Week

Fifteen

Wild Card Week

5-Axis Milling

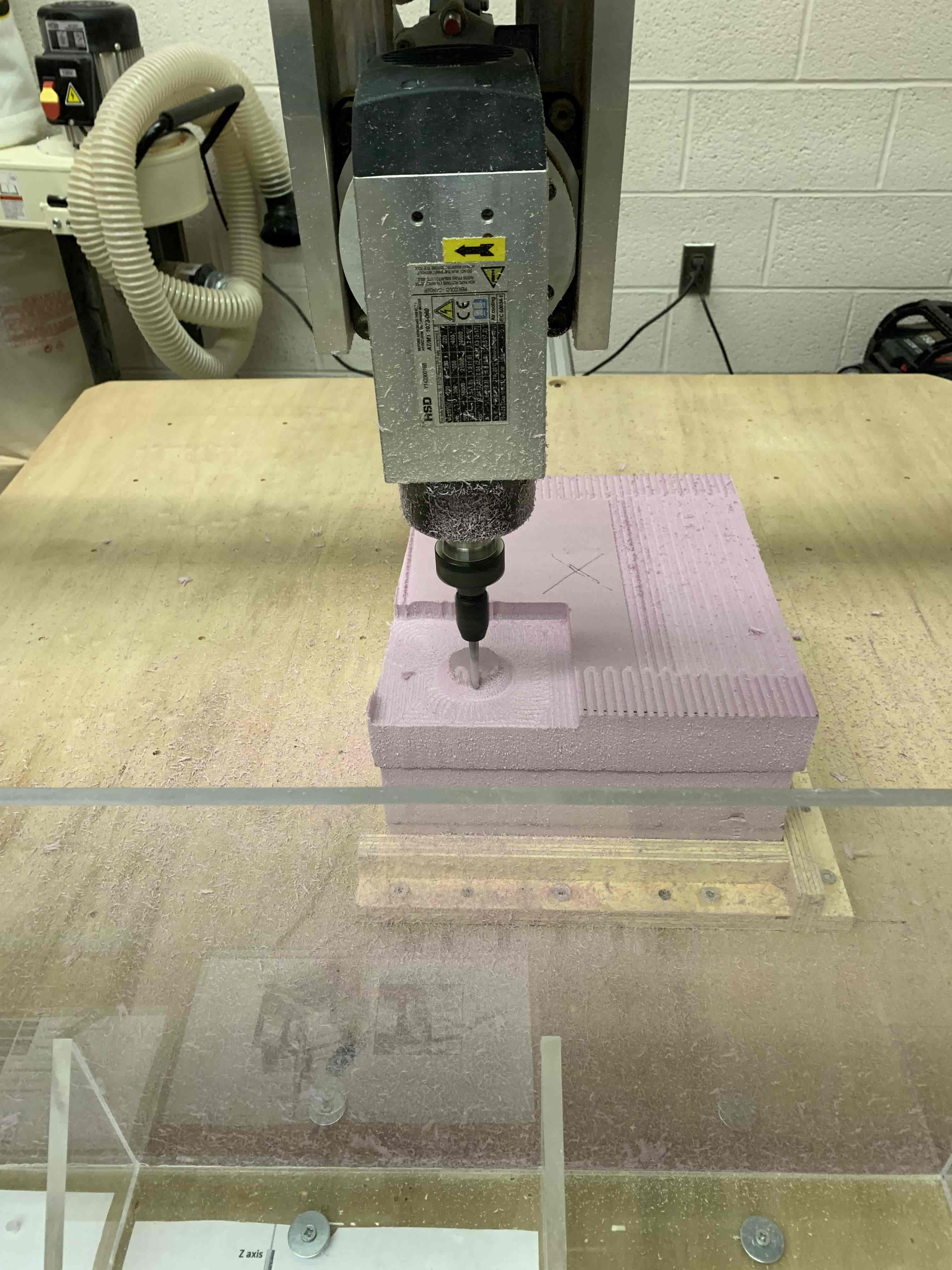

This week when given the options between several different types of digital fabrication myself and several other students decided to try to use the shopbot mill that we have in the shop for it's 5-axis capabilities. The problem is that only one person at the school has managed to actually carve anything with the 5-axis, and they were especially busy this week with needing to get grades finished. With that being the case Madison brought in another instructor from RISD named Larry, who has quite a bit of experience milling, but still none with all 5-axes.

So that left myself with 2 other students and Larry trying to figure out the machine. We certainly did learn something about this machine. What I can say we've learned is that it works spectacularly as a 3-axis mill. In my opinion the shopbot gave very nice results, and the machine was very nice to work with. However as a 5-axis mill, we could not make it work for the life of us. To the point that we found it more effective for us all to just work toward one project instead of doing individual ones, so all of the work I'm going to talk about here was done in conjunction with Jesse.

