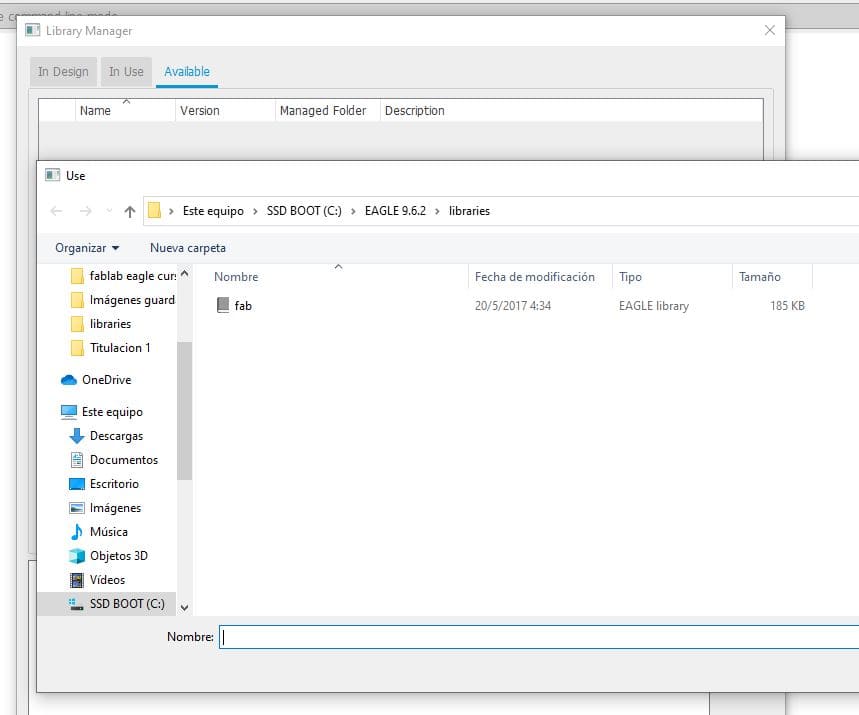

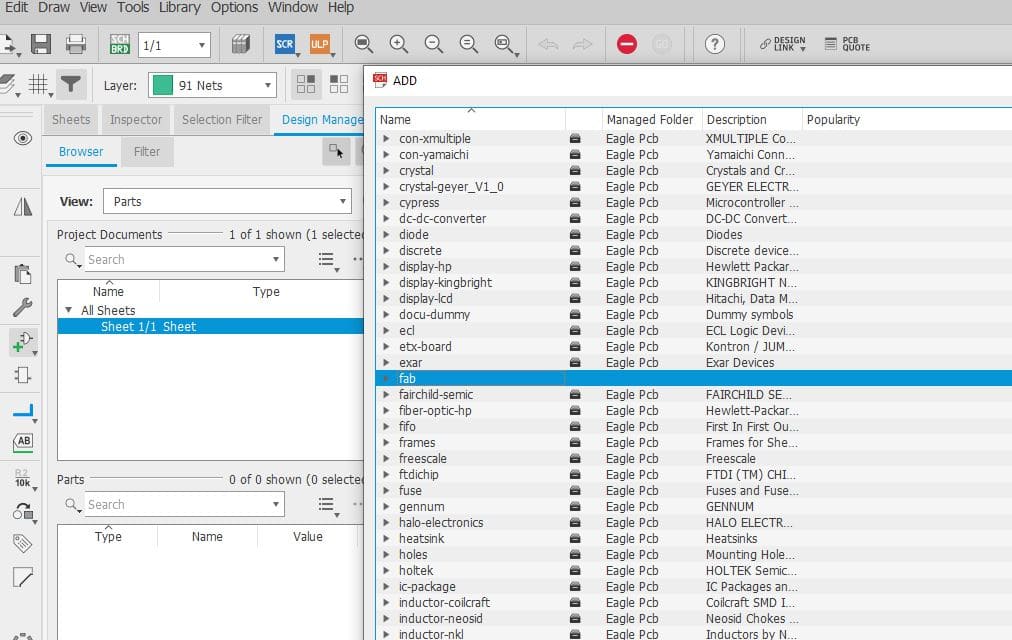

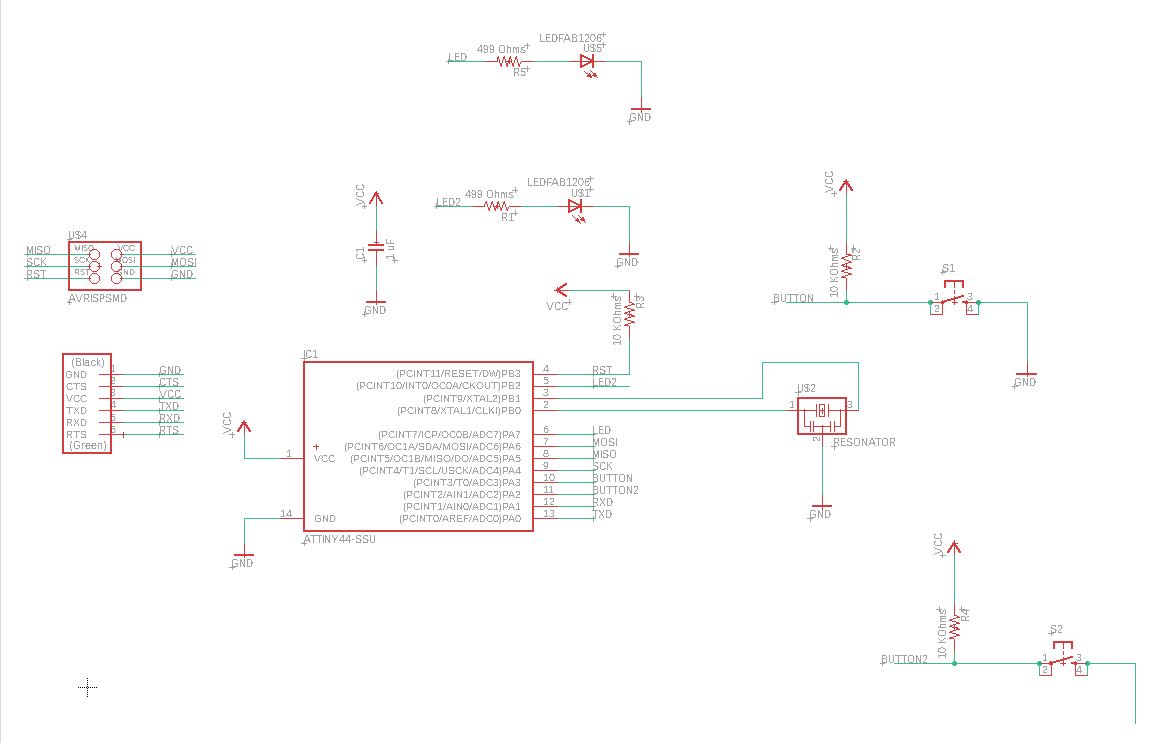

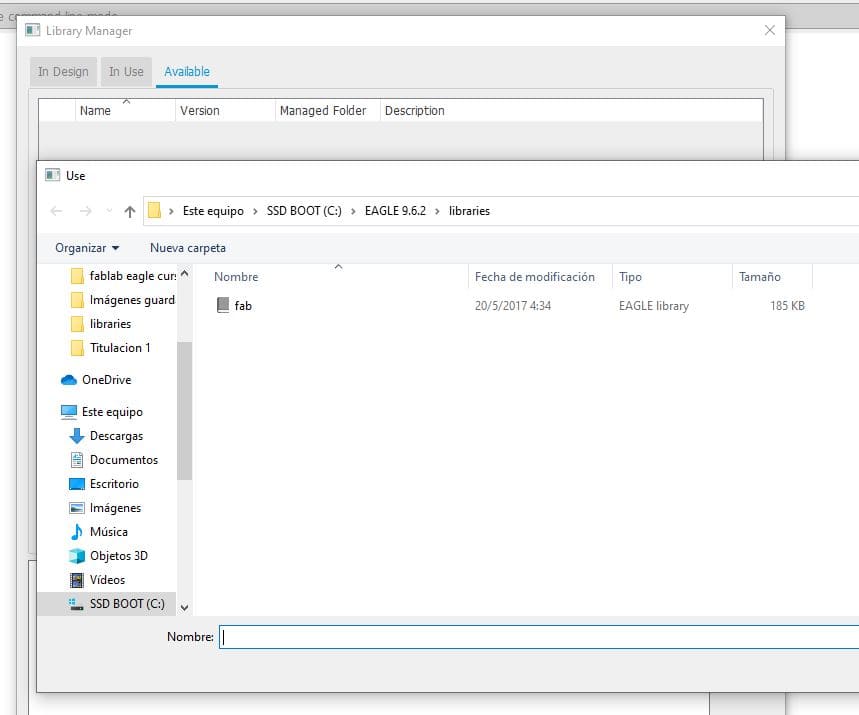

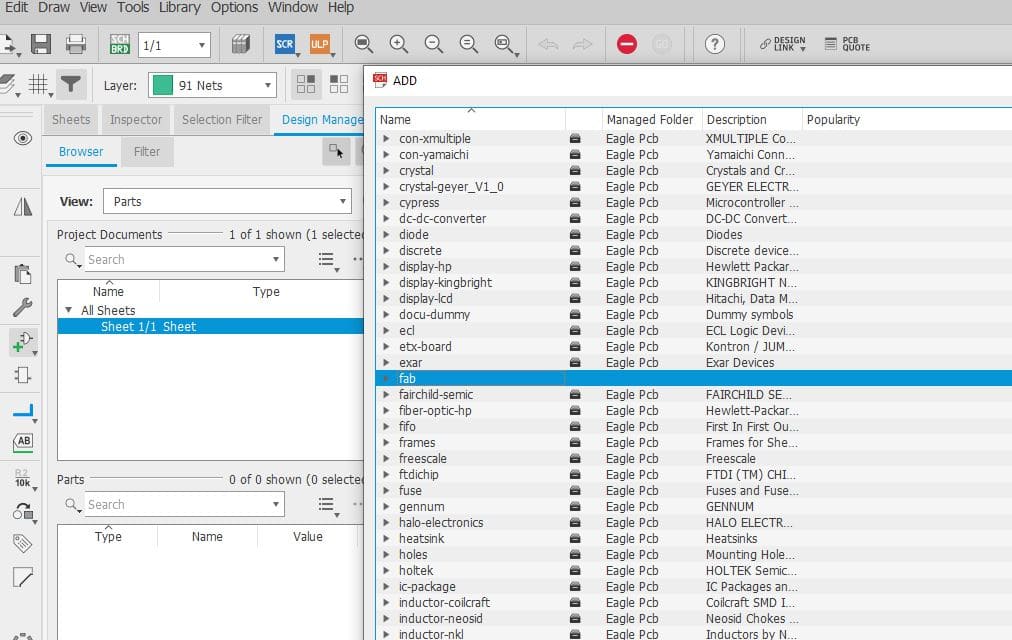

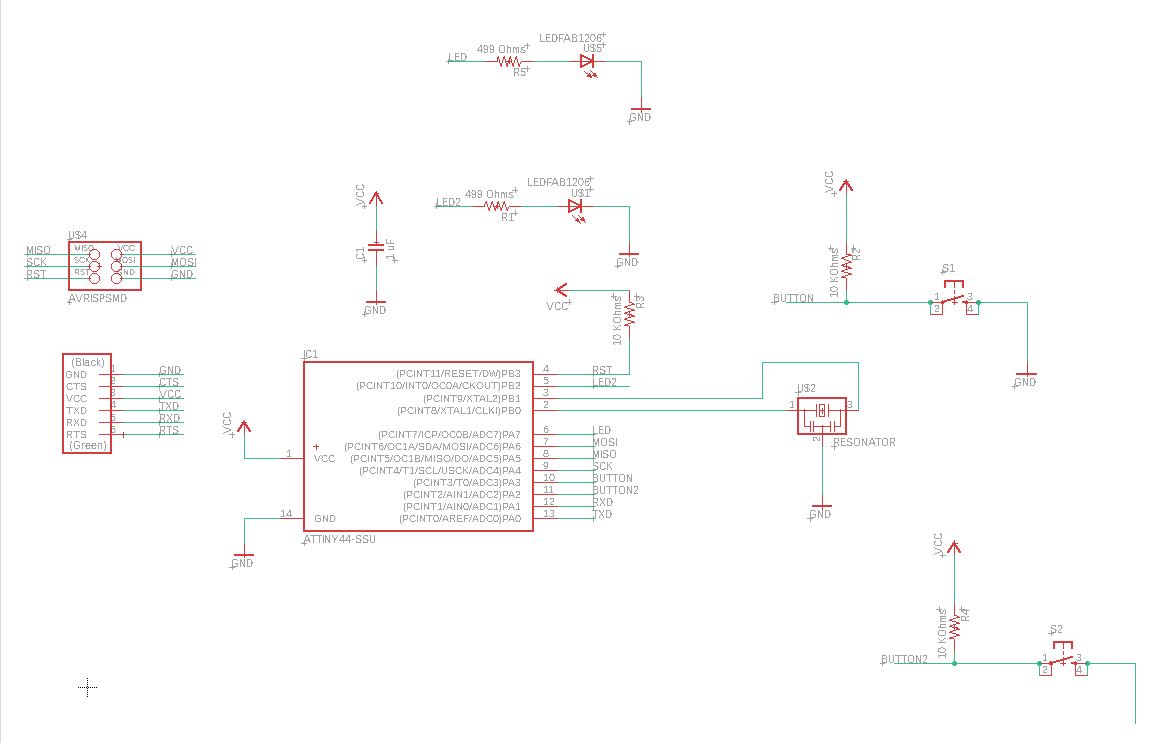

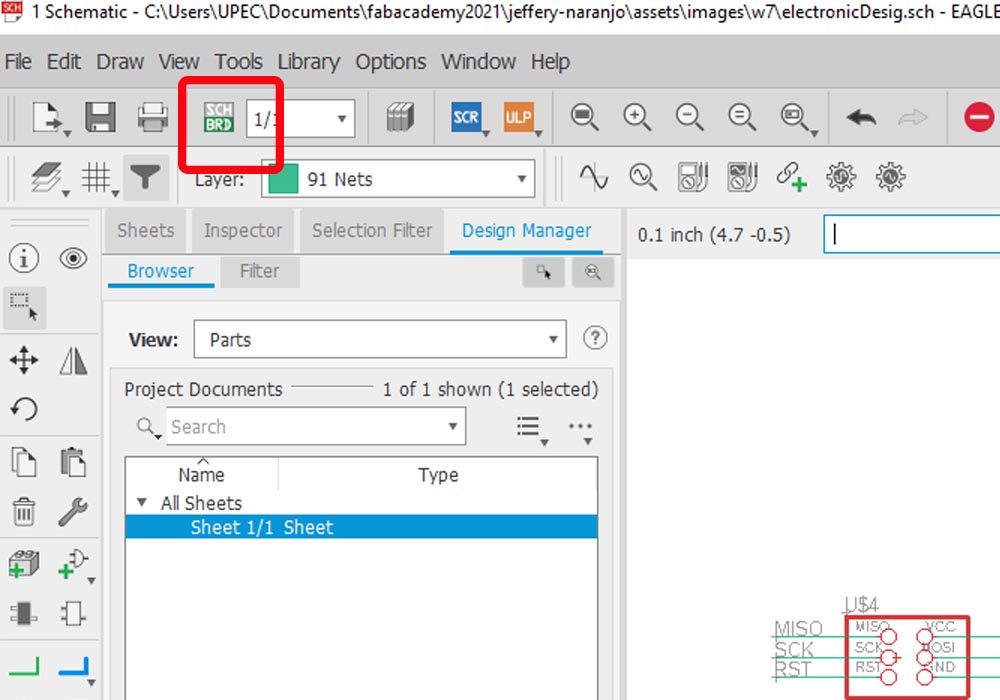

To start with the design, we loaded the Fab component library. it is important to be careful with the parameters of the components

