4. Computer controlled cutting¶

This week I learned about Vinyl Cutter, Laser Cutter, Parametric construction kerf.

Vinyl cutting¶

i started to do my work from vinyl cutter it is also known to be sticker cutter.

Before designing the the sticker,i got to know about vinyl cutter.

The key factors which are important in using vinyl cutter are;

1.speed

2.pressure(the force given to the blede, to cut the vinyl)

The vinylvcutter we use is the software used for running this machine is cutstudio

I designed LOGO using inkscape software then i made screen shoot and i saved as image in PNG and import in cutstudio as image.i used youtube tutorials click here.

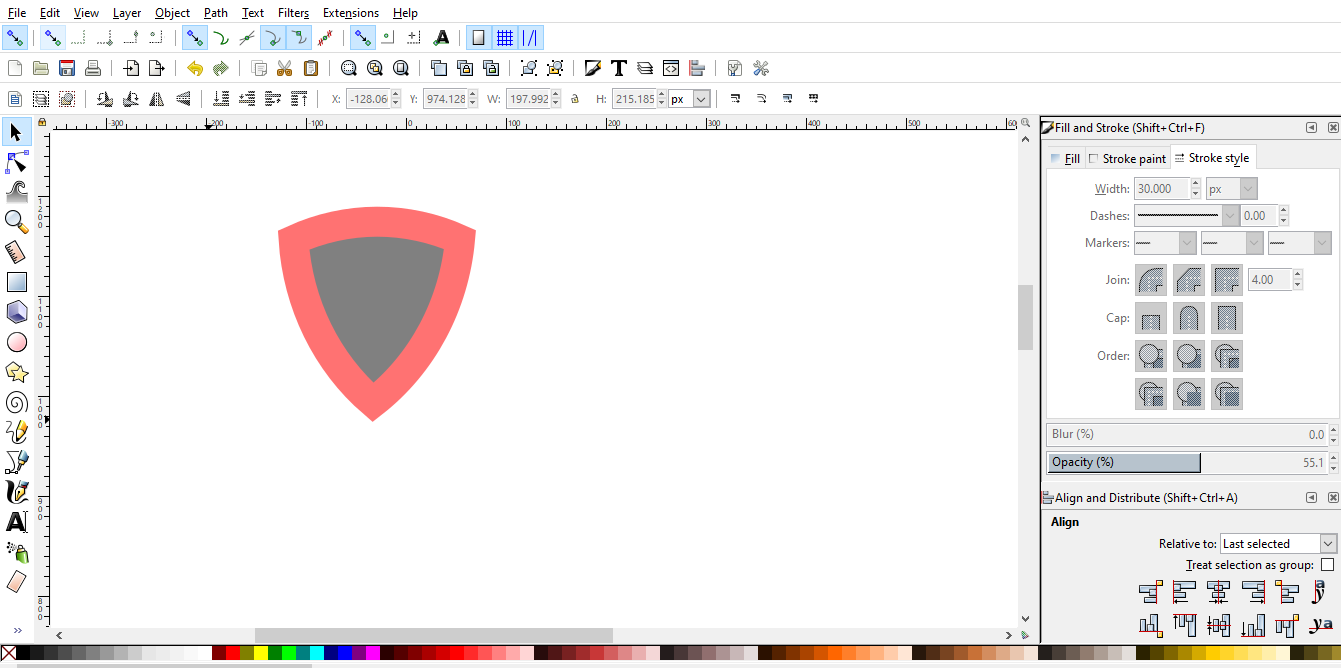

I started designing the logo in inkscape.

I used youtube designing Logo and change some of its words.

Like this, the sticker is feed and placed in the vinyl cutter and ready to cut out

I am smashing the printed logo from blue paper to white paper.

I had to remove part of logo.

I had put sticker logo on my loptop.

Remove part that doesn’t correspond to the design.

the final result I transfered printed logo to my loptop.

Laser cutter¶

Laser machines can cut wood,paper, plastic, fabric and much more with such high precision and speed, giving lasers aclear advantage over other types of cutting technologies.