5-Axis vs 2+3-Axis milling

So in doing this work we found discovered that there are two different ways to use the 5-axis functinality to carve things out the way we would want to. There are standard 5-axis cuts. These involve the machine moving in the X Y and Z planes while rotating around the A and B axis to carve out whatever sort of design is required. However in Fusion 360 the cut types that have actual 5-axis functionallity do not work well at actually clearing lots of material. So in order for this to work it is usually done in conjunction with a 3-axis cut to clear away most of the material. Whereas 3-2 milling involves moving the axis so that Z-axis could carve in each direction, and then setting the bit to be at a certain angle and then doing a standard 3-axis cut.

Results

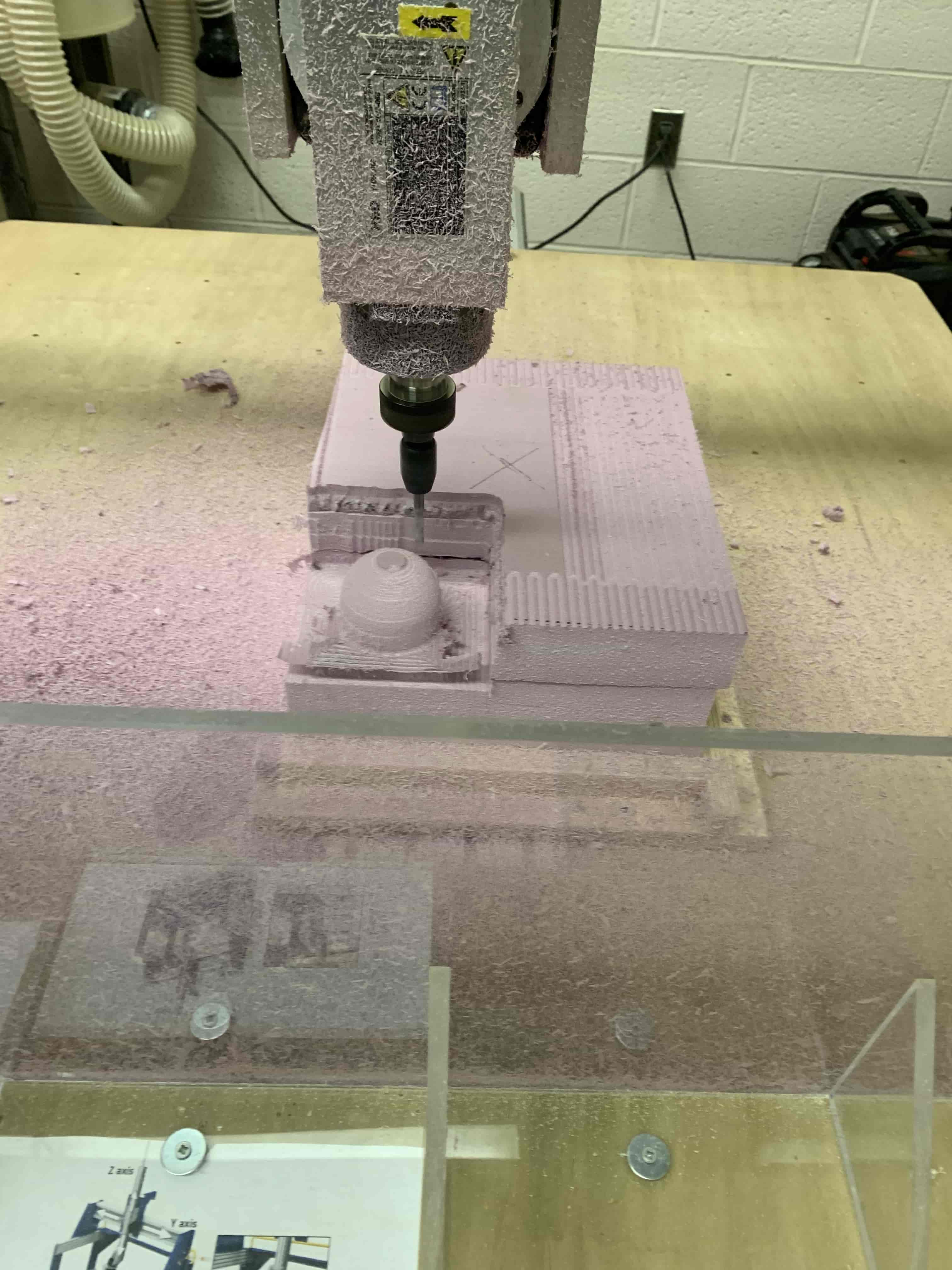

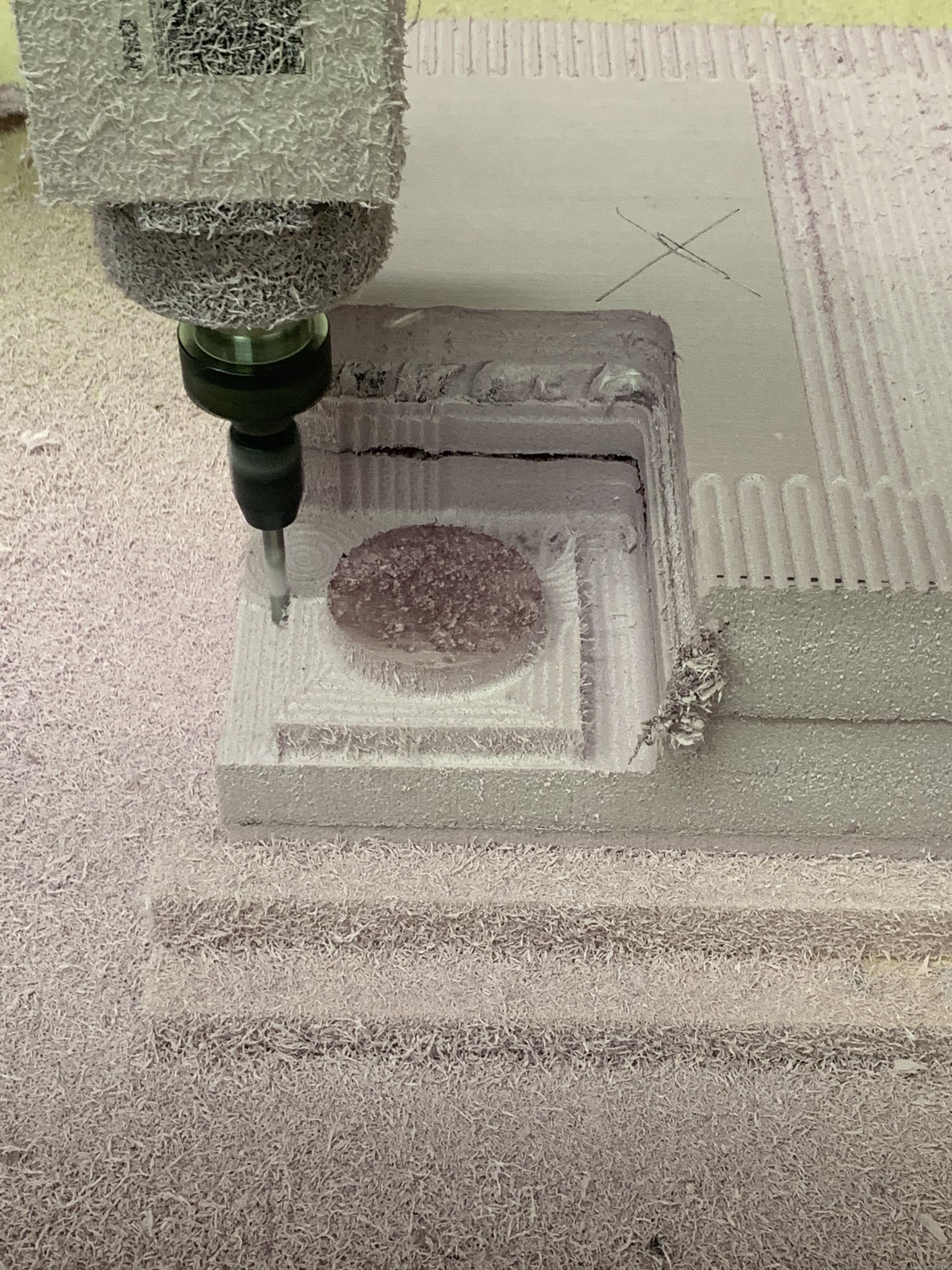

Like I said earlier we found that the machine worked very well as a 3-axis mill. So whenever we had a tool path that was only using that functionality we didn't run into problems. However without fail whenever we tried to use the other two axes it failed. Initially we tried to do a 2+3 cut since we saw how well the 3 axis cut. However we found that for whatever reason the mill would not follow anything close to the tool path that the simulation in fusion showed. Naturally this seemes like it could be post processing issue however even going through the settings to read all of them, and trying the ones that even might do something, nothing actually changed. What we figured the issue was was that in order to do a 3+2 cut the axis directions in Fusion need to be changed, and we figured that must be causing some sort of confusion on the side of the machine. Since our theory had to do with us changing the axis we thought that with a 5-axis cut, where the changing axis is done automatically by Fusion, then the problem would probably resolve it's self. Unfortunately that was not the case at all. The surprising thing that we found was that for whatever reason it appeared that tool path got turned to be off by several inches in the Z and Y and also turned at 45 degrees for some reason. At this point after trying to cut our shape in two different ways, and fiddling with every setting we could think of we finnally had to email the person with the experience on campus, and unfortunately up to this class we were unable to meet up to work on this. That is why as of now we unforunately don't have anything to show for all of our work.

So Update

Hey so a quick update.. the machine got taken apart like 3 days once it was done, and was not put together by the time I went home. Sooooo we were never able to actually get a 5-axis or 3+2 axis milling design and we just have a standard 3 axis cut. Below I'll have some photos of cutting out my design. You'll see at one point it looks like the piece breaks off. That is because it does, the holder hits the pillar and it breaks off. This is actually a perfect example where 5-axis milling would be awesome alas it didn't happen. I'll also have a brief video of the piece shooting off into the distance like I wrote about previously.