as well as their polarities

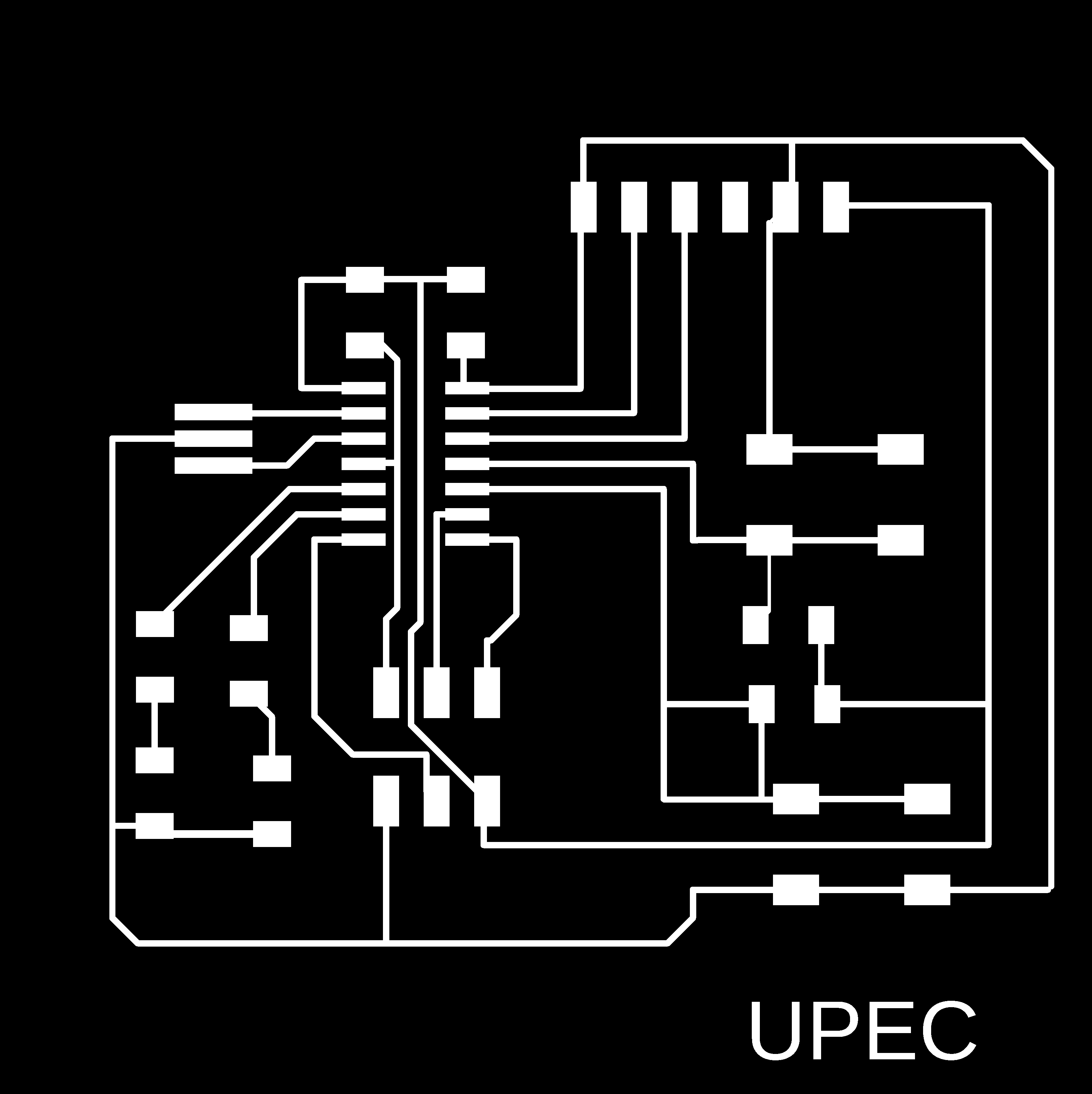

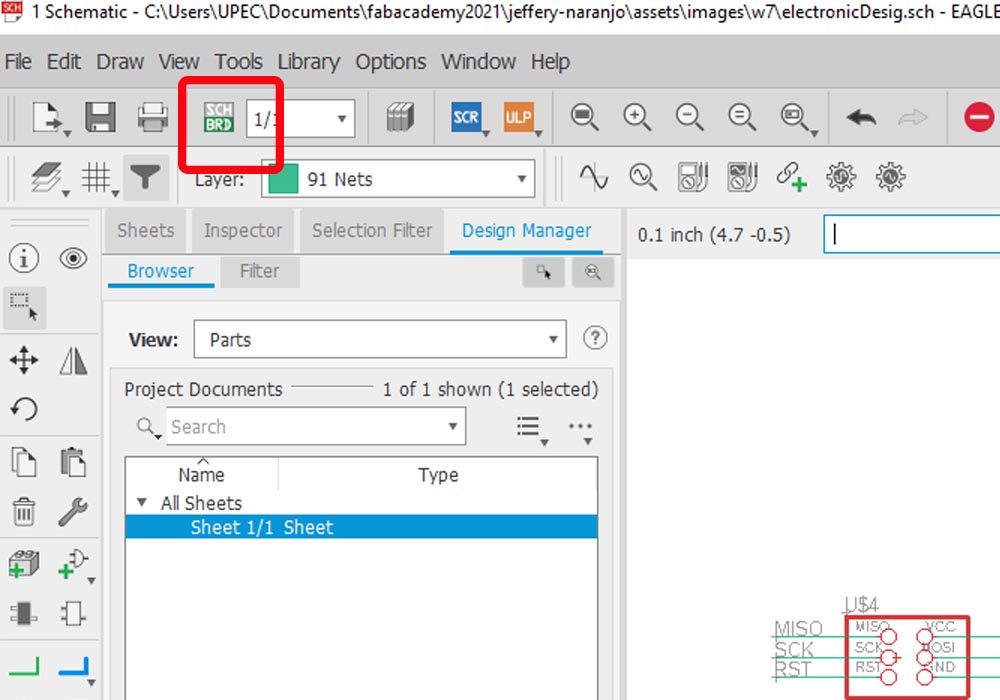

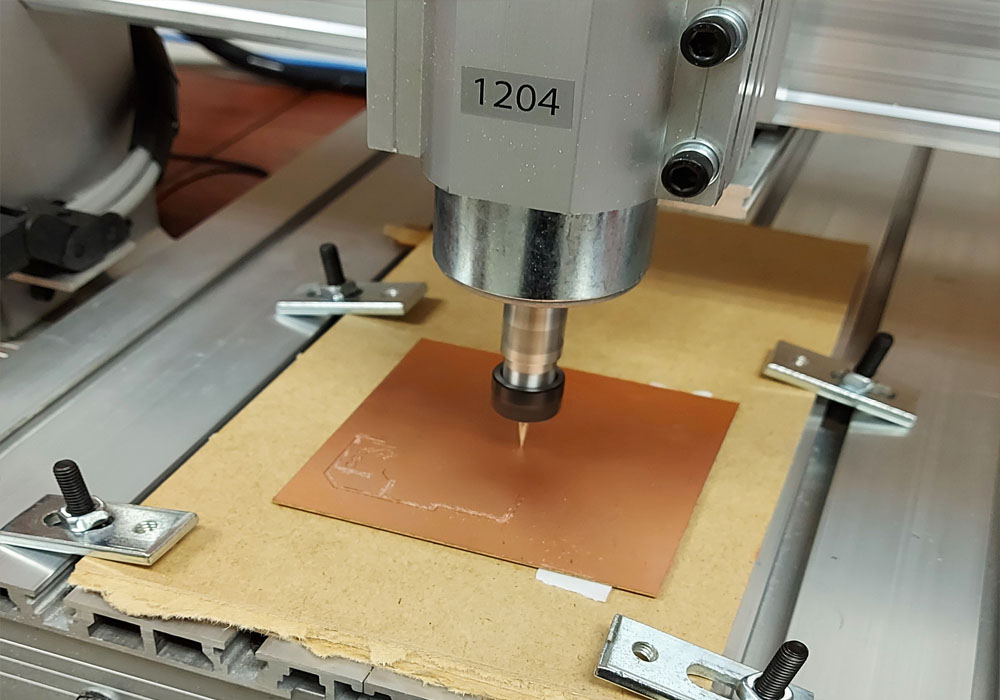

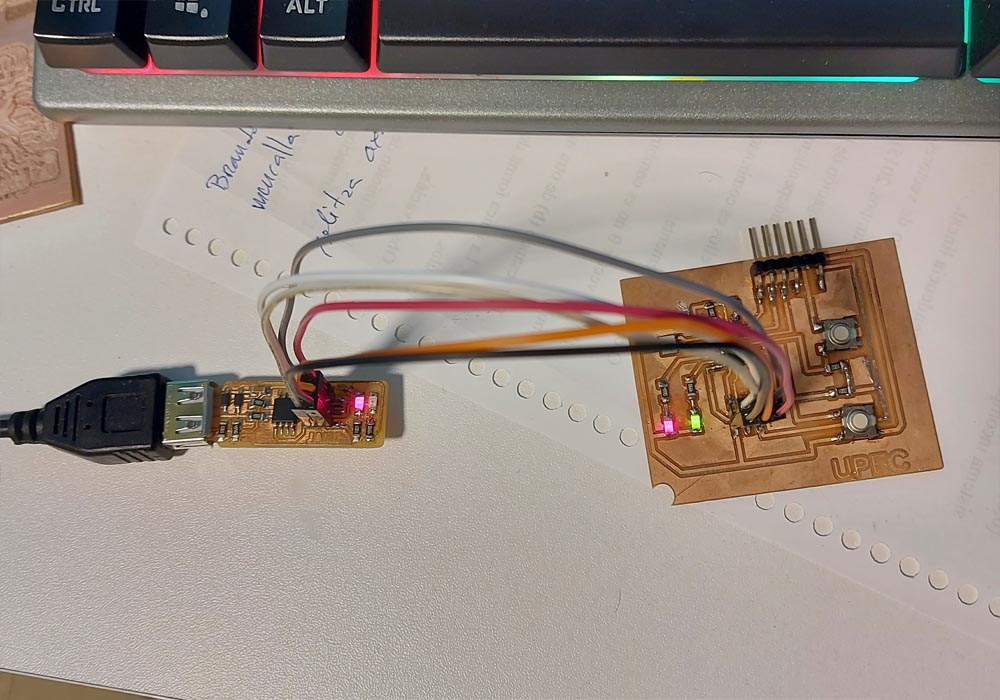

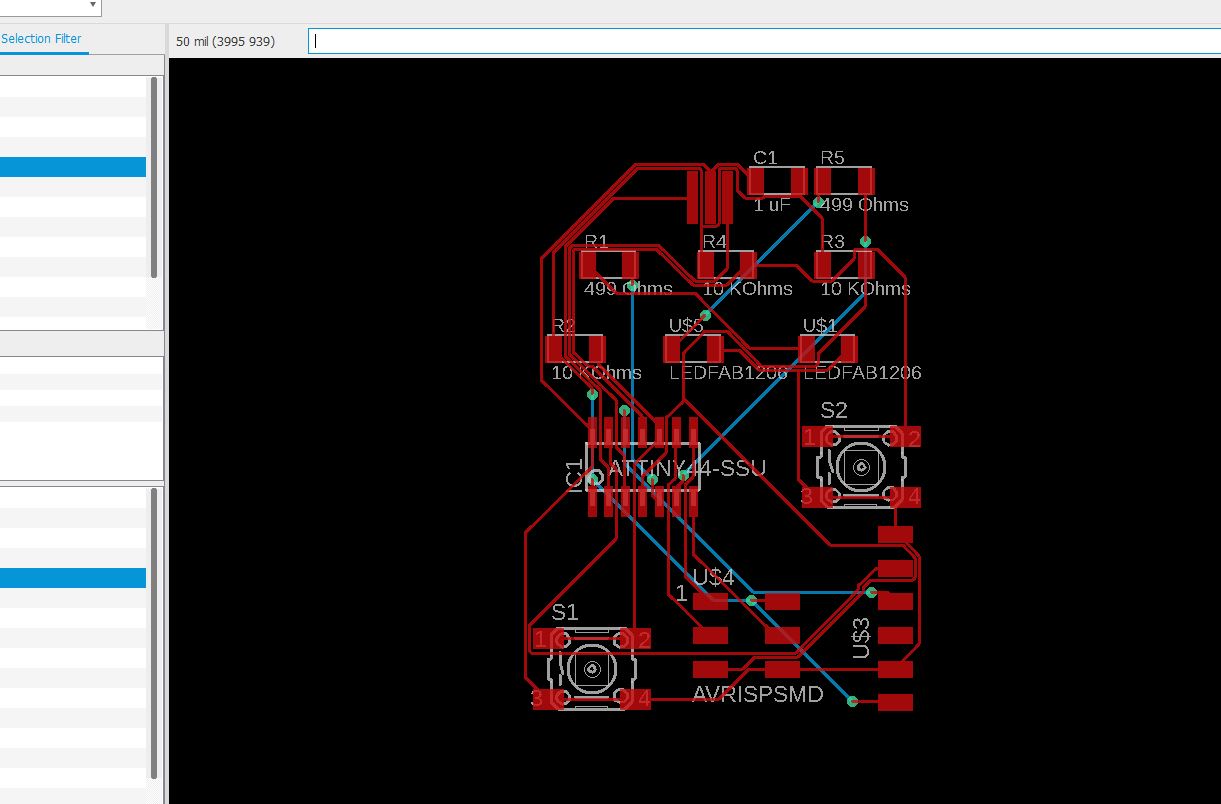

Making the board

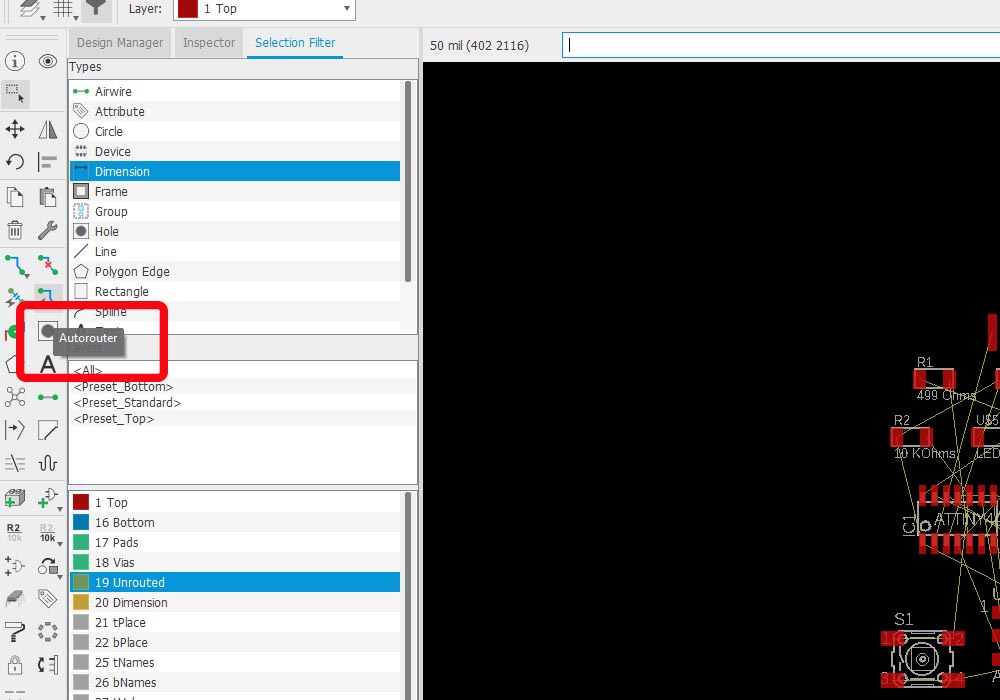

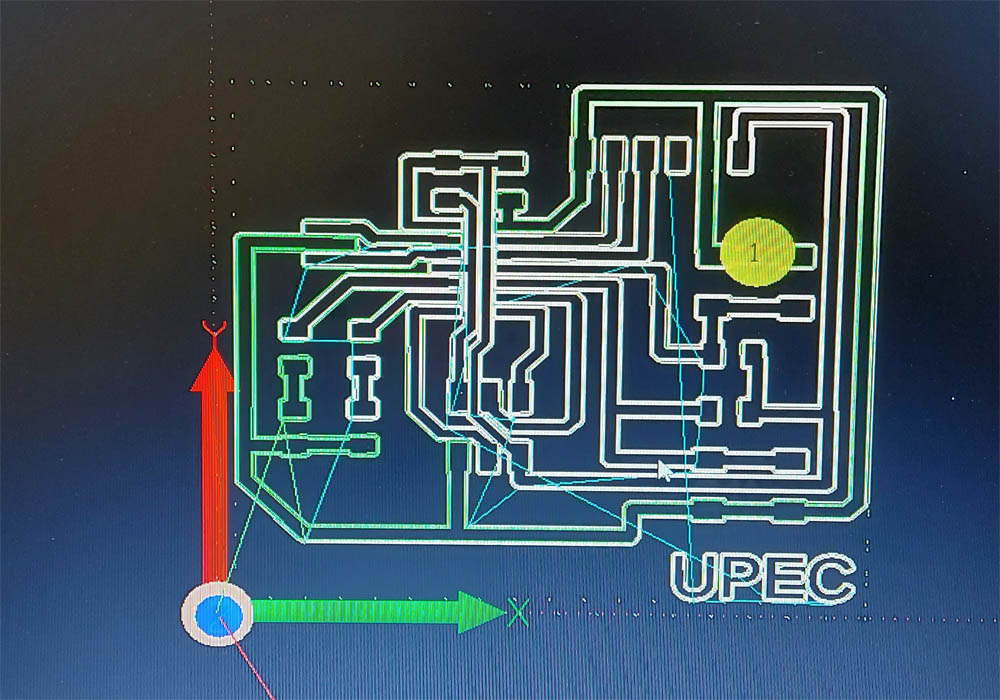

Finished our schematic design, we will proceed to place the components on our pcb board, for this we click on the button,

