Starting

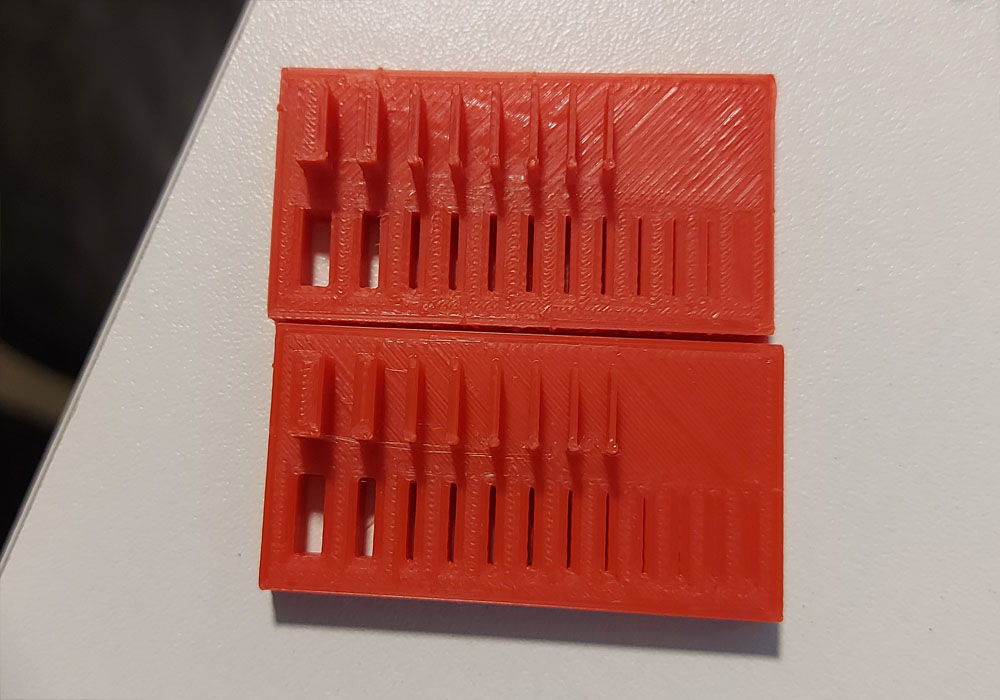

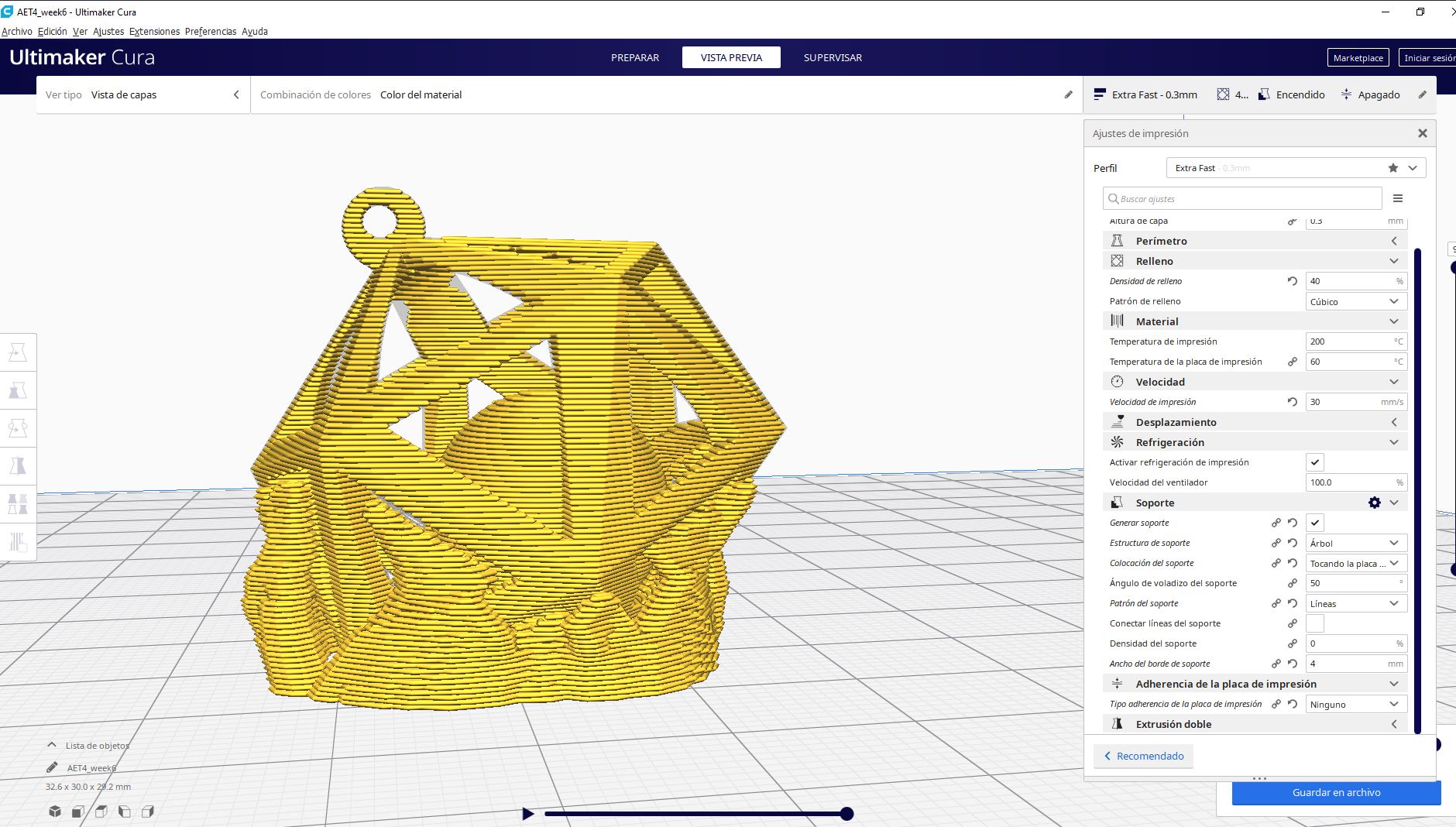

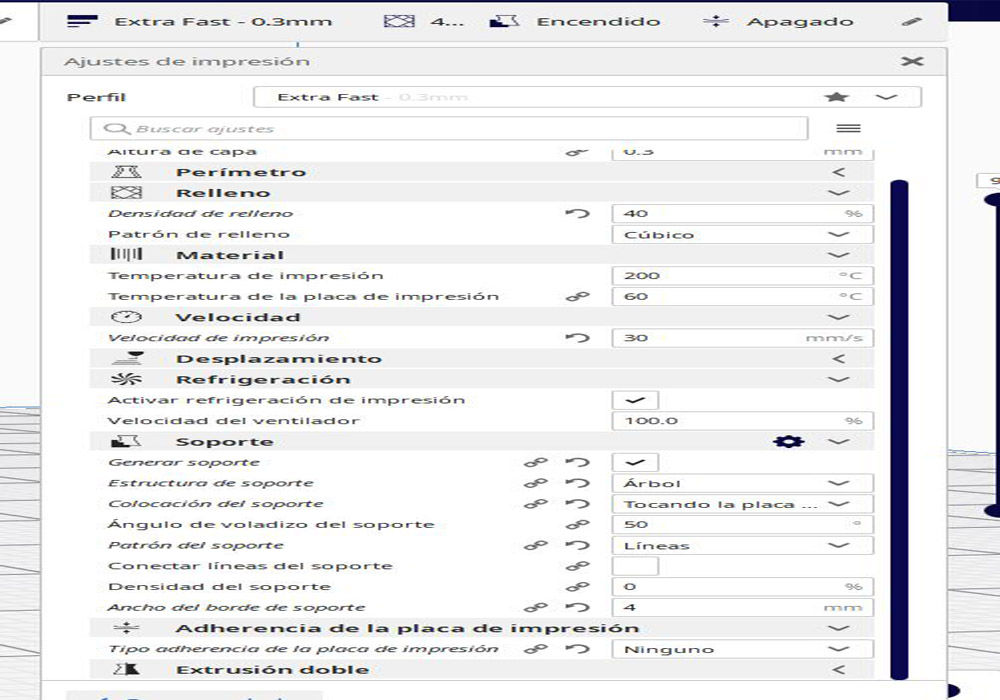

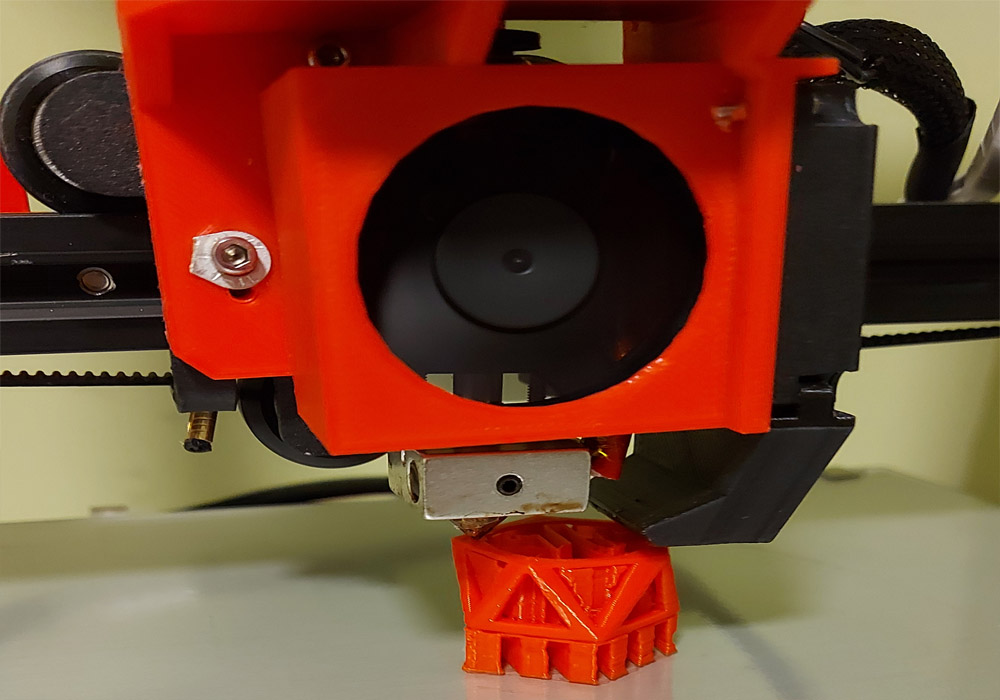

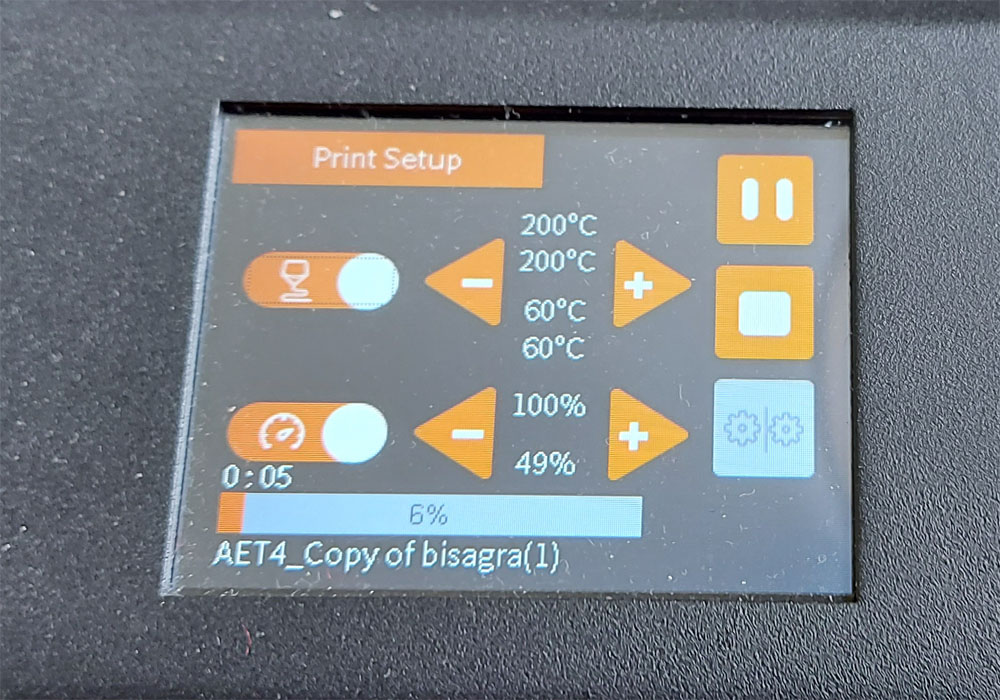

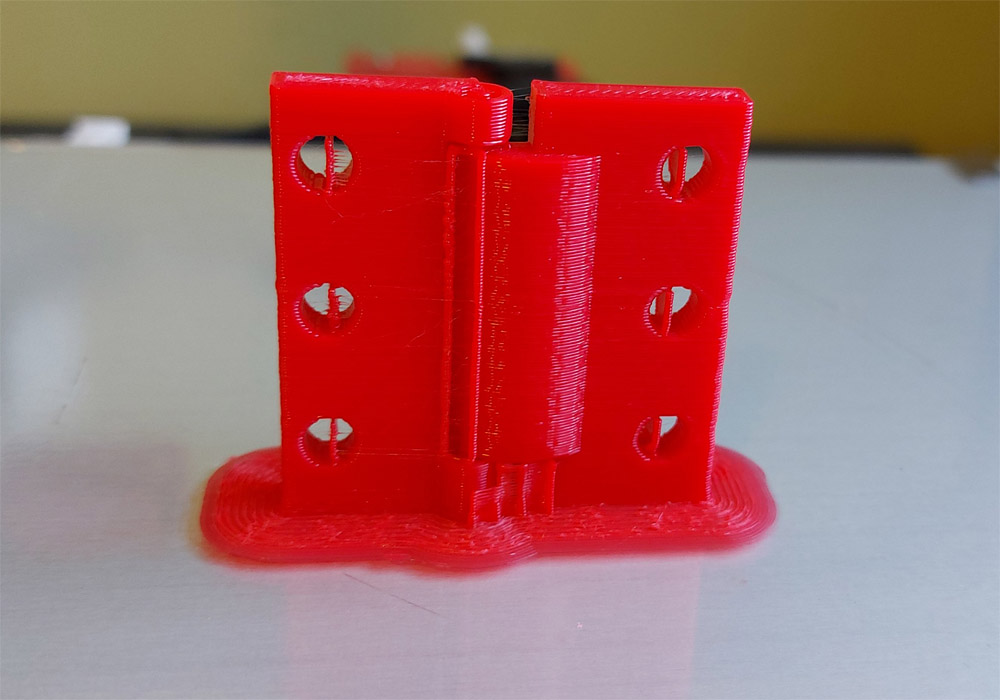

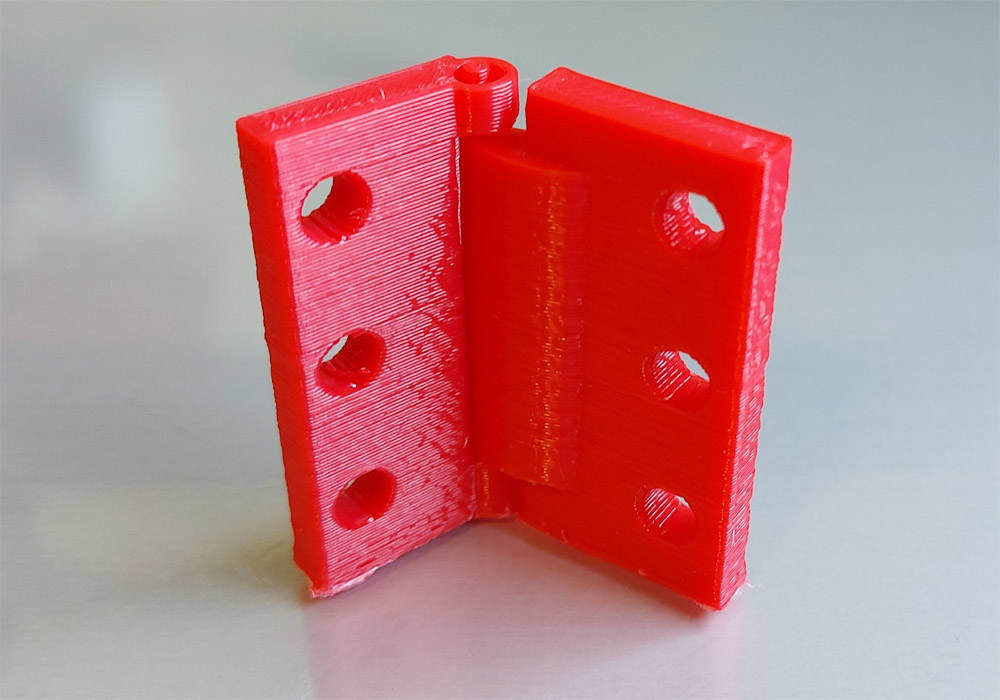

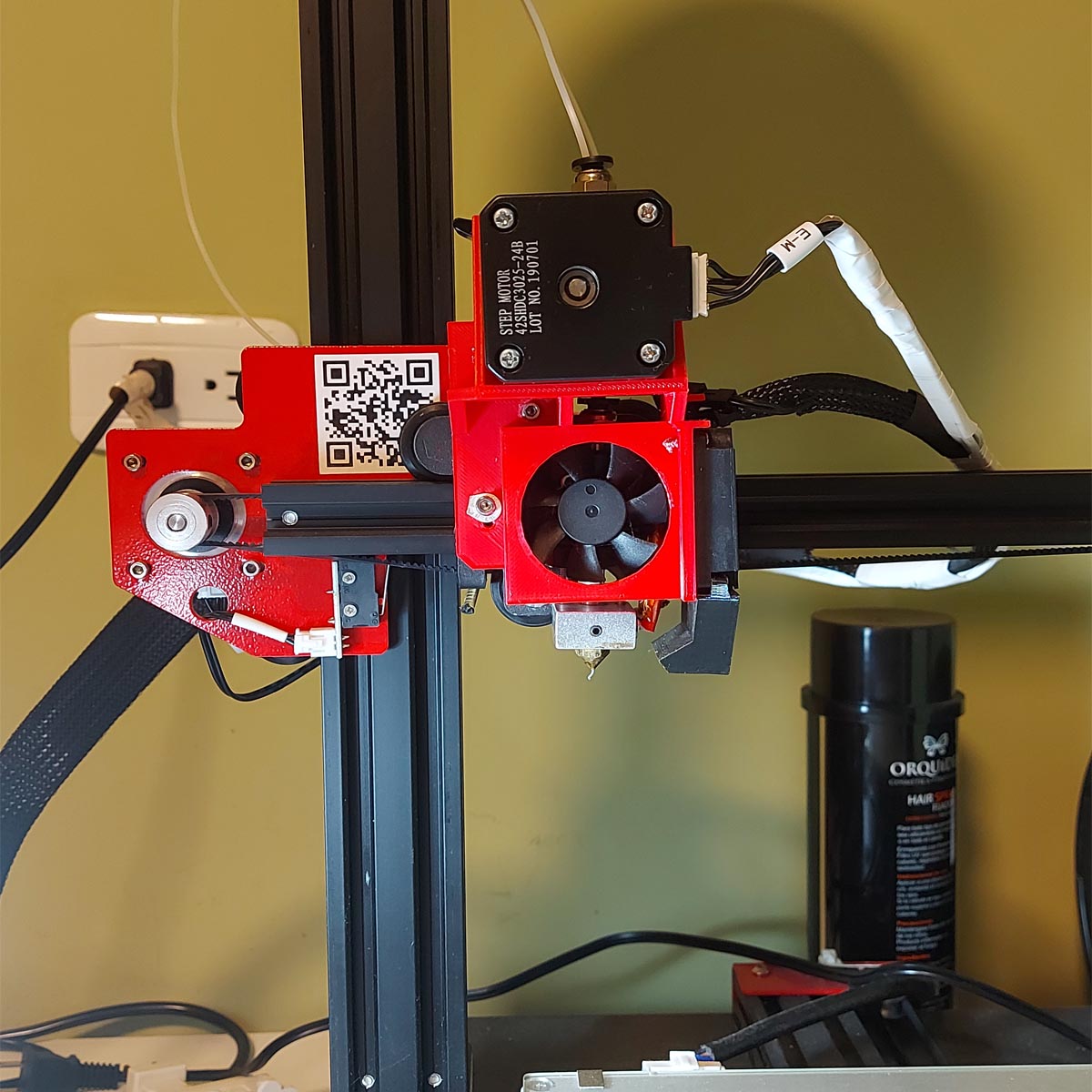

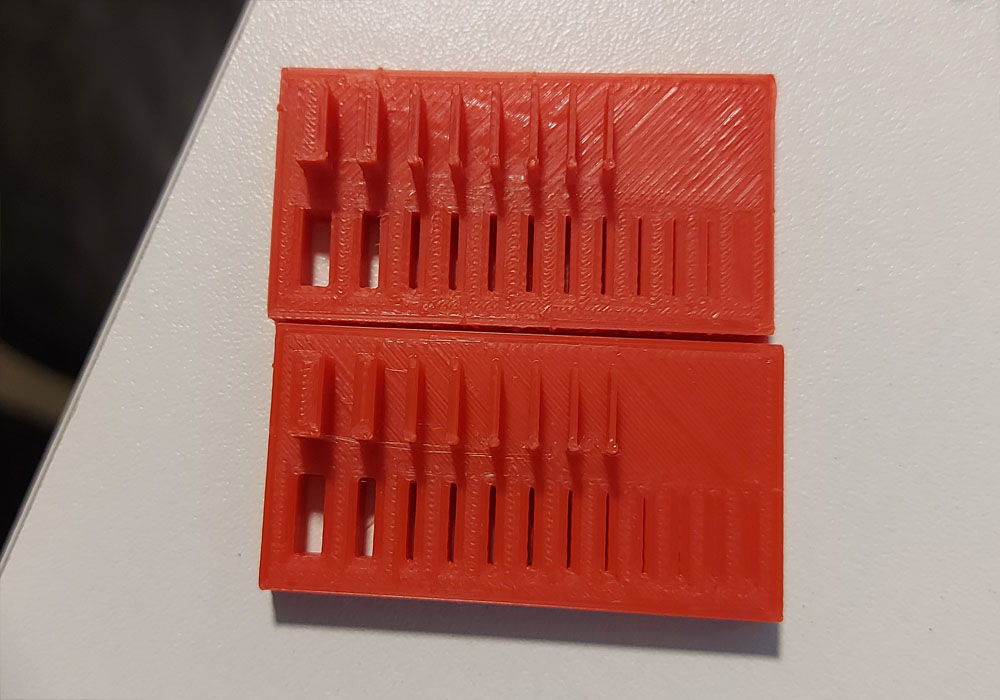

