Final Project

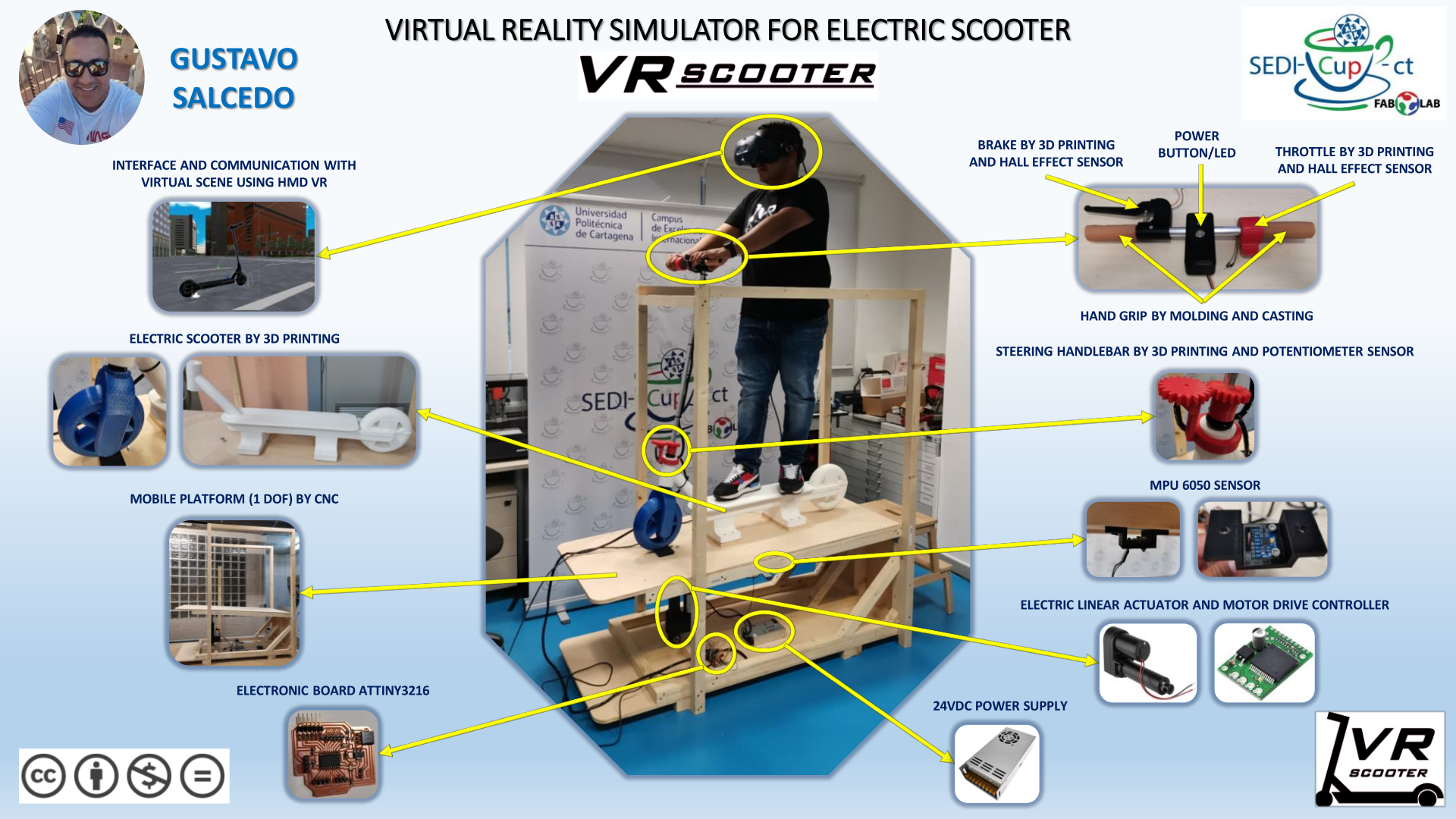

My idea for the final project is to build a Virtual Reality Simulator for Electric Scooter. "VR SCOOTER"

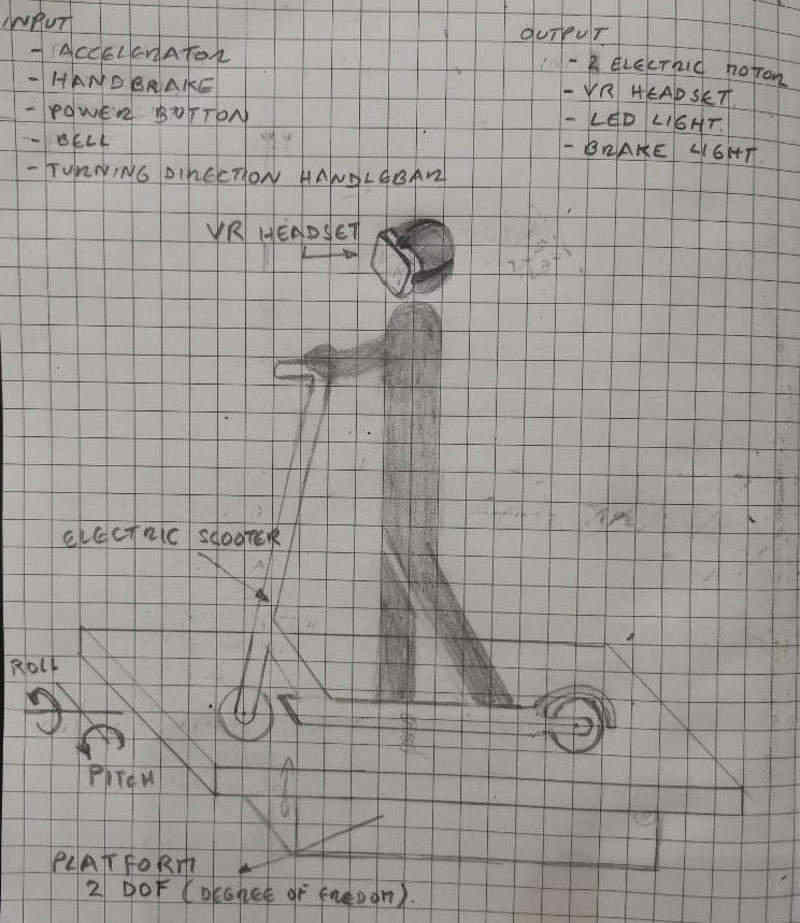

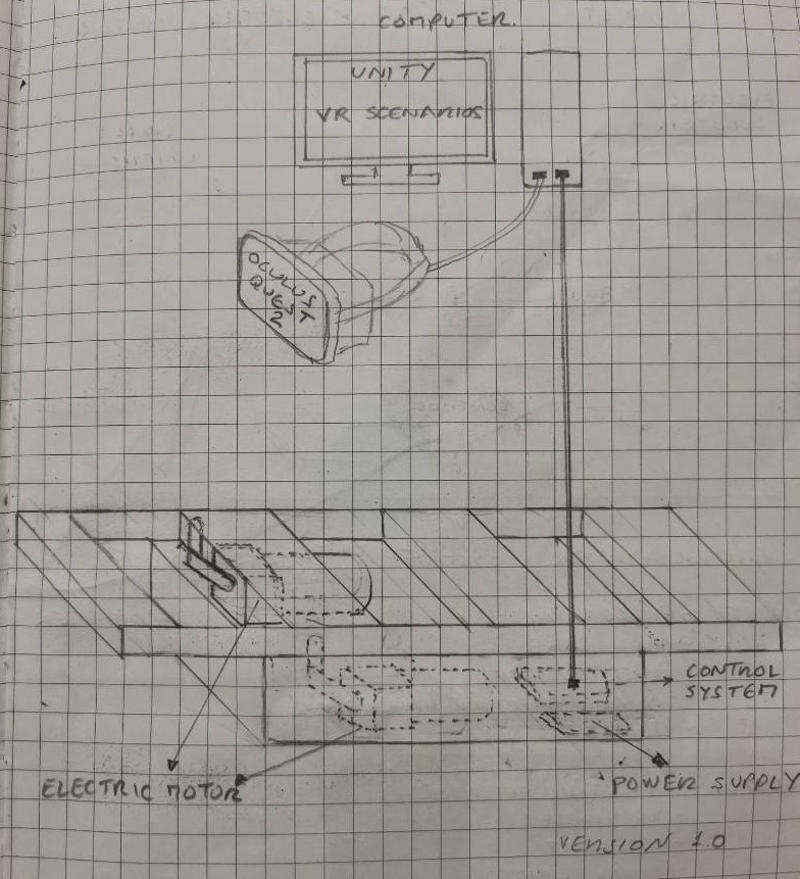

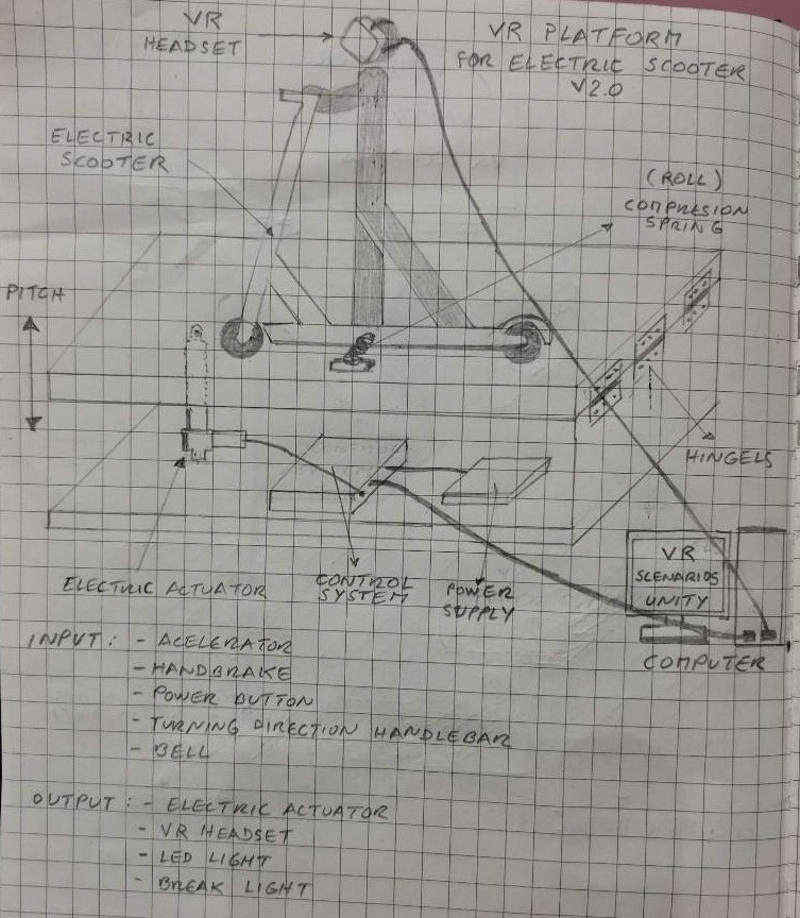

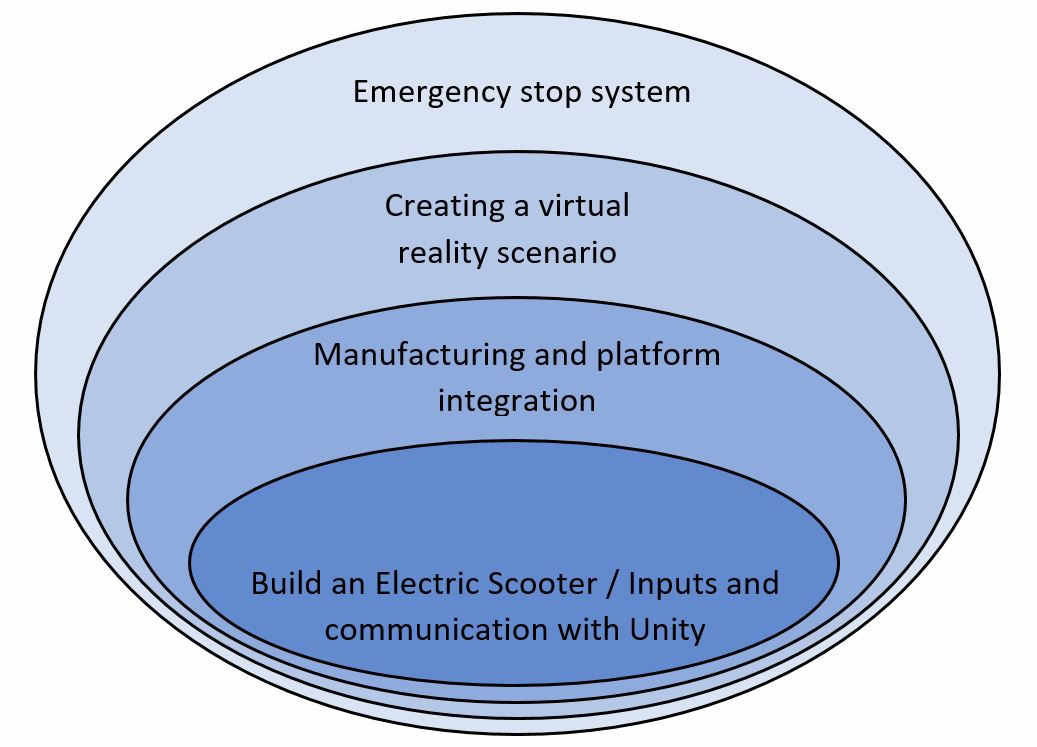

I am going to design and build an electric scooter on a simulation platform that will integrate the movements made by the user in a virtual scenario created in Unity software, and it can also be viewed using Oculus Quest2 RV glasses. This project is composed in 3 parts:

- Desing and construction of an electric scooter (not funcional). Replicate the structure and inputs.

- Design and development of a 1 degree of freedom platform.

- Creation scenario VR in Unity software and communicate with platform.