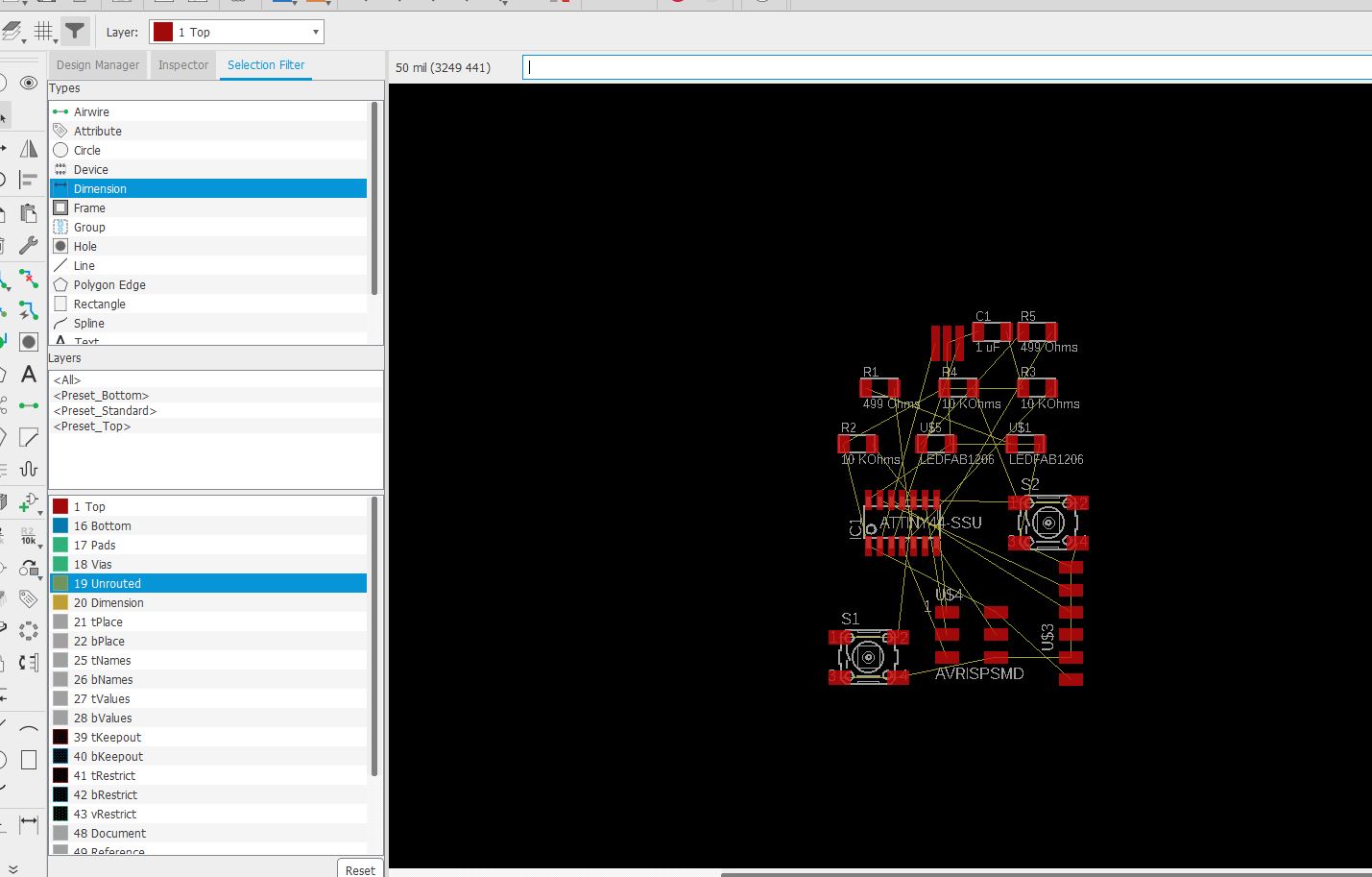

generate switch to board, this will send us to another window where we can see our components but placed in no specific order.

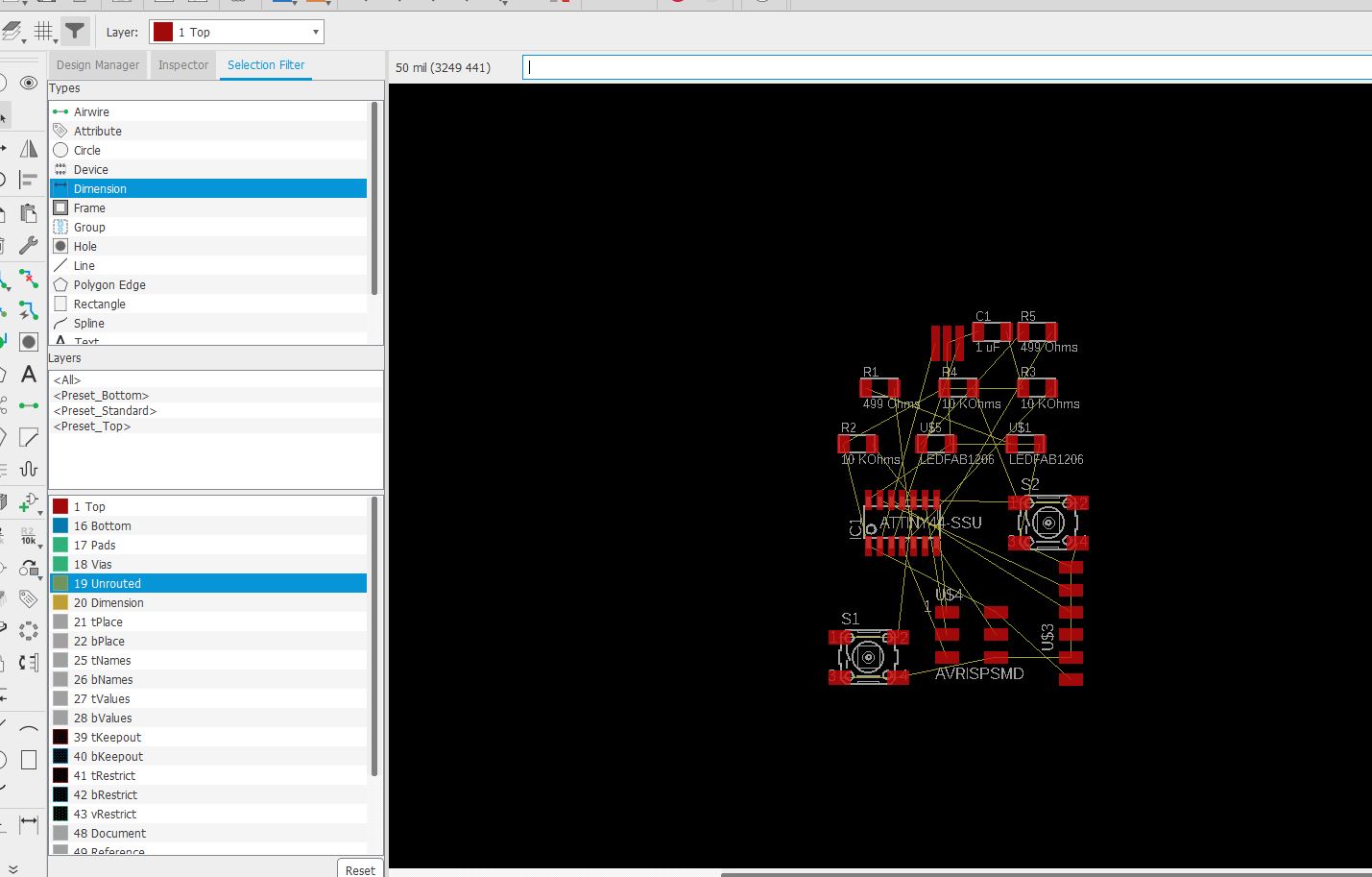

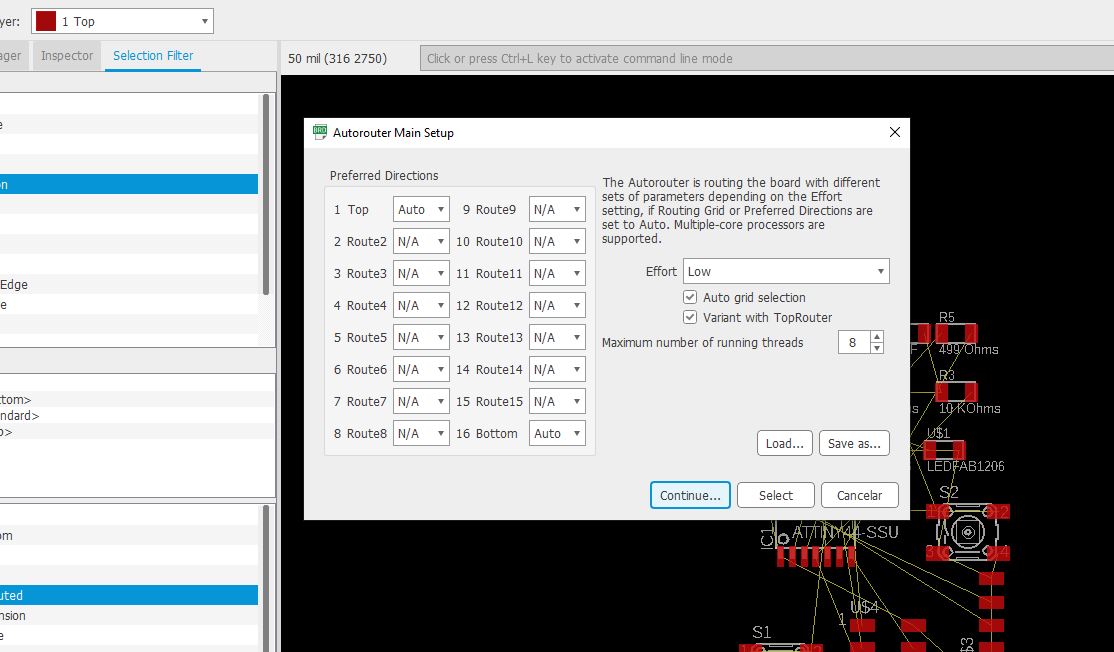

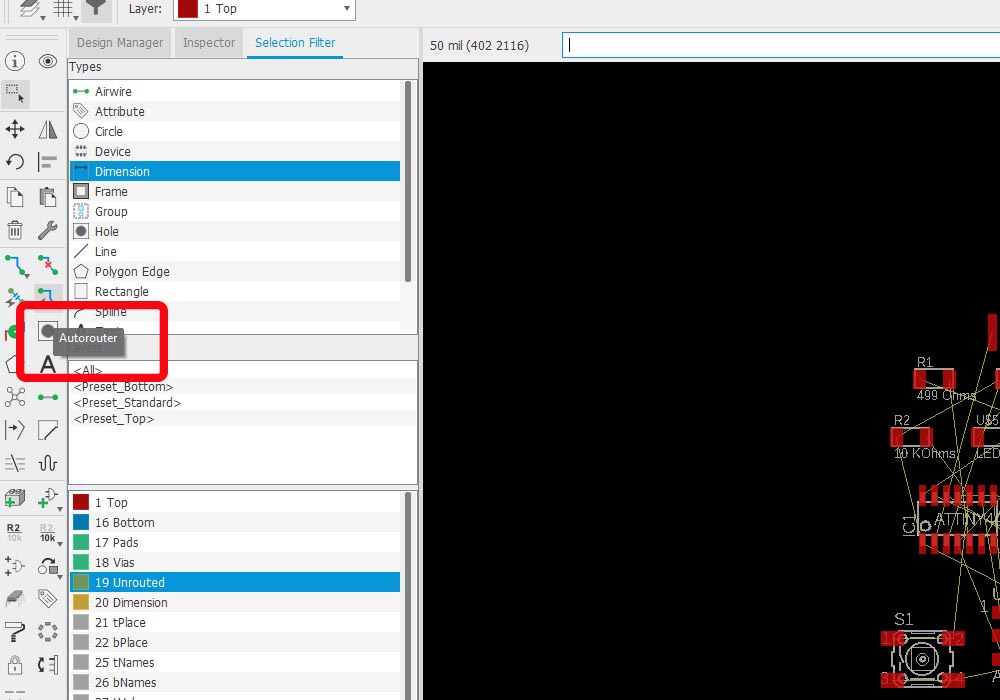

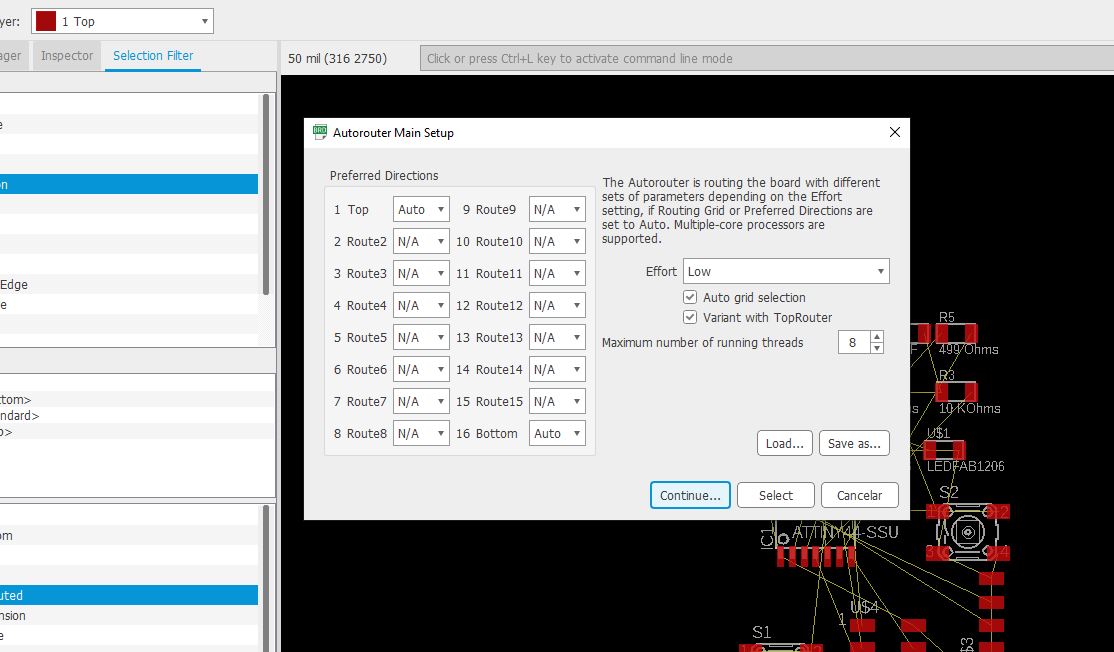

At this point we can use the auto-routing option, but with this we leave it to the machine to make the decisions

about where to place the components, and it doesn't always work out well, since it can place tracks behind the board.