I had used the same tutorials used in venycutter to carry out work in lasser cutter.

I used youtube tutorials to carry out this assignment click here.

i have used inkscape to design my logo in vector 2D

Open inkscape software, draw circle with capacity 50% black color,make duplicate to other 2 circles, select all circles then make Align distribute, go to interface click path then click intersection.

Go to interface select path click stroke path to paint color at edge of sketch, go to text and font editor write ENOCCK MWINE then apply in the centre of logo, duplicate and select difference,increase color capacity to 100%, from tool bar select star insert it in logo make duplicate to other 2 stars then select path then click difference

I used coredraw software to cut my logo in laser cut, i have to go in settings to check the following, power: 100% ,speed:10%, frequency 250hz sheet. there fore i have to use cardbpard of dimmension thickness: 3mm

This is laser cutter machine which i used to cut my work.The Laser cut machine i used is EPILOG LASER was made in USA

This is cut logo from laser cutter.

Parametric construction kit¶

1.using FREECAD

I will be creating laser cut cardboard pieeces that can stick together. I started by opening up FREECAD in order to start the designing process. i began by creating a basic rectangles that i added the parameters of cardboard thickness so that the pieces i will create which i will create will be able to stick together.

I start open the freecad software, i draw spreadsheets.

spreadsheet.width=50.00mm, spreadsheet.length=60.00mm,spreadsheet.height=10.00mm,

Below,from tool bar select design and draw the rectangle with length = 60mm, width =50mm.

Below,extrude for height =10mm

Below, each side draw small rectangle length = 10mm, width = 2.8mm

Below, cut those rectangles remaining is parametric.

The Laser cut machine i used is EPILOG LASER was made in USA

.parameters used;

sheet thickness: 3mm

power: 100%

speed:10%

Laser cutter is cutting parametric kit using laser beam

Below, i have to construct parametric kit

2.using solidworks

I started by opening up SOLIDWORKS in order to start the designing process. i began by creating a basic hexagon,rectangle,triangle and corner that i added the parameters of cardboards thickness so that the pieces i will create which i will create will be able to stick together.

I start open the SOLIDWORKS Software.

