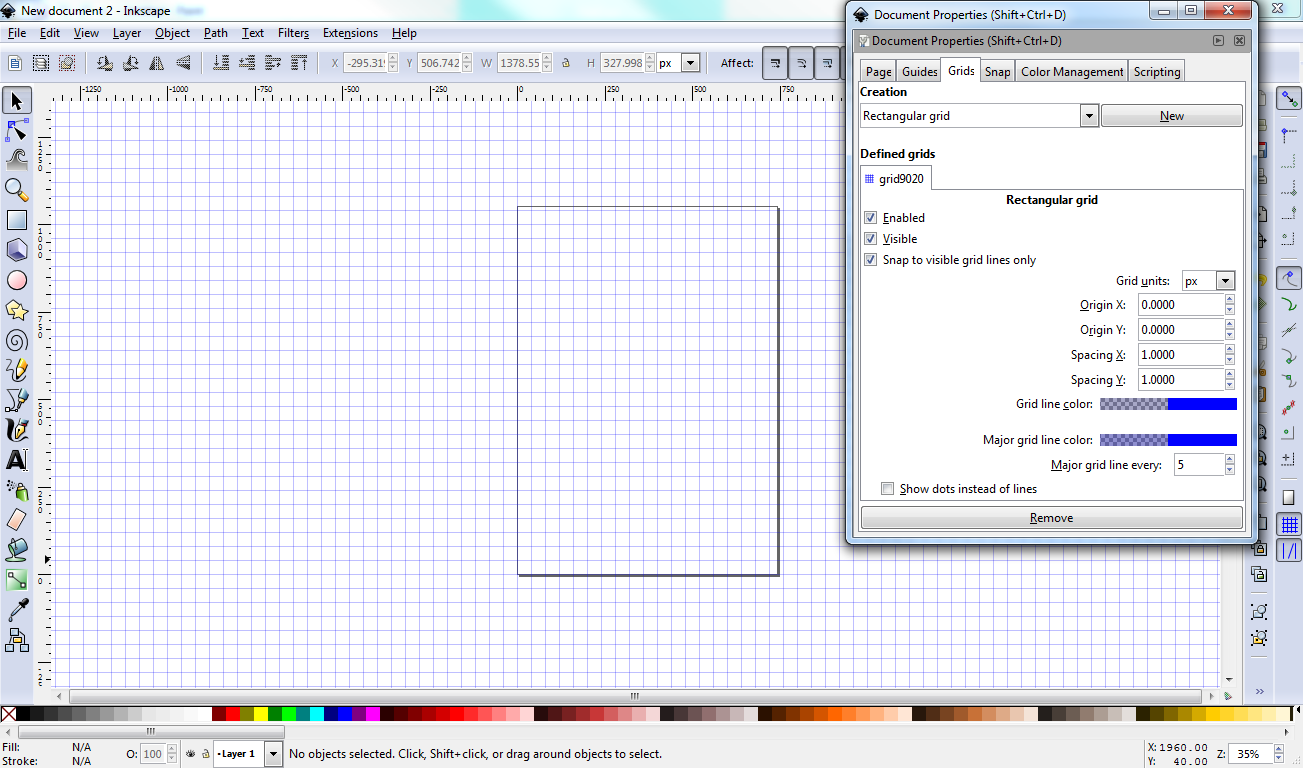

Starting with readying the Environment i enable the grid by pressing the '#' button