The most recommended is to place each of the elements by hand, and so we can give the design we want to our board

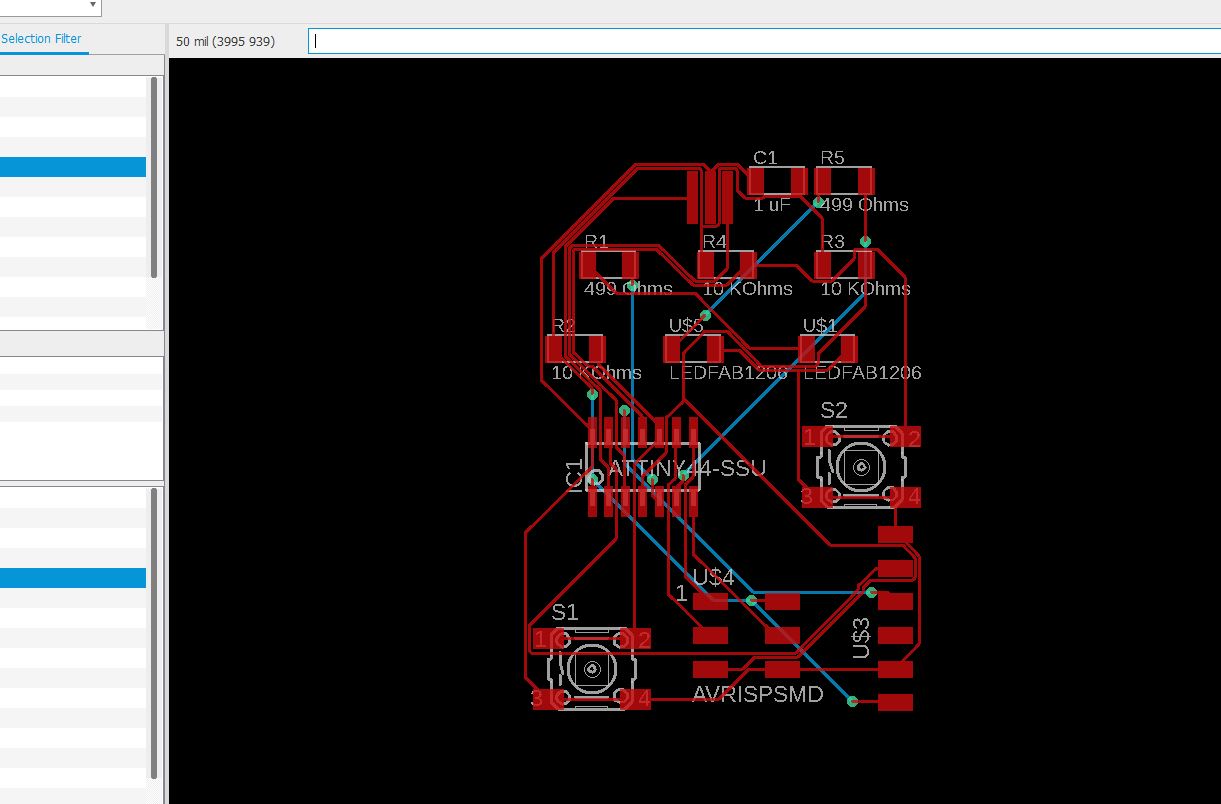

The yellow lines indicate the connections between components, we can also place each of the components in layers, it is important to give an adequate

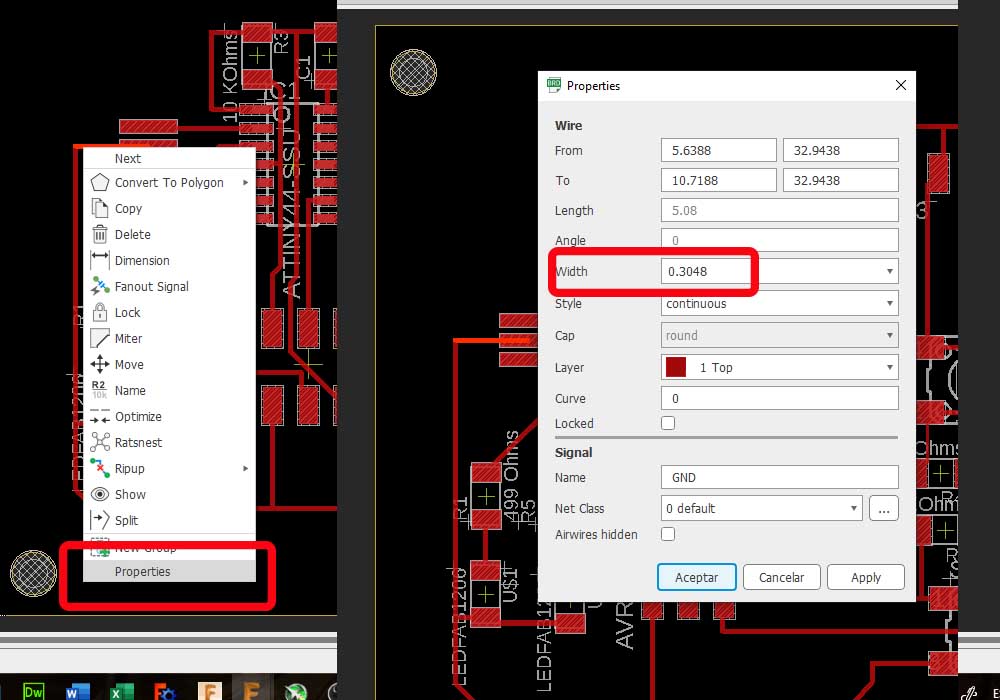

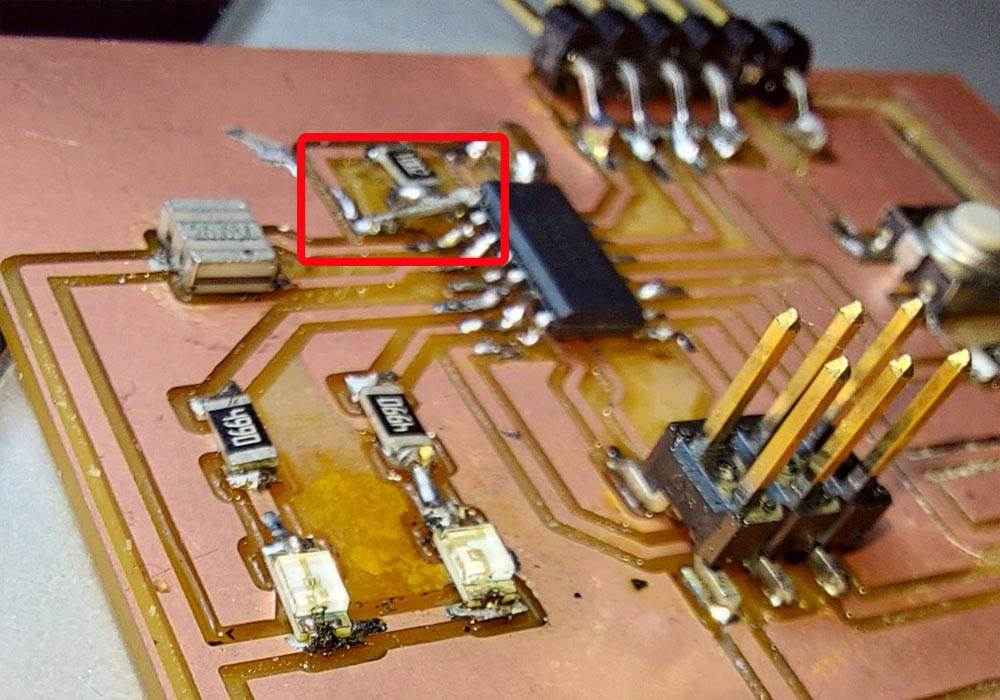

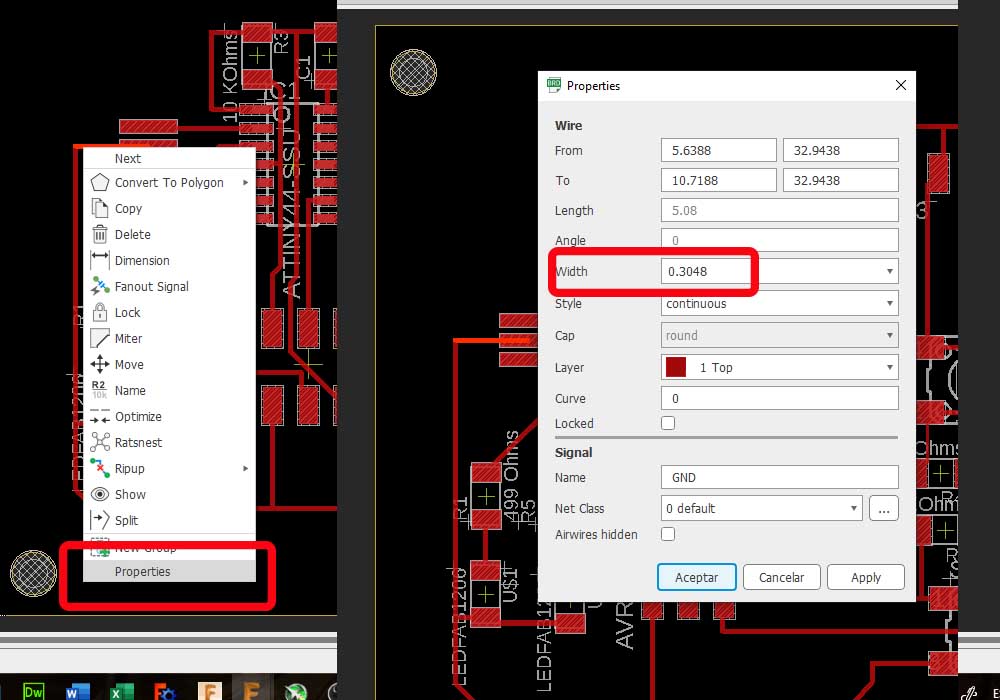

thickness of the traces, if we make them very thin, the safest thing is that they come off when welding.

We can change the thickness of the tracks by right clicking properties and changing the value

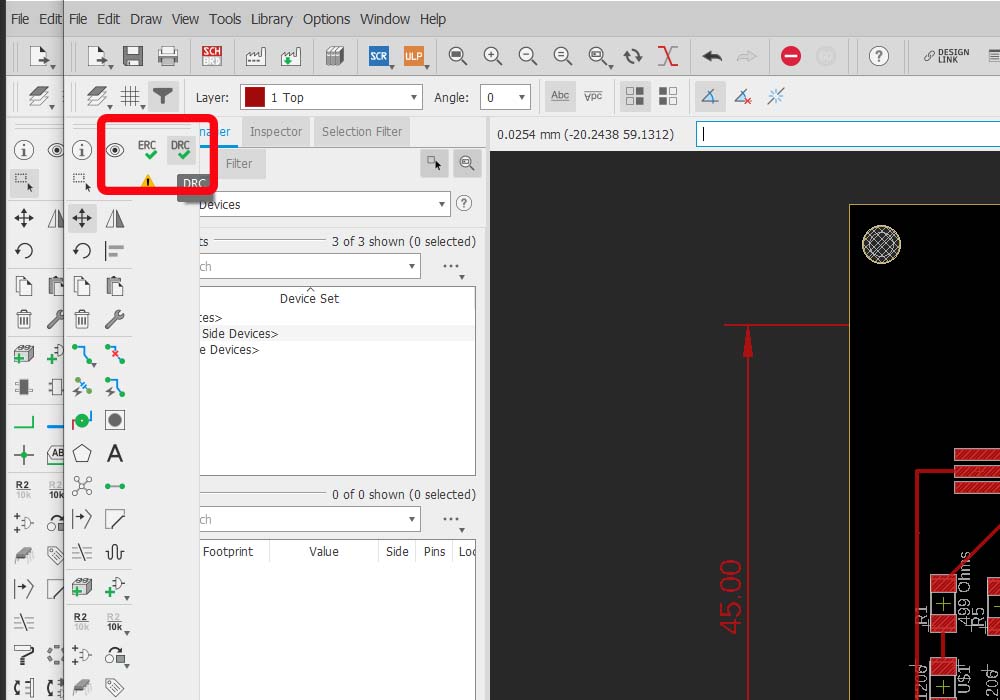

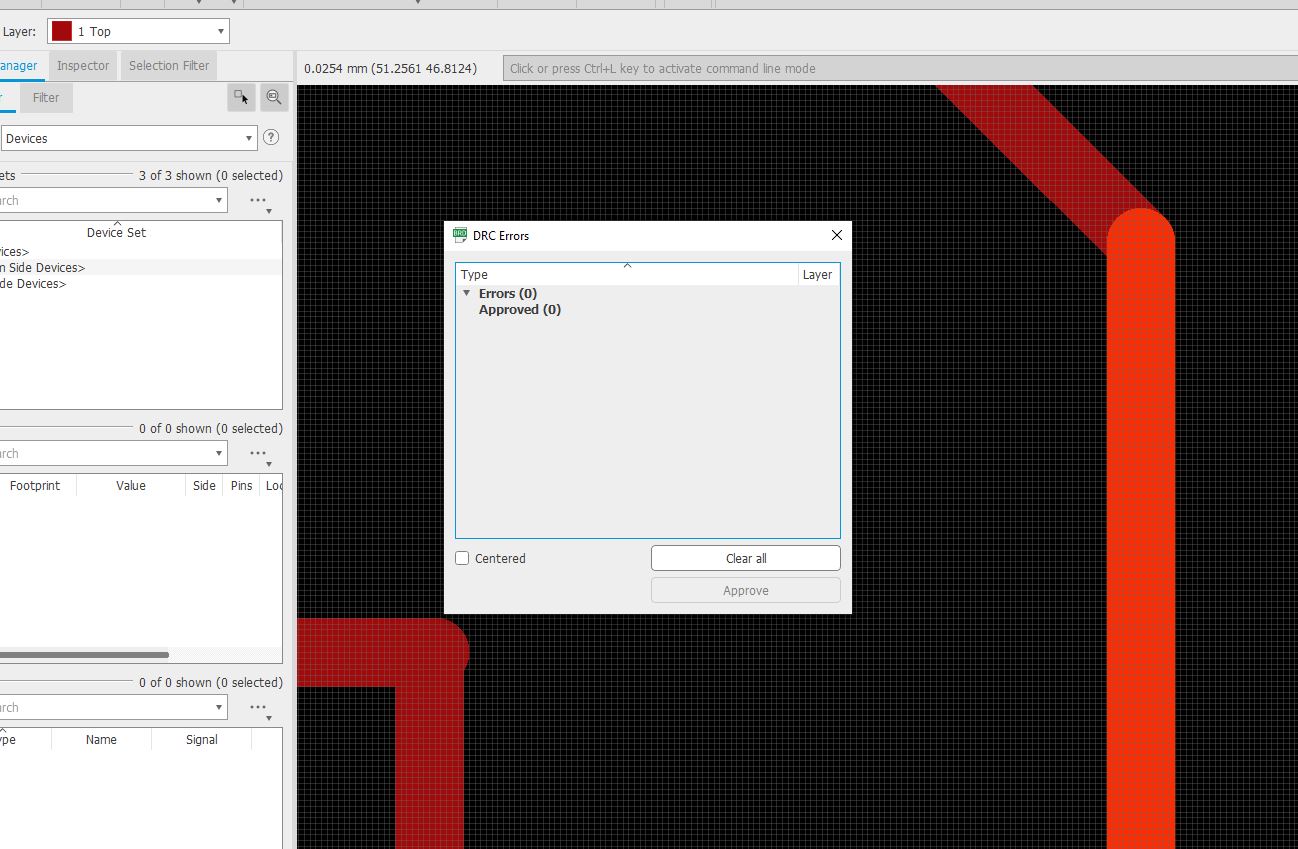

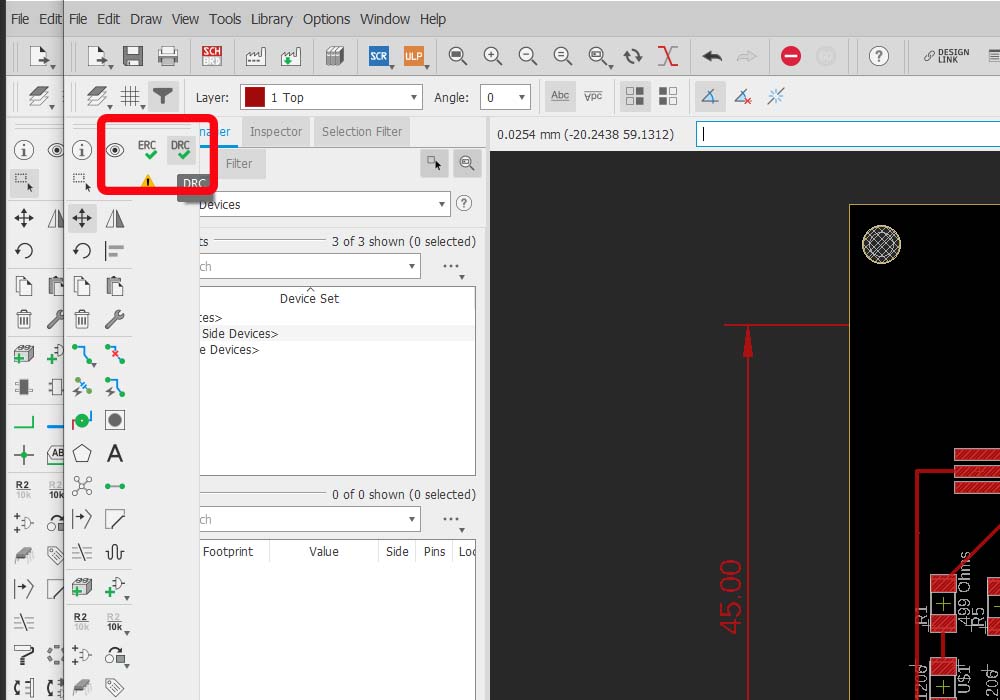

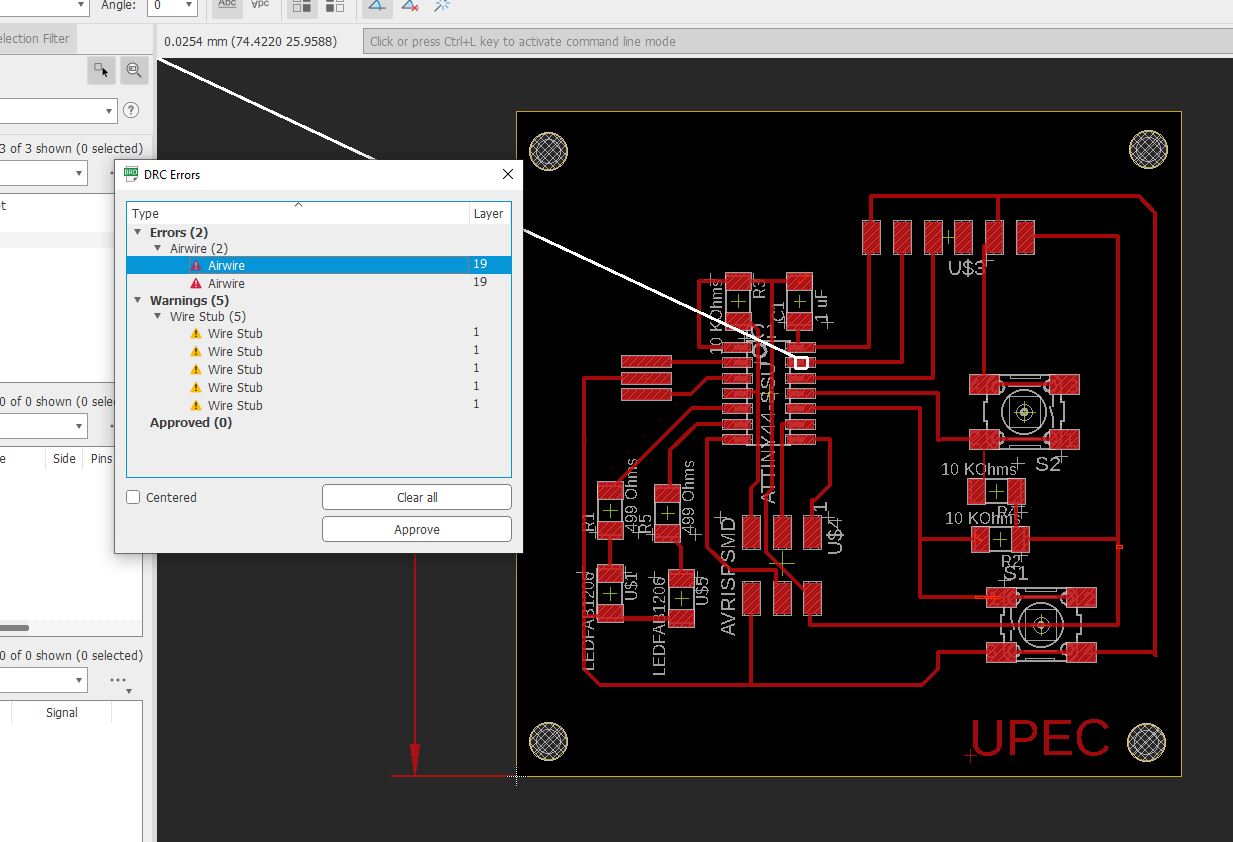

Design rules (DRC)

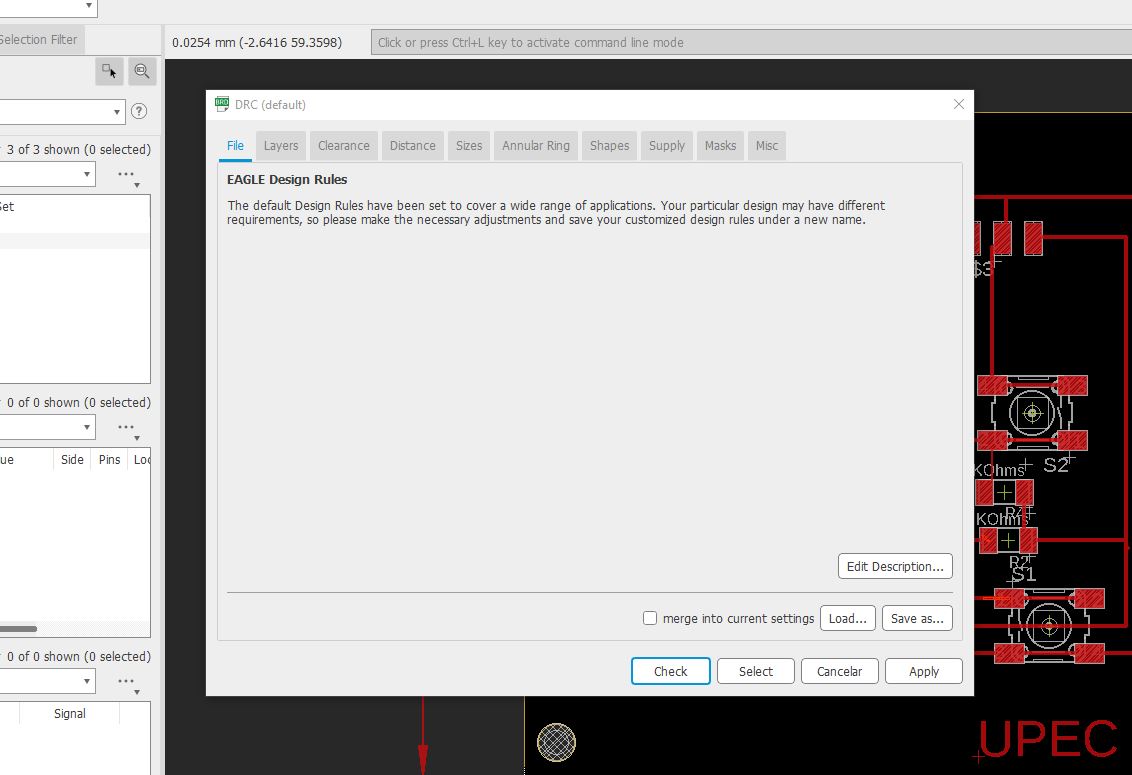

One of the tools that Eagle provides us, is an option called DRC (design rule verification) this tool warns us about

space and design problems that could affect the production of our pcb circuit board.

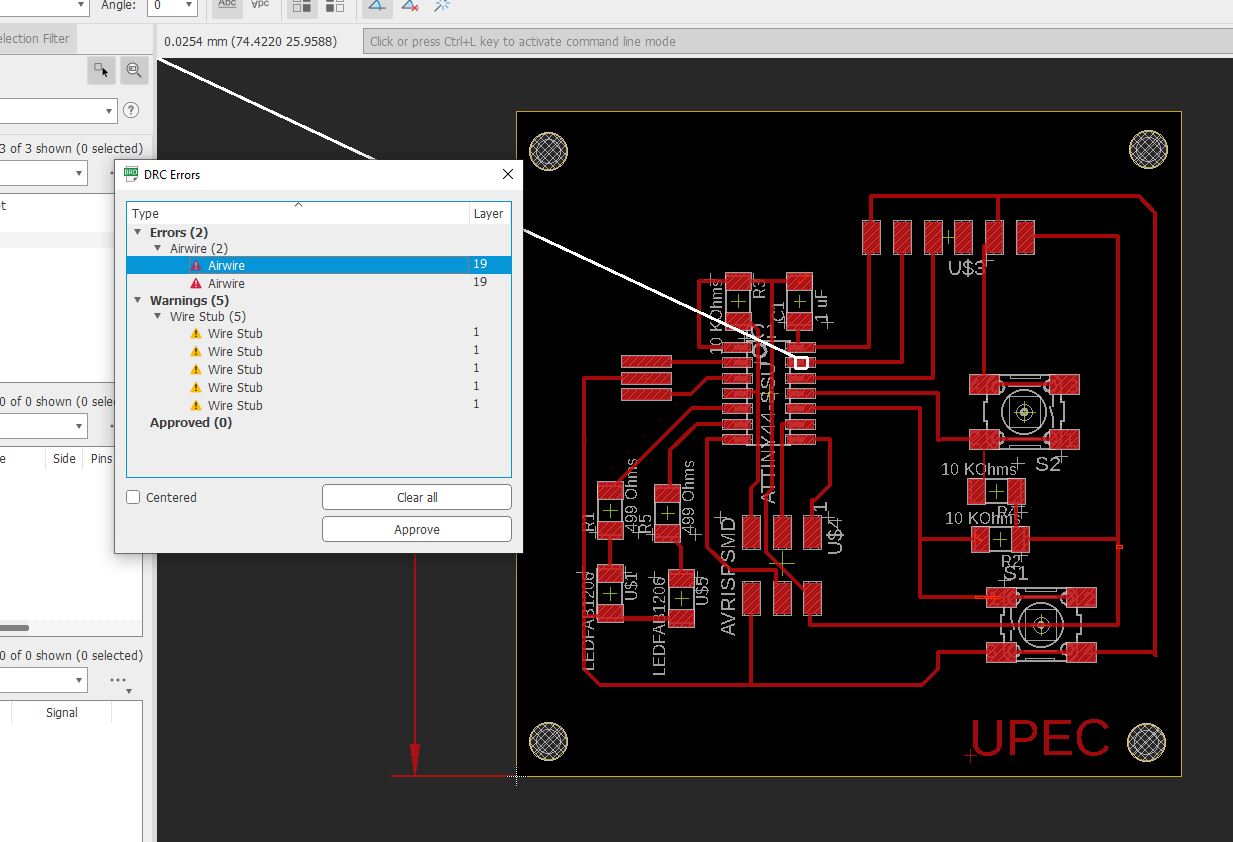

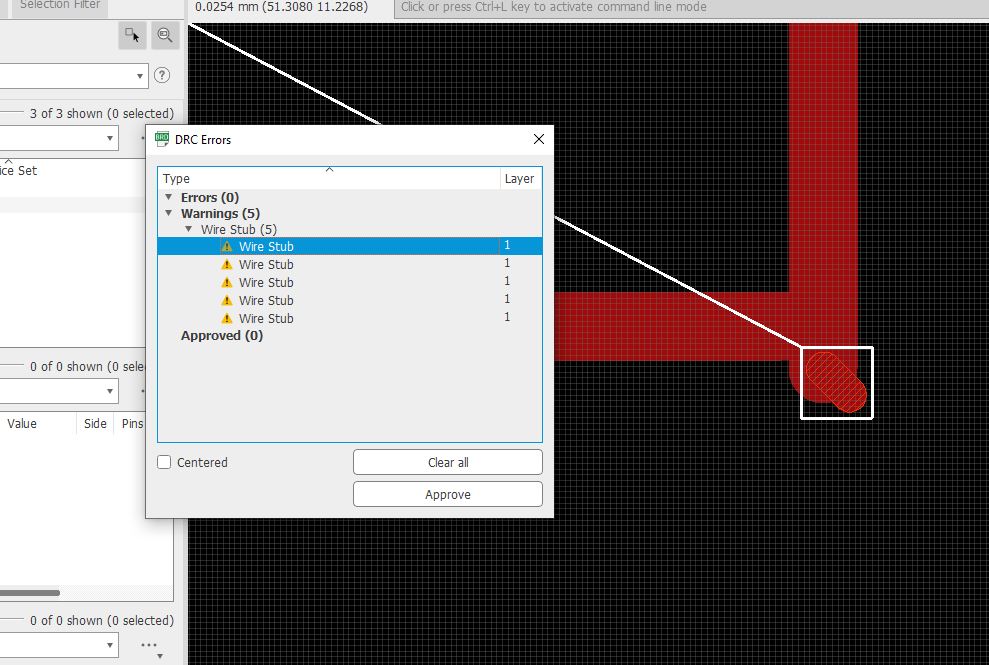

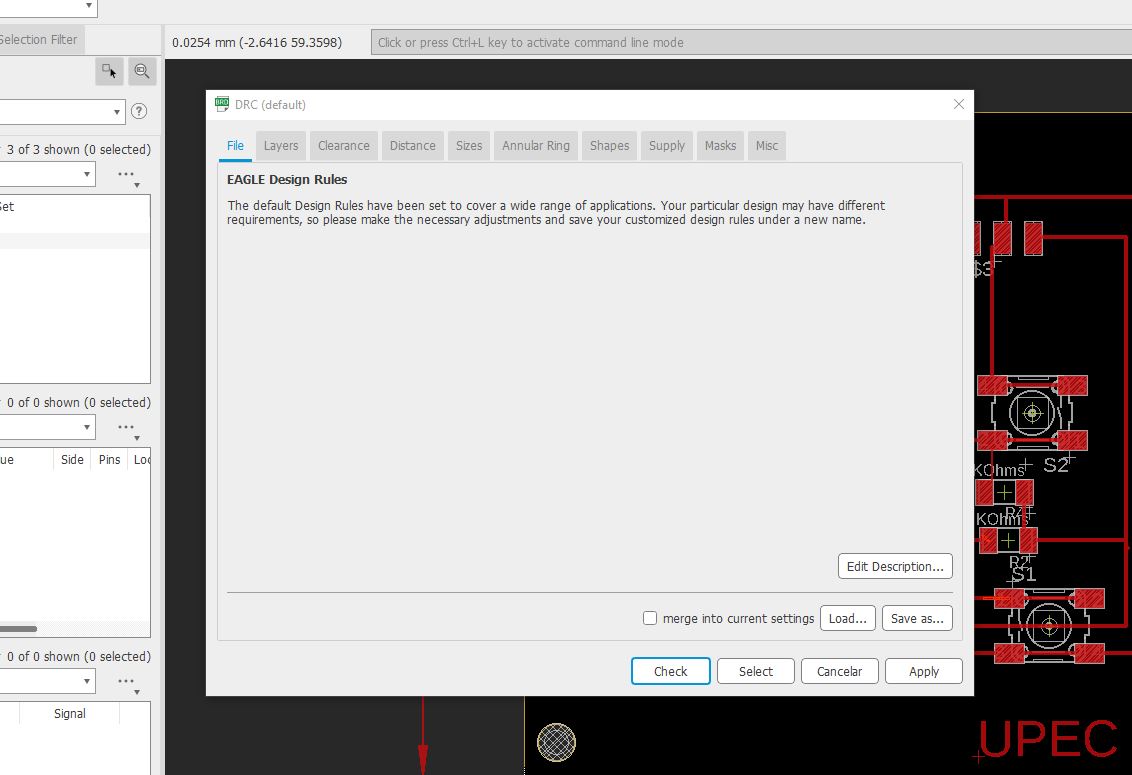

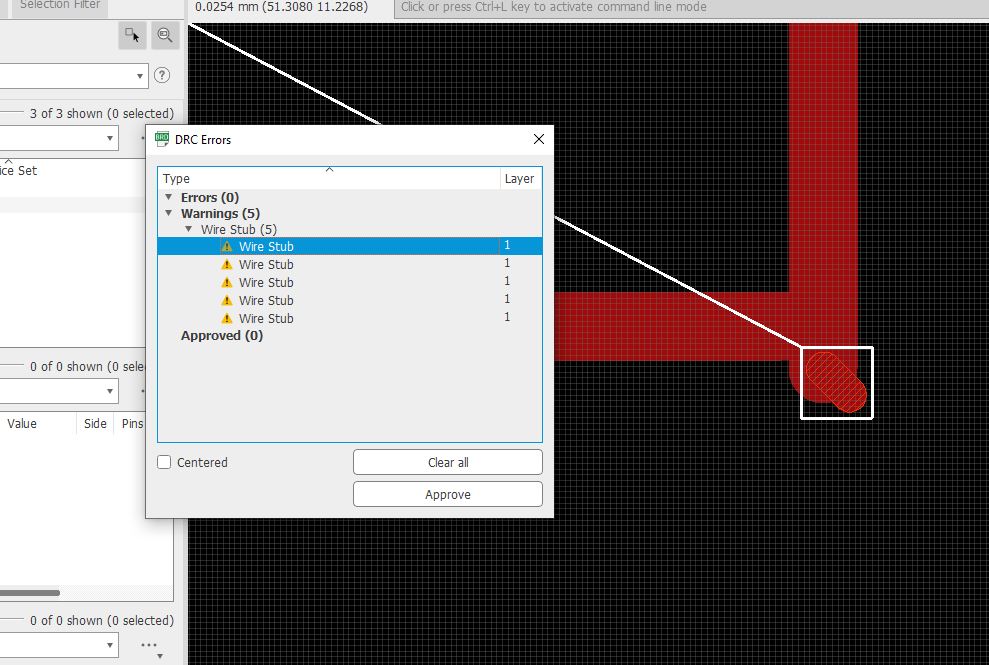

Once the tool is executed, we click on the check button, this opens a pop-up window, it shows us the errors and warnings,

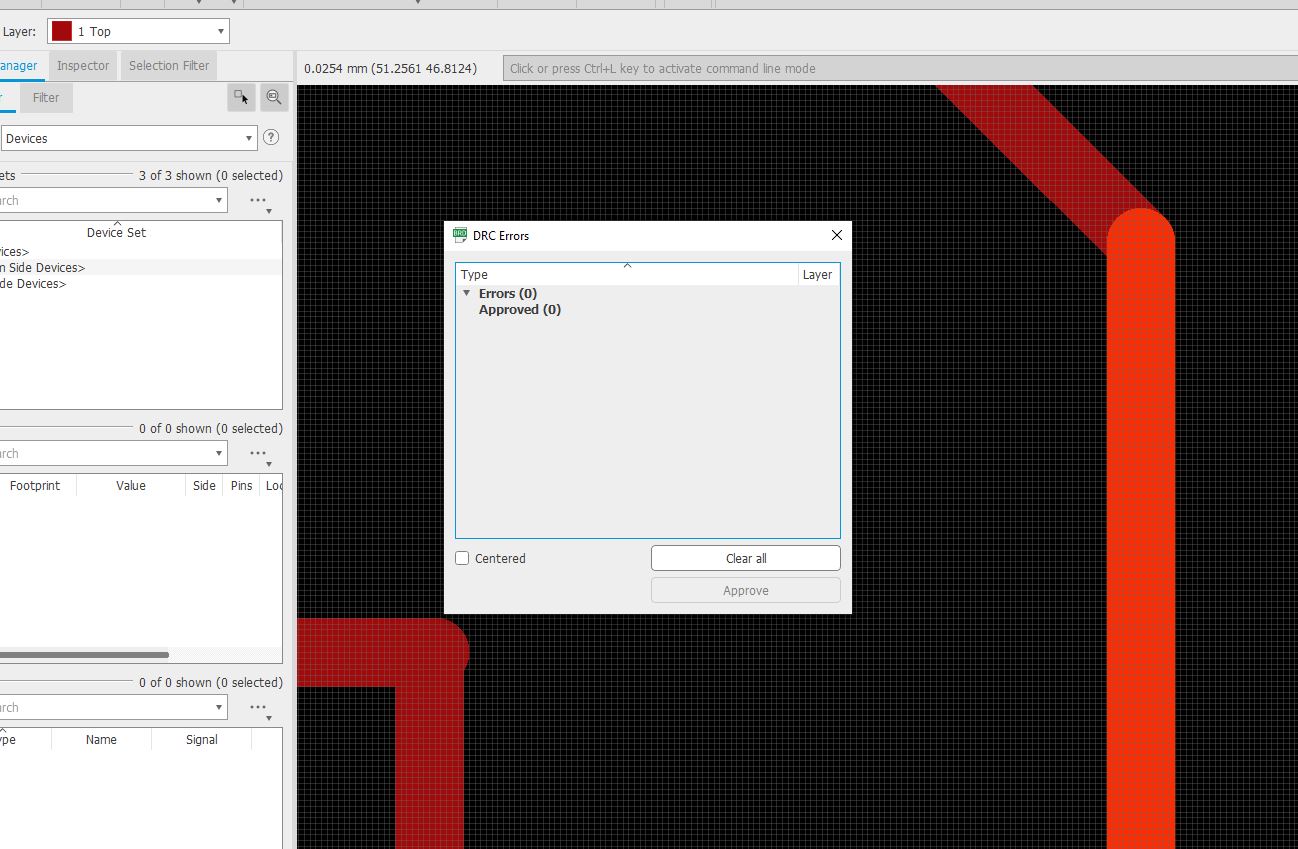

clicking on them, takes us to the exact part where the problem is found, in this way we can delete the line or correct its trajectory

and / or thickness to eliminate the error

once the corrections are finished we will have an indication that we no longer have errors or warnings we can save the Design Rules Check File

