Week 3. Computer Controlled Cutting

week 3 group assignment is to characterize our lasercutter's focus, power, speed, rate, kerf, joint clearance and types

Overview

So this week we are gonna design and make 2D objects by using cutting machines.Mainly focused on Vinal cutting and Laser cutting process. So with the the help of the instructors we Learned about the machines that we are gonna use this week.

Laser Cutting

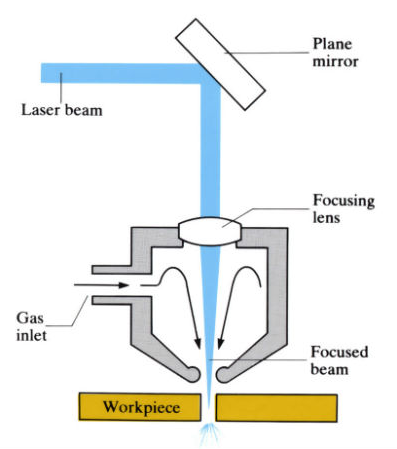

Laser cutting is a type of thermal cutting process which use a focused laser beam in the cutting area to melt the material and then a gas or Air used to eject the molten material for making it cut.

The above figure shows a basic components of the laser cutting machine's nozzle. The machine is based on a 2 axis CNC it will have two motors to drive each access according to the given x,y coordinates. Laser machines are widely using today we can see them near by Acrylic or wood working shops. They available in different shapes and different power that totally depends the material being used to the cutting process.

Trotec Speedy100

In Our FAB LAB we have two different types of Laser cutting machines.One is used for the FAB academy it can Cut Acrylic,wood,cardboard...etc. The other one is Fiber laser cutting machine part of the Super Fab Lab It can engrave circuits to make PCB. Both are manufactures by same company But,little more power full than the other one