17. Applications and implications¶

What will it do?¶

The main function I want this machine to have is the hability to produce parts for other machines very reliably. That`s the main reason I want to use leadscrews with anti backlash nuts.

Who´s done what Beforehand?¶

I made a list of fab academy students that made CNC machines on my Final project´s page

What will you design?¶

I will design a Robust, low budget Aluminium Frame CNC Router.

What materials and components will be required?¶

Where will they come from?¶

Most of the Parts, I already had laying around in my Shop, they where most remainigs from other machines, for example, the aluminium frame was the base of an old 3D systems Cube Pro duo.

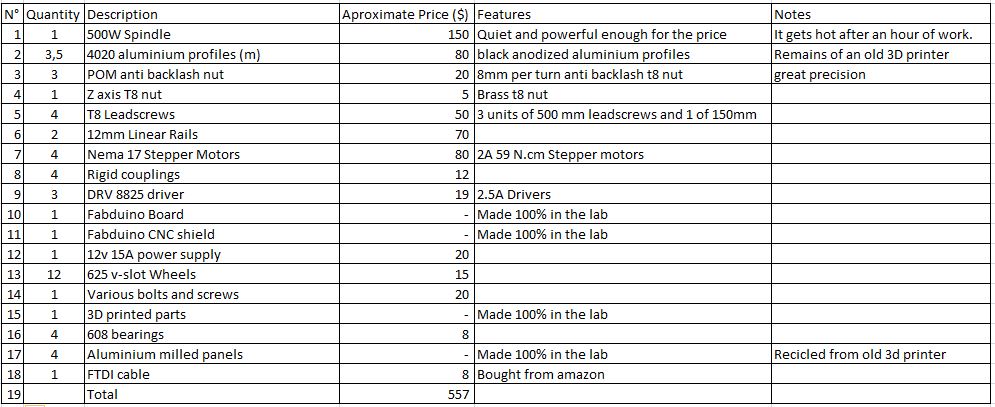

How Much will they cost?¶

If I will build it from scratch, it will probably cost around 600$, taking in consideration all the work putted into it, it cost probably around 1200$ or more as a product. I would also have to sell it with warranty and how to use guides, so I would probably sell the machine for 1400$ with the whole service.

What parts and systems will be made? / What processes will be used?¶

Parts made

- CNC milled Aluminium panels.

- CNC routed Clamping surface.

- 3D printed motor mounts.

- 3d printed bearing mounts.

- 3D printed m6 clamps.

- CNC milled PCBs (motherboard and cnc shield).

- Laser cutted prototypes.

What questions need to be answered?¶

- Will my mainboard work?

- will the Y motors be able to handle the 2Amps connected in series?

- will it be enjoyable to operate?

How will it be evaluated?¶

It will be evaluated practically, making engravings and movement tests.