1. Principles and practices

Intro

It really was, once again, a very inspiring opening lecture. I have to confess that I have already watch a handful of times that same lecture, and I keep enyoying every slide in it.

I really wonder how is it going to be, once we get closer to the ribosome way of working, using bits of matter that will stay below our perception threshold that autoassemble.

I also wonder how is the Fab City project going on. I think that, if played well, it can be a real game changer in our inmediate future.

This week I worked on defining my final project idea and started to getting used to the documentation process.

Tasks for the week

- Read the Fab Charter

- Sketch final project idea

- Describe what will it do and who will use it

The Fab Charter

One of the reasons I like so much the Fab Lab echosystem is the Fab Charter. Besides what it states, I really like the analogy Neil makes with libraries, being Fab Labs the equivalent to them: thanks to this movement, millions of people will go from illiterate to literate in technologhy, as it happened with books in the state thanks to Andrew Carnegie in the late ninetinth century.

I am really looking forward to learn and help to spread the word, and I am really sure that the future URJC Library Fab Lab will go in that direction.

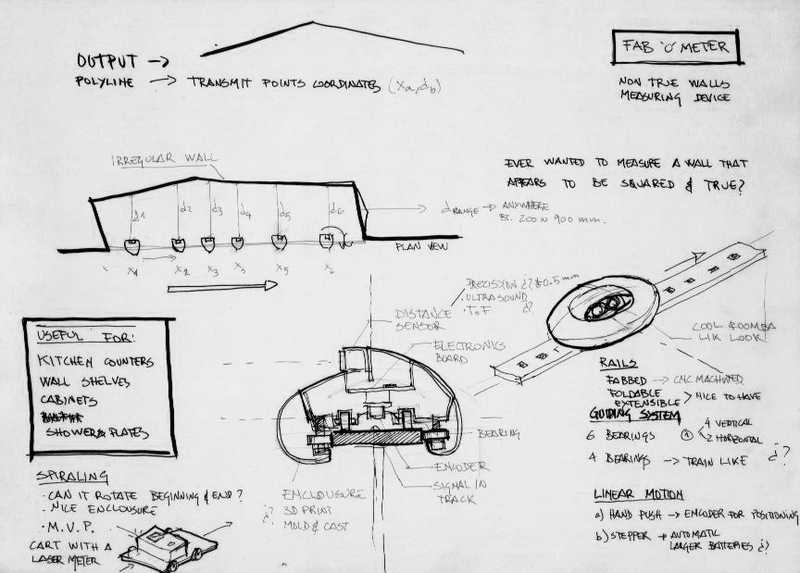

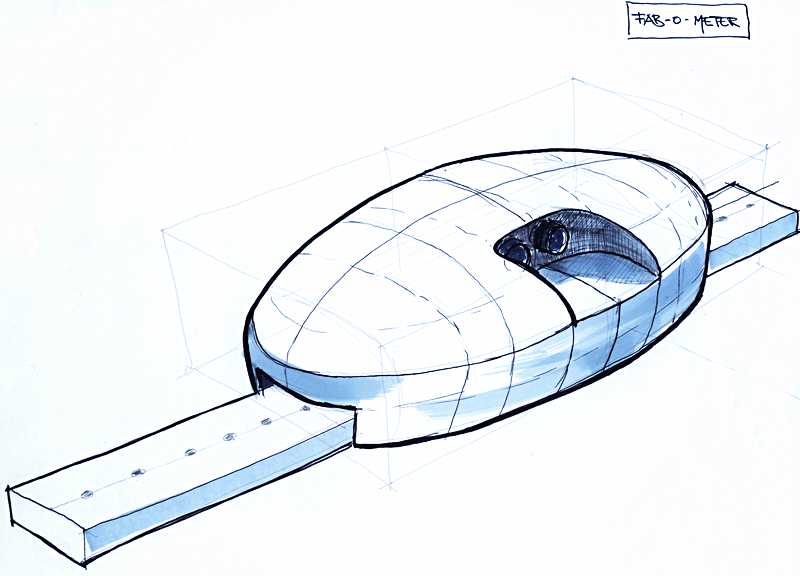

Introducing the Fab-o-Meter

Have you ever tried to measure accuratly one of those out of square walls in order to fit something afterwards? It can be tedious and frustrating, and the results usually suboptimal. I would like to build a device that can measure distances from a straight rail, so we can have a polyline as a result, and create a toolpath that wil cut a board that matches whatever woobliness the wall had.

