3D printing. Group 1.

Group members

Week 5 group assignment 3D printing

Introduction to the 3D printers

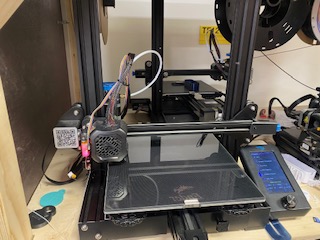

Creality Ender-3 v2

www.creality.com

Most common consumer 3D printer nowdays. FDM prinsible printer with heated bed. Very affordable price ranges from 200-350€ depending on version.

Picture1:Ender-3 v2

Raise 3D pro2

www.raise3d.com

FDM style dual extruder multimaterial printer. Larger print volume compared to Ender.

Picture2:Raise 3D pro2

Formlabs Form2

www.formlabs.com

Picture3:Formlabs Form2

Stratasys Fortus 380 mc

www.stratasys.com

Older generation industrial 3D printer. FDM prinsible with heated chamber. Very expensive proprieraty materials. Not very relevant by today standarts.

Picture4:Fortus 380 mc

Print settings

Table 2:

| Printer | Ender 3 pro | Raise 3D pro2 | Formlabs form 2 | Fortus 380 mc |

|---|---|---|---|---|

| Layer height | 0.2 mm | 0.2 mm | 0.16 mm | 0.254 mm |

| Material | PLA | ABS | Resin: Grey V4 | ABS |

| Bed temp | 60 C | 100 C | Operating temp | (Oven temp) 315 C |

| Material extruder temp | 200 C | 240 C | Melt point 250 | 130 C |

| Print time | 2h 56min | 3h 34min | 2h 1m | 1h 14min |

Table 3: Printers setting's for TEST2

| Printer | Ender 3 V2 | Raise 3D pro2 | Formlabs form 2 | Fortus 380 mc |

|---|---|---|---|---|

| Layer height | 0.3 mm | 0.2 mm | 0.16 mm | 0.254 mm |

| Material | PLA | ABS | Resin: Grey V4 | ABS |

| Bed temp | 60 C | 100 C | Operating temp | (Oven temp) 315 C |

| Material extruder temp | 200 C | 240 C | Melt point 250 | 130 C |

| Print time | 36min | 1h30min | 1h30min | 27min |

| TABLE 4: Printers' Settings for TEST3 | ||||

|---|---|---|---|---|

| Printer | Ender-3 pro | Raise 3D pro2 | Formlabs form2 | Fortus 380 mc |

| Layer height | 0.2 mm | 0.2 mm | 1.6 mm | 0.254 0mm |

| Material | PLA | ABS (hips support) | Resin | ABS |

| Support | Zig Zag | None | No internal support | SR3 |

| Bed Temp | 60 | 100 | - | 92 |

| Material Extruder Temp | 200 | 240 | - | 230 |

| Support Extruder Temp | 200 | 250 | - | 230 |

| PrintTime | 2h 55min | 1h 56 min | 1h 30 min | 1h 27 min |

Table 5: General specification

| Printer | Ender 3 V2 | Raise 3D pro2 | Formlabs form 2 | Fortus 380 mc |

|---|---|---|---|---|

| Nozle diam. | 0.4 mm | 0.4 mm | - | 0.4 |

| Build volume (mm) | 220x220x250 | 305x305x300 | 145x145x175 | 356x305x305 |

| Printing presision (mm) | +-0.1 | +-0.01-0.25 | +-0.1-0.05 | +-0.127 |

Testing for design rules

Test 1

Picture5:Test1 - Ender 3 V2

Picture6:Test1 - Raise 3D pro 2

Picture7:Test1 - Formlabs Form2

Picture8:Test1 - Fortus 380 mc

Angle and overhang:

Ender 3 V2: flawless overhang until 60 degrees after that quality starts declining

Raise 3D pro2: flawless overhang until 60 degrees after that quality starts declining

Formlabs Form2: best result, overhang looks flawless all the way

Fortus 380 mc: worst result, flawless overhang until 50 degrees after that quality starts declining, filaments start hanging

Bridging:

Ender 3 V2: there is some loose filament on some bridges

Raise 3D pro2: bridging looks good, no problem

Formlabs Form2: bridging looks good, no problem

Fortus 380 mc: worst result, all bridges are failing

Hole:

Ender 3 V2: holes look good

Raise 3D pro2: holes look good, best result for FDM style printers

Formlabs Form2: best result, holes look very good

Fortus 380 mc: worst result, but still looks good

Scale:

Measurement in design 10 mm

Ender 3 V2: horizontal measurements x 9,9 mm and y 10 mm, vertical measurement 10,1 mm

Raise 3D pro2: both horizontal measurements 10,25, vertical measurement 10 mm

Formlabs Form2: both horizontal measurements 10,5 mm, vertical measurement 9,6 mm

Fortus 380 mc: both horizontal measurements 10,2 mm, vertical measurement 10 mm

Stringing:

Ender 3 V2: looks good, we don't see any oozing

Raise 3D pro2: with very close inspection (one eye closed) we found some little oozing

Formlabs Form2: best result, nothing to report

Fortus 380 mc: worst result, lot of oozing on the test area

Diameter:

Measurements in design 6 mm and 8 mm

Ender 3 V2: 5,5 mm and 7,55 mm

Raise 3D pro2: 6 mm and 8 mm

Formlabs Form2: 6 mm and 8 mm

Fortus 380 mc: 6 mm and 8 mm

Test 2

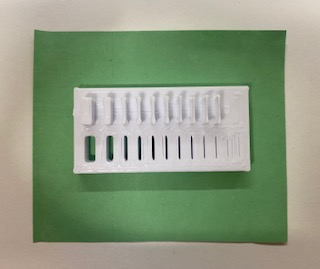

Wall Thickness:

Ender 3 V2: .3 wall was last succesful one. All holes were made. Print quality lower than Raise or Formlabs.

Picture9:Test2 - Ender 3 V2

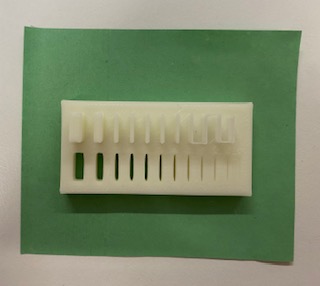

Raise 3D pro2: Overall measurements match, .1 wall didn't print. Print quality excellent.

Picture10:Test2 - Raise 3D pro2

Formlabs Form2: All walls printed ok, with holes .6 smallest that succeeded and with all holes corners were rounded.

Picture11:Test2 - Formlabs Form2

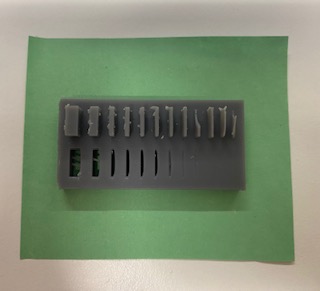

Fortus 380 mc: .5 wall and .3 hole was last succesful. Worst print quality from the group.

Picture12:Test2 - Fortus 380 mc

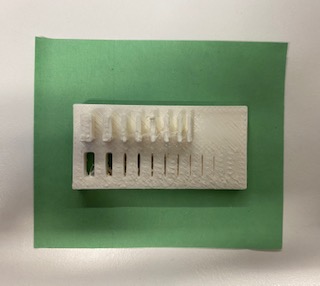

Test 3

Picture13:Test3 - Ender 3 V2

Picture14:Test3 - Raise 3D pro2

Picture15:Test3 - Formlab Form2

Picture16:Test3 - Fortus 380 mc

Overhang:

The test pieces were printed with support.

Ender 3 V2: With supports overhang printed just fine.

Raise 3D pro2: Printed piece missing.

Formlabs Form2: Overhang has failed, but supports haven't been used. Effect is that there's leafing on the overhang.

Fortus 380 mc: With supports overhang printed just fine.

Clearance:

The test pieces were printed with support.

Ender 3 V2: 0.1 and 0.2 clearance between parts was too small; the pieces are not moving. Other move freely.

Raise 3D pro2: Printing was failed and the result is unclear.

Formlabs Form2: Only parts with 1, 0.9 and 0.8 clearance are moving freely, others are stuck. Some resin residual can be seen between axel and tolerance cube in all other cases.

Fortus 380 mc: All parts are stuck, because there is still support material between axel and tolerance cube. Piece should have been longer time in solvent.