Design a machine that includes mechanism+actuation+automation+application.

Build the mechanical parts and operate it manually.

Document the group project and your individual contribution.

Actuate and automate your machine.

Document the group project and your individual contribution.

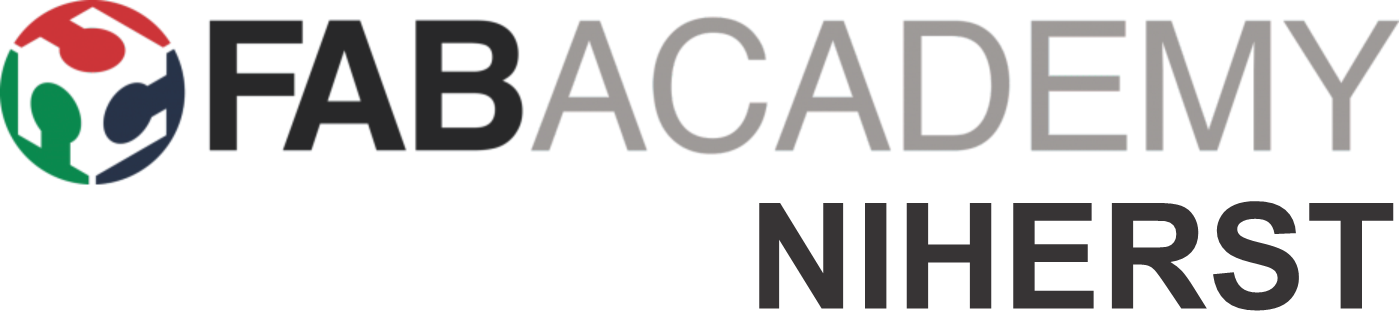

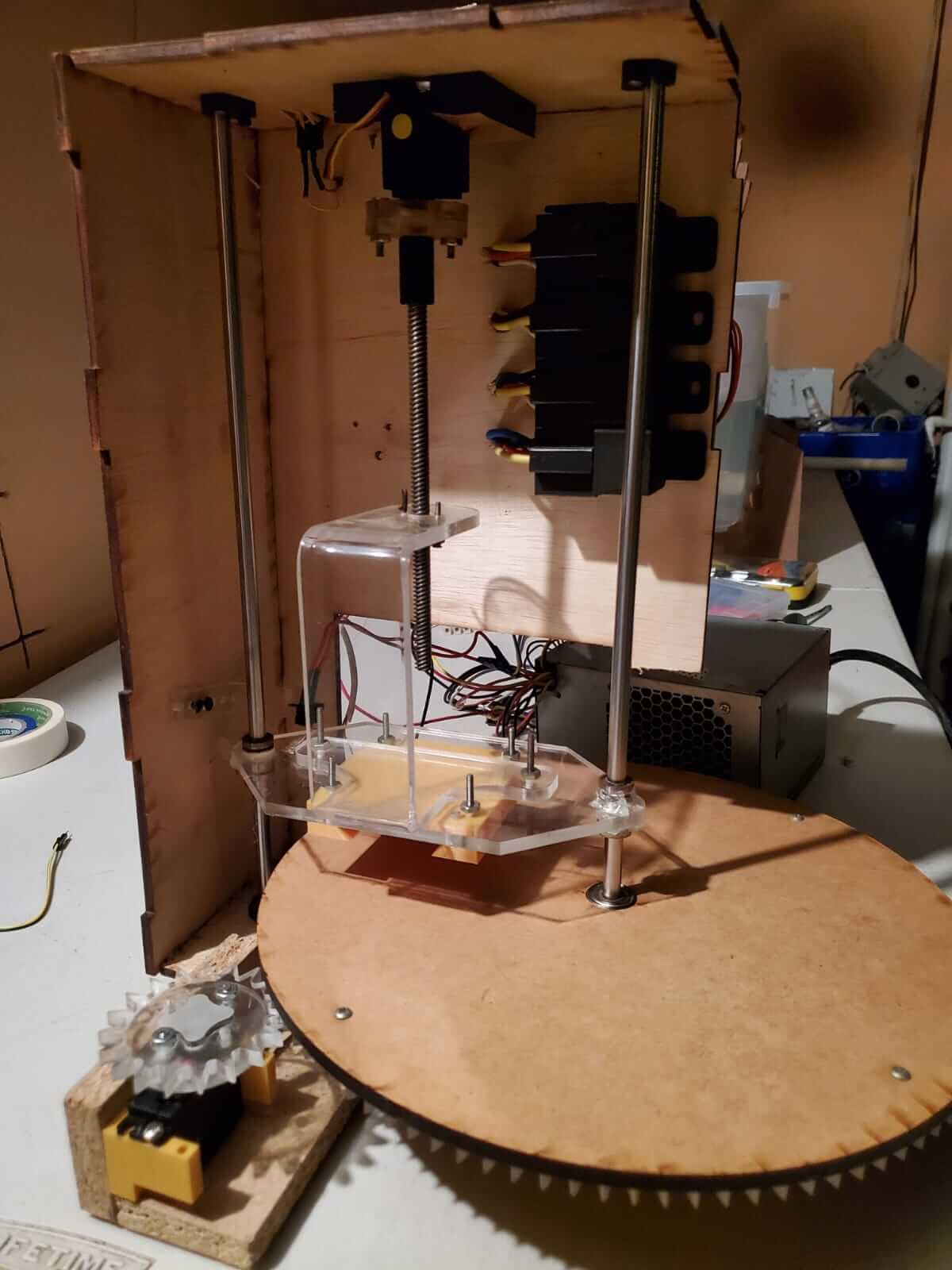

For this assignment, our group designed and built an automated cookie cutter. The machine uses an actuator that pushes a cookie cutter unto a circular conveyer which the cookie dough is placed. The