The Fab-o-Meter will be used by anybody that needs to fit accuratly something to an irregular wall. It will describe how the real wall woobles compared to an straight line. The output will be a polyline.

Design goals

- Build a device accurate enough to meassure distances ranging from 200 to 900 mm, with a margin of error of 1 mm.

- The device should be mounted on a guide system, that enables linear motion, with just one degree of freedom.

- For every measued point, the device must also show its position within the guiding rail.

- The ouput should be an array of 2d points, so a flat polilyne can be drawn from tha data.

- Ease of use.

How am I going to achieve this?

I do not know yet, but I will find out.

Research

So far I have been diving into some sites to see what others have done before hand. I know there are quite a few really high end commercially, that can map and output a huge cloud of 3D points, defining completly huge buildings, such as Faro. On the lower side of the market, but still at around 2000€, there's the Leica approach. Cabinet Vision is a big player in the cabinet bussiness, also with quite a high price tag.

- Leica Disto s-910

- Leica - Cabinet Vision

- Ivan Sánchez - Modular multimeter

- Manu Mohan - Mini Total Station

- Jens Dyvik - Fabricatable Machines

- Adrian Torres - Fab Train

Linear motion

- Sliding by hand, with some sort of encoder to get position.

- Stepper motor and rack & pininon, such as fabricatable machines axis

- Would be a nice to have that the tracks could be easily extended as needed

- Must assure repeteability of the meassurments performed. Absolute tolerance aprox. 1 mm.

Distance sensor

- Ultrasonic.

- Time of flight laser.

- Requirements are precission in the order of 1 mm over up to 1,000 mm of measured distance.

- Calibration ? Gold rule?

Microprocessor

Needs to be able to:

- Recieve either from step or encoder count the triggering signal.

- Send signal to measurign subsistem to trigger an action to measure distance.

- Collect data and ensemble an array of 2d points to send to the communication module.

Commnunication

Send data to a device that is then able to plot the final polyline:

- Bluetooth

- Wi-fi

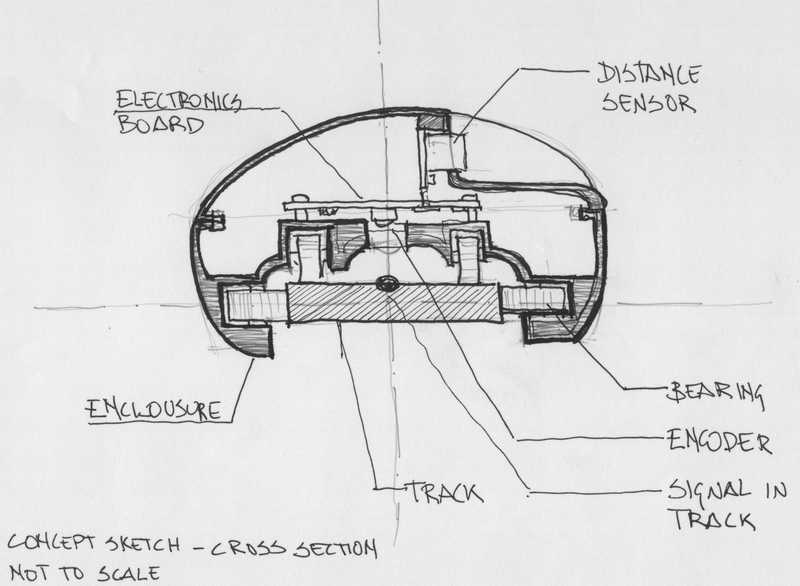

Enclousure

Options to explore, running away from the finger joint lasercut mdf box:

- Plastic, molding and casting.

- 3d printing.

- Machined, carved out from a block of wood.

Interface

- Retrieve data from device.

- Manipulate data.

- Send to machining.

Spiral development - modularity

- Make something that measures with target precission.

- Make something that can set trigger at known intervals.

- Make something that moves with precisiong along a line.

- Integrate parts.

- Make something that stores data from input devices.

Do not forget to have fun all along the journey!

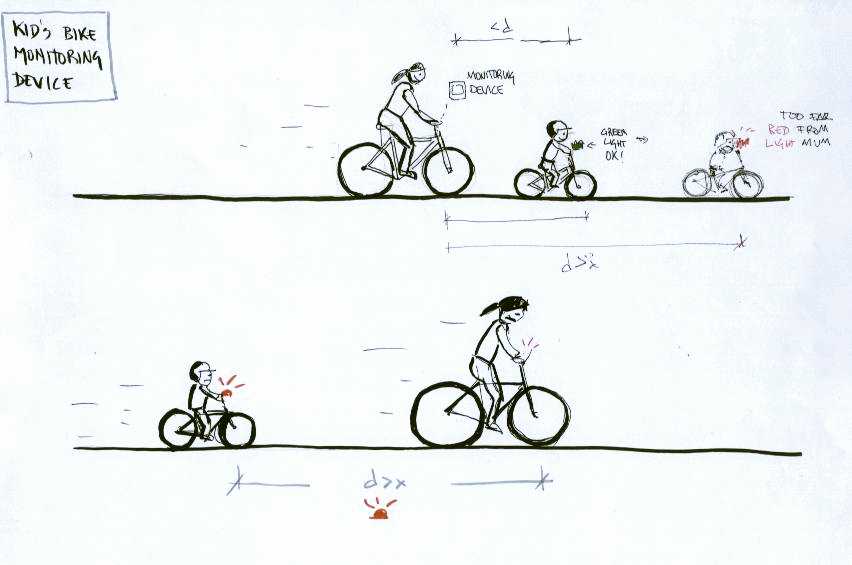

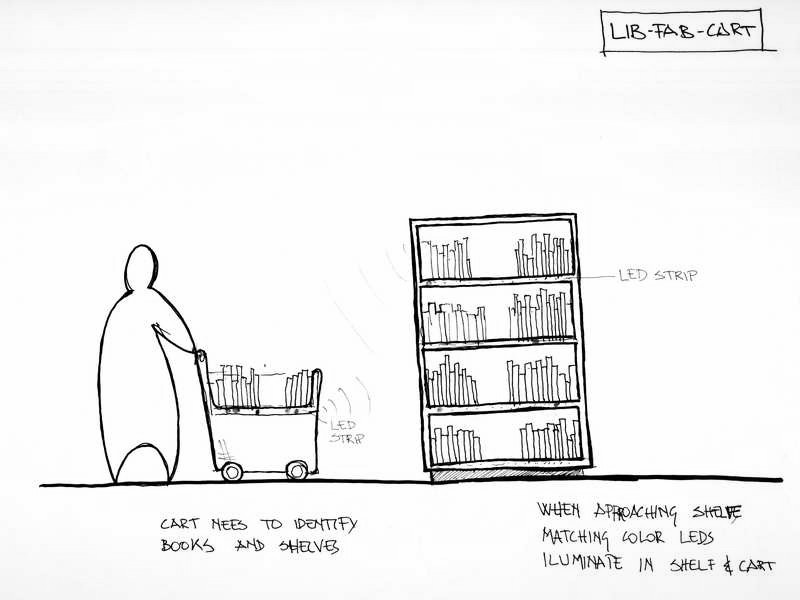

Alternative ideas