Computer-Controlled Cutting

Group assignment:

- characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance

Individual Assignment:

- Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf.

- cut something on the vinylcutter

Group assignment.

Individual assignment:

Design the construction kit.

In Computer-Controlled Cutting assignment, I need to make a parametric press-fit construction kit but first.

What is Parametric Modelling?

Parametric modelling is a method where you use parameters to set the dimensions of part or all of your model. you might say. The cool part is that after your model is complete, and given that everything is in order, you can go back and change the parameters. The model will then change accordingly while still keeping its integrity intact.

This method is however not suited for every project. If the model becomes too artsy or too complex you might quickly run into troubles. But if your model is simple and/or geometric, parametric modelling might be the way to go.

Is Fusion 360 Parametric?

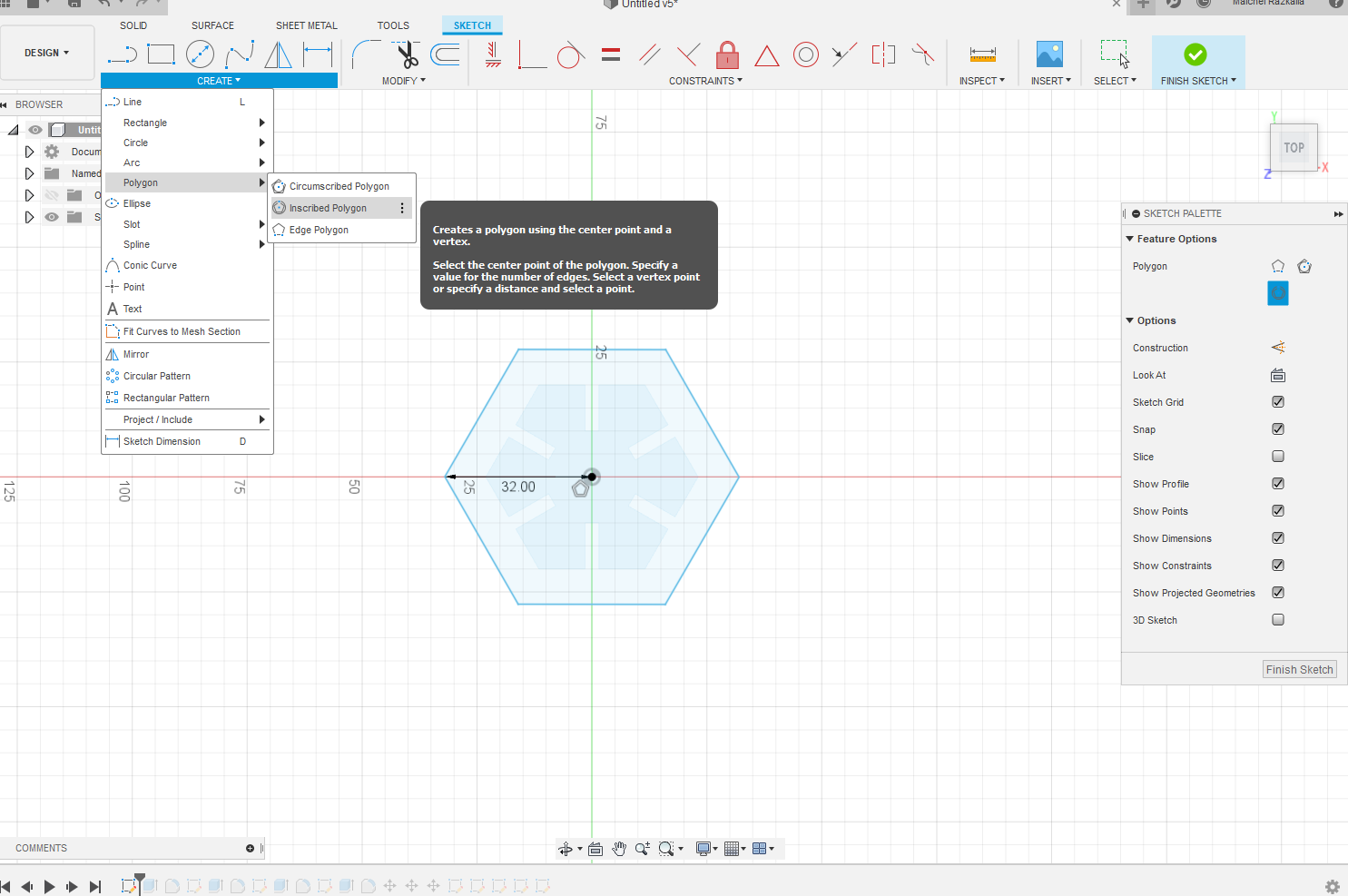

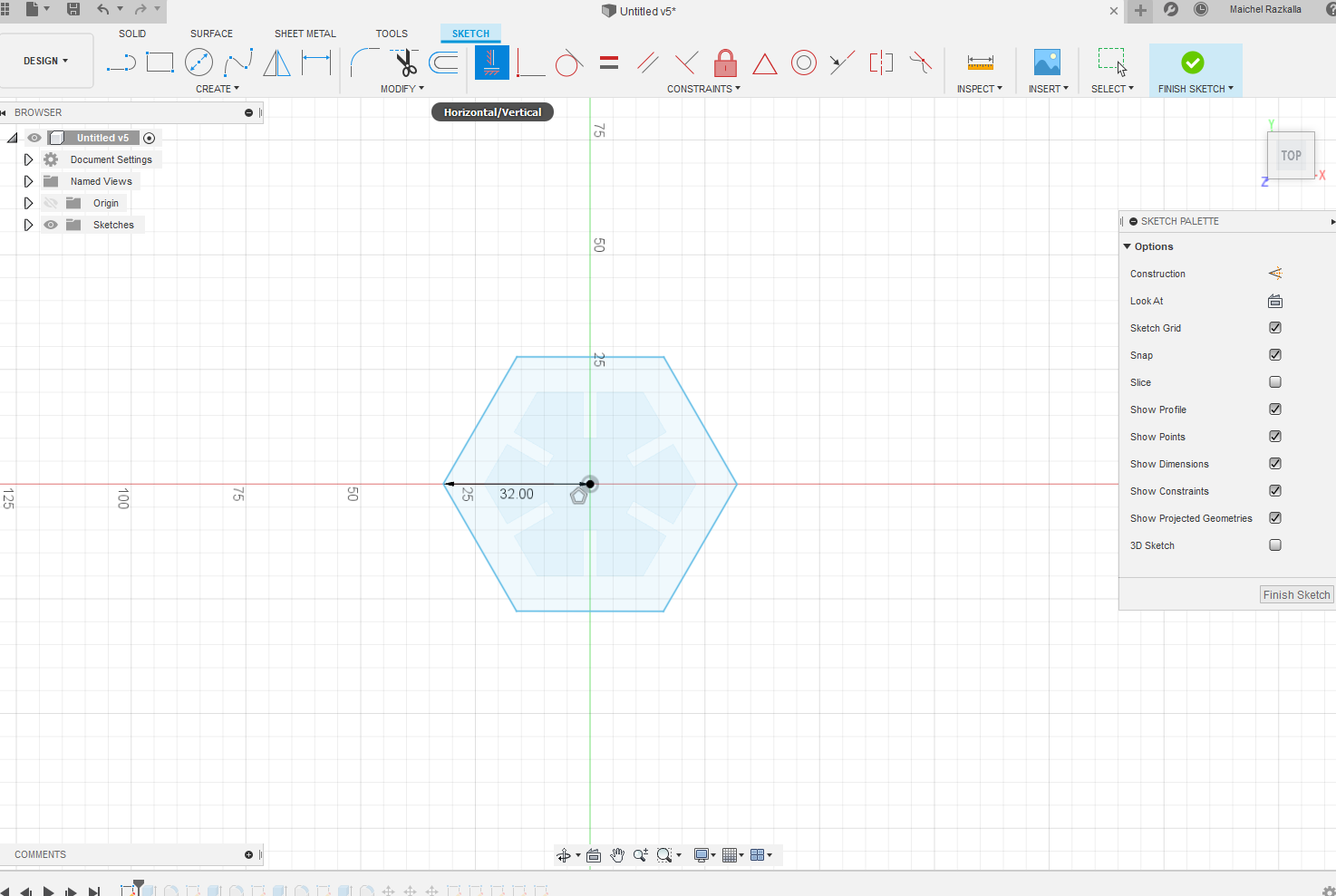

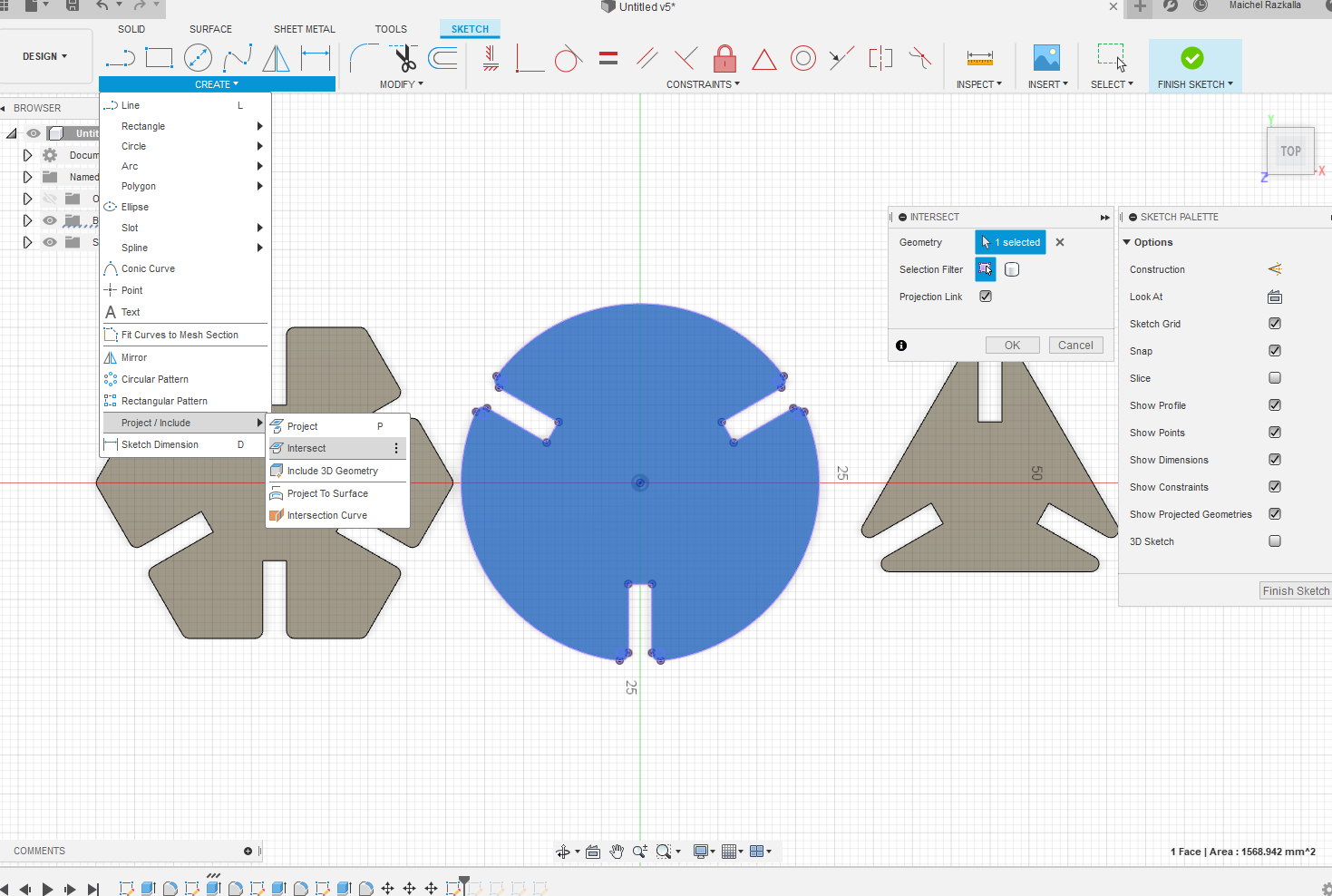

So what I did is to draw basic shapes like square, triangle, and polygon.