cookie dough is cut to shape, the actuator retracts and the conveyer turns with another piece of cookie dough. The cookie cutter shapes can be switched with different mold plates.

This project entails both digital and manual fabrication processes. These processes include:

The housing of the machine was made laser cutting 1/8" ply wood. Details of design can be found on Christopher Proute's page.

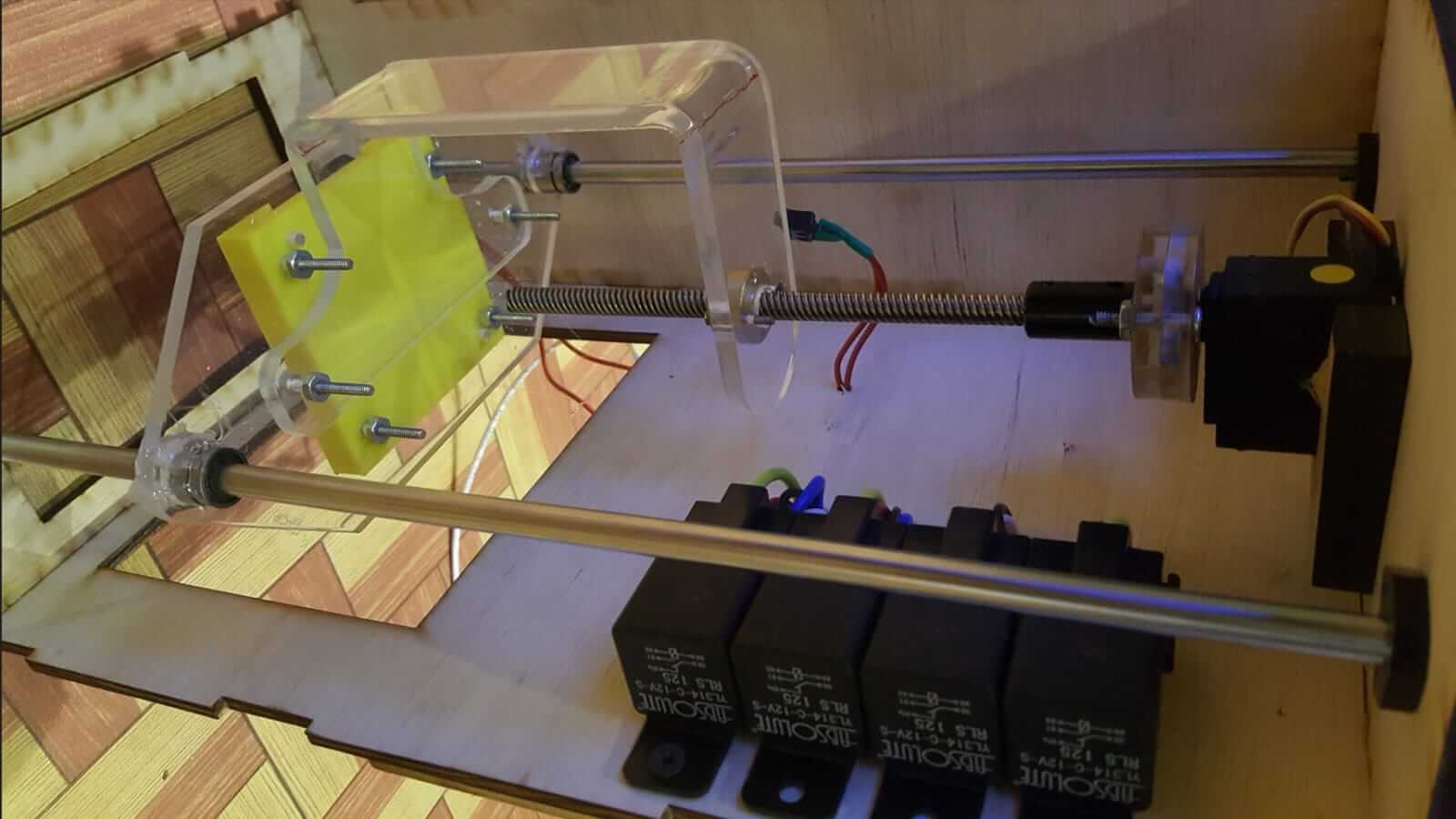

The motor holder and the cookie cutter star mold were 3D printed. Details of design can be found on Nervene Bhagwandass' page.

