The air hockey table (Original Idea)

My final project idea is an air hockey table. I played with one of this machines a lot of time ago when I was a child and since this moment I want to have one, or better, build my own personalized air hockey table.

I'm planning the construction process like this:

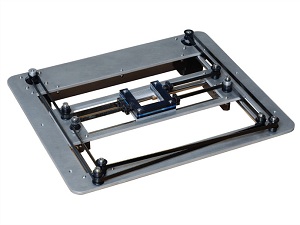

CNC Milling Machine (Final Idea)

After the some advances in the idea of the Air hockey table, we decide to develope and other machine the ZYX Core, inspired in the Core XY cartesian platform. Also we will try to made it portable.

All the material we have to bought in the local markets. Here in Peru is dificult to bouth some elements, normally we need to import this, and it take several time normally. So that we take the desition to develope with local material.

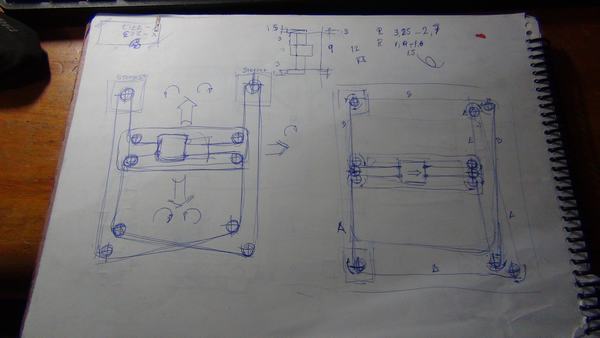

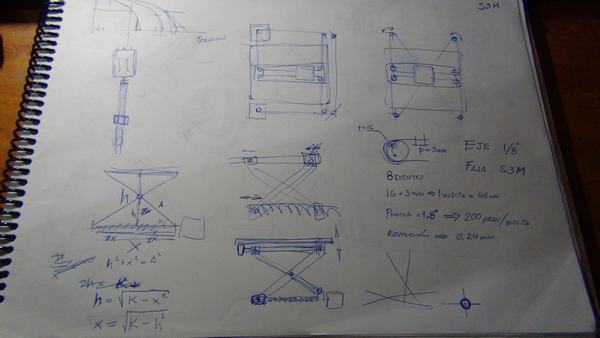

Before start the construction process, I'd draw some sketches in paper of the posicion of the parts and the functión.

(I drawed many others, but these two are de more legibles)

(I drawed many others, but these two are de more legibles)

I take some considerations for the manufacture: