Fab Lab Barcelona SuperNode /Fab Lab Sevilla /Jose Perez de Lama

Weeks 16-19++ / final project

Retablillo de las Maravillas v1.0

Developed july>>august 2013

3./ Mechanics

3.1/ Motorized platform

[3./ mechanics]

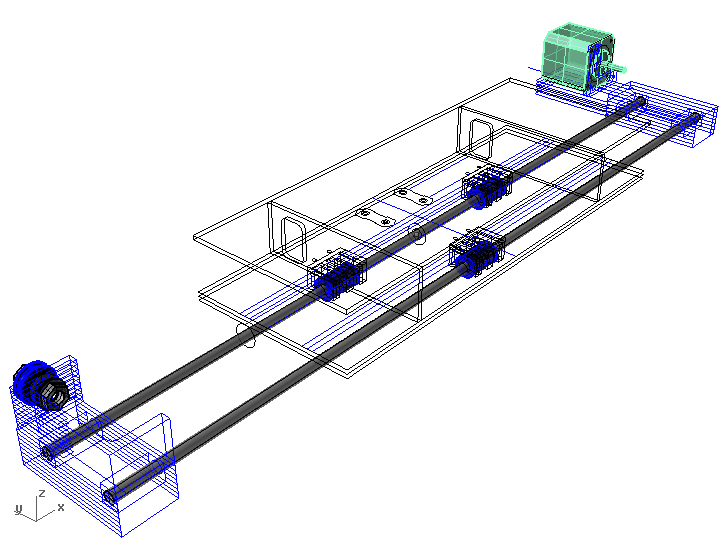

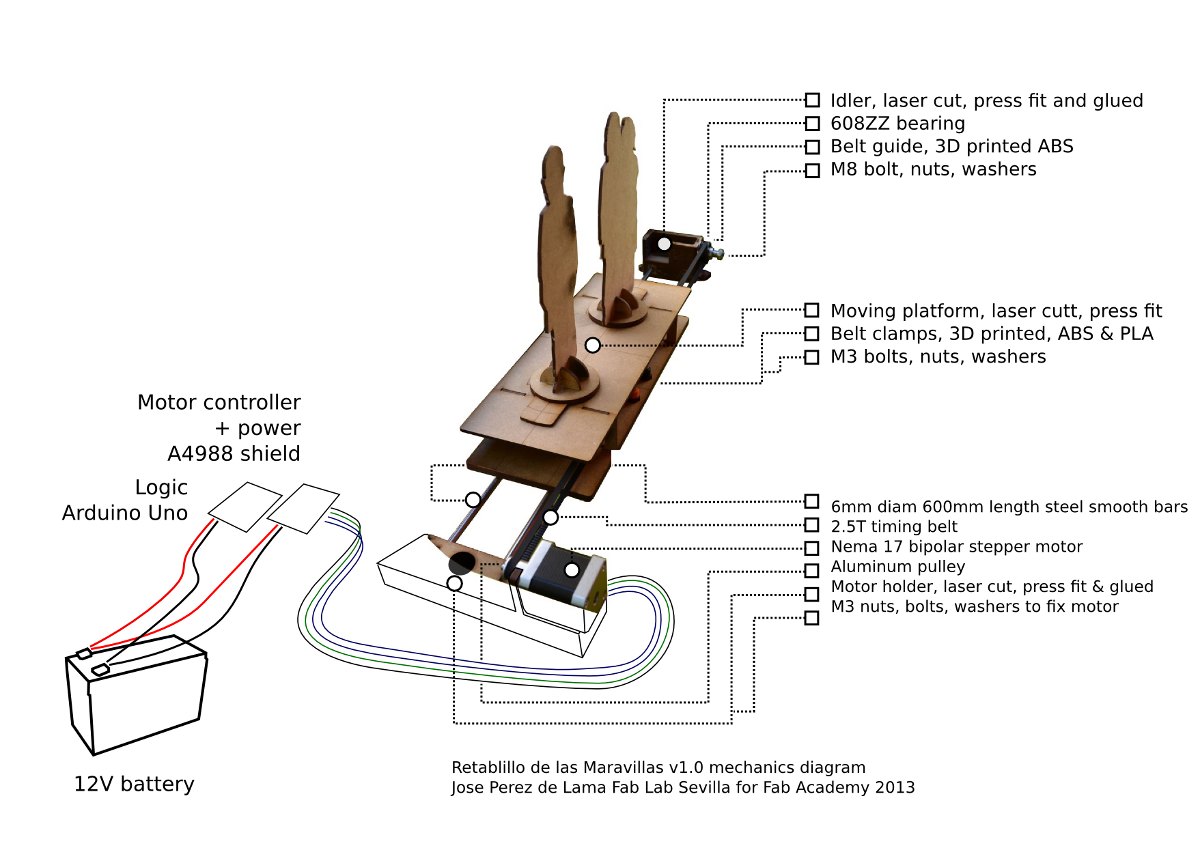

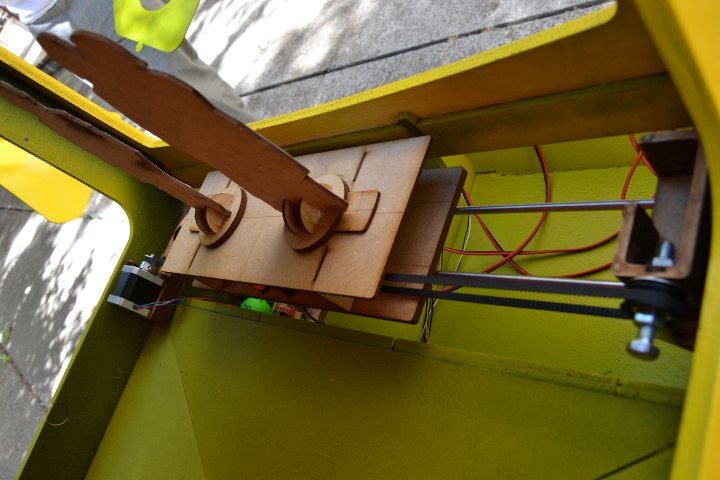

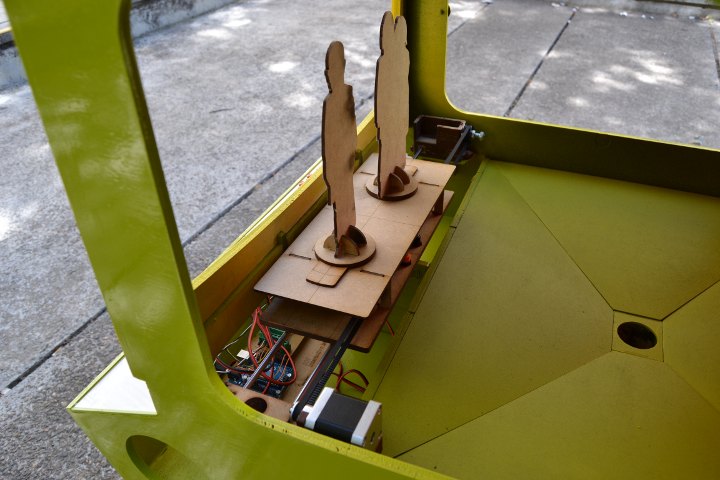

Mechanics consist in the implementation of a platform moving back and forth in a single axis [x]. It is performed adapting the x-carriage design of a Prusa Mendel i2, that we fabricated during Fab Academy 2013, with minor changes.

The system includes a Nema17 stepper motor [Wantai, from reprapworld.com], two 6mm smooth steel bars [instead of the 8mm of the Reprap] 600 mm long, a 2.5T timing belt, one aluminum pulley and one 608ZZ bearing [also from reprapworld.com], 3D printed belt clamps and bearing envelope [printed with a Makerbot Replicator I],

No LM8UU linear bearings have been used, but the smooth rods move directly on wooden laser-cut bushings - lubricated with WD-40 - attached to the lower side of the actual moving platform.

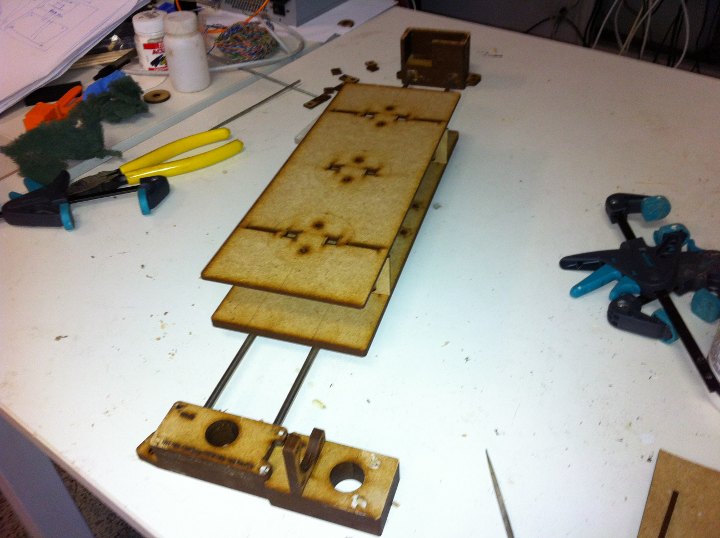

The motor mount and idler pieces where redesigned and fabricated with glued layers of 3mm laser-cut MDF, following a very efficient design we developed for our Prusa i2.

Eventually the actual moving platform was designed to be fabricated with laser-cut 3mm MDF and press-fit connections, leaving the necessary through holes for the timing belt and cables, connecting the switches [associated to the figures] on top of the platform to the I/O PCB.

The carriage works as an autonomous module that can be tested by itself, and then fixed with M3 bolts and nuts into two small shelves, as well laser cut in 3mm MDF, press-fit & glued to the chassis.#

Above: Rhinoceros image capture of a first version of mechanical design for the Retablillo. The linear bearings shown in the image weren't eventually used; the 8mm bars smooth bars 600 mm length, were eventually changed for 6mm diameter bars that were available in the lab. The new design for laser cutting of the idler and motor holder piece can be clearly appreciated in the image. The vertical elements of the platform leave holes for the timing belt to go through. In a final version of the platform a long hole was left in the lower layer to allow for the switches cables to pass down and have easy mobility when the platform moves sideways. Below, images of the assembly and testing process, and of the installed and functioning mechanism.

///

* "El Retablo de las Maravillas" is the title of a short story, “entremés”, by Spanish classic author Miguel de Cervantes, where he depicts a lighthearted while ironic story around a theatrical representation: http://miguelde.cervantes.com/pdf/El%20Retablo%20de%20las%20Maravillas.pdf

///

Unless otherwise stated, information in this page is downloadable under a Creative Commons Attribution-Share A Like license; attribution: Jose Perez de Lama / Fab Lab Sevilla / Fab Academy 2013. Work is based in the documentation provided by Neil Gershenfeld / Fab Academy 2013; and Anna Kaziunas, AS220 Fab Academy 2013; among other sources.

final project home / structure / mechanics / electronics / programming / all files

return home /perezdelama.jose