Week 6 3D Scanning & Printing

by Moritz Begle

Posted on March 04, 2013 at 15:00 PM

The aim of this class assignment was to design/scan and 3D print an object (small, few cm) that could not be made subtractively.

The content of the class can be found "here" .

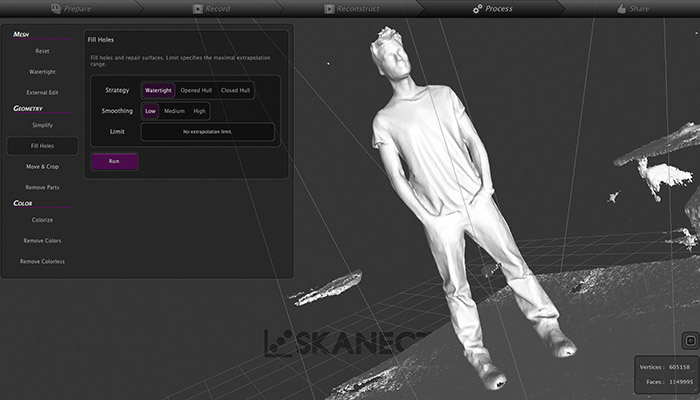

Scanning:With the help of another colleague I scanned myself with the Kinect for Xbox360 using Skanect to translate the datas in a meshmodel. In skanect you directly have the opportunity to repair your mesh, filling the existing wholes and exporting it as an OBJ. file.

Meshrepair:

Meshrepair:

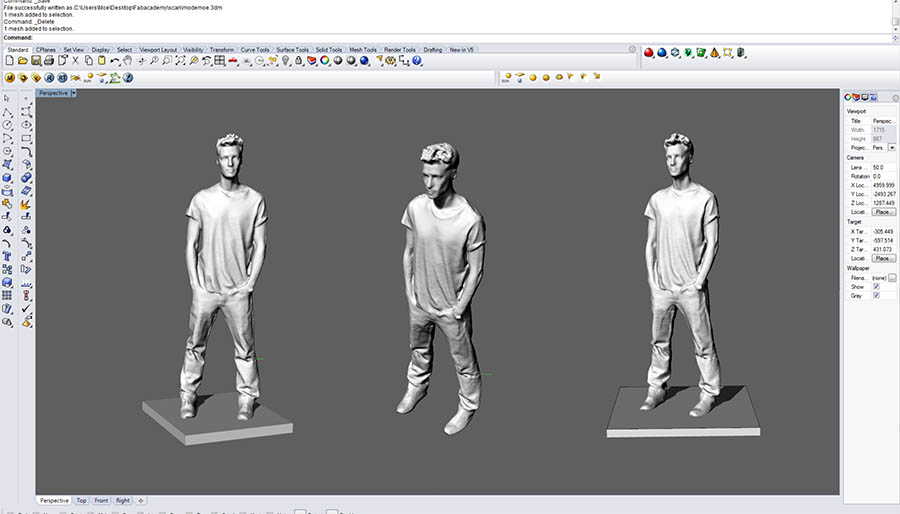

The OBJ.file is being imported to rhino where you make sure that you have a "good mesh" and get rid of the naked edges, manifolds, etc... through the "Meshrepair" funtction. The object then is being exported as an STL file.

Printing:

Printing:

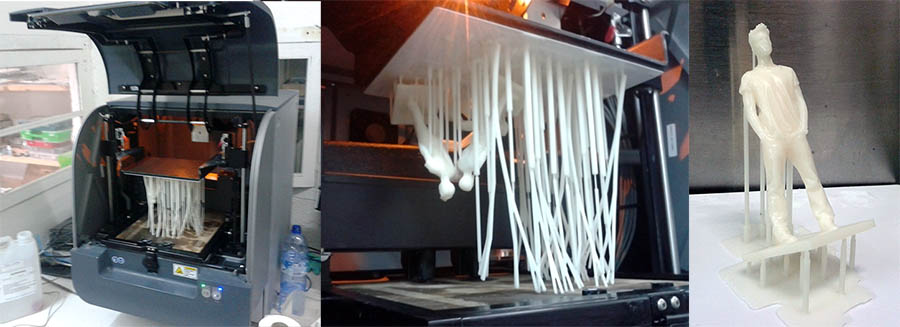

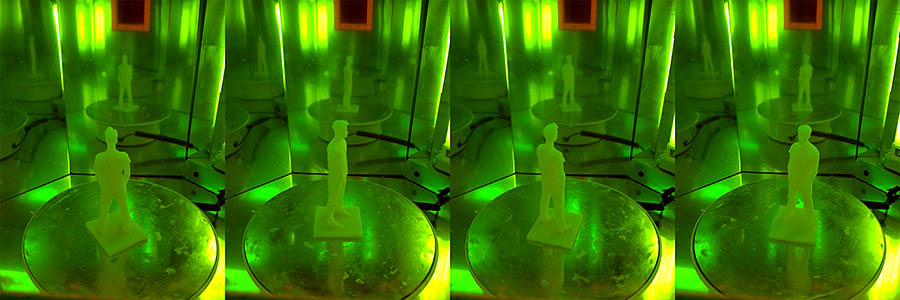

I used the Projet 1500 for the 3D printing process which is using raisin and uv light. The software that comes with it is automatically creating supports for the printed object. The process until to make the Projet "print ready" is quiet time-consuming and expensive. (Building plate, washing unit, cleaning material, raisin, UV Box)

After a printing time of approx. 20h including other projects being printed, the statue has to be cleaned in the washing unit and manuallay with soap. Afterwards its being baked for 15 min in the UV box.

Blog Search

Keywords

3D scanning, 3D printing, Kintect, Mesh Repair, ProJet, Raisin