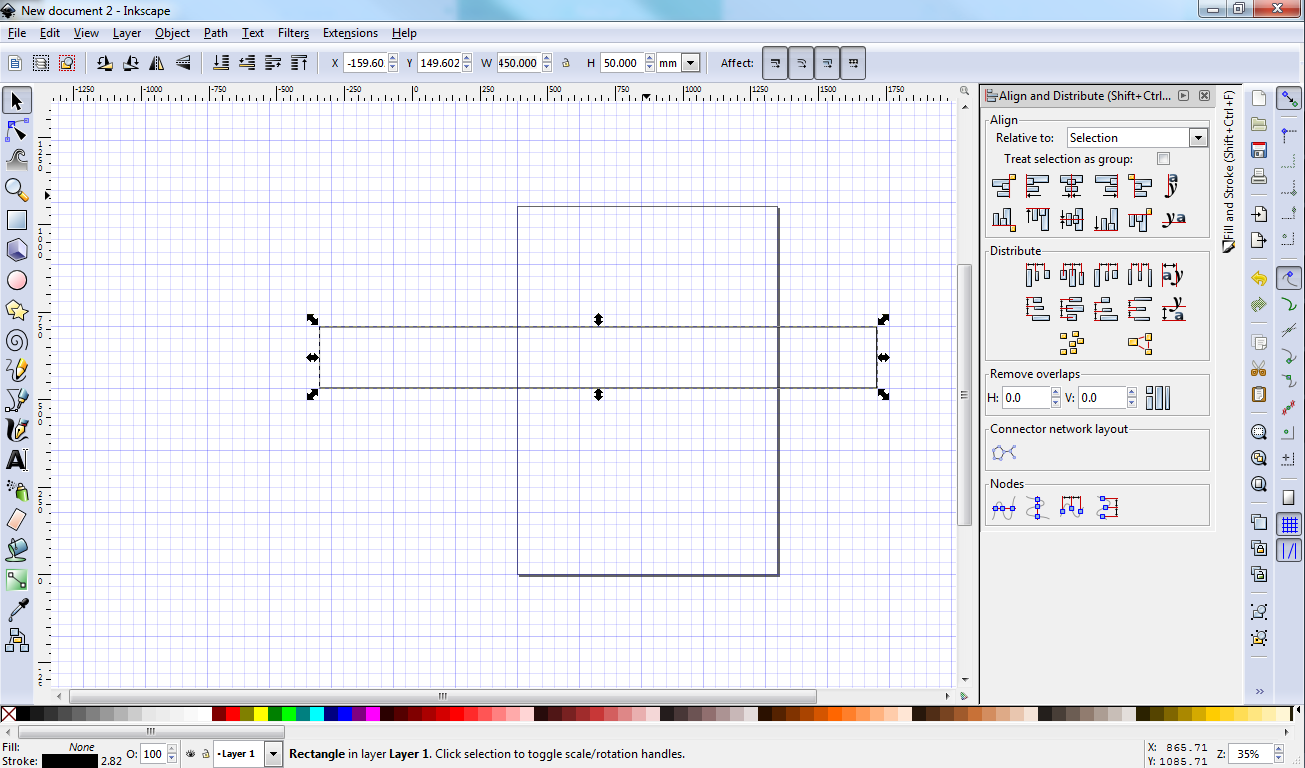

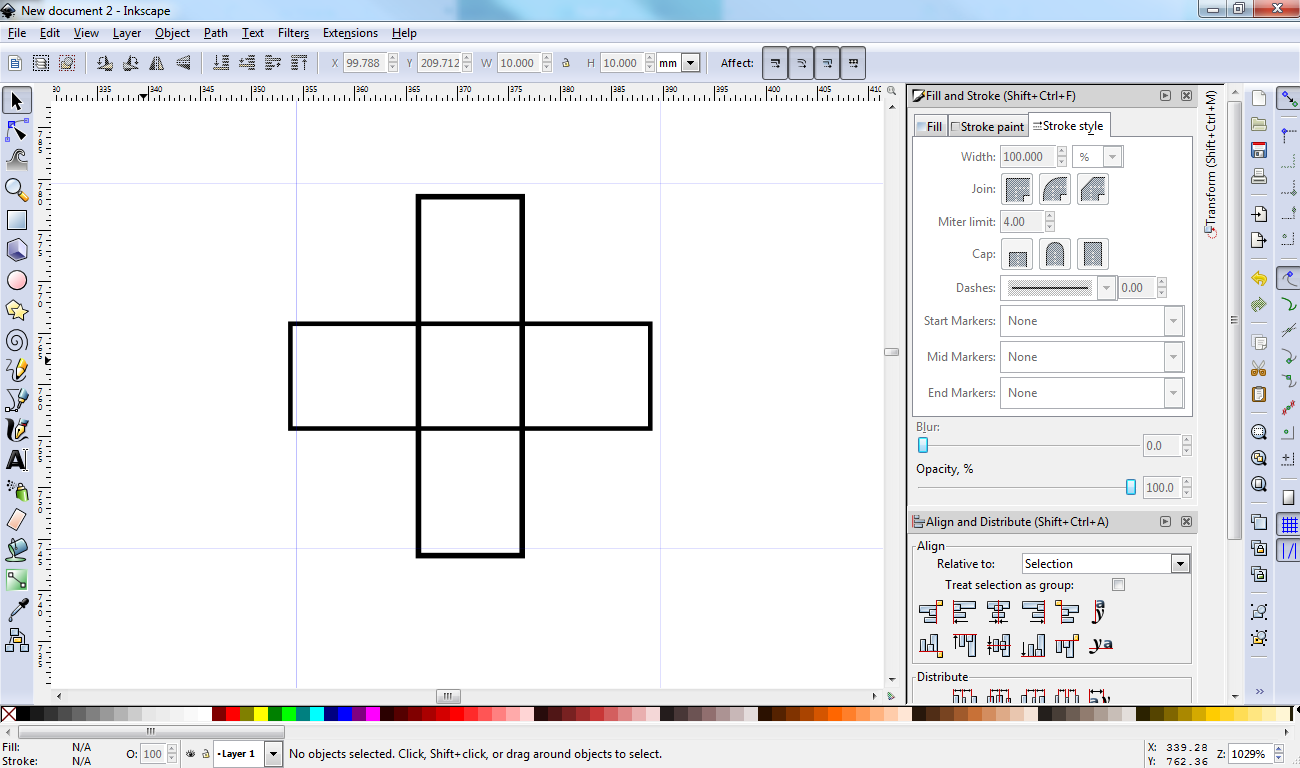

Now using basic shapes in combination i start sculpting out the shape

and after placing the objects at the right X,Y coordinates using a bit of math and some boolean operations i was able to create a part with 1 side

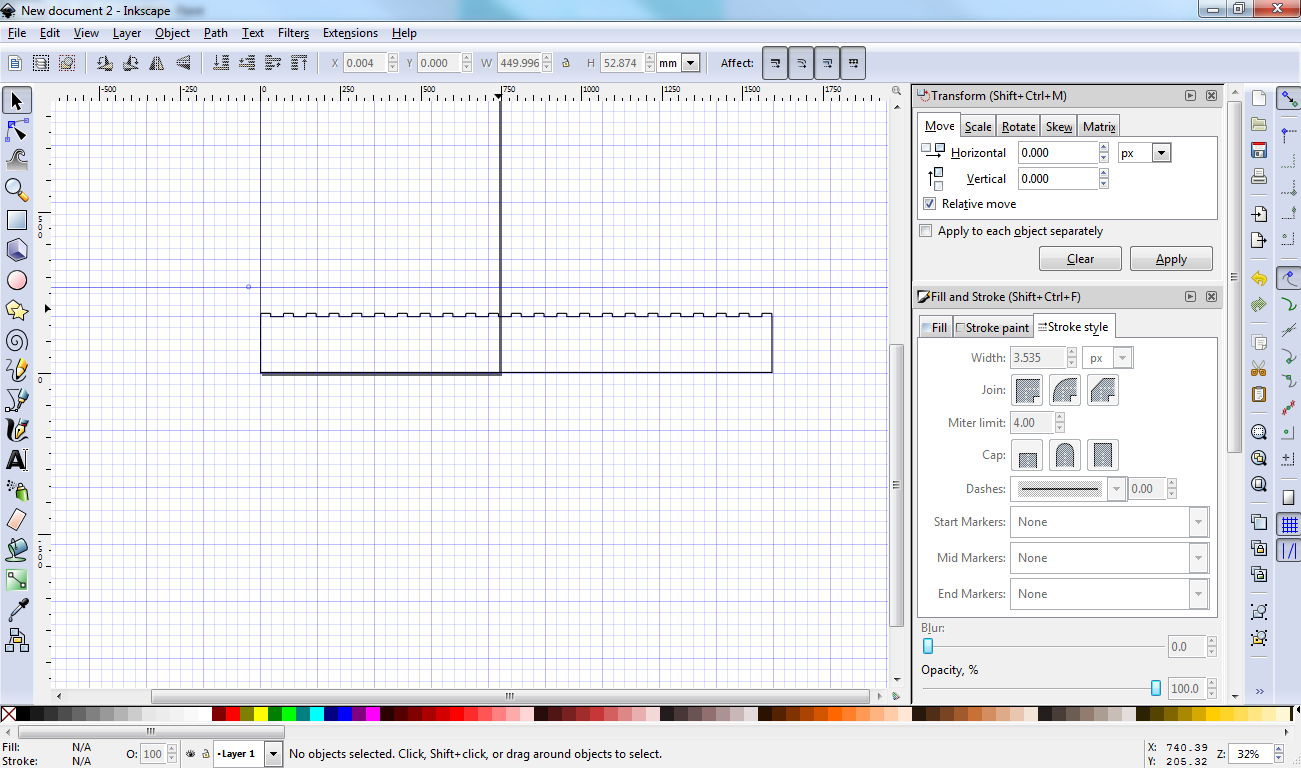

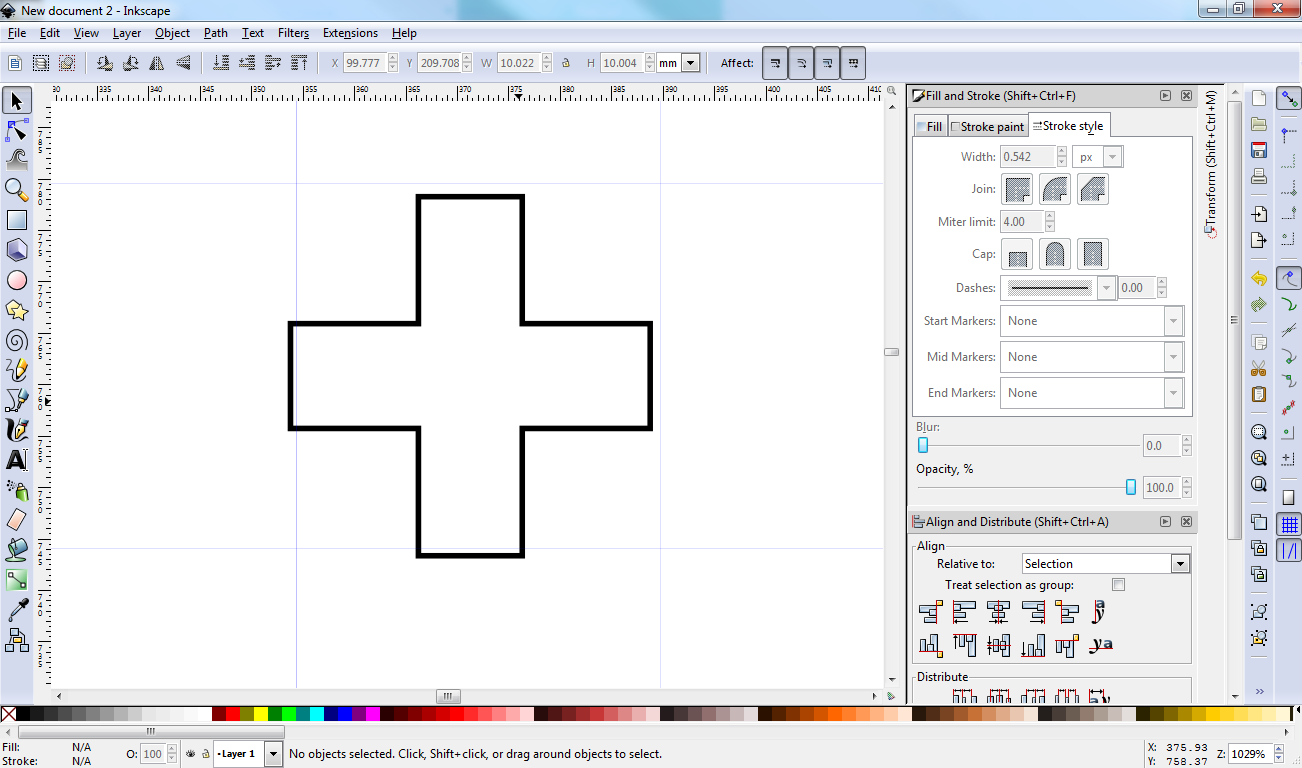

Now for the connector pin openings

X,Y math and Boolean Operation Gives:

and now initializing the grid

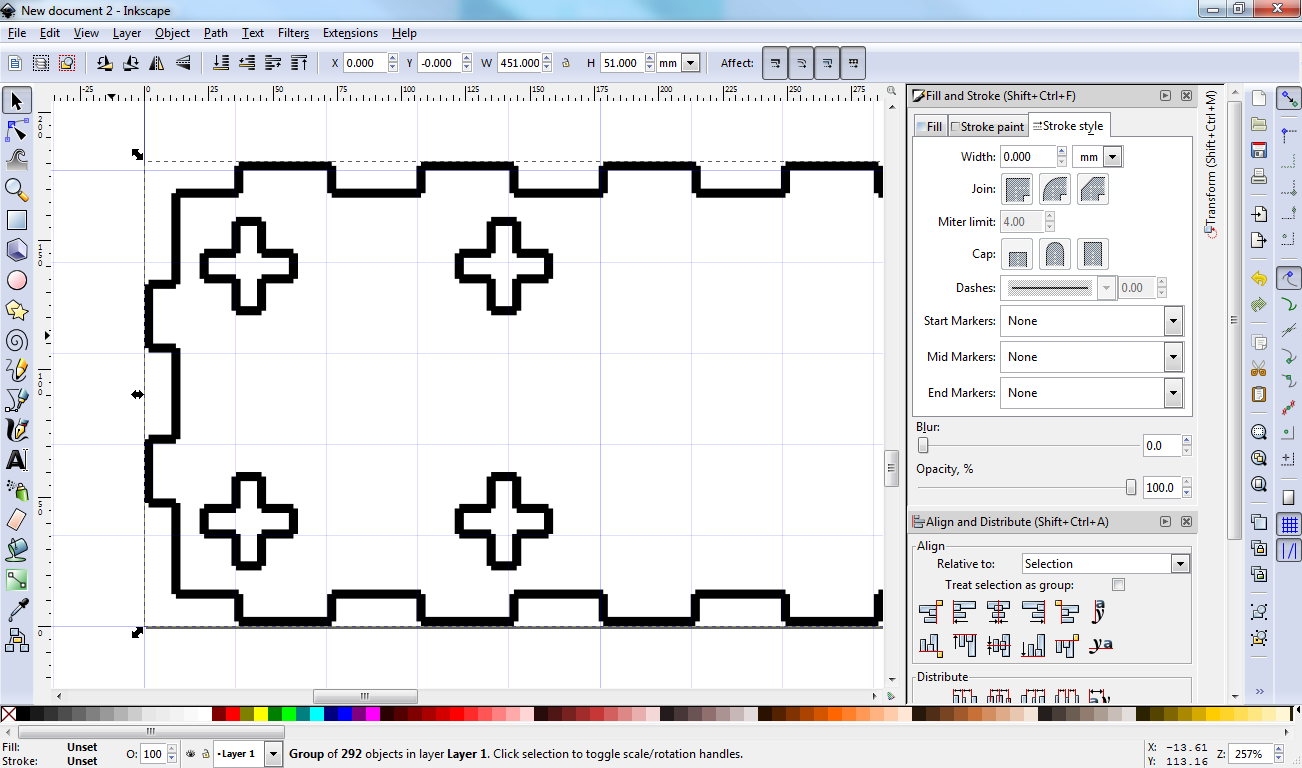

now after a bit of work using almost the same operations Shapes started to emerge