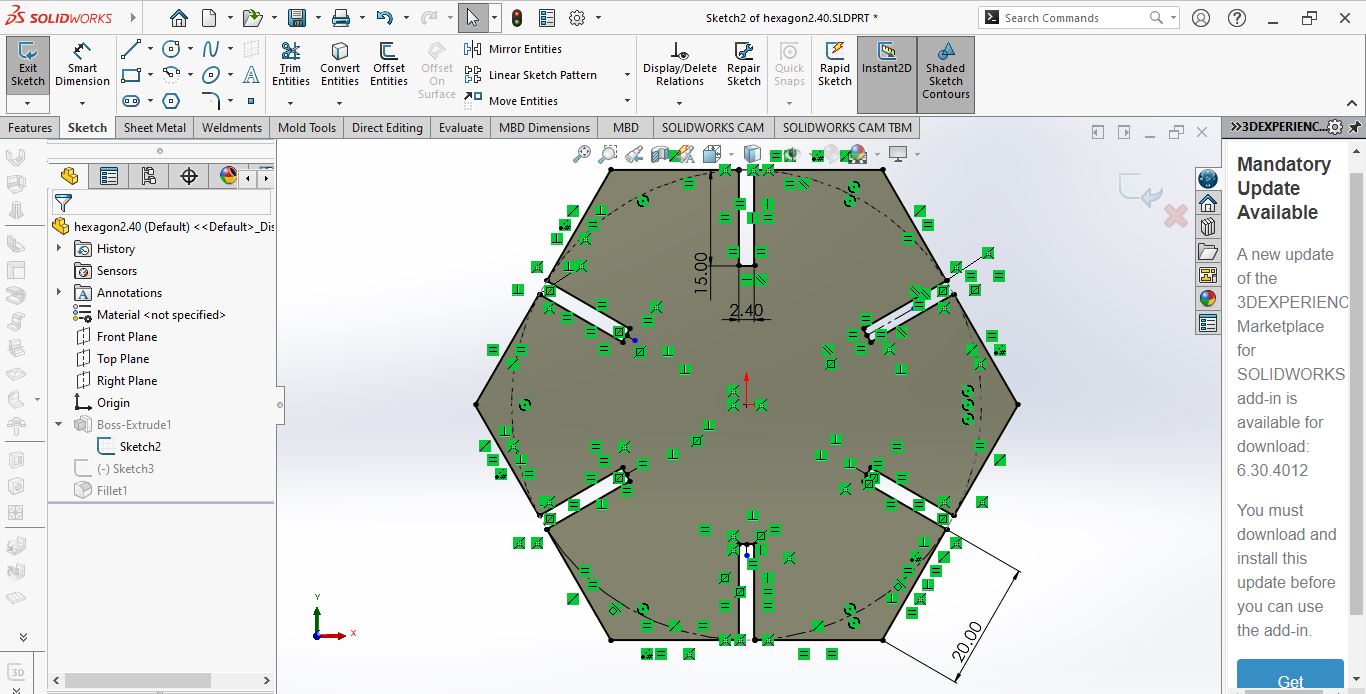

1.Hexagon

I opened solidworks software and i selected polygon on interface. i choose hexagon of six sides and i selected dimmension from interface, i choose diameter =60mm. I add relations by press ctrl click all sides and click equal sin

On each side of hexagon i draw rectangle of length =5mm and width =3mm.I add relations by press ctrl and click lengths of rectangles then click equal sin,press ctrl and click widths of rectangles then click equal sin

From interface click extrude cut and figure got cut

Below is hexagon figure shape which cut rectangle shape all sides

I have to check if it is parametric varying lengths and width i changed one length from 5mm to 15mm all length changed and varying width from 3mm to 2.4mm all width changed.and side varying from from age to cut shape is 20mm

Below is final hexagon figure shape which cut rectangle shape all sides length of 15mm and width of 2.4mm

2.Rectangle

I opened solidworks software and i draw rectangle figure of length 60mm and width 50mm, on each side i draw rectangle of length 8mm and width of 3mm. I add relations by press ctrl click all lengths click equal sin,press ctrl click all widths click equal sin.

From interface click extrude cut and figure got cut

Below is rectangle figure shape which cut rectangle shape all sides

I have to check if it is parametric varying lengths and width i changed one length 30mm from edge to cut side and width to 25mm and cut length changed from 5mm to 15mm and width from 3mm to 2.4mm

Below is final rectangle figure shape which cut rectangle shape all sides length of 15mm and width of 2.4mm

3.Triangle

I opened solidworks software and i draw triangle shape of sides 60mm. i add relations all sides are equal and i draw rectangle on one side

I add relations by press ctrl select all lengths click equal sin and also press ctrl select all width click equal sin.

From interface click extrude cut and figure got cut

Below is rectangle figure shape which cut triangle shape all sides

I have to check if it is parametric varying lengths and width i changed one length 30mm from edge to cut side and cut length from 5mm to 15mm and width from 3mm to 2.4mm.

Below is final rectangle figure shape which cut rectangle shape all sides length of 15mm and width of 2.4mm

4.Corner fixer

I opened solidworks software and i draw i draw shape which will help me to fix corners. I add relations by press ctrl select lengths click equal sin and press ctrl select width click equal sin.

I add dimensions big length =20mm inside length 8mm and width 3mm

Below is corner fixer figure shape which has rectangles all sides

I have to check if it is parametric varying lengths and width i changed length from 5mm to 15mm and width from 3mm to 2.4mm

Below is final fixing corner figure which has rectangle shape all sides length of 15mm and width of 2.4mm

The Laser cut machine i used is EPILOG LASER was made in USA

.parameters used;

sheet thickness: 2.4mm

power: 100%

speed:10%

Below, i have to construct parametric kit

MY FILES

Here i am uploading the filles that i have been making this week

PARAMETRIC CONSTRUCTION KIT File