The cookie cutter fish shaped mold was 3D printed. Details of design and print can be found on Ravi Baldeo's page.

The cookie cutter Hex and Heart shaped mold was 3D printed. Details of design can be found on James Khan's page.

The conveyer was designed and cut using the laser cutter. The conveyer base was made with 1/4" MDF and the gears were made with 1/4" Acrylic. A small bearing was placed in the center to make rotation smooth. Details of design can be found on Marvin Holloway's page.

The cookie cutter press was made with 1/4" acrylic using the laser cutter. Its actuator was was made using a threaded bar connected to a motor and 2 linear shafts to guide the press. Details of design can be found on Terrence Carew's page.

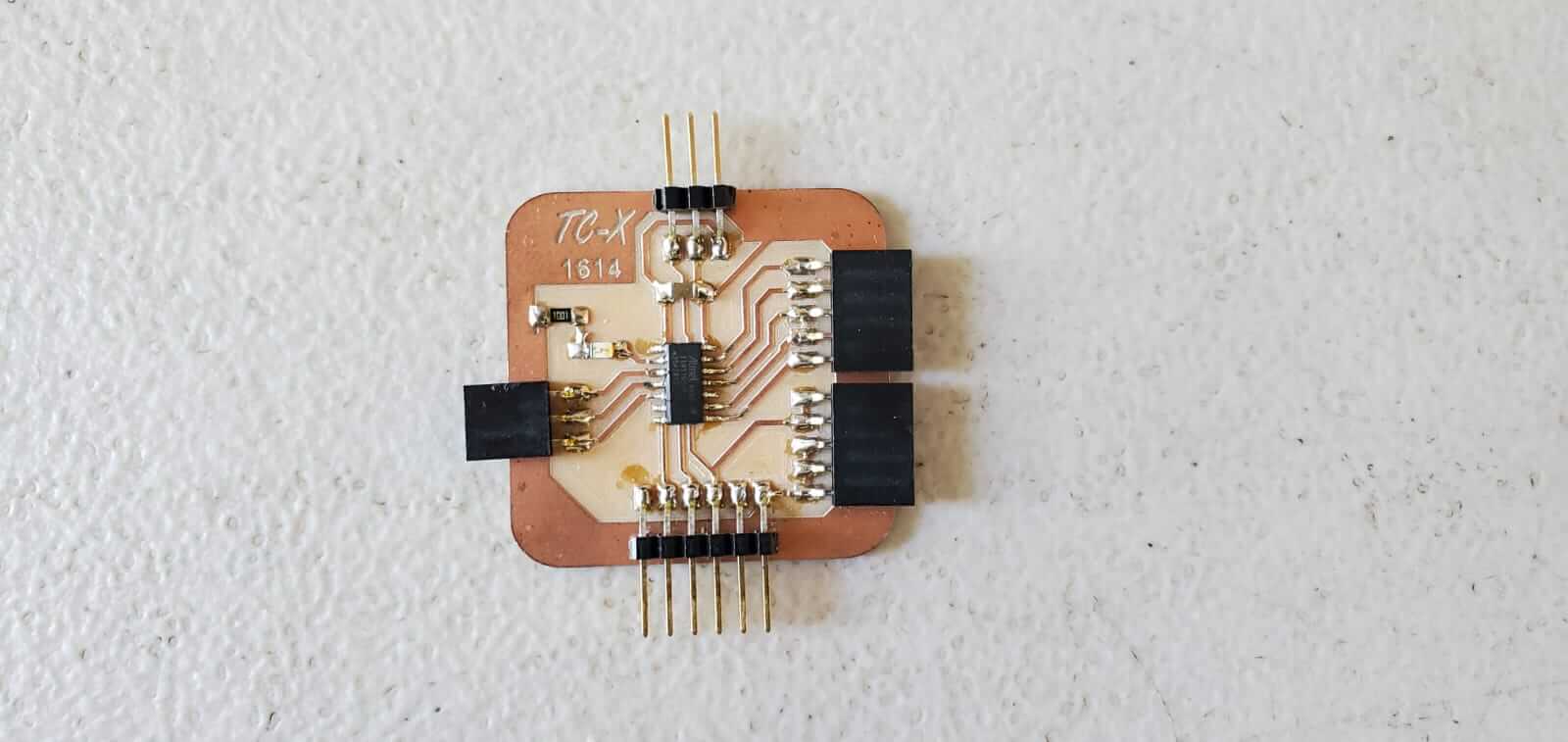

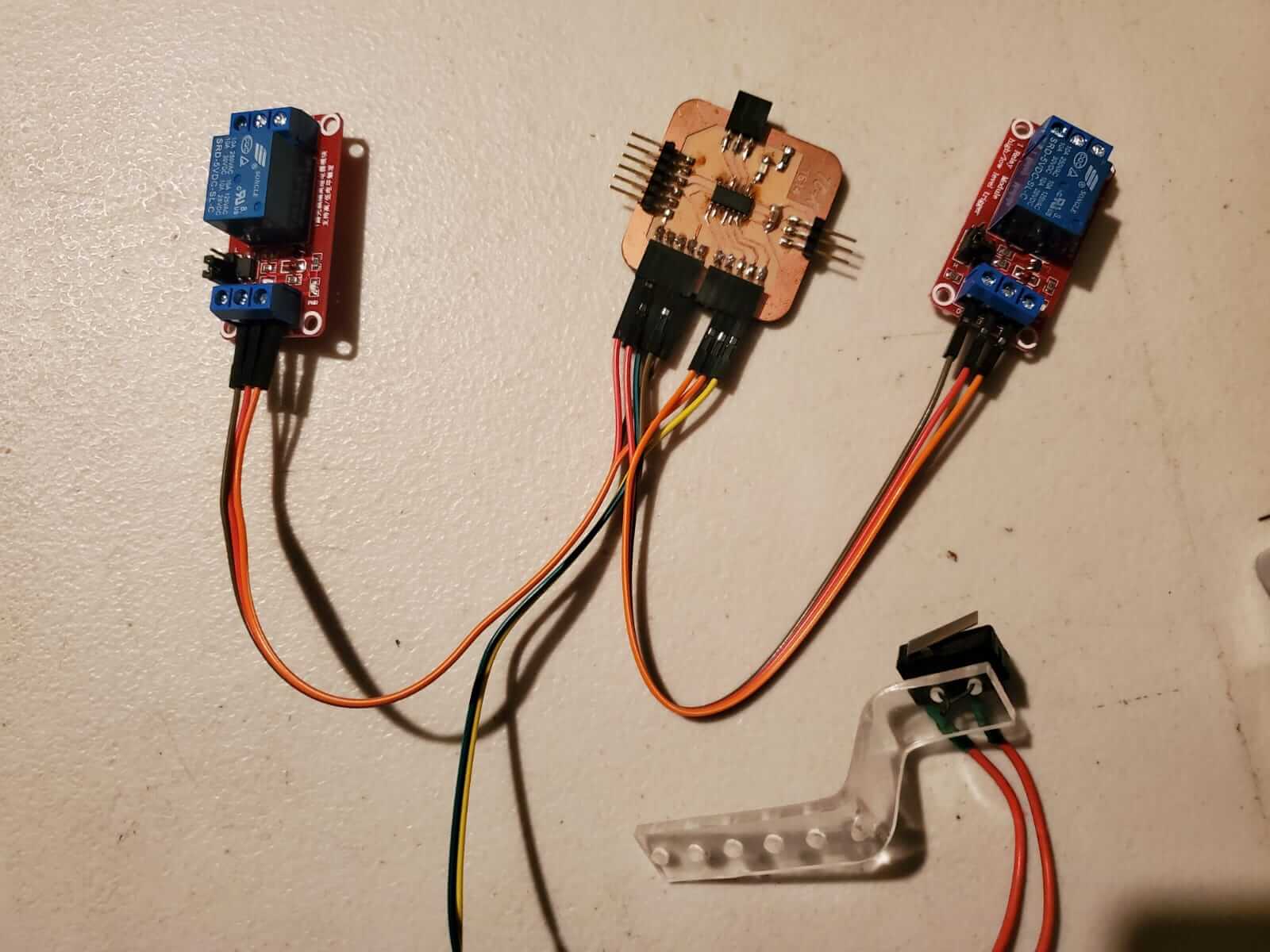

Electronics was controlled using an ATTiny 1614 microcontroller board. The board was programmed to controller 2 5V relays and read a limit switch. One 5V relay powered the conveyer motor and the other controlled the direction of the press actuator motor. Details of design can be found on Terrence Carew's page.

The Automated Cookie Cutter.

The cookie cutting molds needed to be deeper for a better cut and also our "cookie dough making skills" aren't so good.