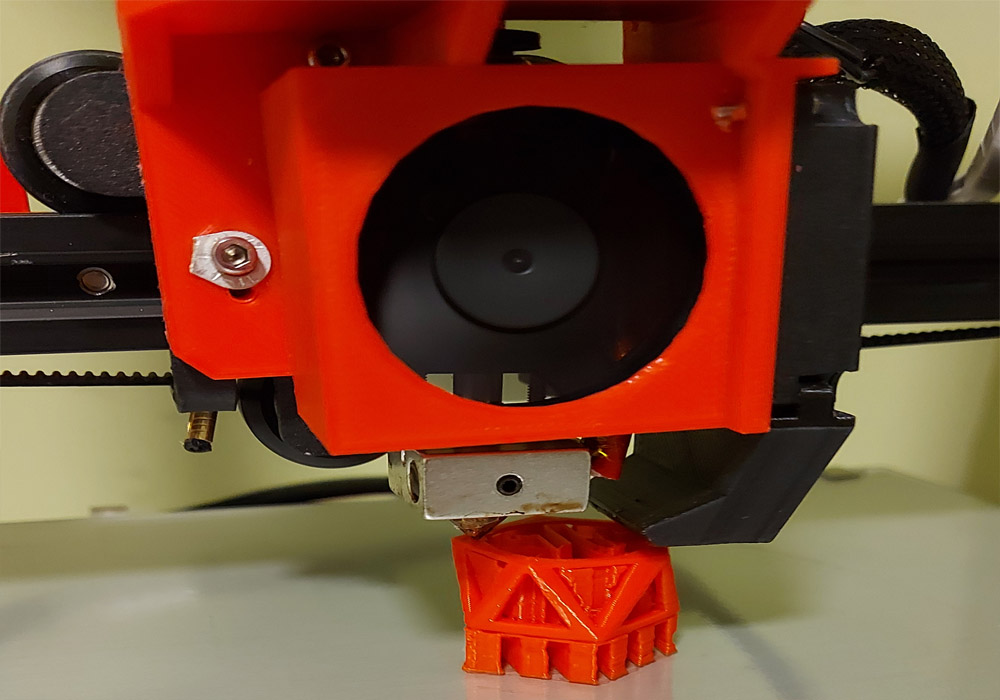

Testing the 3D printer

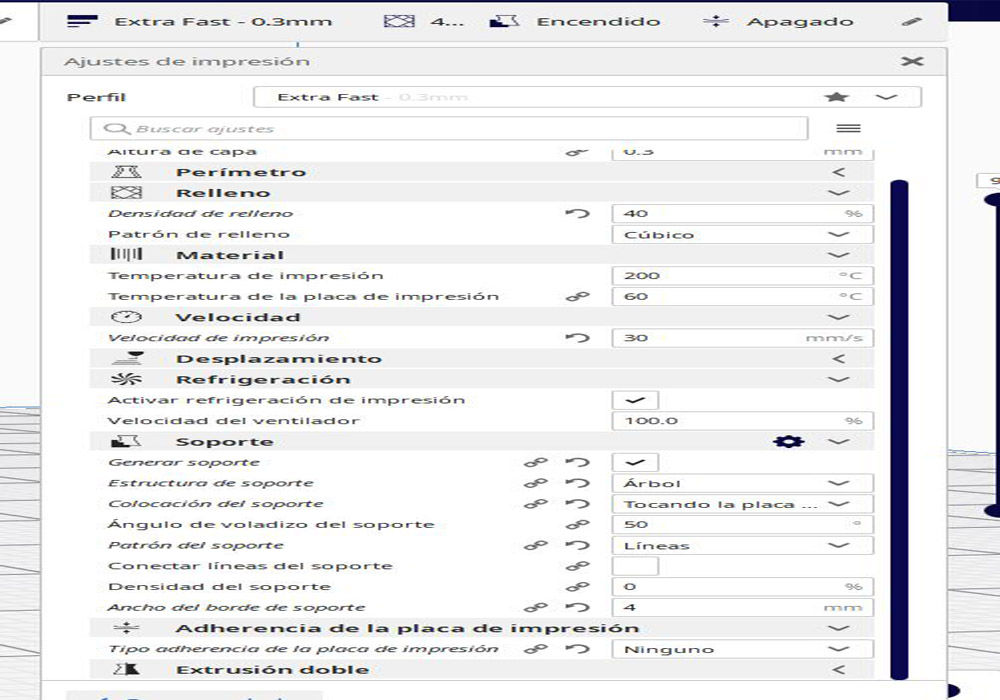

When testing the different printing parameters such as: temperature, speed, layer height, among others,

I could understand the importance of these in the final product, the quality of the printing will be severely

affected and each parameter directly affects the other. in print quality.

If we want a better print quality that will take much longer to print.

file download

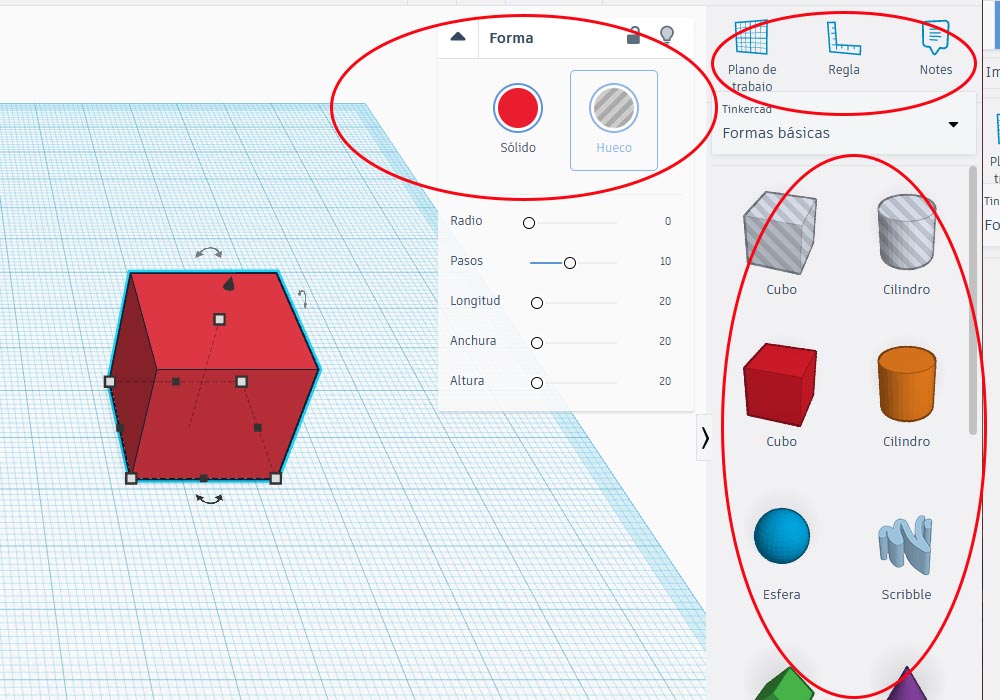

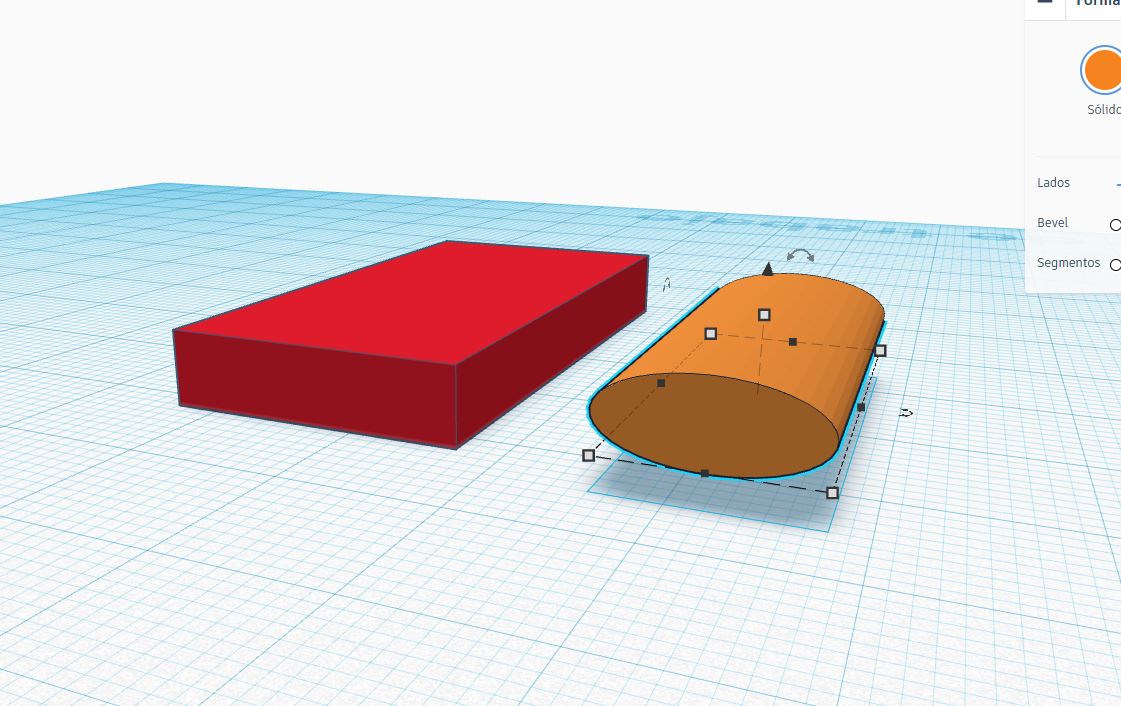

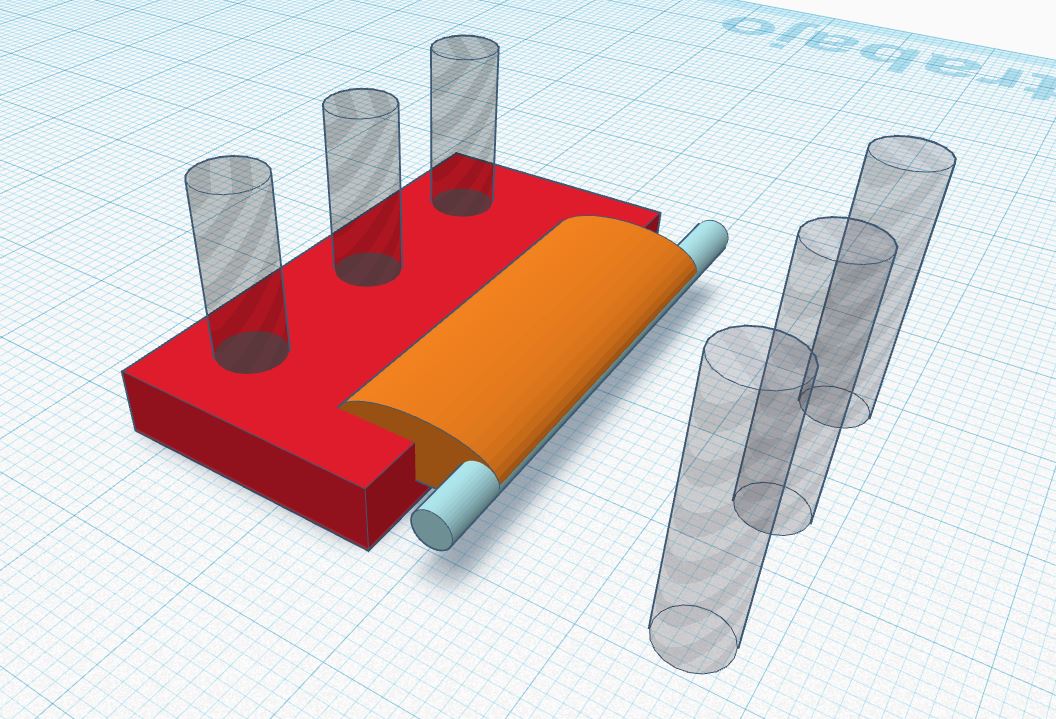

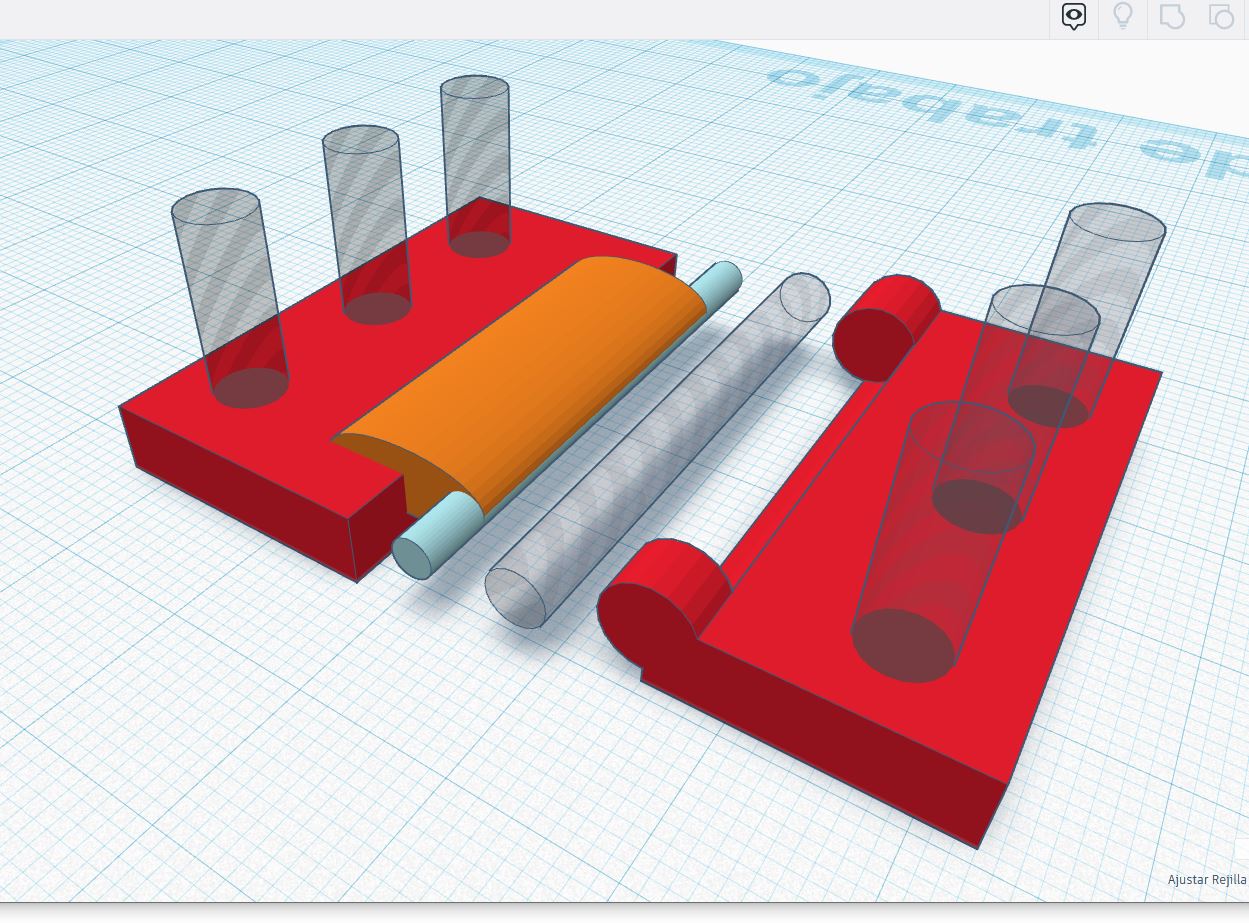

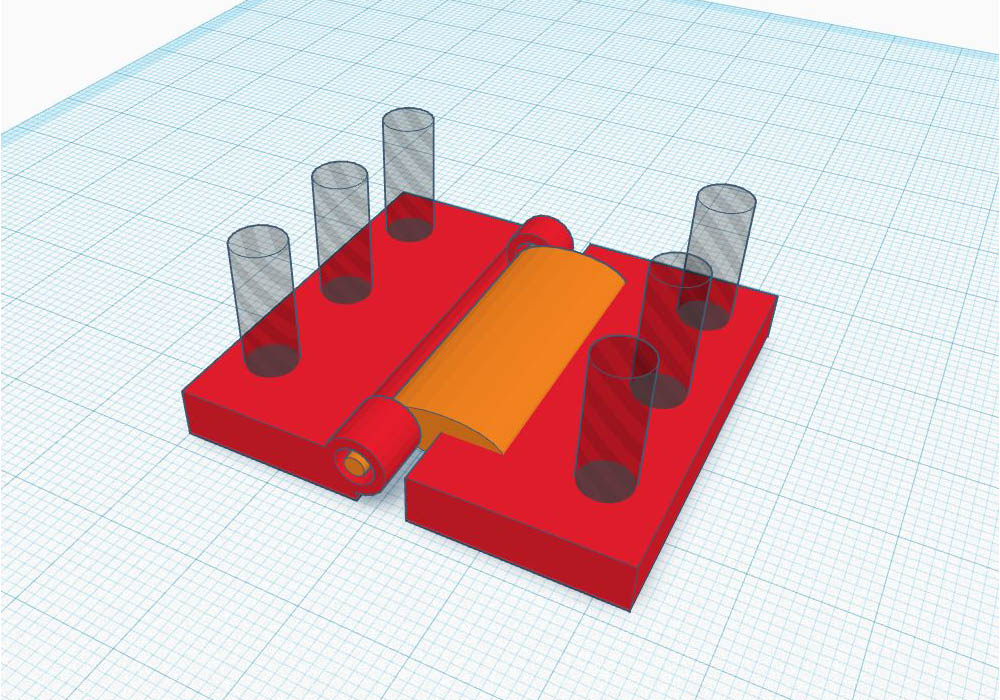

Practice in TINKERCAD

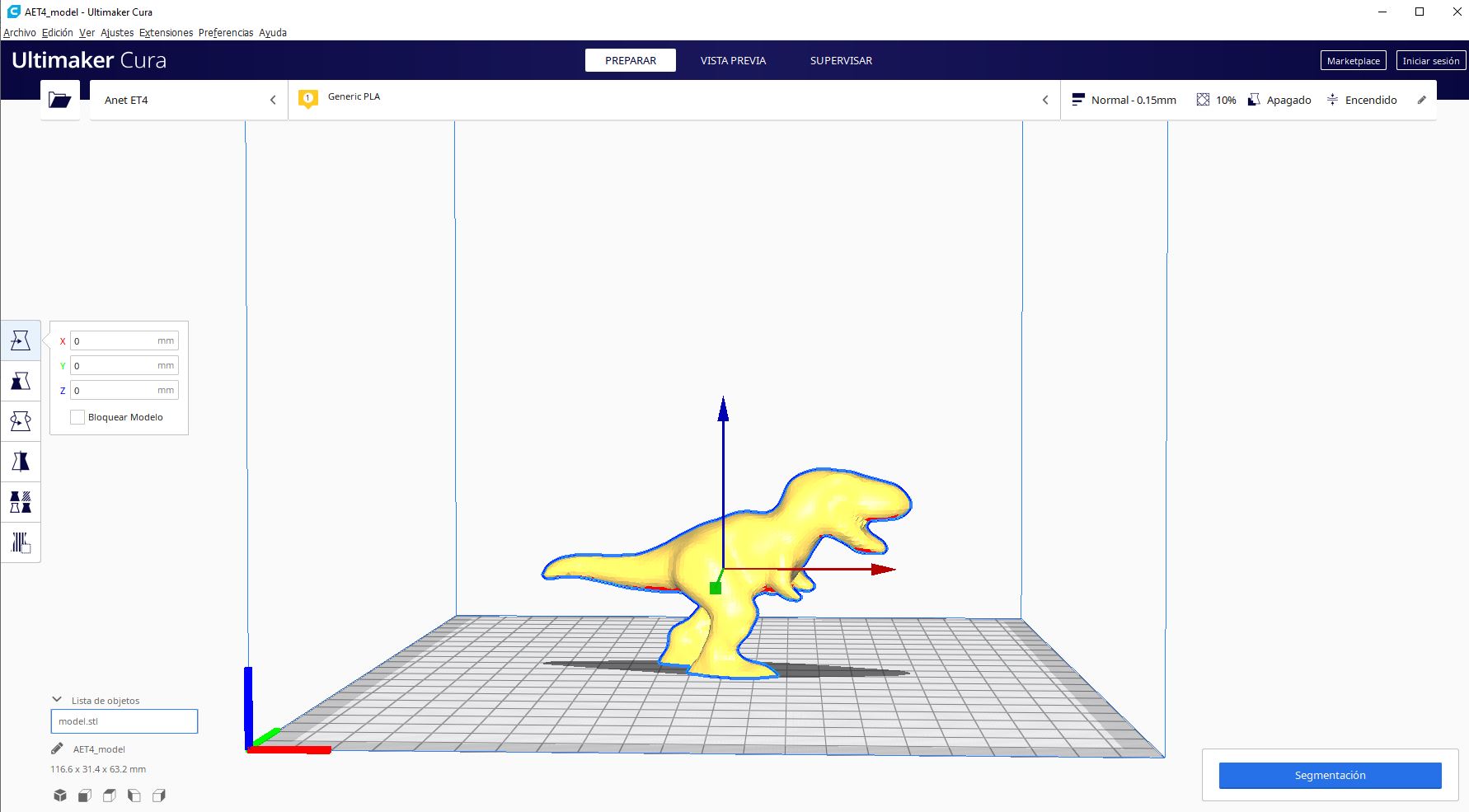

Design and 3D print an object (small, few cm3, limited by printer time)

that could not be made subtractively.

