Exercise 10 - Applications and Implications2/4/2020 to 15/4/2020

The assignment this week is to propose a final project masterpiece that integrates the range of units covered.

Since next week (9 April to 15 April 2020) is the break, I have 2 weeks to think about the final project.

Based on the assessment guidelines, this proposal must address the following questions:

- What will it do?

- Who and what has been done beforehand?

- What will you design?

- What materials and components will be used?

- Where will these come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

Aditionally, the project must:

- incorporate 2D and 3D design

- additive and subtractive fabrication processes

- electronics design and production

- microcontroller interfacing and programming

- system integration and packaging

We are also to make rather than buy the parts of the project whenever possible. Below is my final project proposal. Changes are expected as I acquire more knowledge over the next few weeks.

1. What will it do?

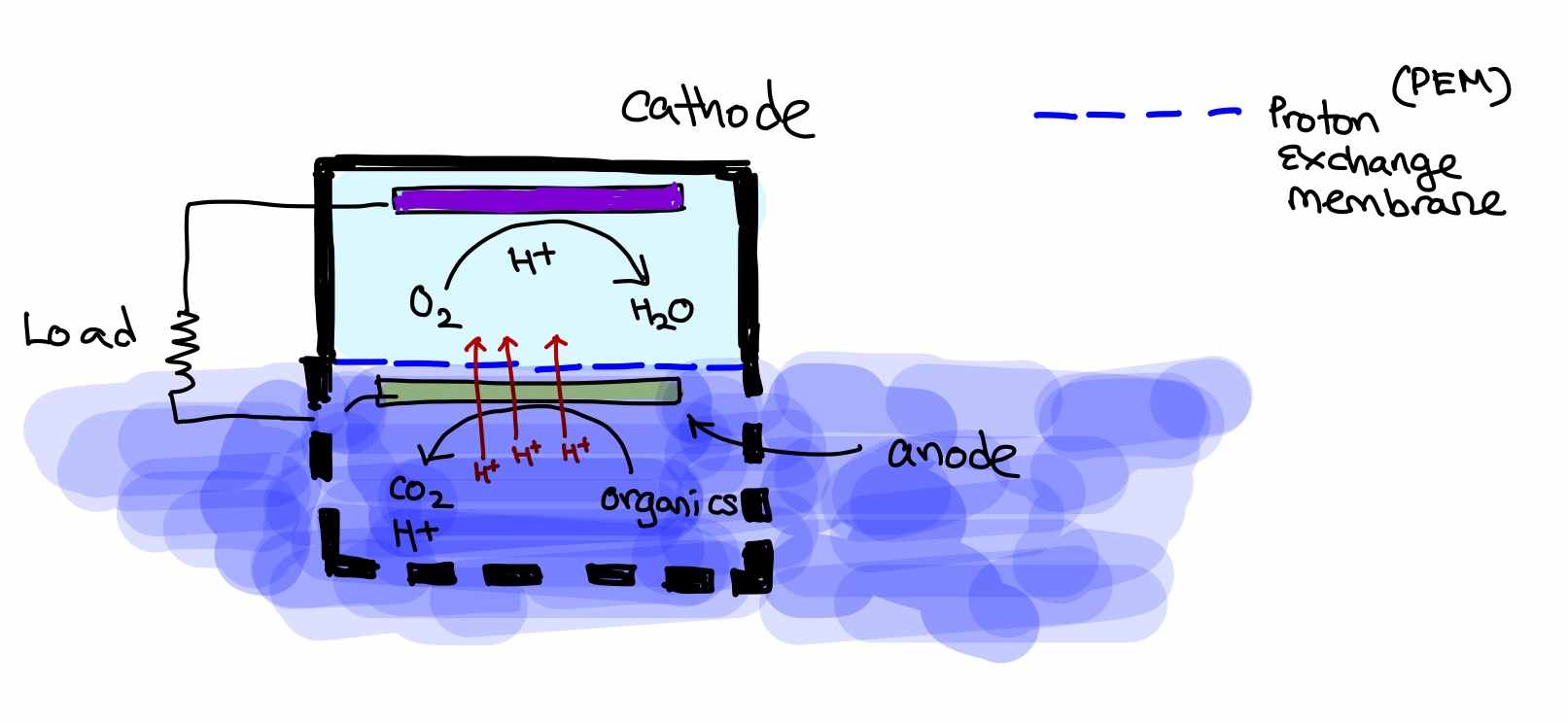

My final project is a Microbial Fuel Cell (MFC) Biosensor for wastewaterwhich will produce a voltage based on the amount of organic contaminants in the water. The heart of the biosensor is the MFC which comprises of 2 chambers separated by a proton exchange membrane (PEM). Microbes are immobilized into the anodic chamber. These microbes generate electrons and protons by oxidizing organic compounds. Electrons are captured by the anode and leaves for the cathode through an external circuit. Protons will migrate to the cathode through the PEM to keep charge balance.

Anode/Cathode Reactions in a Fuelcell

2. Who's done what beforehand?

Almost all MFC biosensors are fabricated in the research laboratories. There is no commercial product available when an internet search is made. The product that come close is the MudWatt.

Some relevant journal papers that I referred to are as follows:

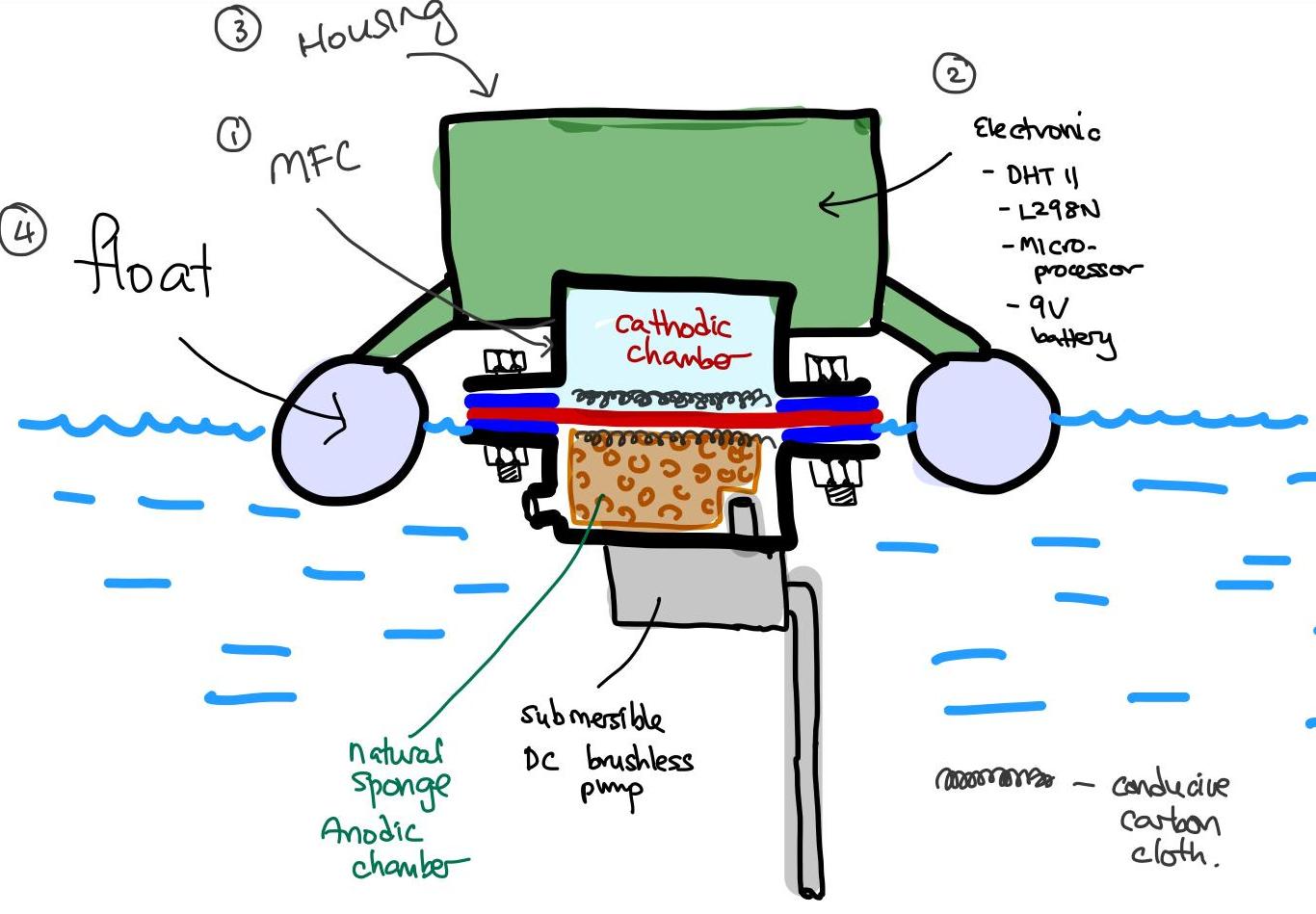

Project Implementation Plan

Below is a rough sketch of the biosensor that I plan to design and build. The description of the various parts are in the following sections.

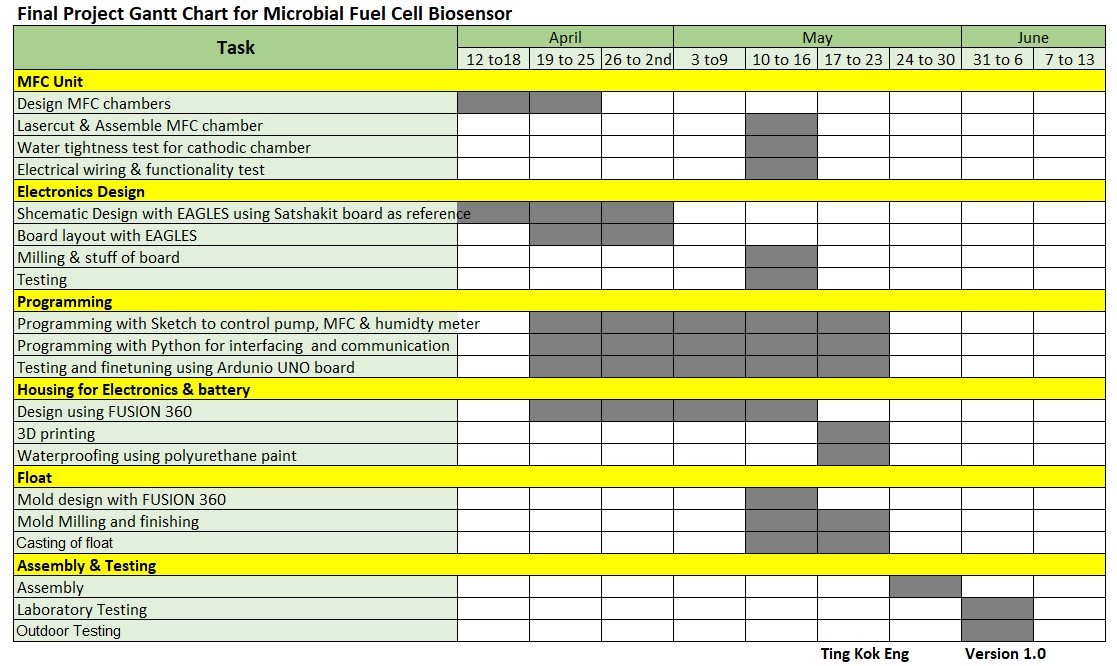

3. Project Gantt Chart

SP Fablab is currently closed due to COVID-19 till 4 May 2020, hence from now till 4 May 2020, tasks requiring machines such as the miller and 3D printer have to be scheduled later.The project gantt chart is a below. but basing on the current situation, significant changes may be expected

4. What will you design and make?

4A. I will design and fabricate the following:

A. Electronic board that can do the following:

- take in reading from the MFC and transmit the data to a nearby laptop/handphone via Bluetooth/wifi.

- power a small submersible pump to intermittently draw water into the anodic chamber

- monitor the humidity of the chamber to check for water seepage or moisture penetration.

B. 3-D printed housing to hold the electronics components together.

C. Acrylic Microbial Fuel Cell that comprises of:

- Acrylic anodic chamber to contain the immobilised microbes and carbon electrode.

- Acrylic cathodic chamber to hold the cathode electrolyte and electrode

- Acrylic proton exchange membrane holder.

Subtractive technology (laser cutting will be used).

D. Flotation device, so that the entire assembly can float on water.

4B. What materials and components will be used?

- how much will they cost?

- Where will come from?

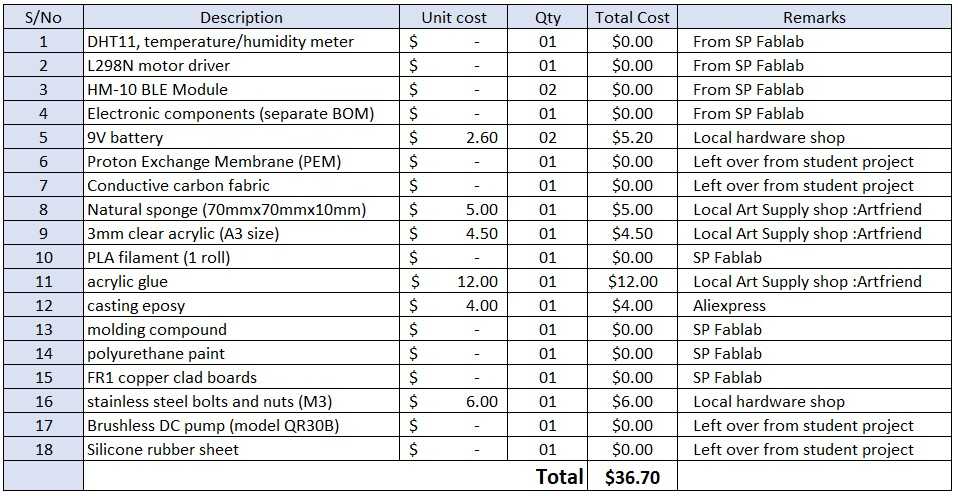

Most of the items are obtainable from SP Fablab, items not available are bought from local Art supply shop and hardware shops. Some of the items such as the proton exchange membrane, the DC brushless pump and silicone sheet are left over from student final year projects.

The bill of materials (BOM) is as below, a separate BOM will be prepared for the electronic components such as resistors and capacitors when the schematic design is completed.

4C. What processes will be used?

- 2D/3D Design using Autodesk Fusion 360 software

- PCB Designing using Autodesk EAGLE software

- PCB fabrication process

- Stuffing of components

- 3D printing (additive manufacturing process)

- Laser Cutting & engraving (subtractive manufacturing process)

- Molding and Casting

- Testing and troubleshooting of electronics

4D. What machines and equipment will be required?

- Stepcraft 420 milling machine for milling of PCB board

- Soldering station (includes soldering iron, hot air gun, magnifying glass with light, tweezer)

- Ultimaker II for 3-D Printing

- Laser Cutter

- Molding and casting equipment

- Oscilloscope and multimeter for testing

5. What questions need to be answered?

- How can I make the cathodic chamber water tight?

- How can I reduce moisture permeability of 3D printed parts?

- How do I fit the various electronic components inside the enclosure?

- How should the various electronic components be connected together?

- How to ensure that the biosensor remains upright in water?

- How will it be powered?

6. How will it be evaluated?

- Fabricated biosensor is water-tight and can produce a voltage.

- Fabricated electronic board can integrate with the humidity meter, water pump and microbial fuel cell biosensor, data can be transmitted via Bluetooth to laptop or handphone.

Next to Design Process