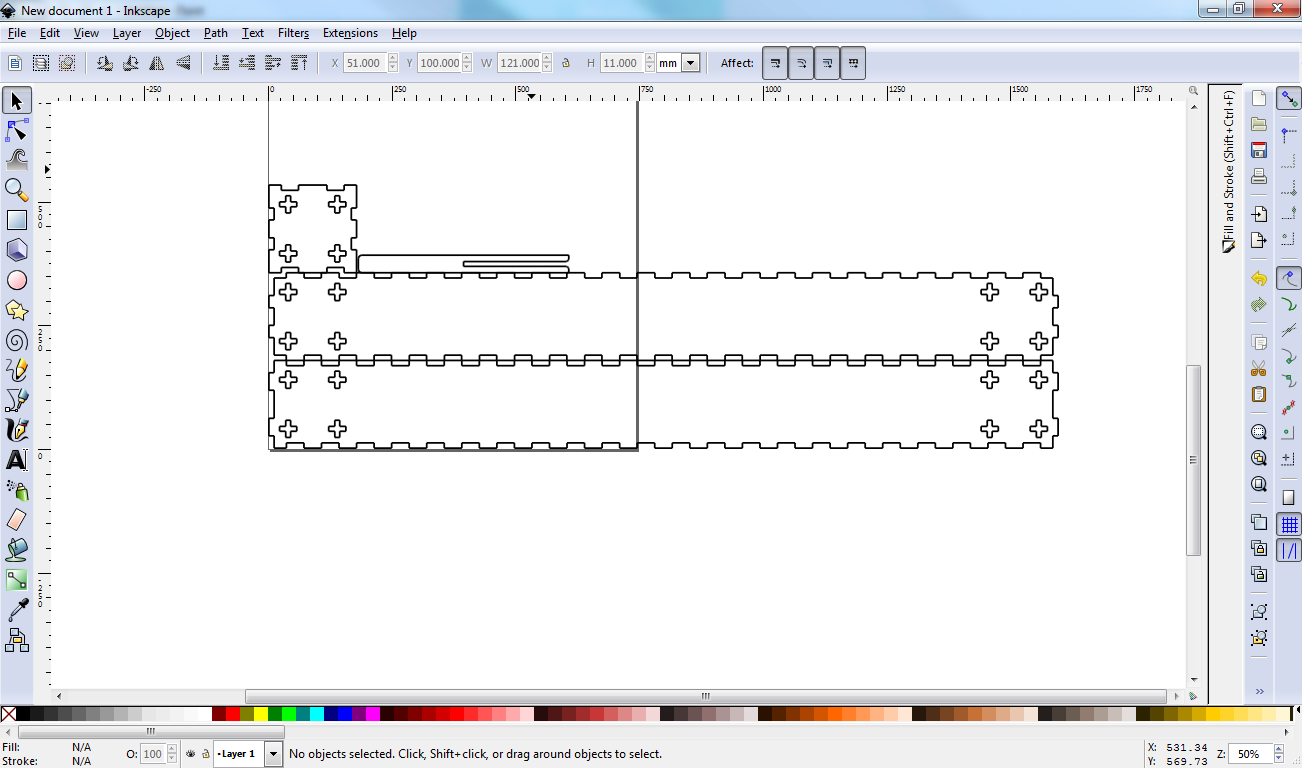

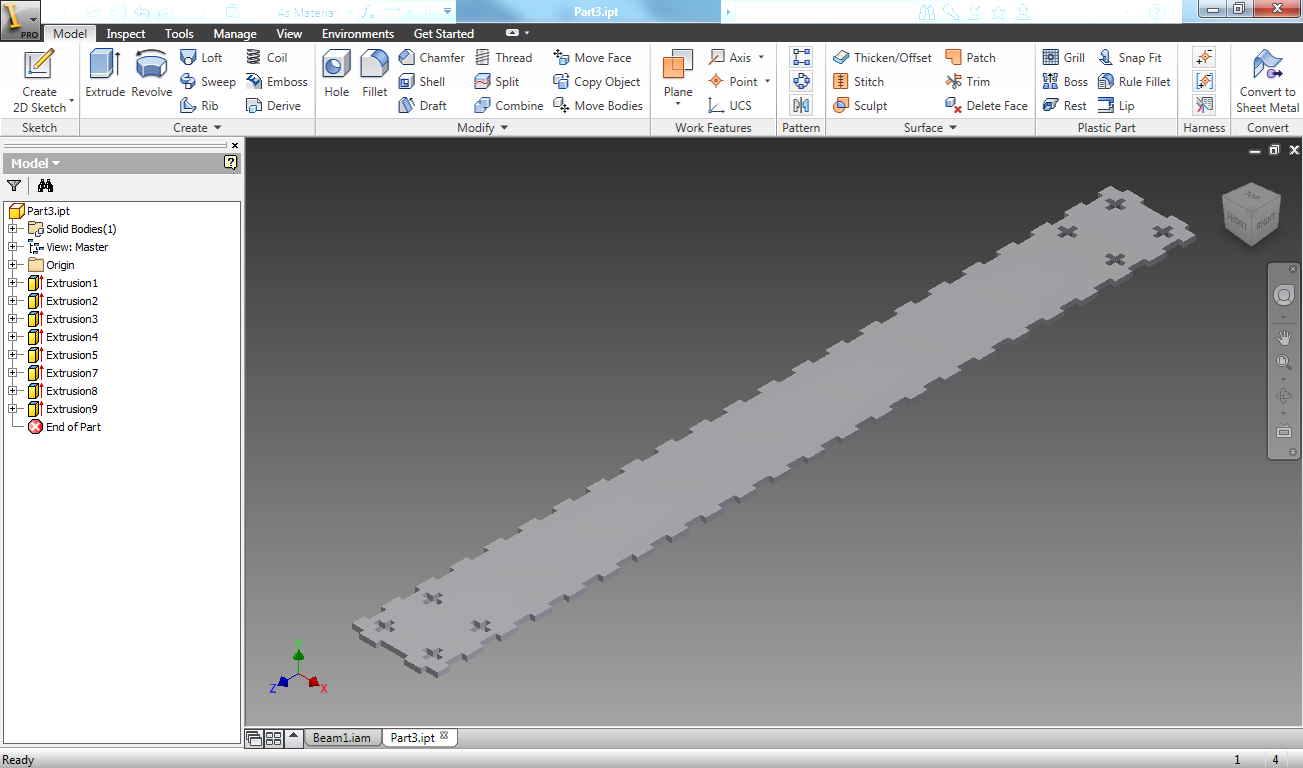

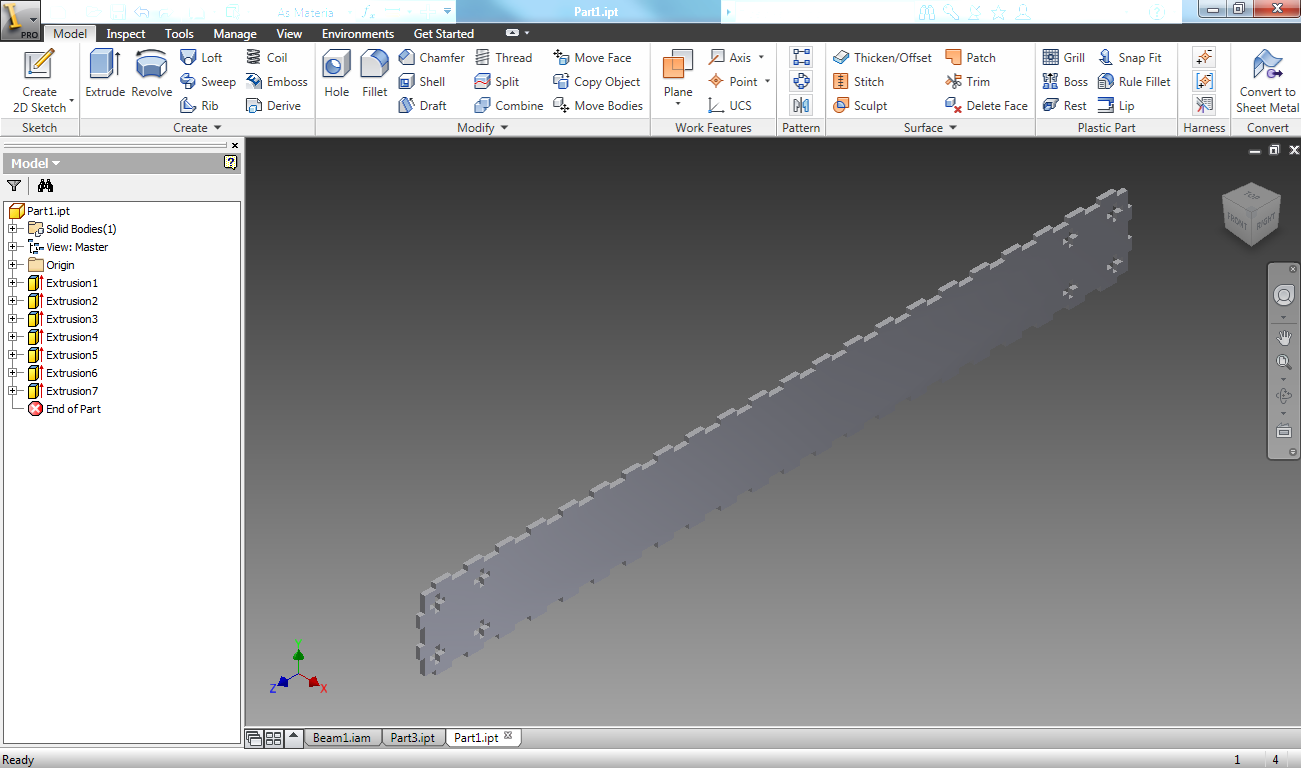

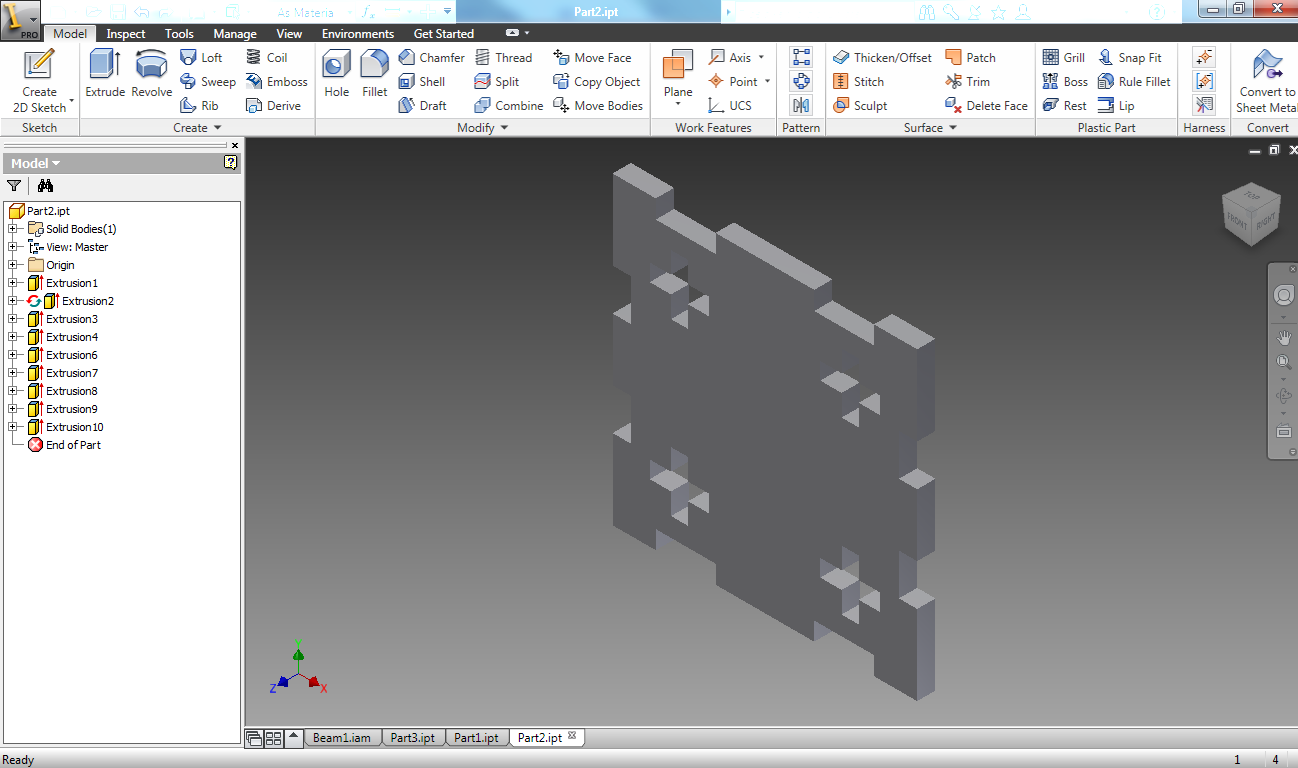