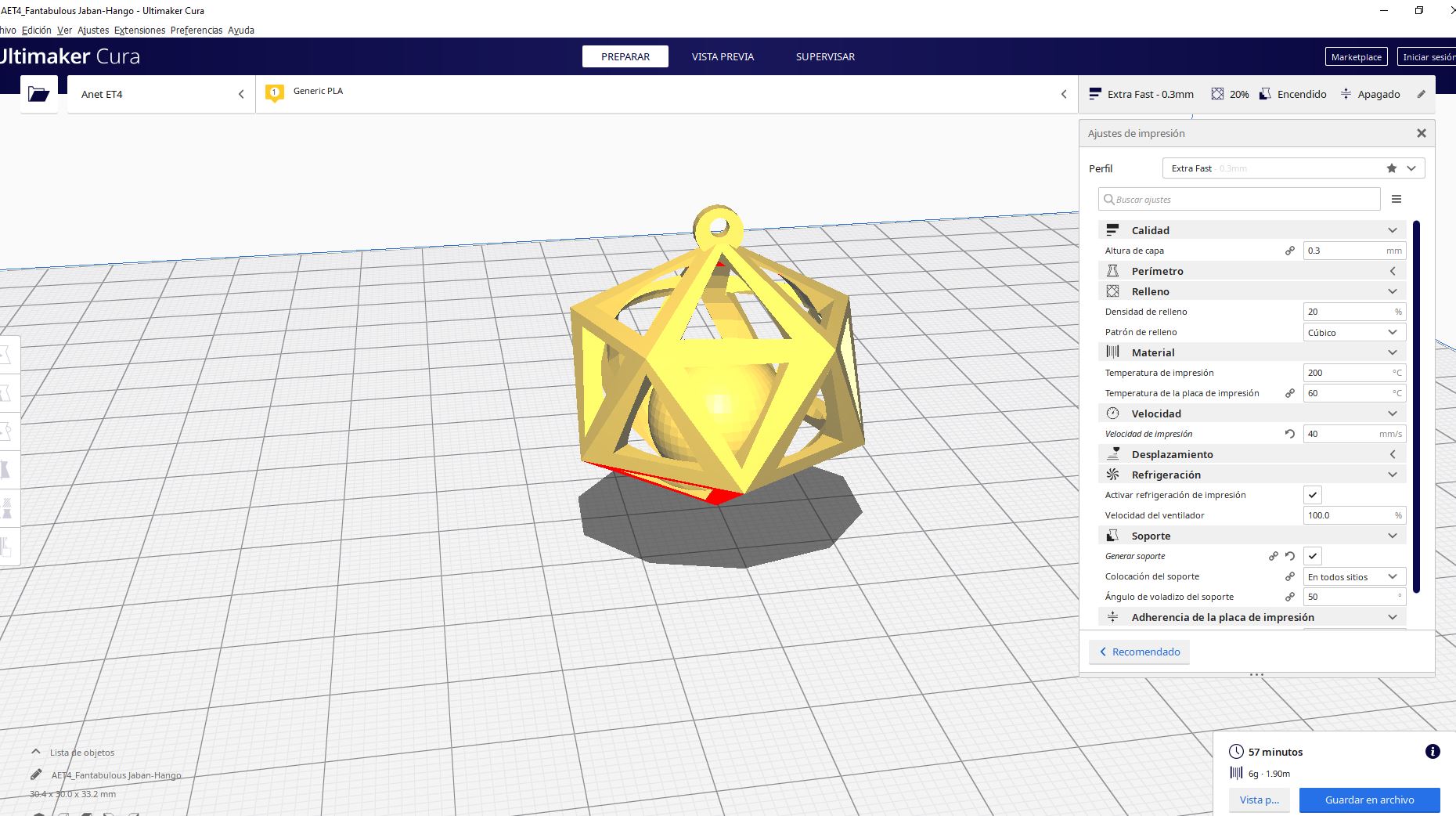

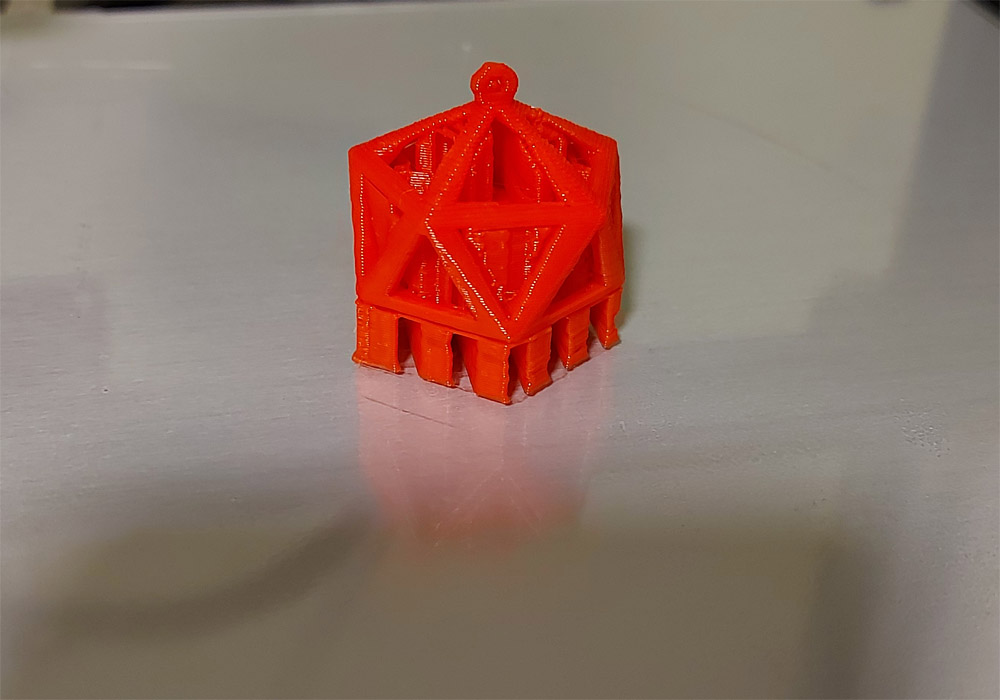

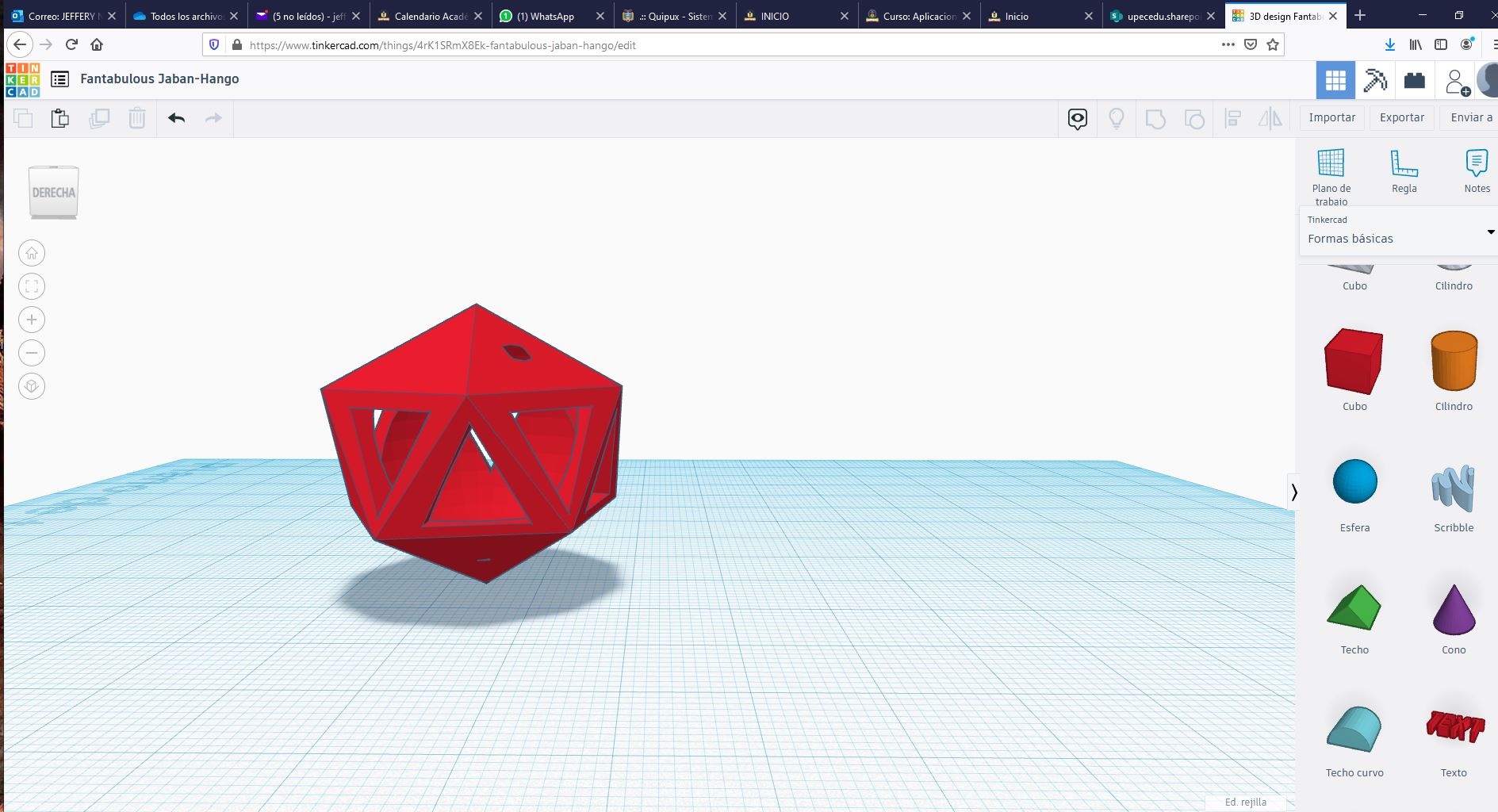

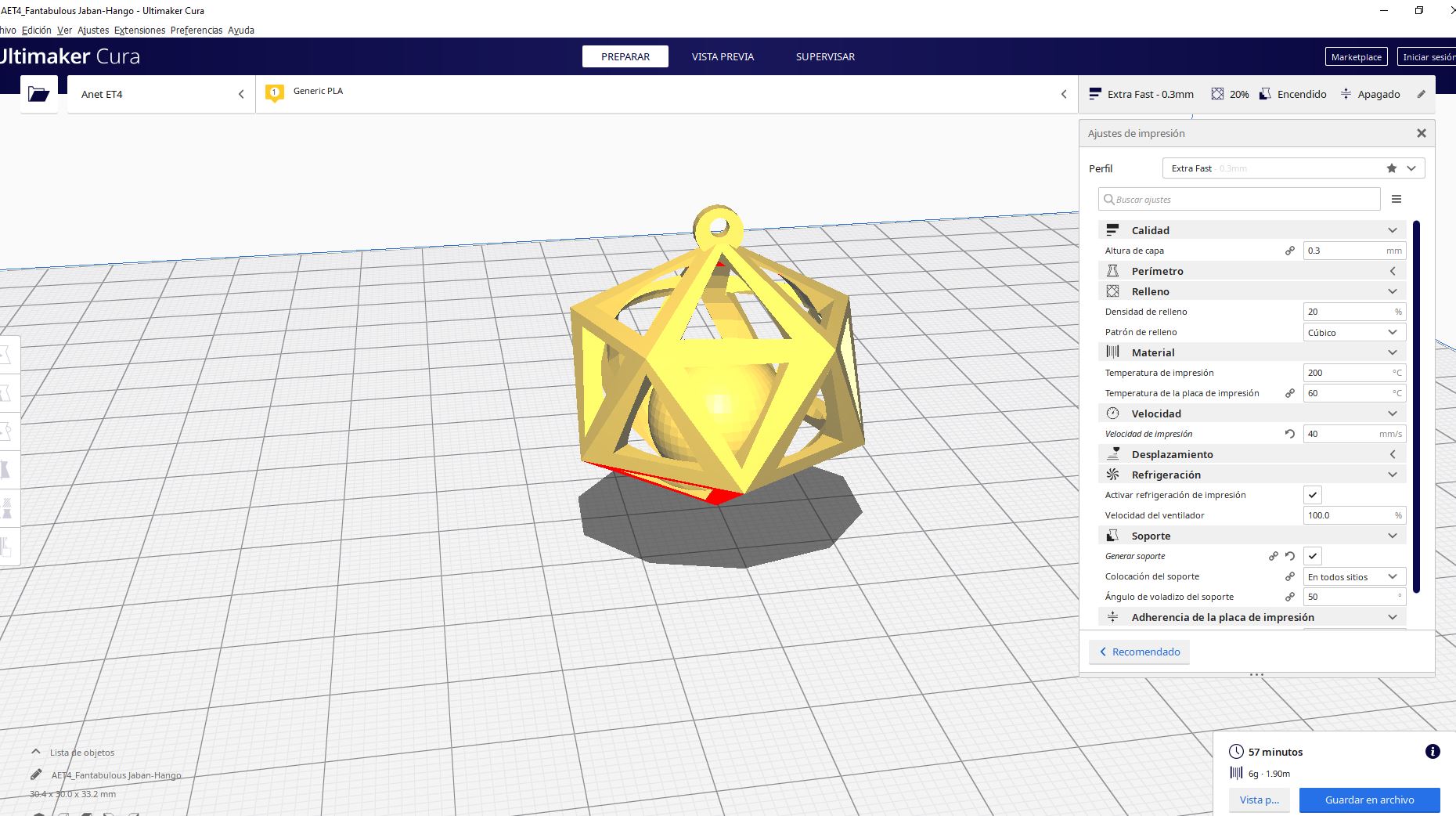

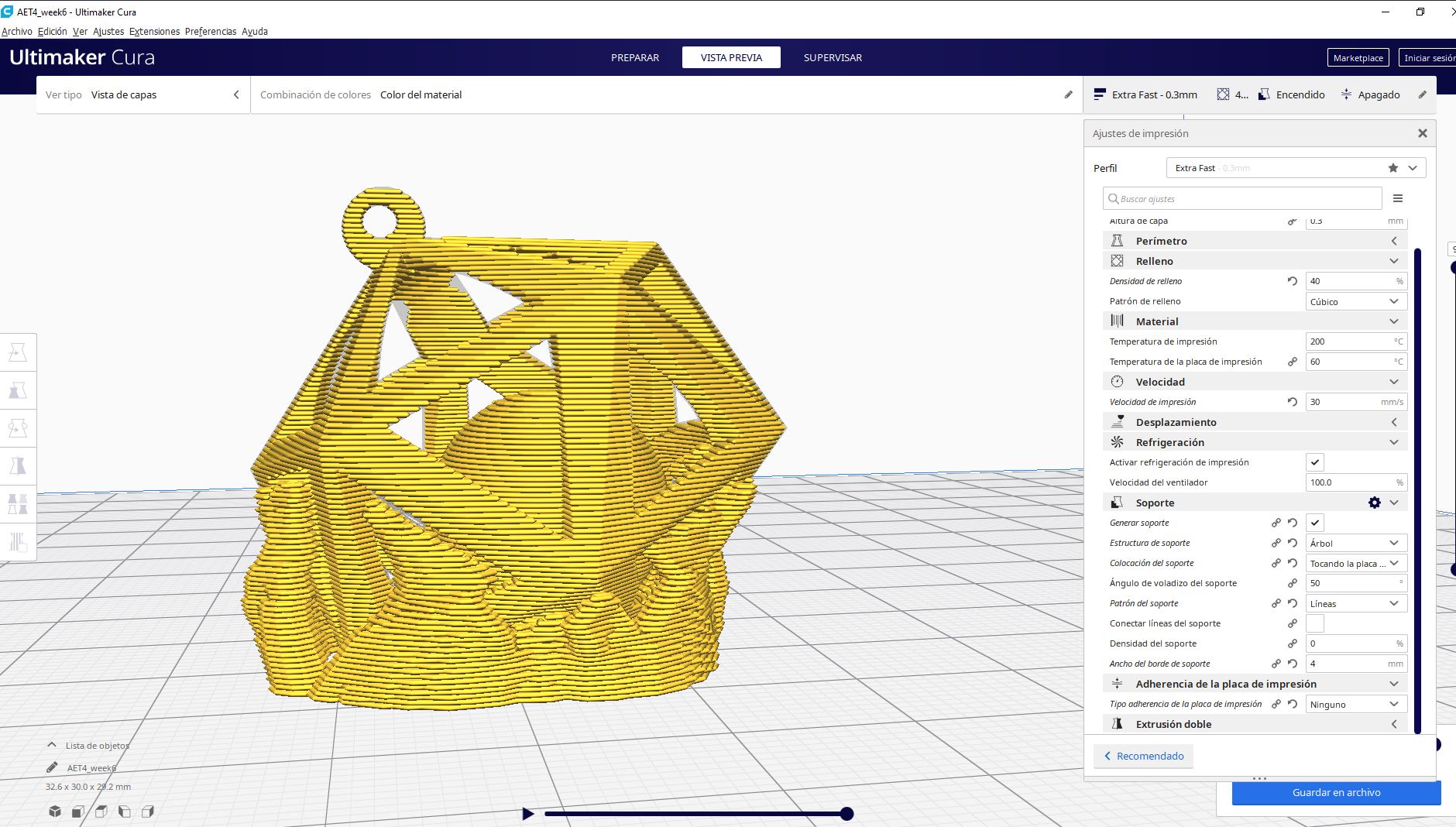

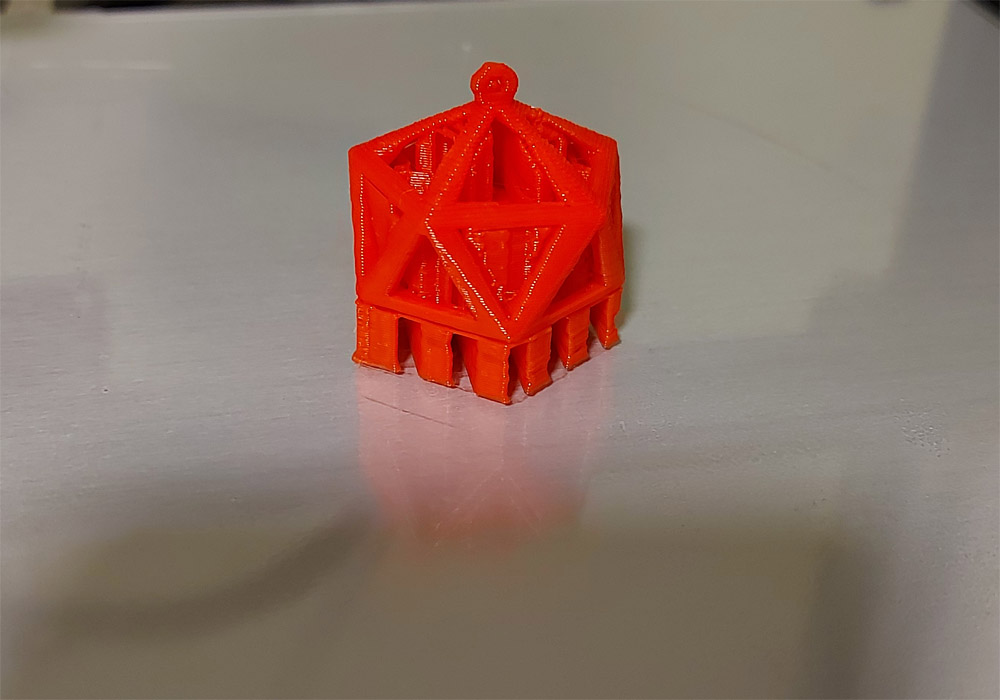

For this practice I will try to print a figure with several edges that contains a sphere inside, for this I will use Tinkercad to make the model to print

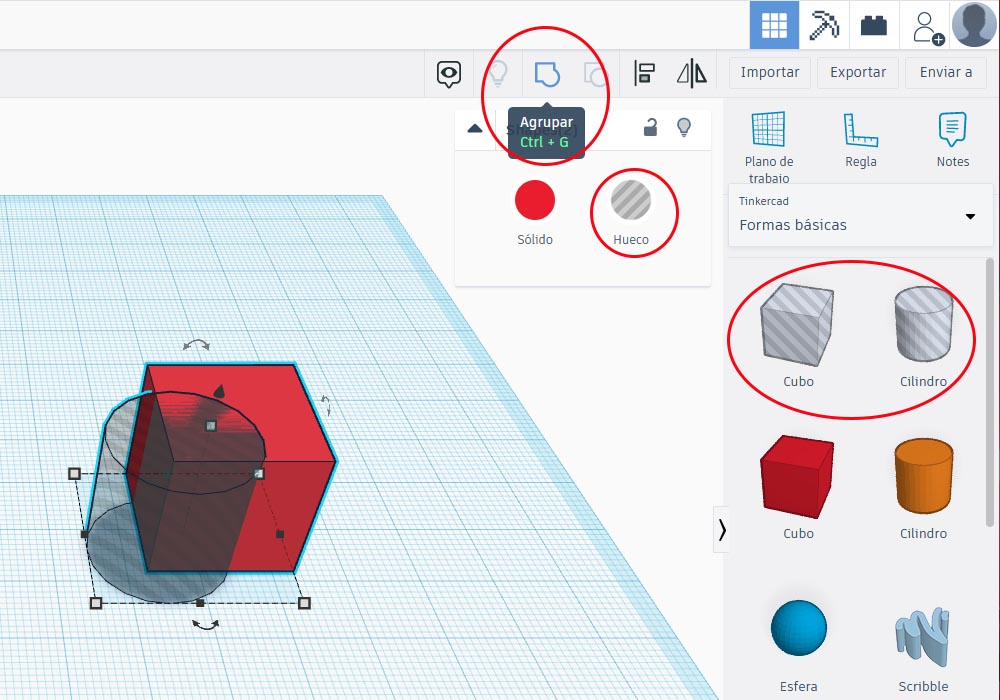

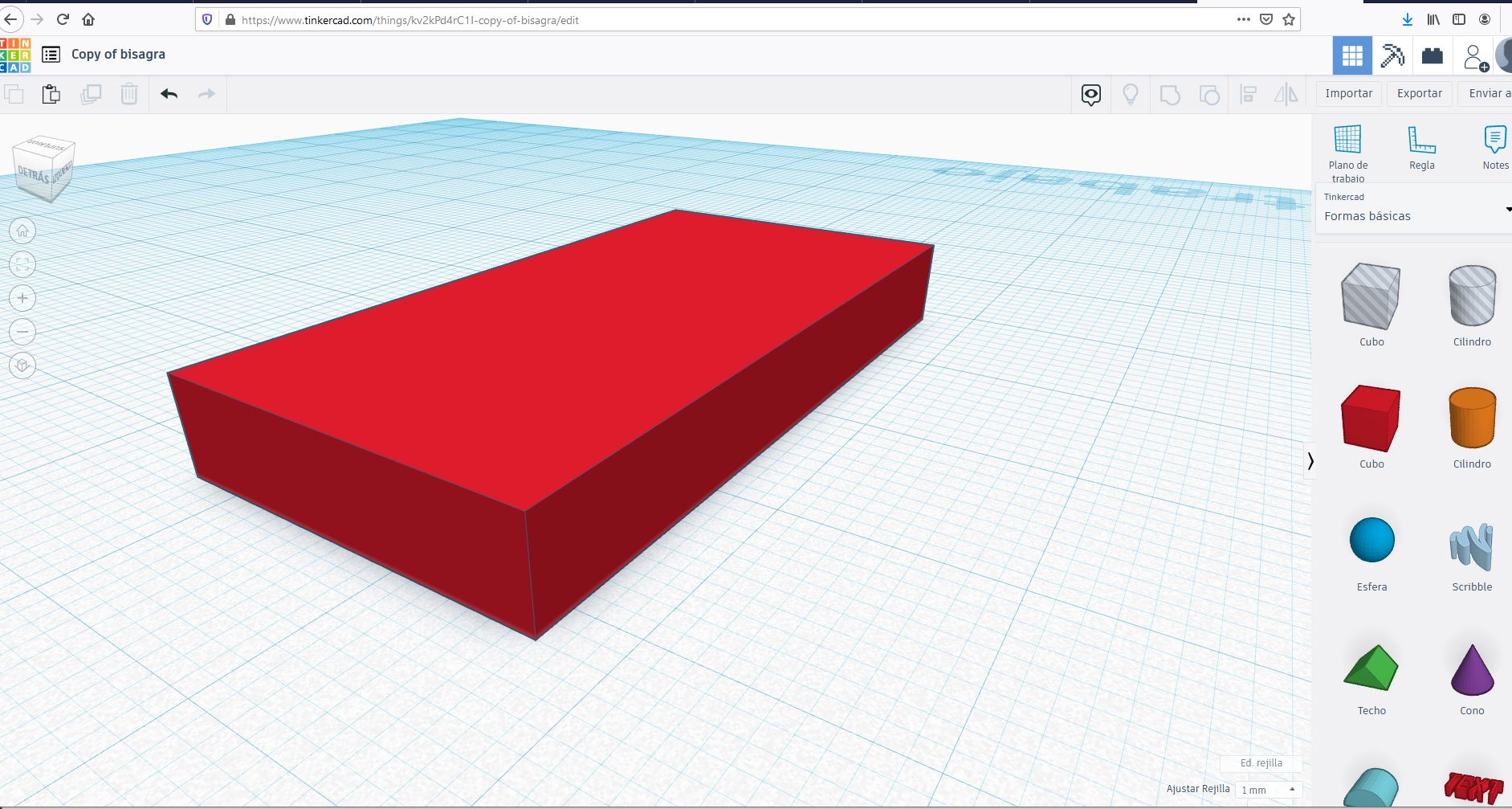

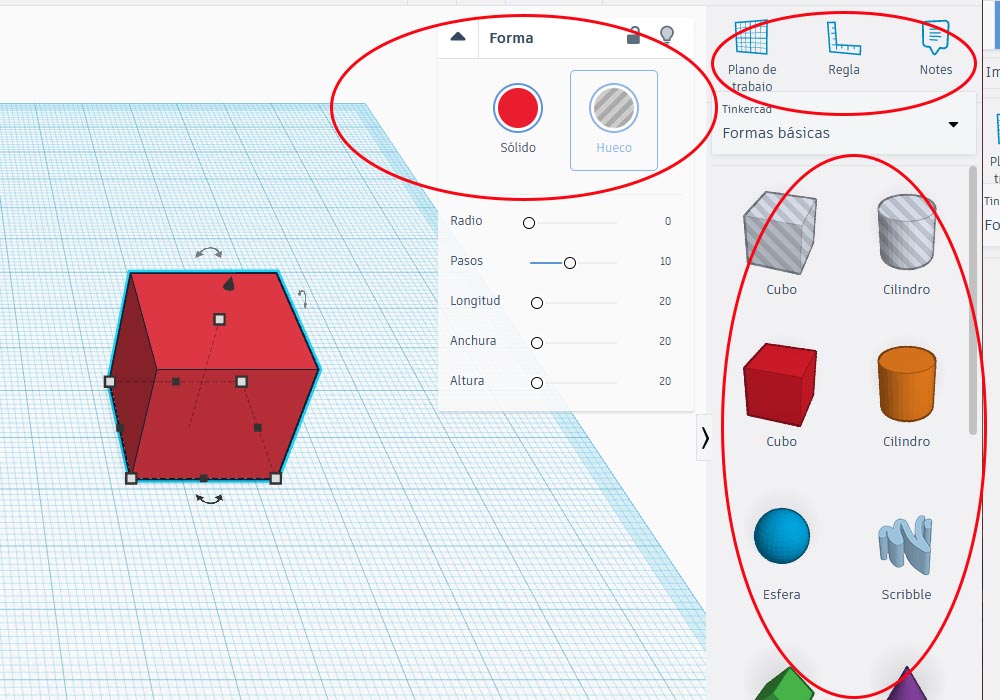

Tinkercad is a very intuitive and easy-to-use tool, on the right side we have several basic shapes, texts, characters, numbers, connectors among others, in the

upper right we also have some tools that help us group shapes, align and duplicate

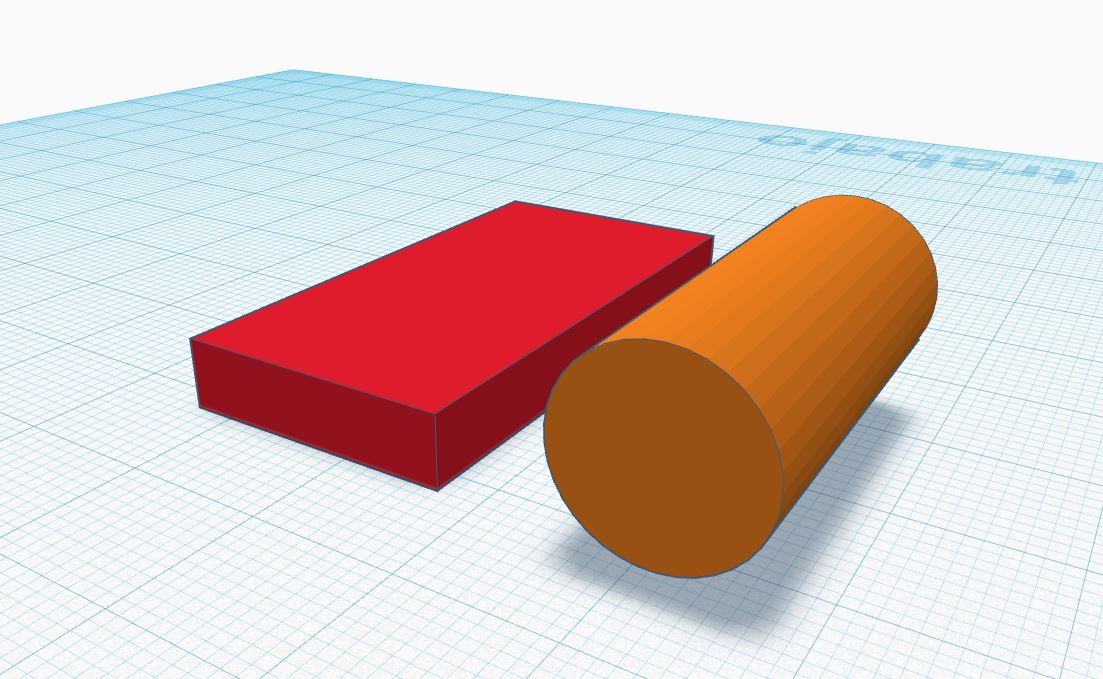

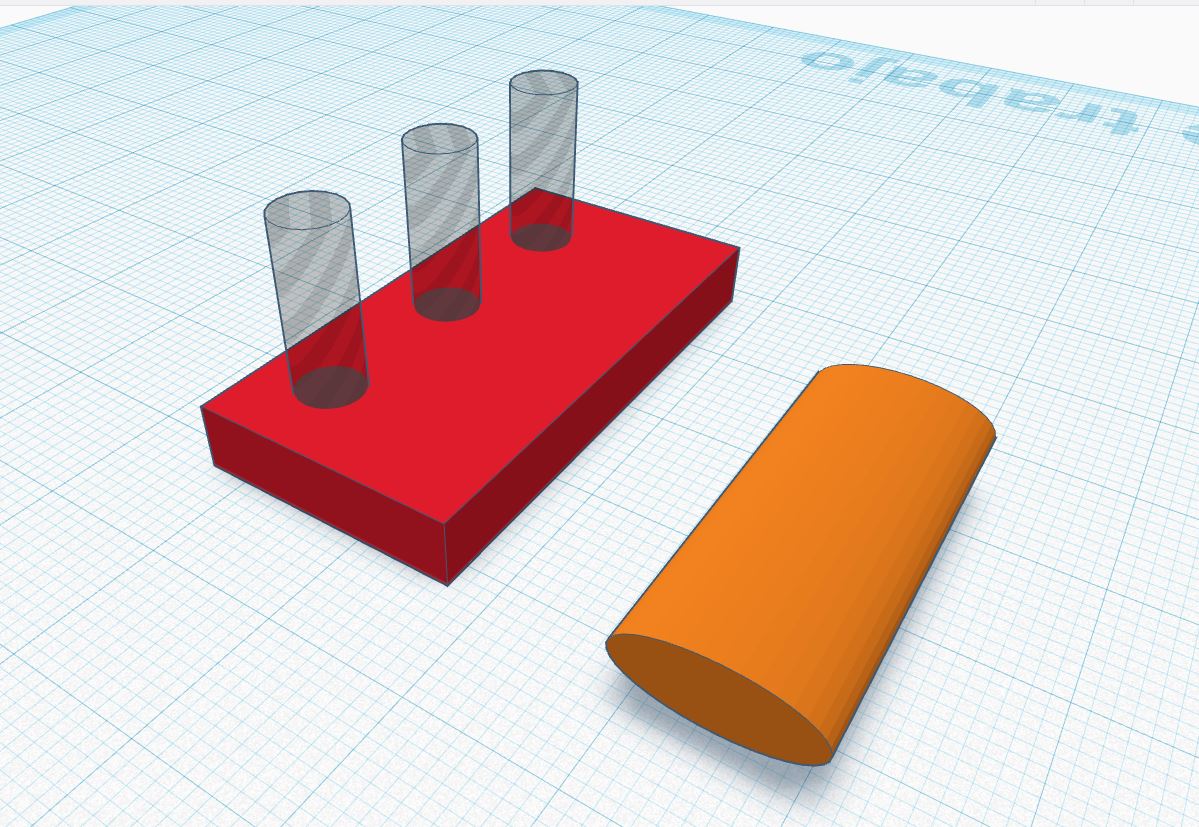

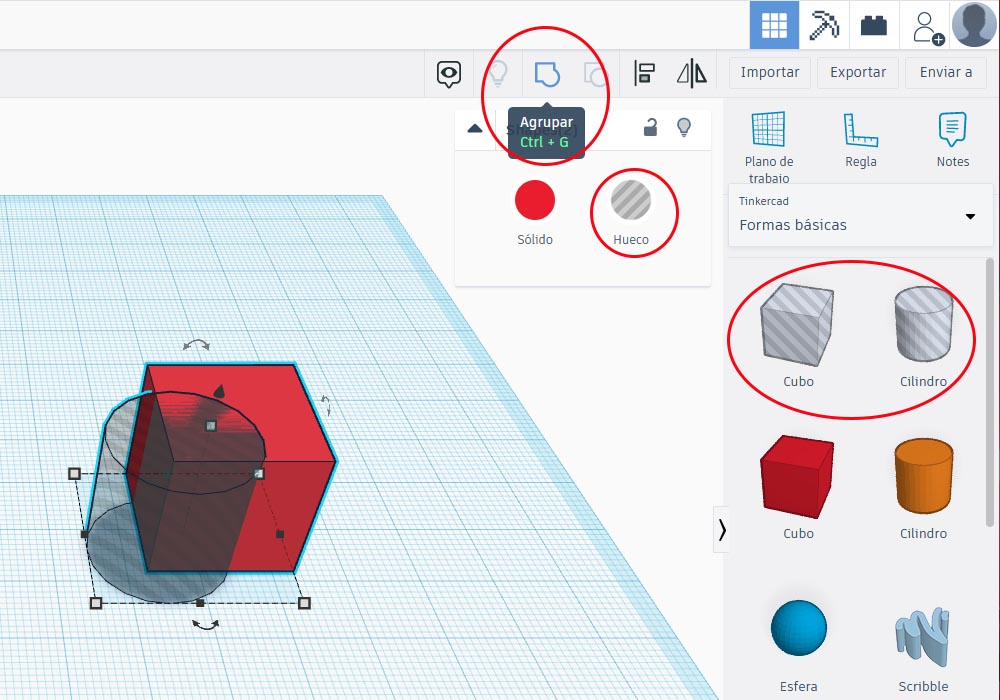

In TinkerCad imagination is very important, being able to visualize the final result from basic shapes, for example we can place a cube and inside it a hollo

cylinder, then we can group the figures and we will obtain a cube without the cylinder part

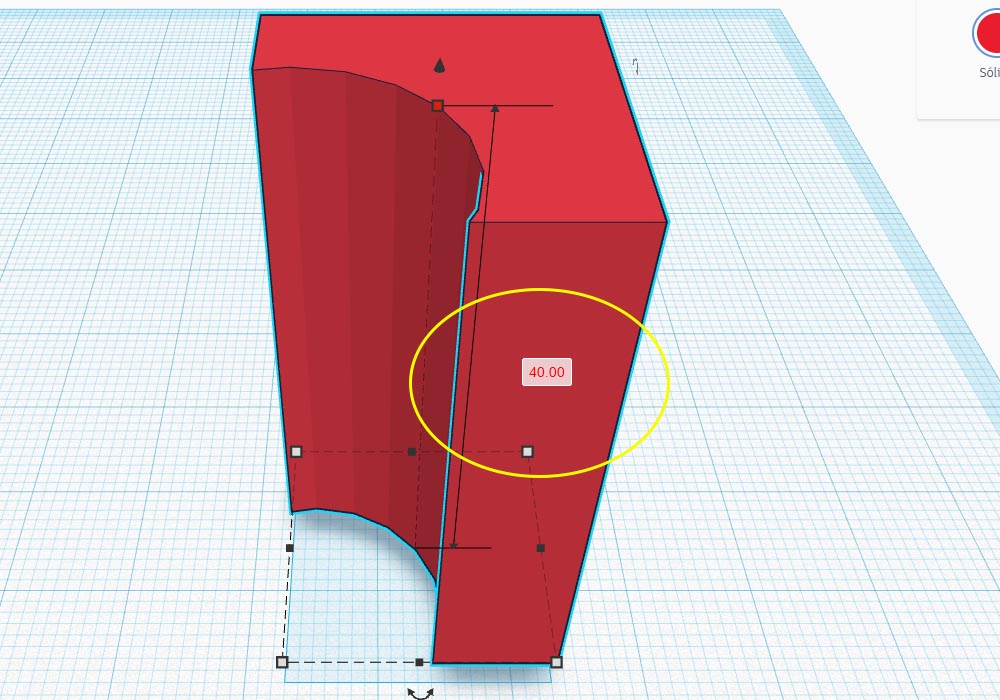

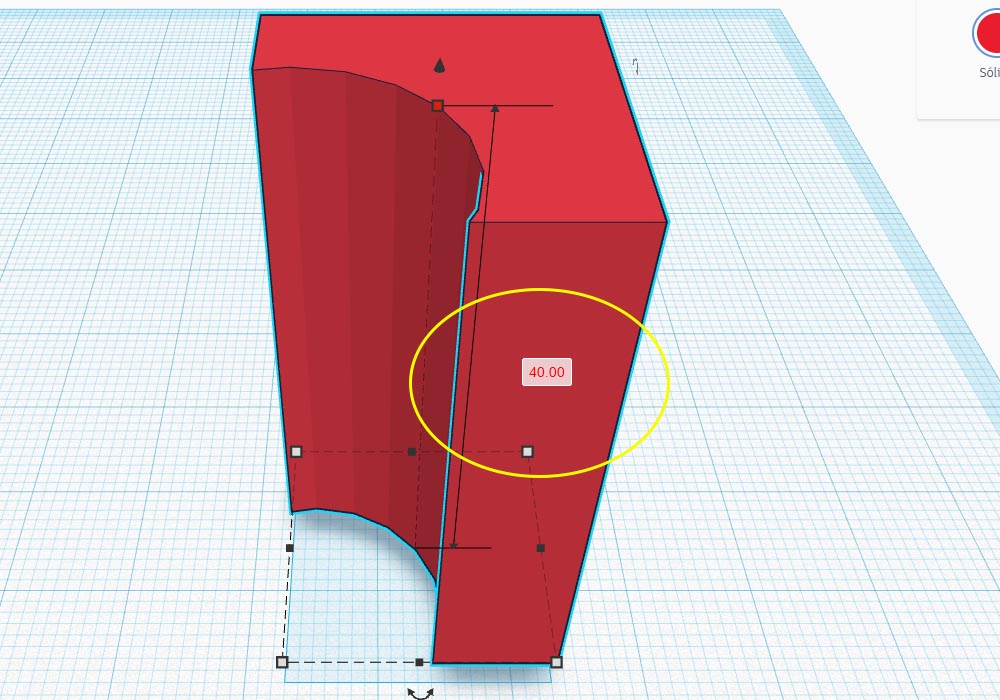

TinkerCad also allows us to manipulate all the dimensions of the figure that we are editing

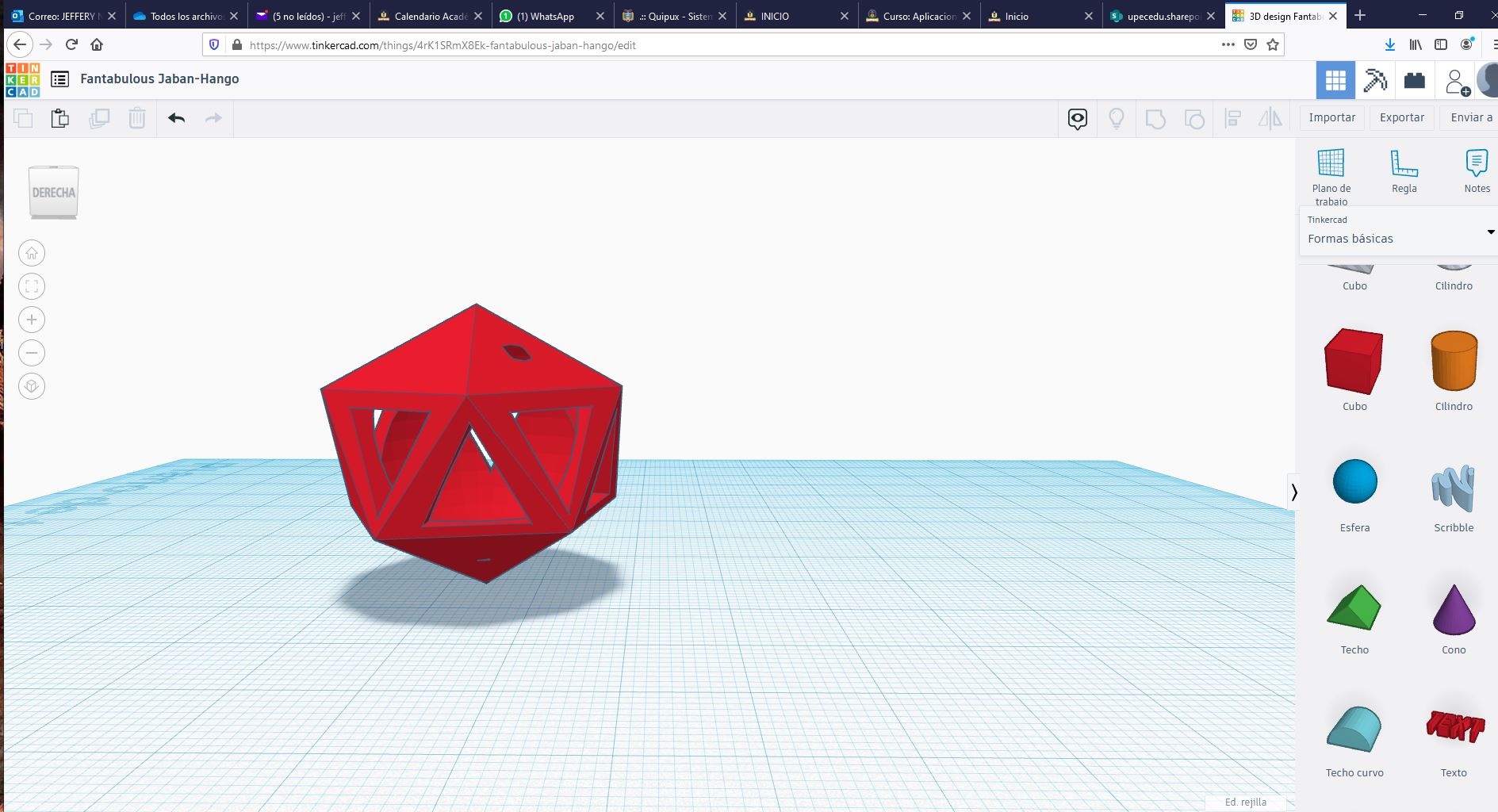

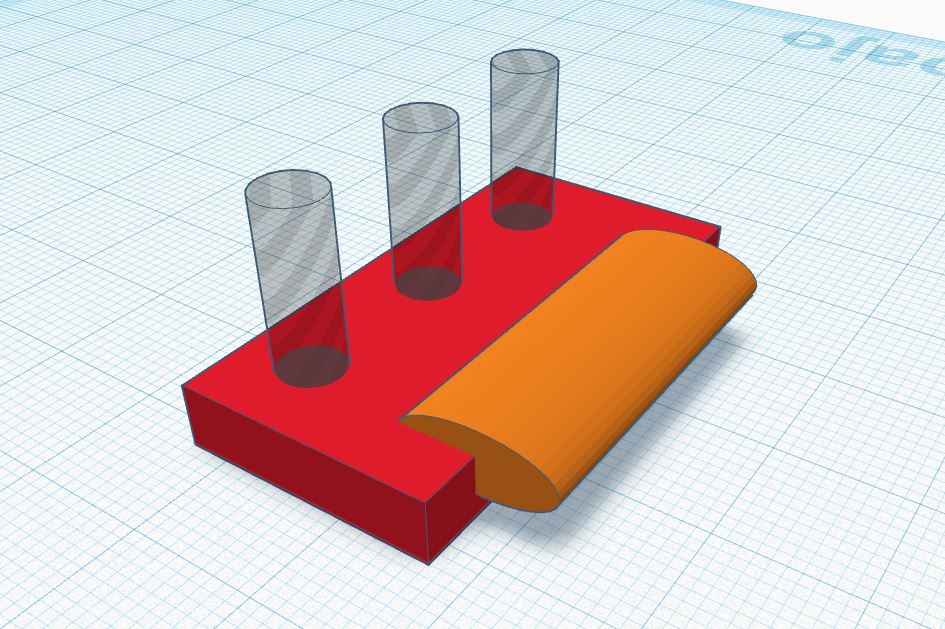

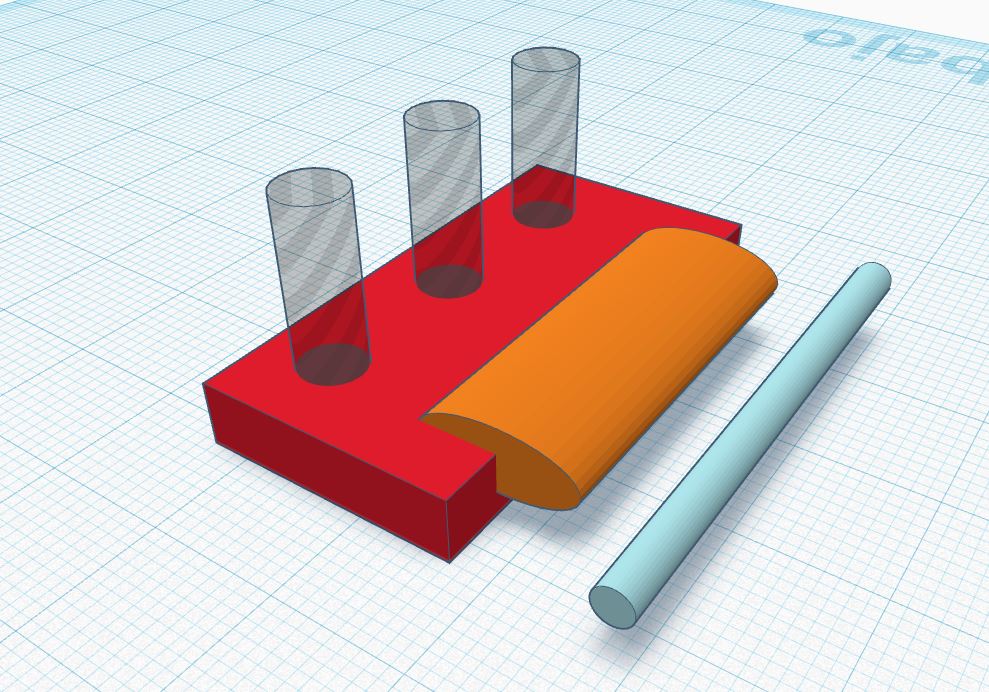

In this way we will start the design of a figure that in principle, due to its shape, could not be built with subtractive techniques as with a cnc

For this we will use a cube and two opposing pyramids, then we will hollow out the piece by inserting hollow triangles and we will group the pieces

until we achieve a result as in the following image

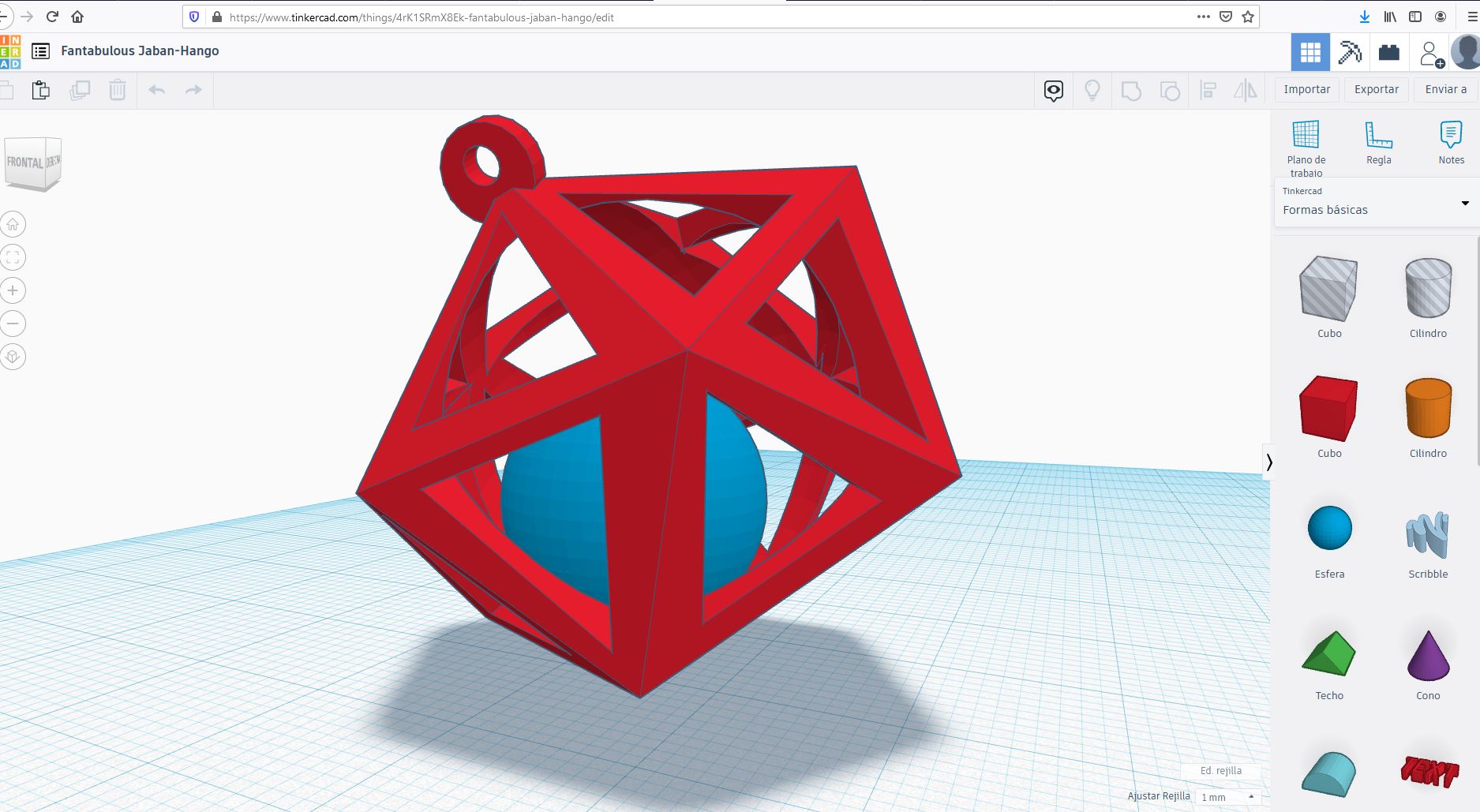

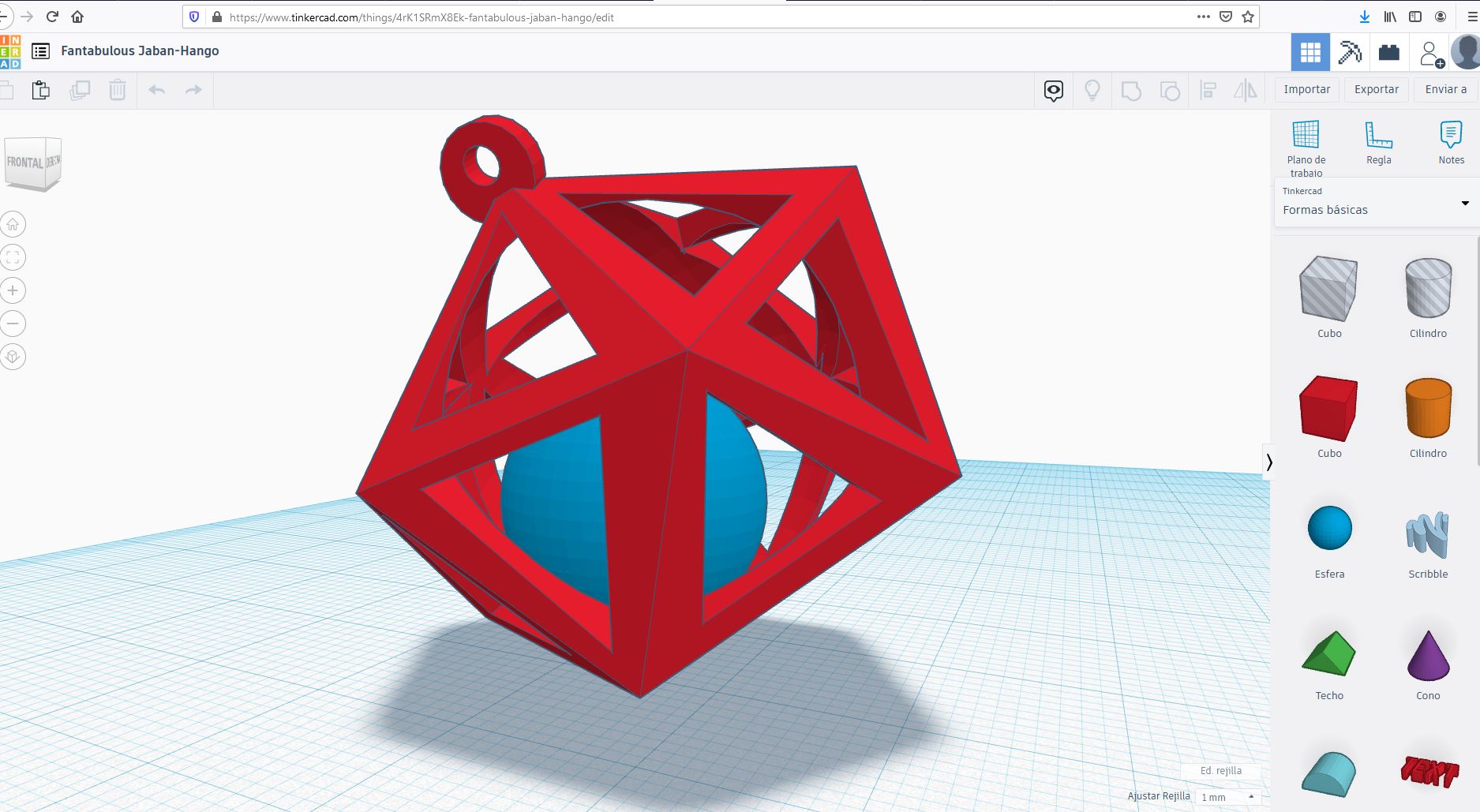

Finally, we will place a sphere inside the figure, this is achieved by changing the height and position parameters, this sphere should not touch

the outer figure, for at the time of printing, it is created with supports that later we must break to free the sphere.

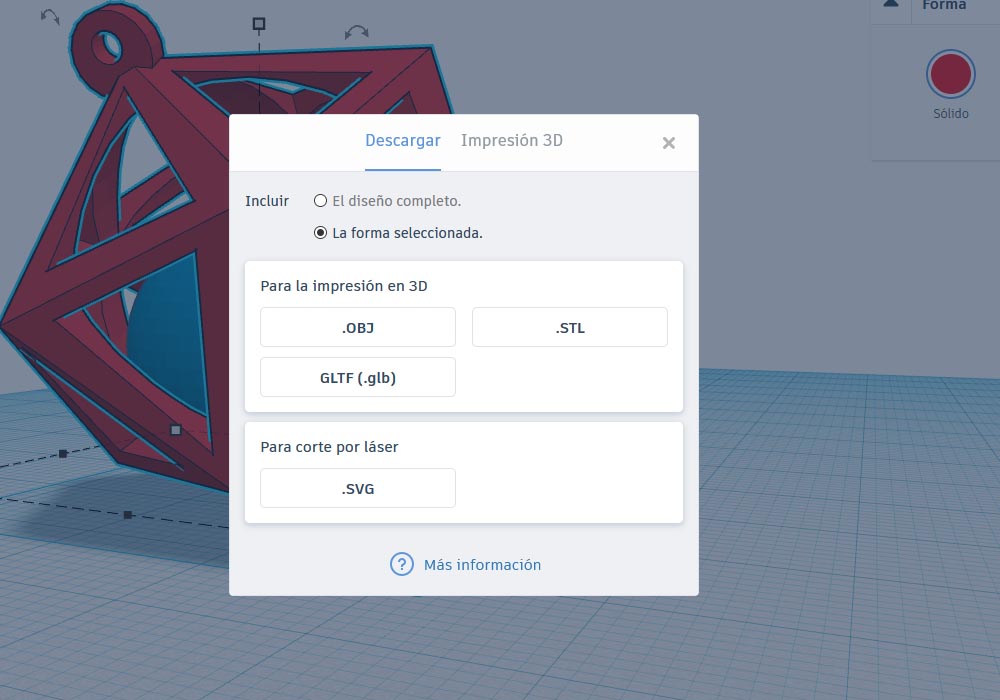

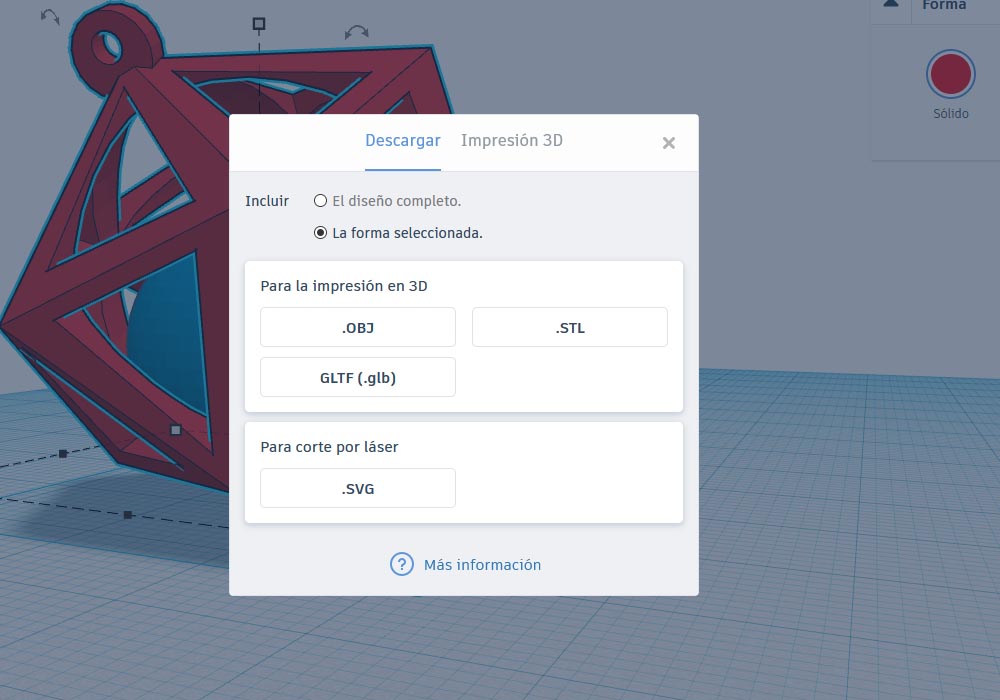

TinkerCad allows us to export our figures to be printed on our 3D printer so we can obtain OBJ, STL and GLFT formats and even SVG format for laser cutting

file download