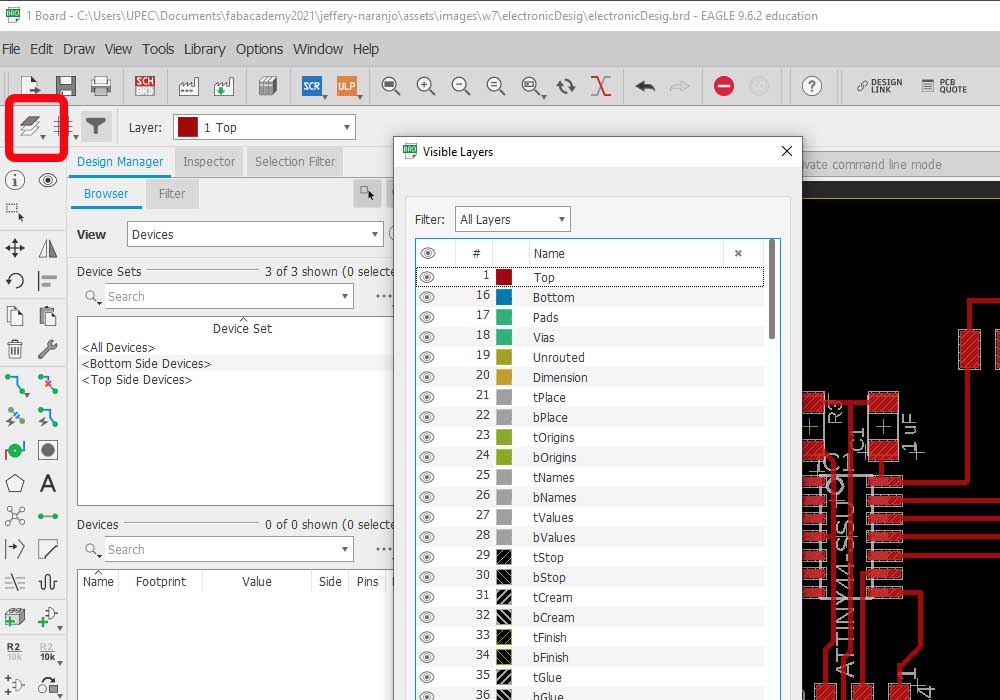

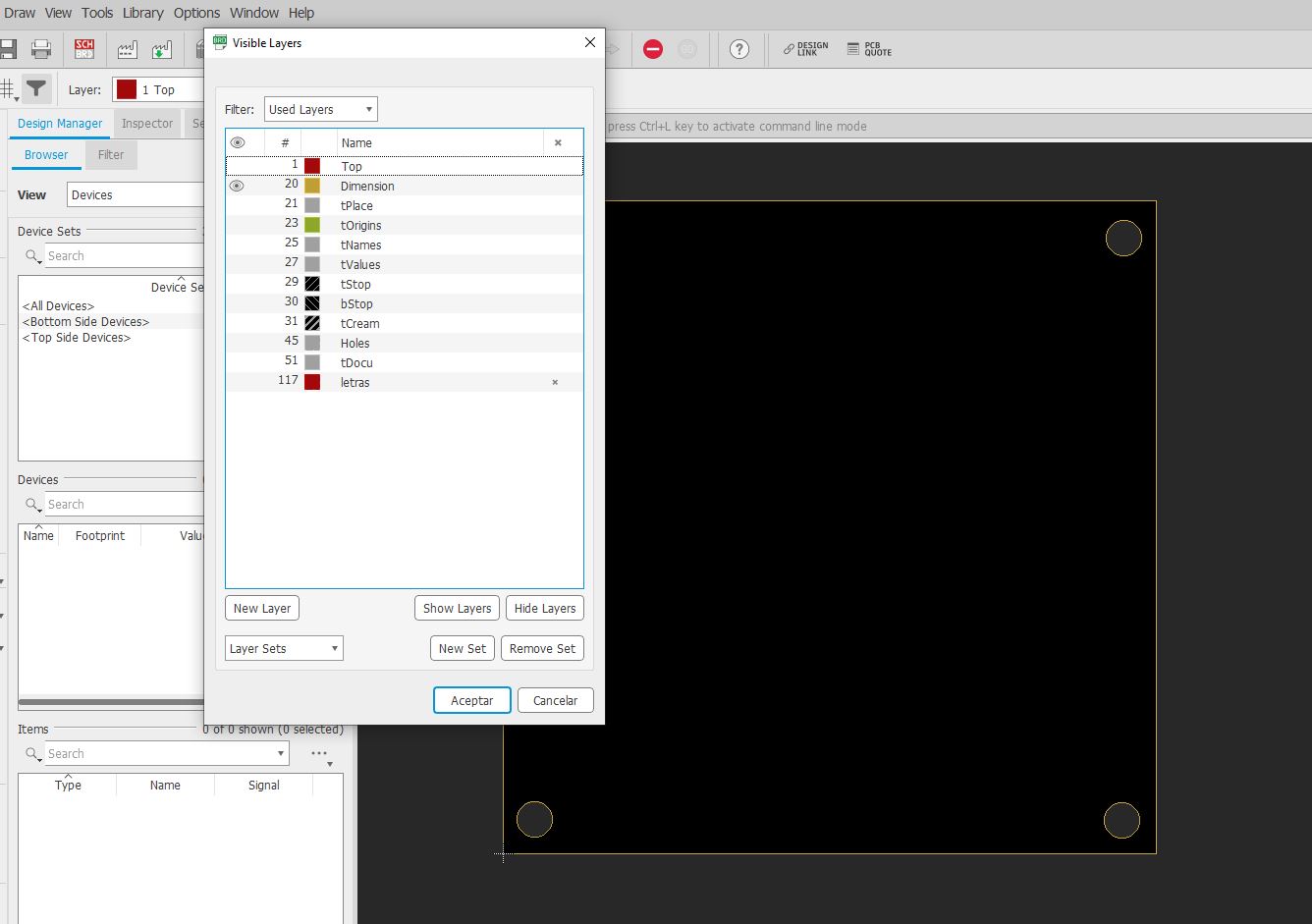

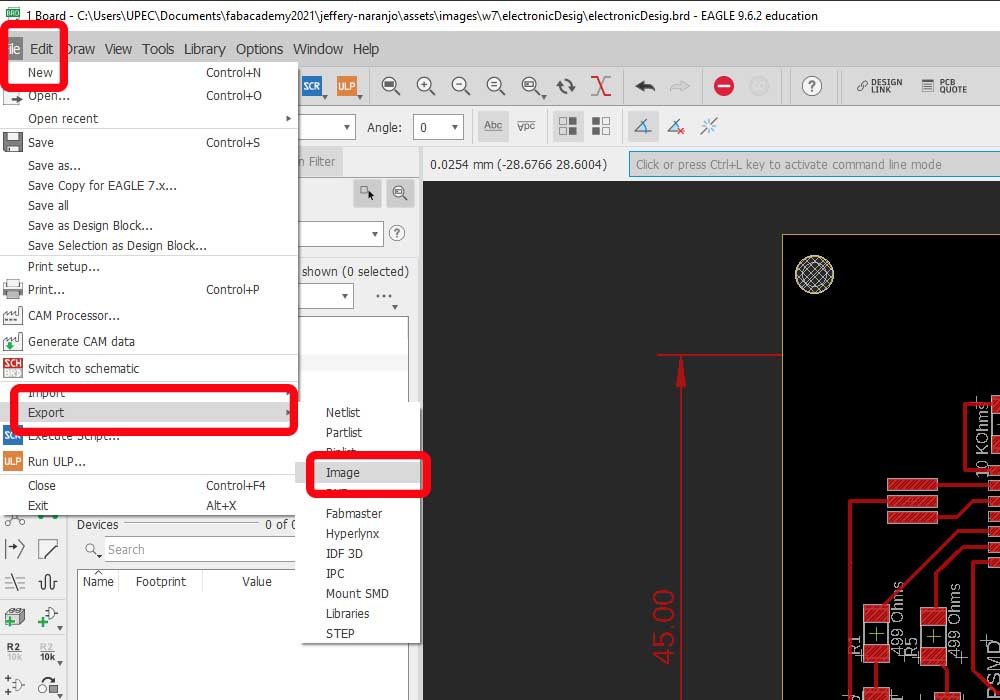

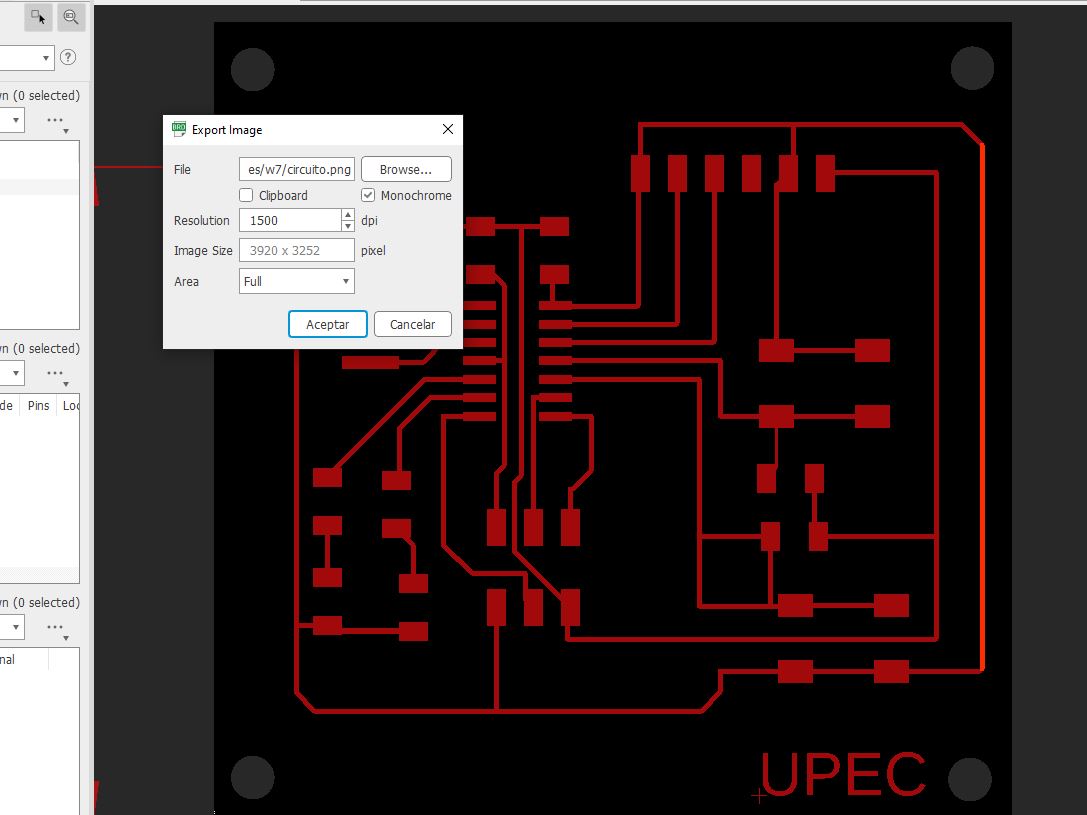

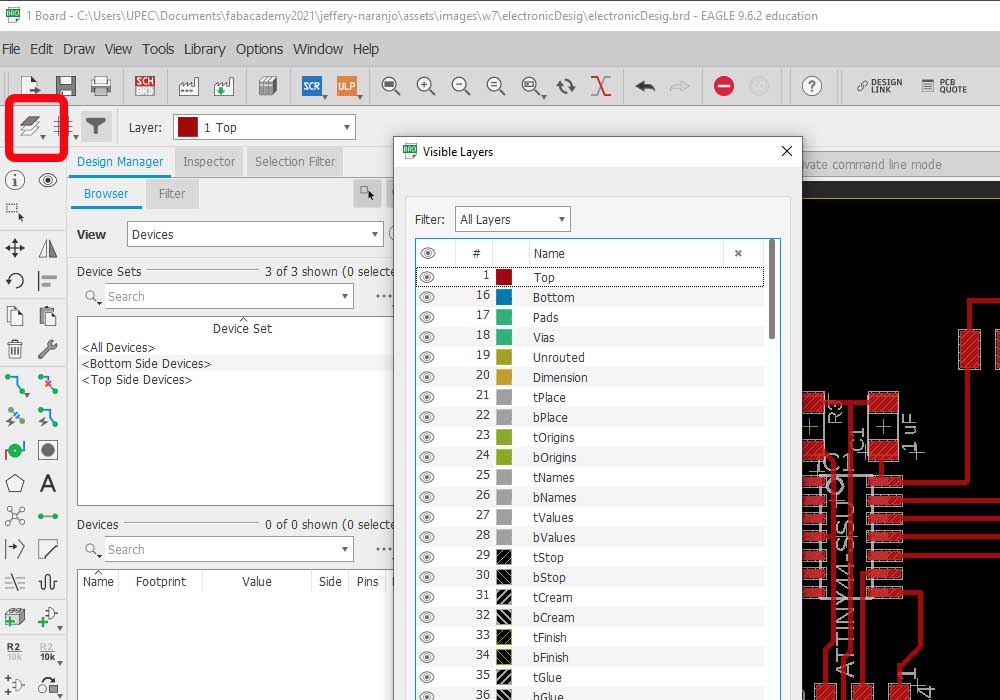

Exporting PNG file

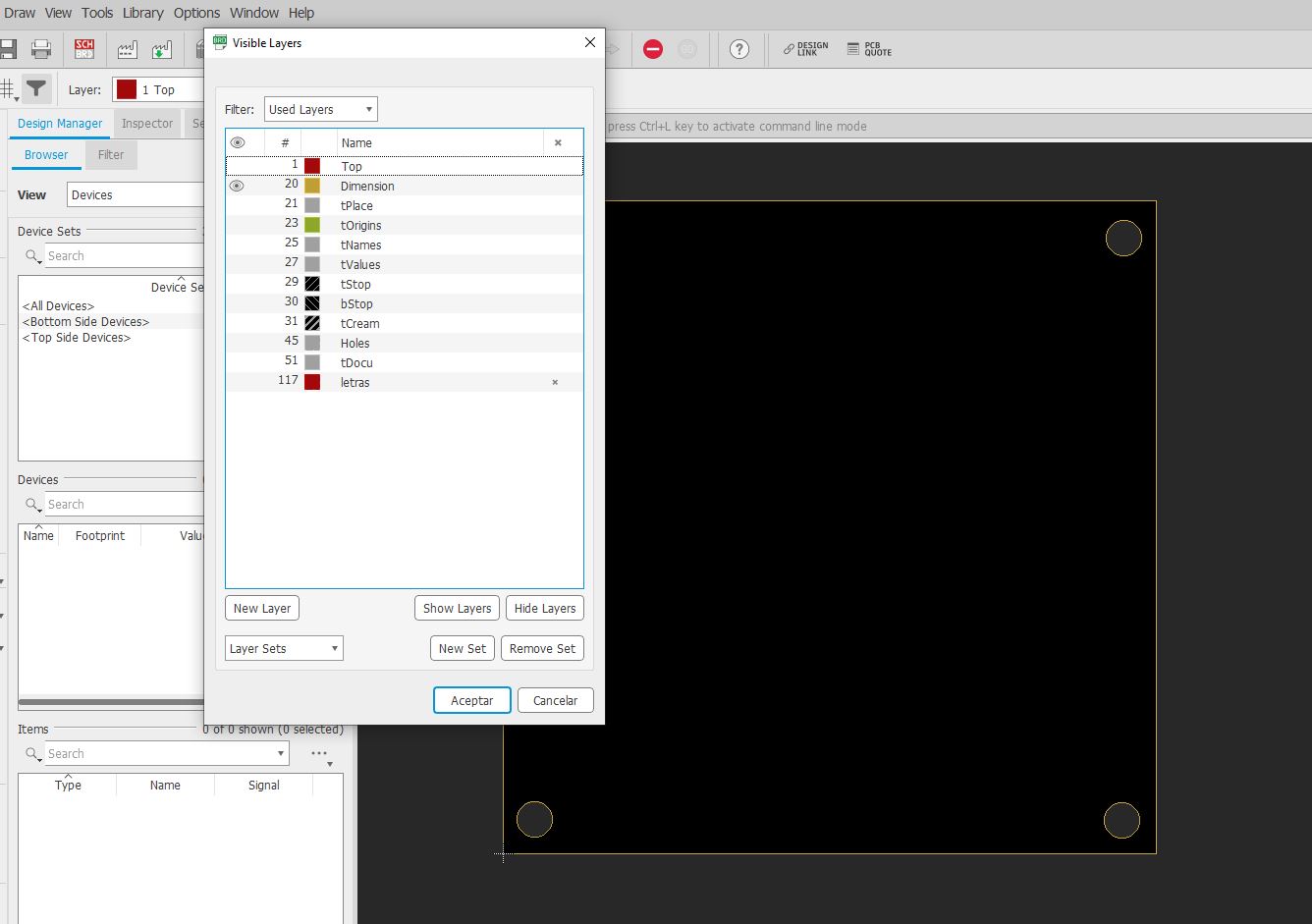

Before exporting our file we are going to hide all the layers and leave only the tracers layer on

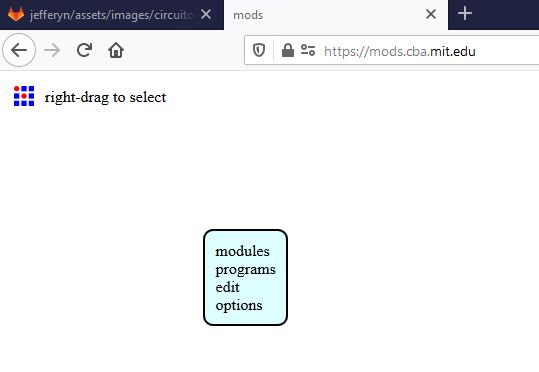

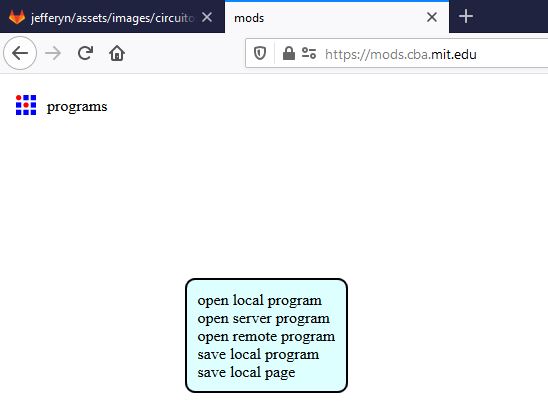

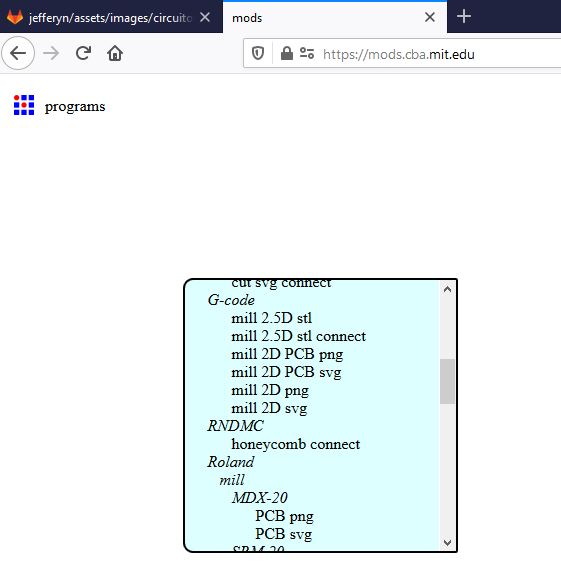

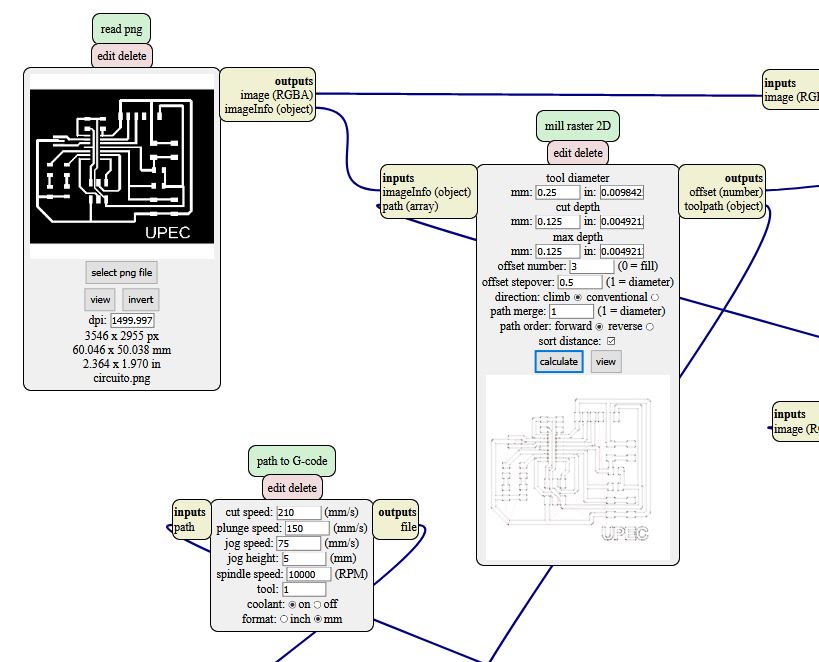

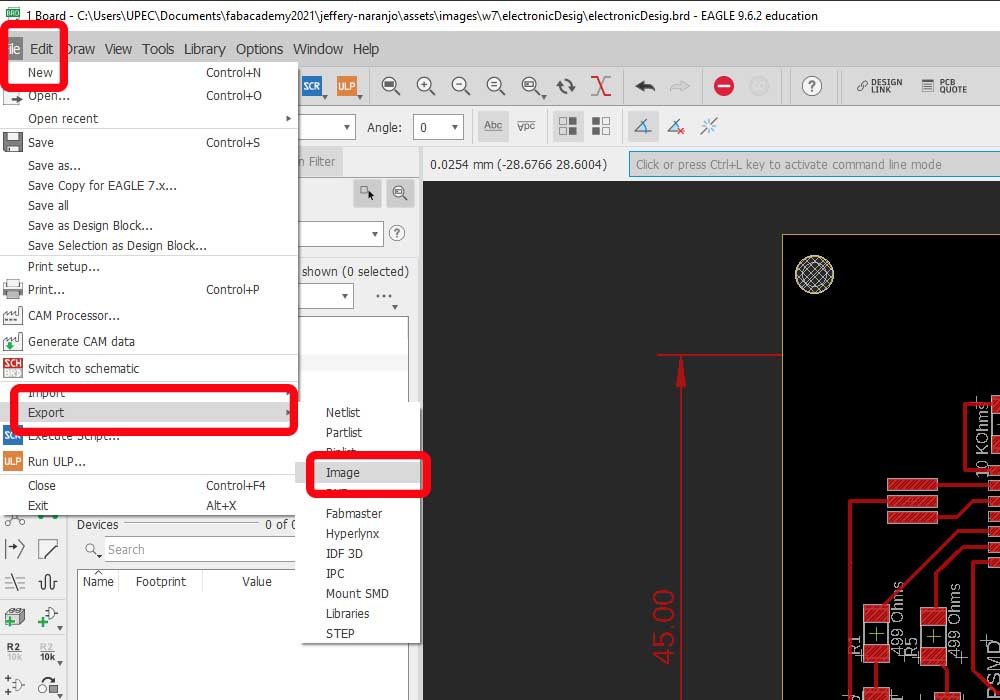

Finally, to export our work in PNG format in order to generate the G-codes through MODS, we go to the toolbar, export, image.