Replicate the structure of an electric scooter on the market (xiaomi pro 2), the functionality of the scooter is to integrate the following inputs (accelerator, handbrake, power button, bell and direction)

VR Scooter 1.0: Initially I have thought of a sketch of a 2 degree of freedom (pitch / roll) platform driven by two electric motors. In this new version the platform will only have 1 degree of freedom of movement, I will use an electric actuator for the movement (pitch), I have ruled out the movement (roll) since the user could fall from the platform and suffer an injury, in addition, the stage Virtual will simulate the tour of a city where you would only find slopes up and down.

The platform will be composed of:

- a power supply (230vac - 24vdc)

- a motion control system

- an electric actuator

- a fastening system for the electric scooter (a shock absorber is included to simulate a roll due to the inertial movement due to the movement of the user's body)

- the support structure

Creation of a virtual reality and communication scenario A computer will be used to create the scenario in the UNITY software and to communicate through the serial port with the platform. The visualization of the scene will be done through virtual reality HMD (Vive Cosmos).

SPIRAL MODEL DIAGRAM

VR SCOOTER

The user’s brake, throttle and steering handlebar actions are transferred to the virtual scene and their road slope are replicated on the platform.

SLIDE

VIDEO PRESENTATION

On this link you can see in more detail the development of the project.

In the Assignment: Applications and implications you can see the proposal for the final masterpiece of the project.

The total price in material to manufacture the fountain is: 953.405 €.

Table of materials

In the Assignment: Week 17 Invention, intellectual property and income you can see the type of license chosen.

You are free to:

- - Share — copy and redistribute the material in any medium or format.

The licensor cannot revoke these freedoms as long as you follow the license terms. Under the following terms:

- - Attribution: You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

- - NonCommercial: You may not use the material for commercial purposes.

- - NoDerivatives: If you remix, transform, or build upon the material, you may not distribute the modified material.

4. Conclusions of the Final Project

what went wellk?

The designs in Fusion360 have allowed me to capture the ideas of my final project, every week I was improving the designs including the modifications.

I have taken advantage of most of the weekly assignments to develop the stages of my final Project, this has allowed that at the end of fabacademy I had most of the components and structures of the scooter and the mobile platform.

In milling the wooden platform with the Barcenas CNC Milling Machine I have not had any problems and the software is easy to use.

I have also had no problems with 3D printing the small parts for the throttle, brake, handlebar, and steering mounts. Ender3pro printers are reliable and have few misprints.

I did the programming of the sensors and the entire control system first with the Arduino Uno boards, for each of them I created a program in the Arduino IDE to check that it worked correctly separately, then when I made my ATiny3216 board, I added one to one of each program to integrate it into the final programming.

I have used Unity in previous projects of virtual environments with simulators, so it was easy to create the interface of my Final Project, I have imported an asset from a virtual city and the electric scooter model imported from fusion360 to Unity.

what would you do different next time

I had many problems with large format 3D printing due to the cooling system, so my recommendation is to print the scooter in several sections and avoid putting so much support material that it is difficult to remove later as it is a more mechanically resistant PLA and then assemble them with resistant glue all parts.

what could be improved

This is my first version of the VR Scooter, I want to make improvements to the design of the scooter to make it stronger and even lighter.

I will modify my electronic board to include more 5V and Gnd power pins to avoid the external connections and splices that I currently have. In addition I would like to include more sensors to obtain more external data. I am going to design and 3D print a box to put the electronic board and the motor control board.

The communication between the electronic board and Unity is fluid when I use it without the VR glasses (HMD), but when doing it with the glasses I can see a small delay in the communication of the signals and a lag, so I have to optimize the programming script in Unity and also the program in Arduino IDE. I also want to learn how to use Unreal to make virtual environments more realistic and improve the graphics of the virtual scene.

I am going to paint the deck to give it a more professional presentation and enhance its appearance.

Acknowledgements

I want to thank Lola Ojados and Álvaro Macián, my local Sedicupct instructors for guiding me during all these weeks in this learning stage. Also to Nuria Rubles, Pablo Nuñez and Adrian Torres for the guidance in the regional reviews.

Thanks to my local evaluator "Lola Ojados y Alvaro Macian" and my global evaluator "Henk Buursen" for reviewing all individual and group assignments and the final project. Your corrections and recommendations have improved in content and form all the work I have done.

Thanks to Hector Flores with whom I have developed all the group assignments and we have supported each other every week in the individual assignments.

All this would not be possible without the support of my family, especially my Yenny and my princesses Alejandra and Daniela, who have been encouraging me every moment.

Finally, thank Neil Gershenfeld for creating this Fablab movement and giving me the opportunity to be another member of the fabacademy. Those months of intense learning have changed my way of seeing the future and have given me a new vision on how to use these technologies so that anyone can take advantage of them.

It has been an unforgettable experience where I have pushed my feelings and knowledge to the limit. I cannot say that the fabacademy is easy, because in reality it has been the biggest challenge I have had in my life, it is satisfying to look back and remember all the experiences, the difficult moments and the happy moments.