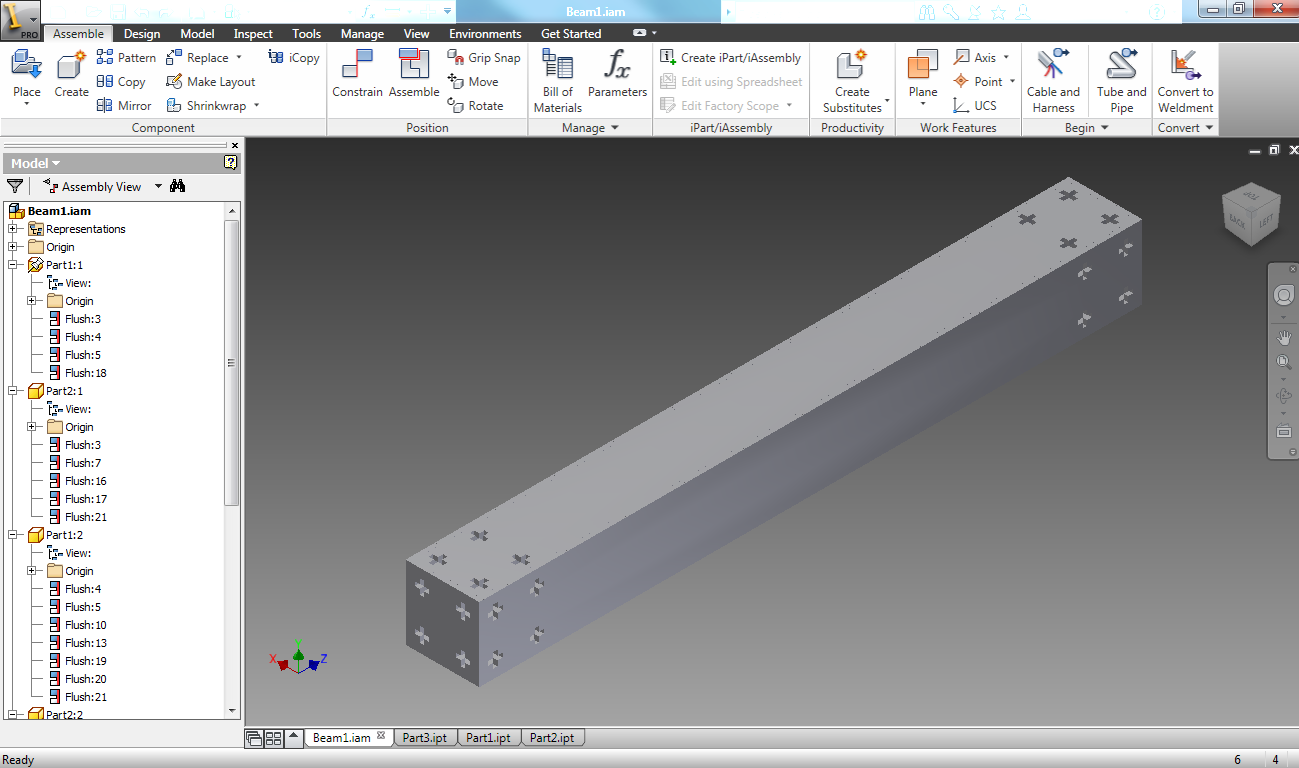

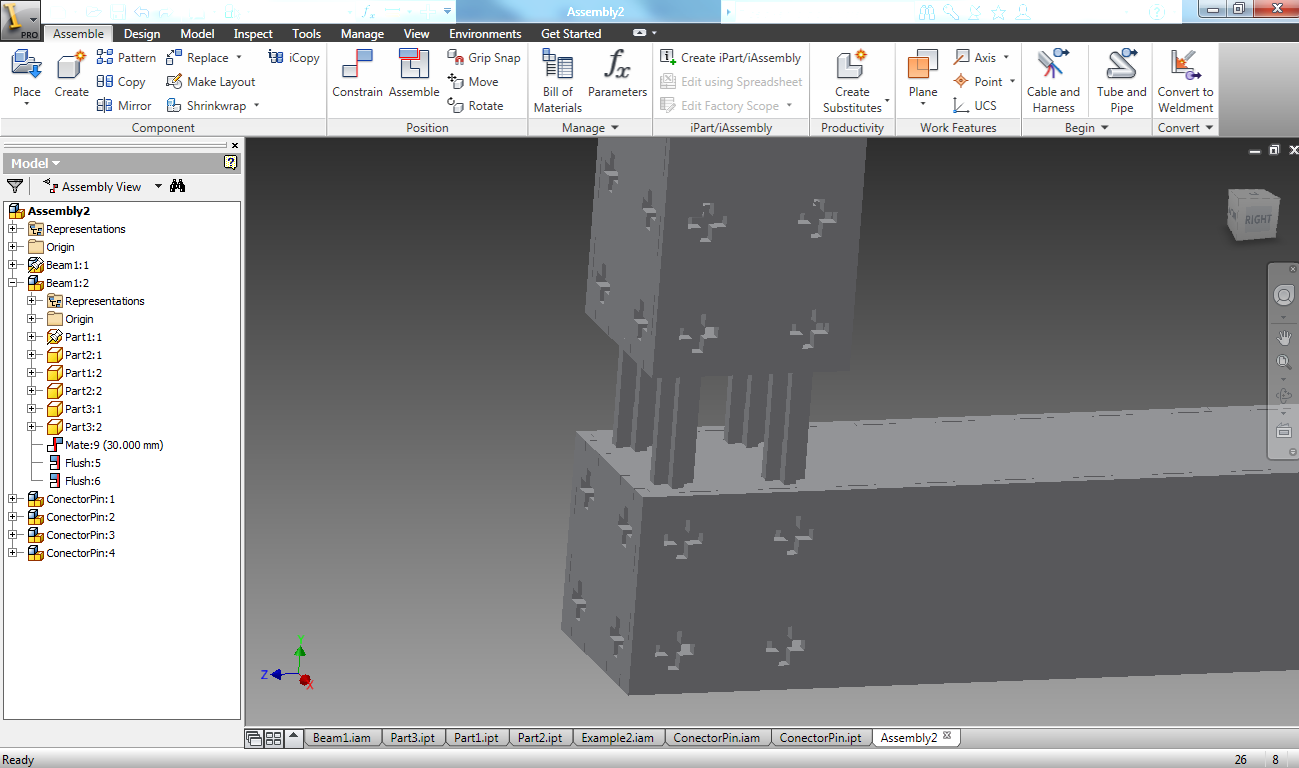

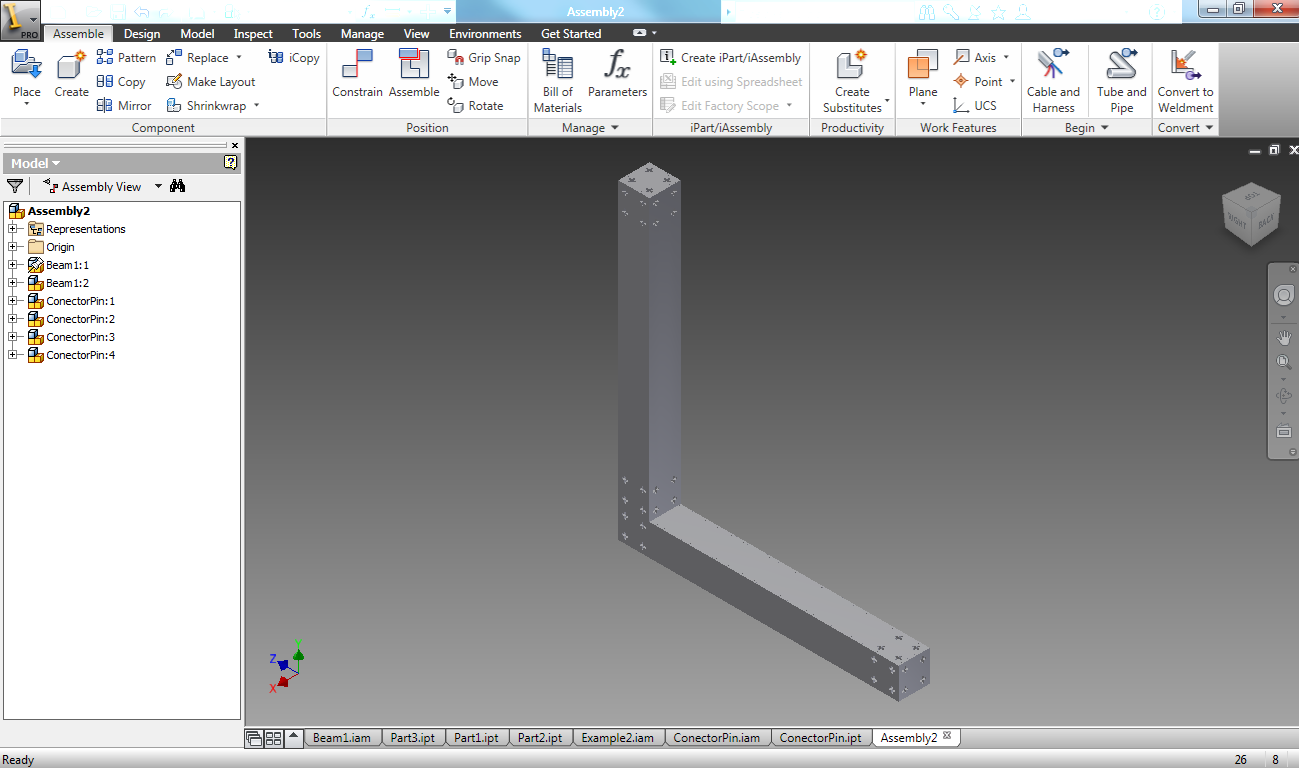

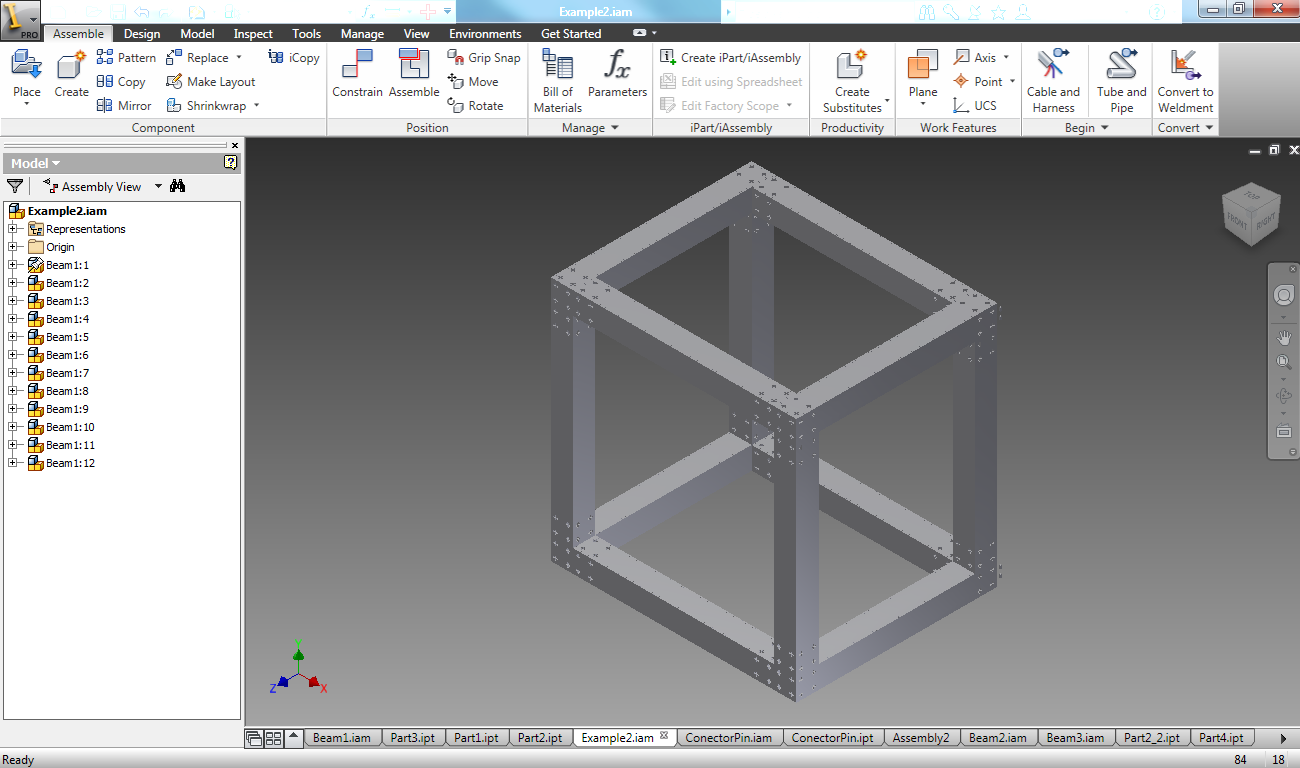

but stopping there for me was not going to be good so i also imported the files into autodesk inventor for 3D visualization and virtual Assembly to build some virtual Structures and to test the geometry