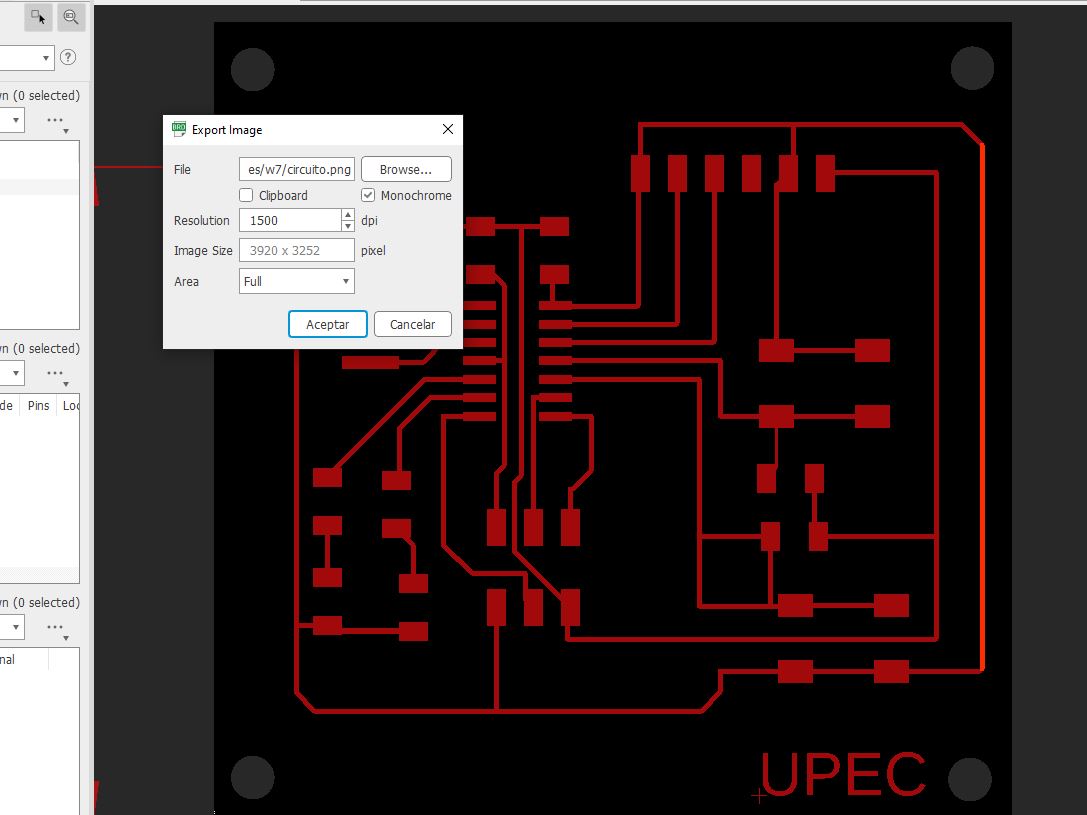

Here there will be a pop-up window where we will indicate the place where we will save our image, we will indicate the resolution, here it is recommended 1500 dpi

We will use the same procedure to cut the outline, the holes, etc.

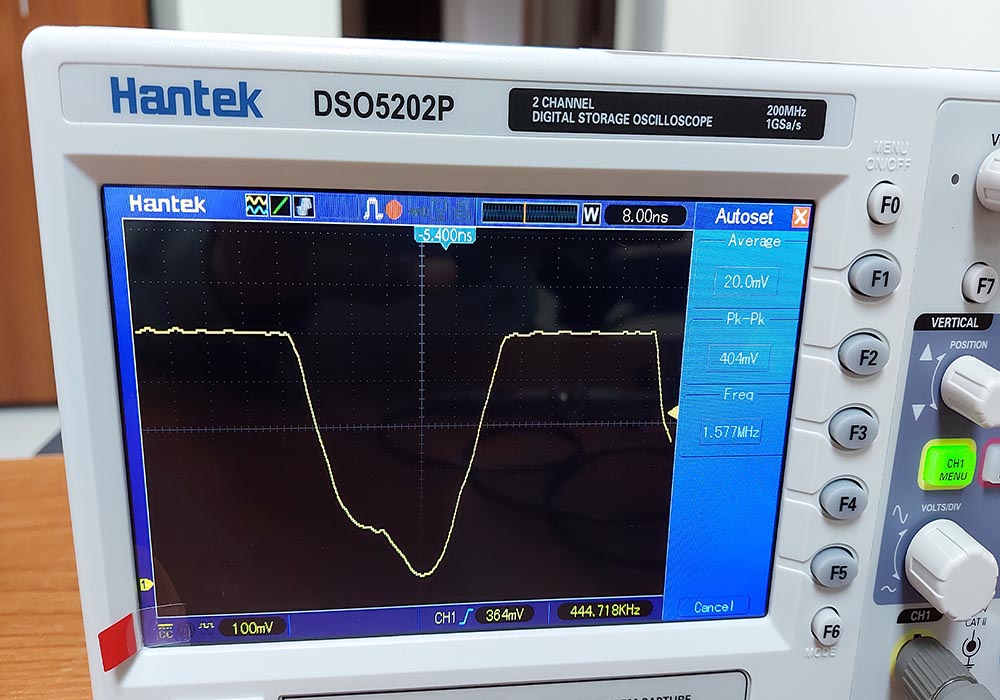

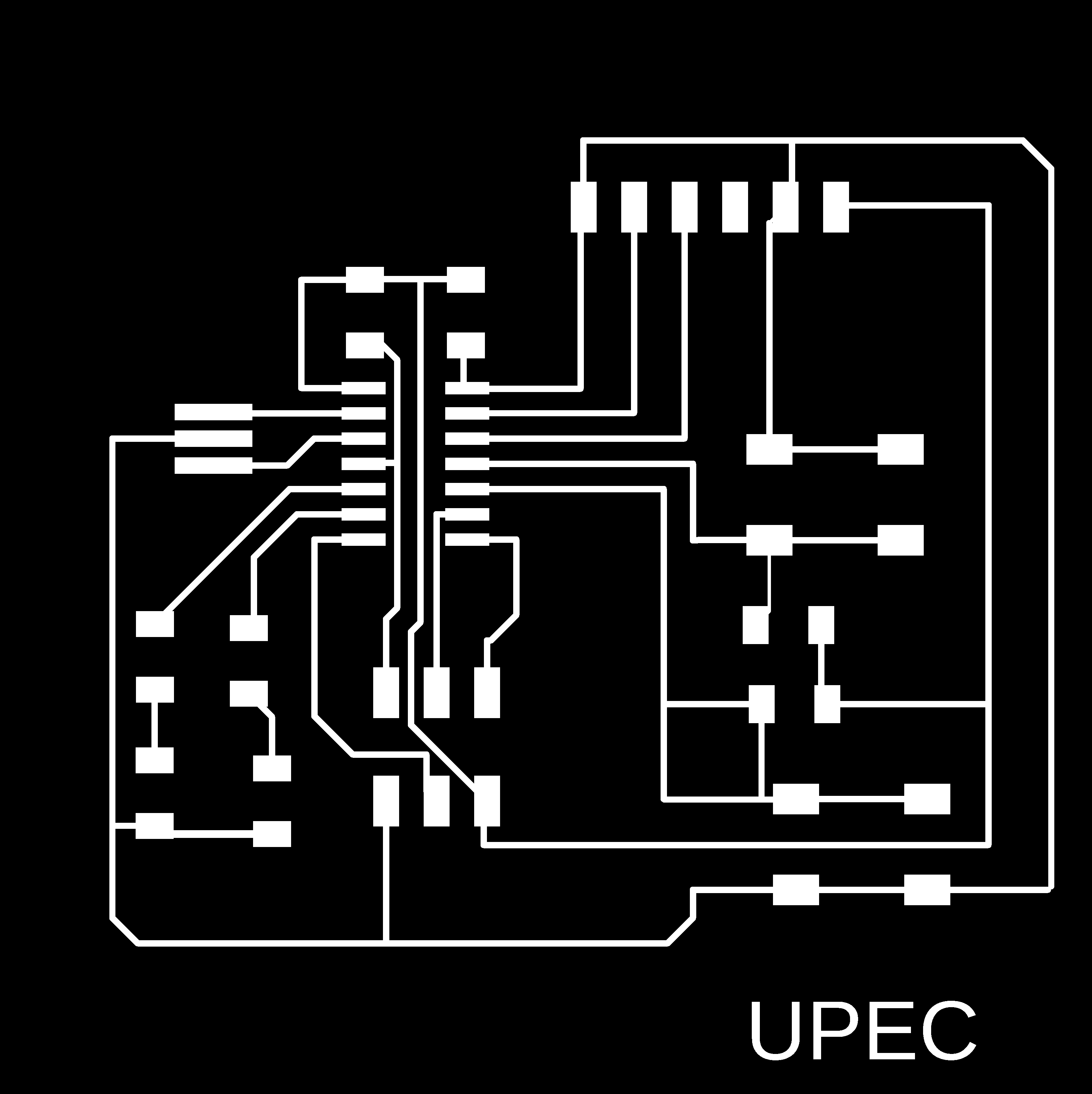

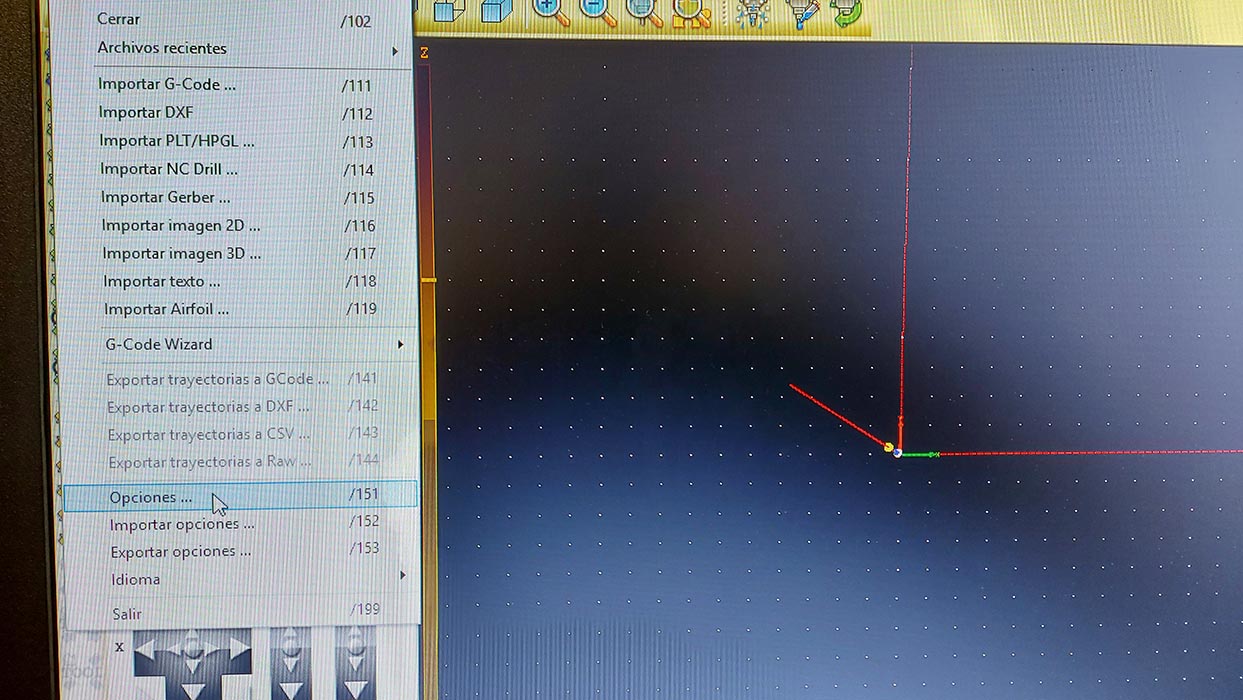

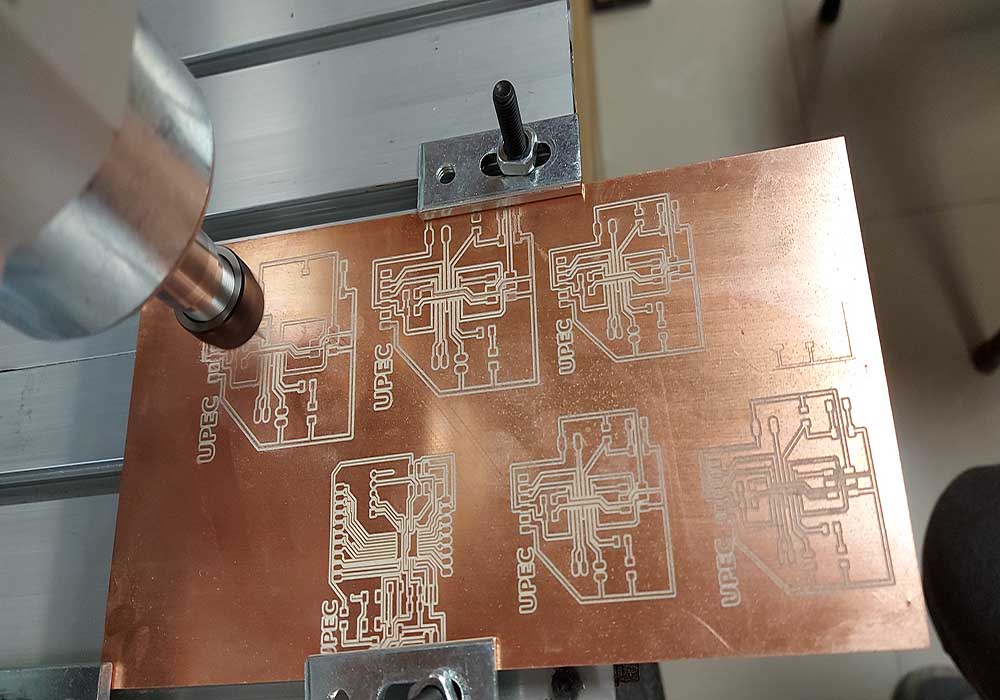

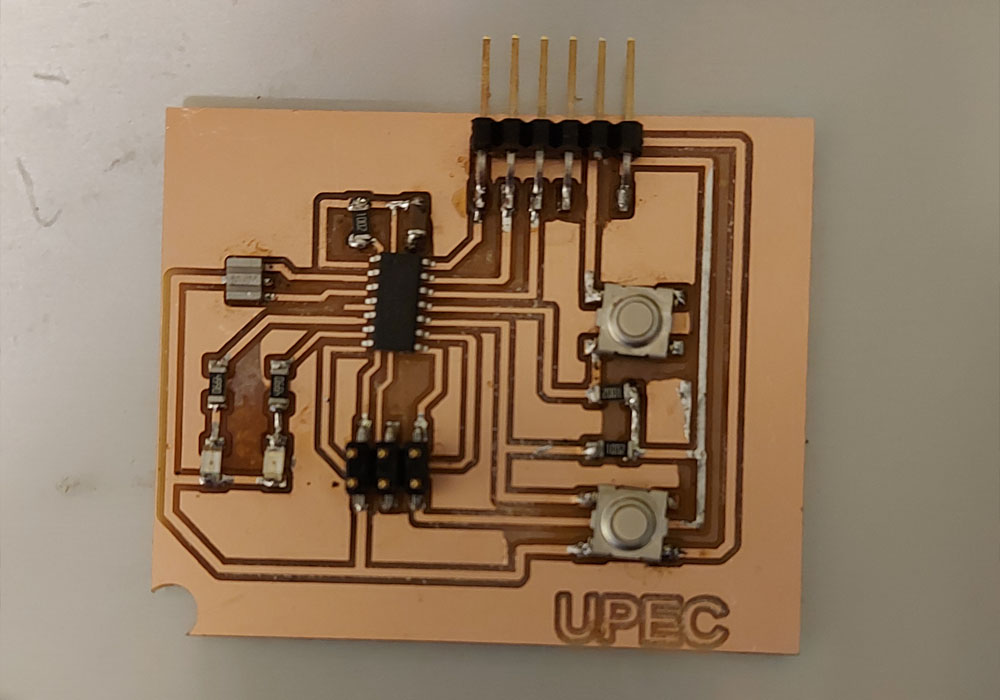

Now we will see some images with the final result of the generation of the files