and after assembly of the 2D parts

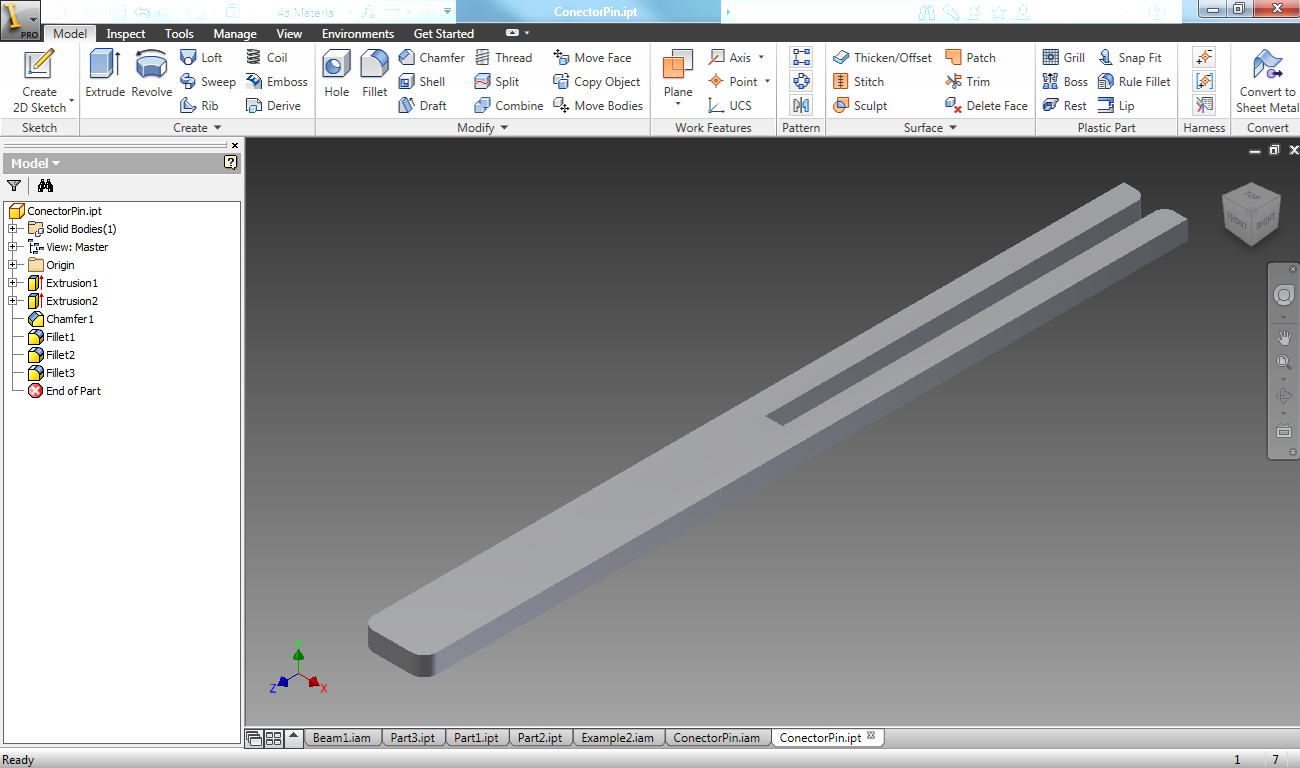

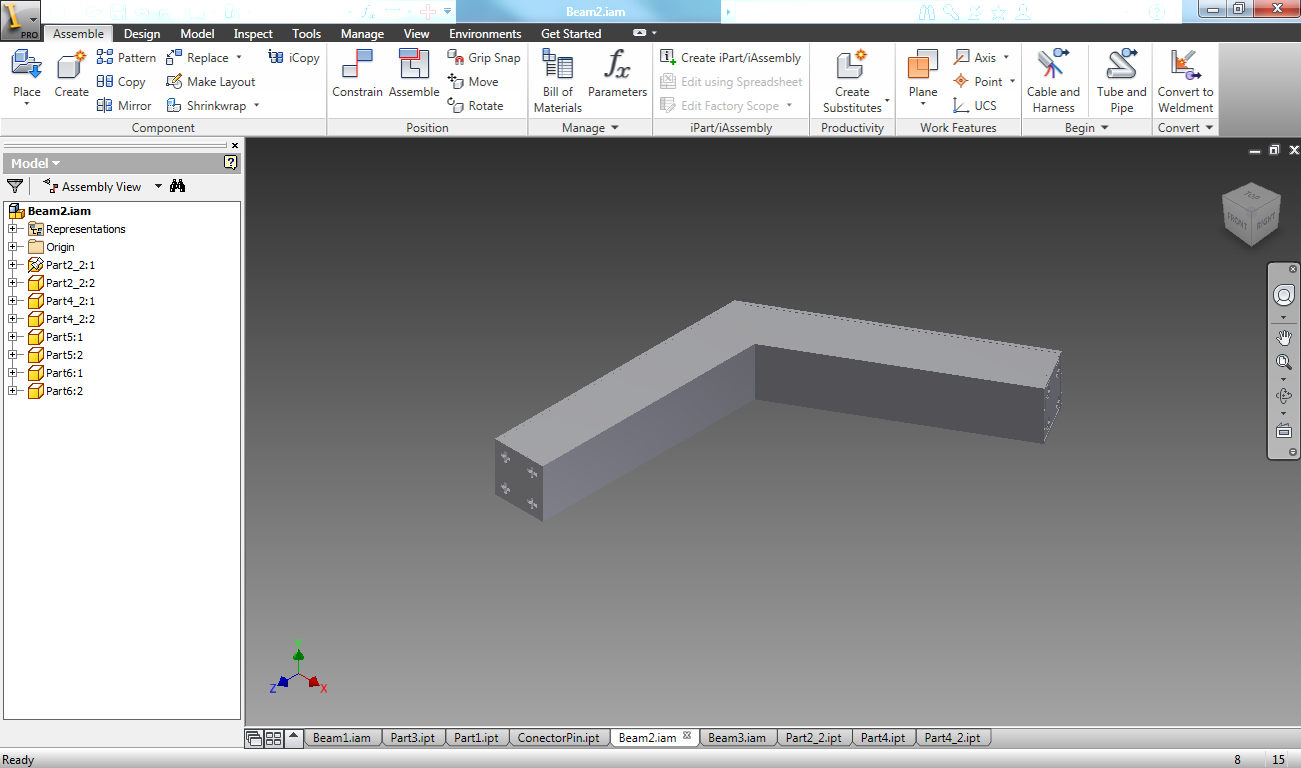

and now we have a 450mm long straight beam Boring, but now lets add the connector pin

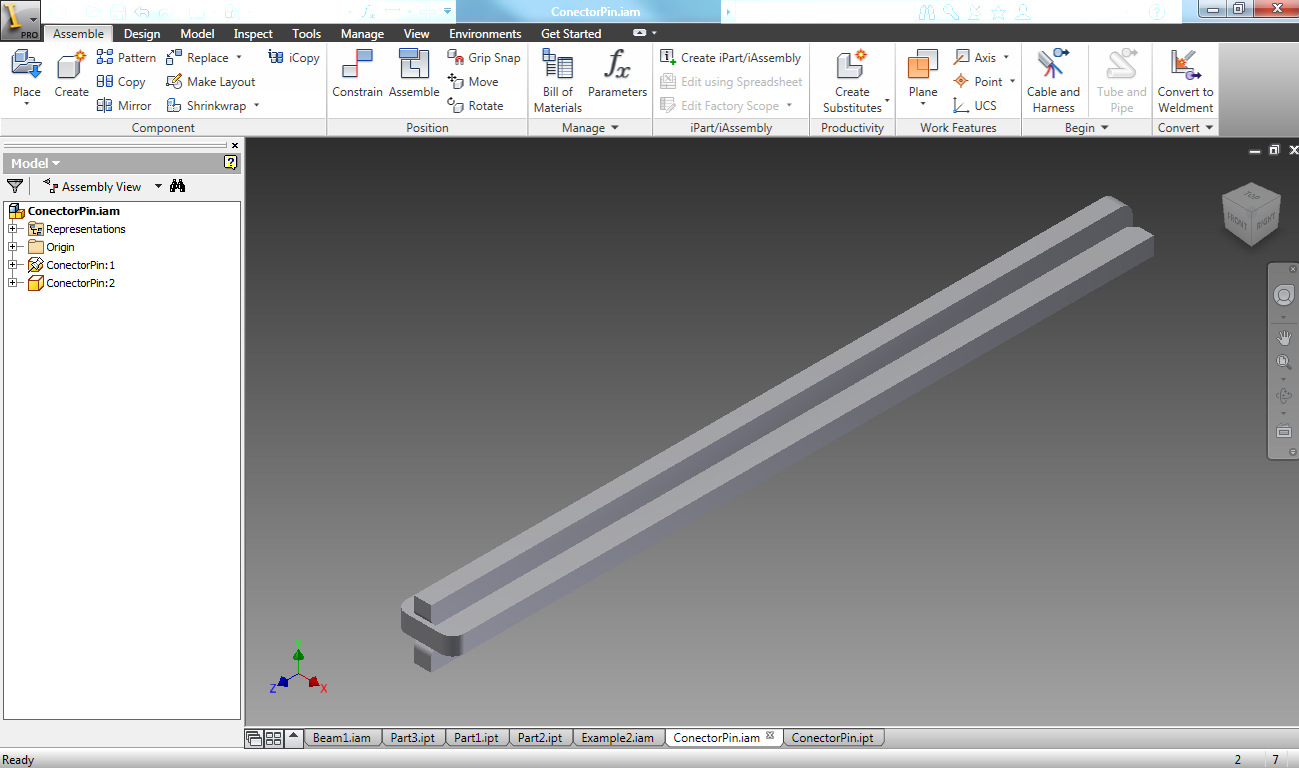

Assembling the beams with the connector pins in this fashion

and now i can build

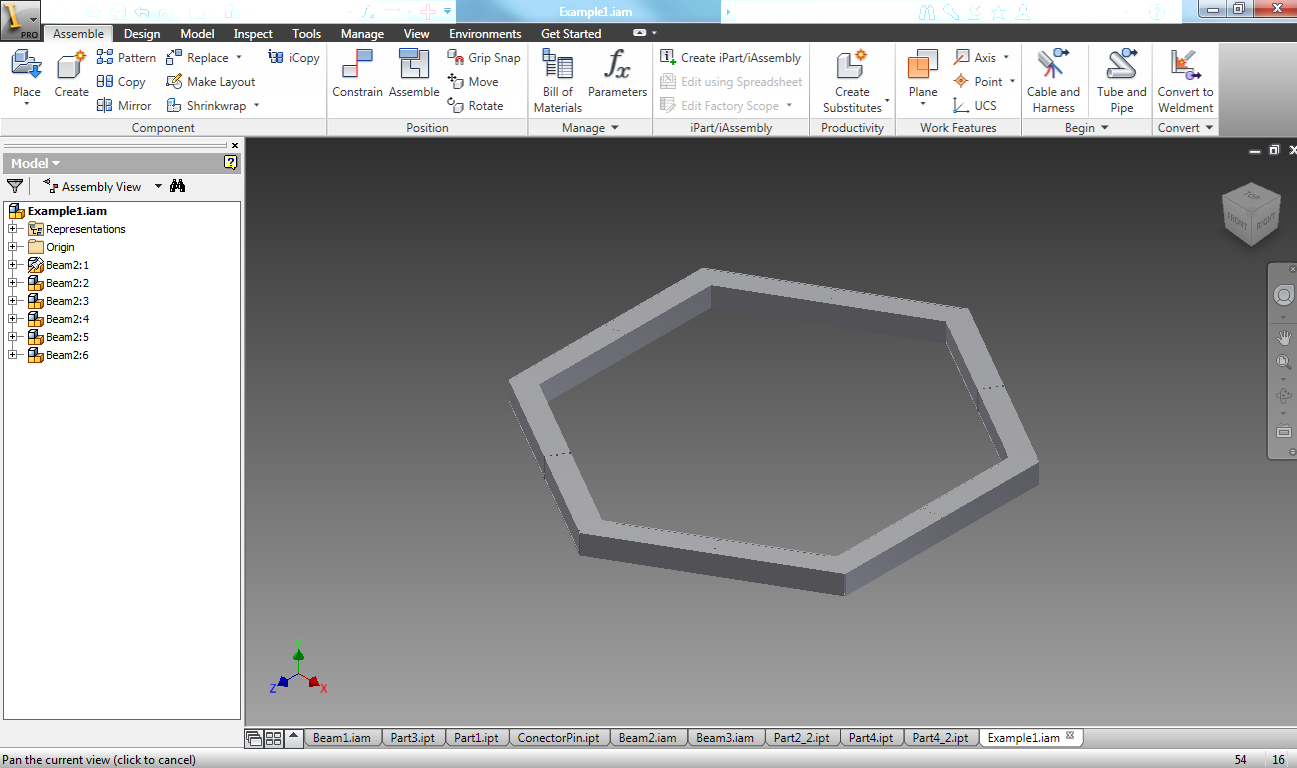

But i am not Stopping there how about building a Hexagon, Drawing a 120 deg Beam is no big deal now

And So:

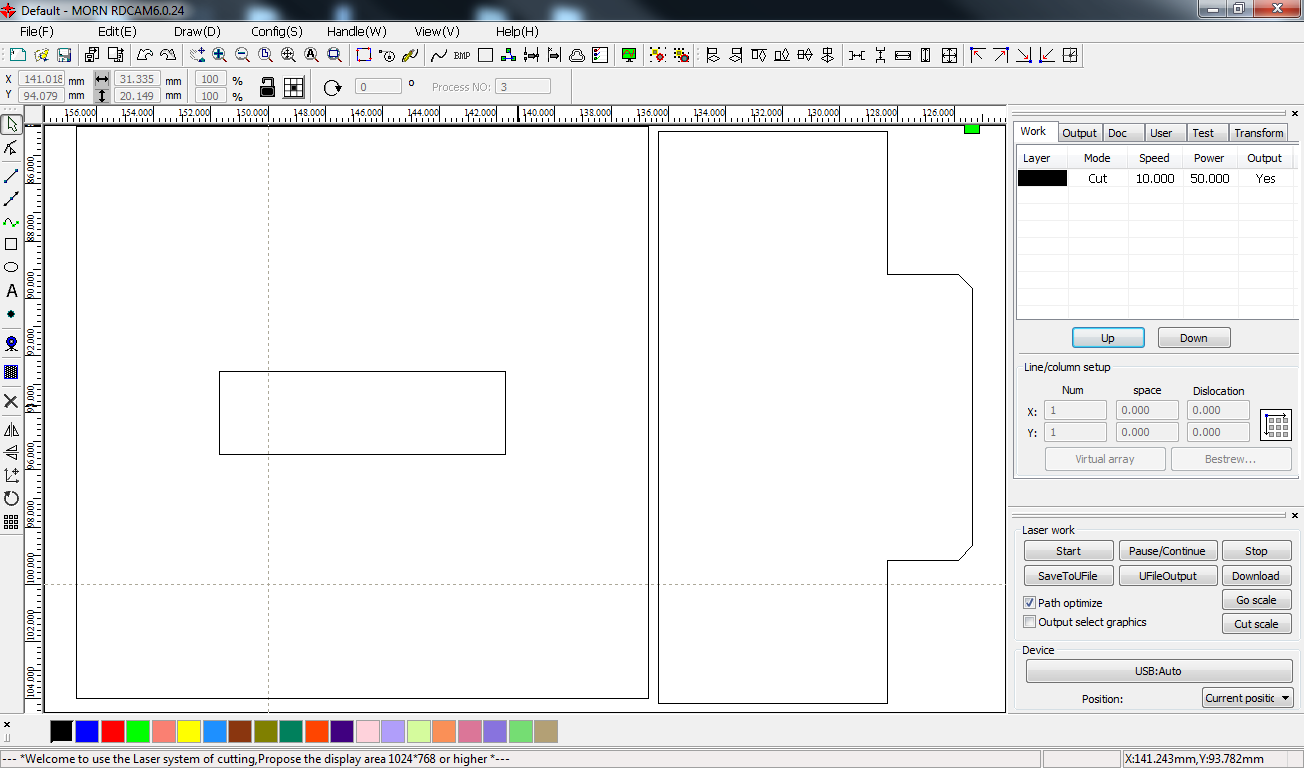

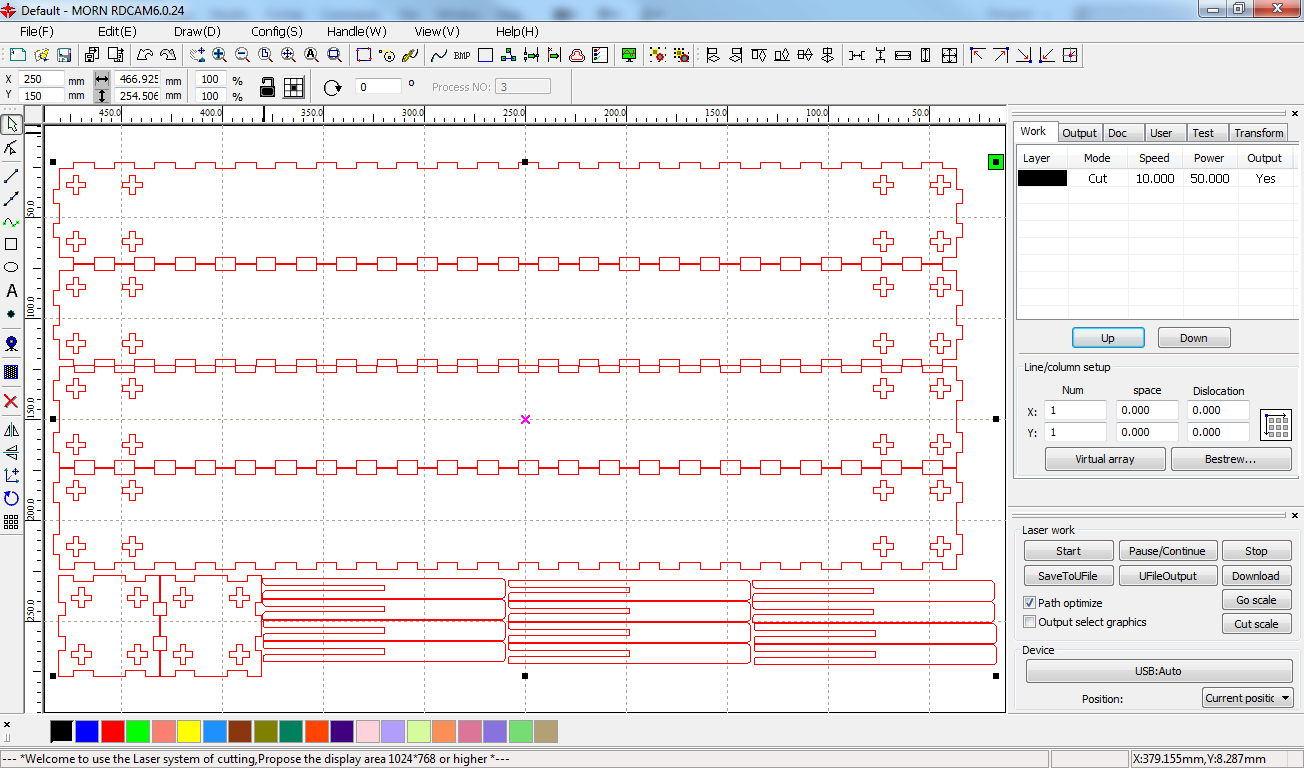

Now comes Fabrication, We have a MORN Laser cutter that uses the MORN laserworks software to communicate to the Laser Cutter it takes DXF files so after exporting the files form Inkscape you can cut them but before cutting the real parts i had to cut a small test piece to make sure that the press fits are snapping together nice and tight

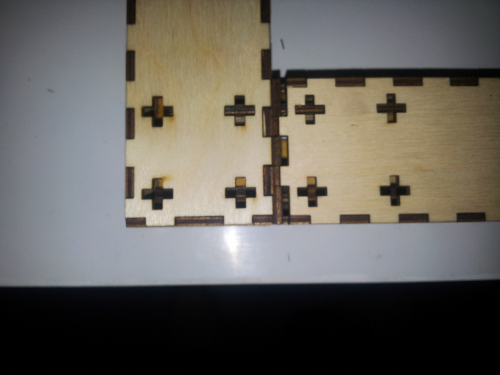

using 3mm material my 1st trial allowed me to find the Kerf of the laser cutter by looking at the kerf table and then measuring the difference thus the right amount to compensate for is 0.09mm and thus i was off to cut out all the parts

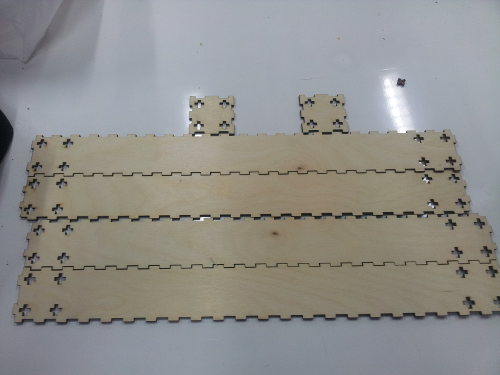

And after a successful cut

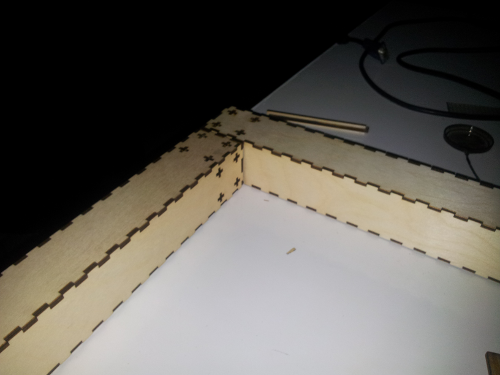

and now assembly

after assembling the individual Beams now comes the joint making a right angle

And that's it for this week there is a lot of thing that i still need to tweak in this project but nonetheless it came as good as as i expected and i am seeing myself using it in several project including the ROSADP Project