- I draw the polygon, then I drew a construction line in the middle of the polygon

- Next, I used the "Horizontal/Vertical" from constraints tools to align the polygon

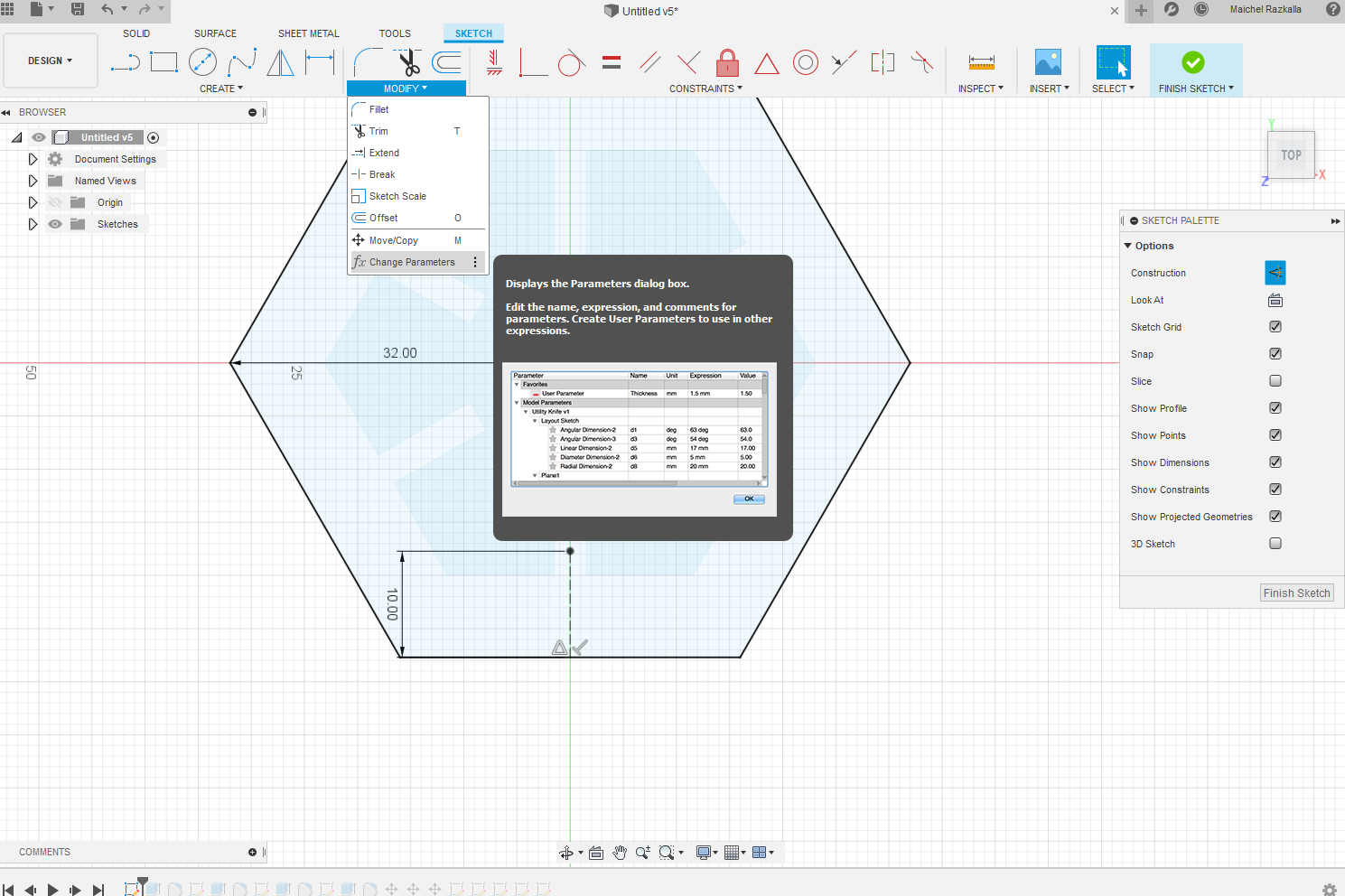

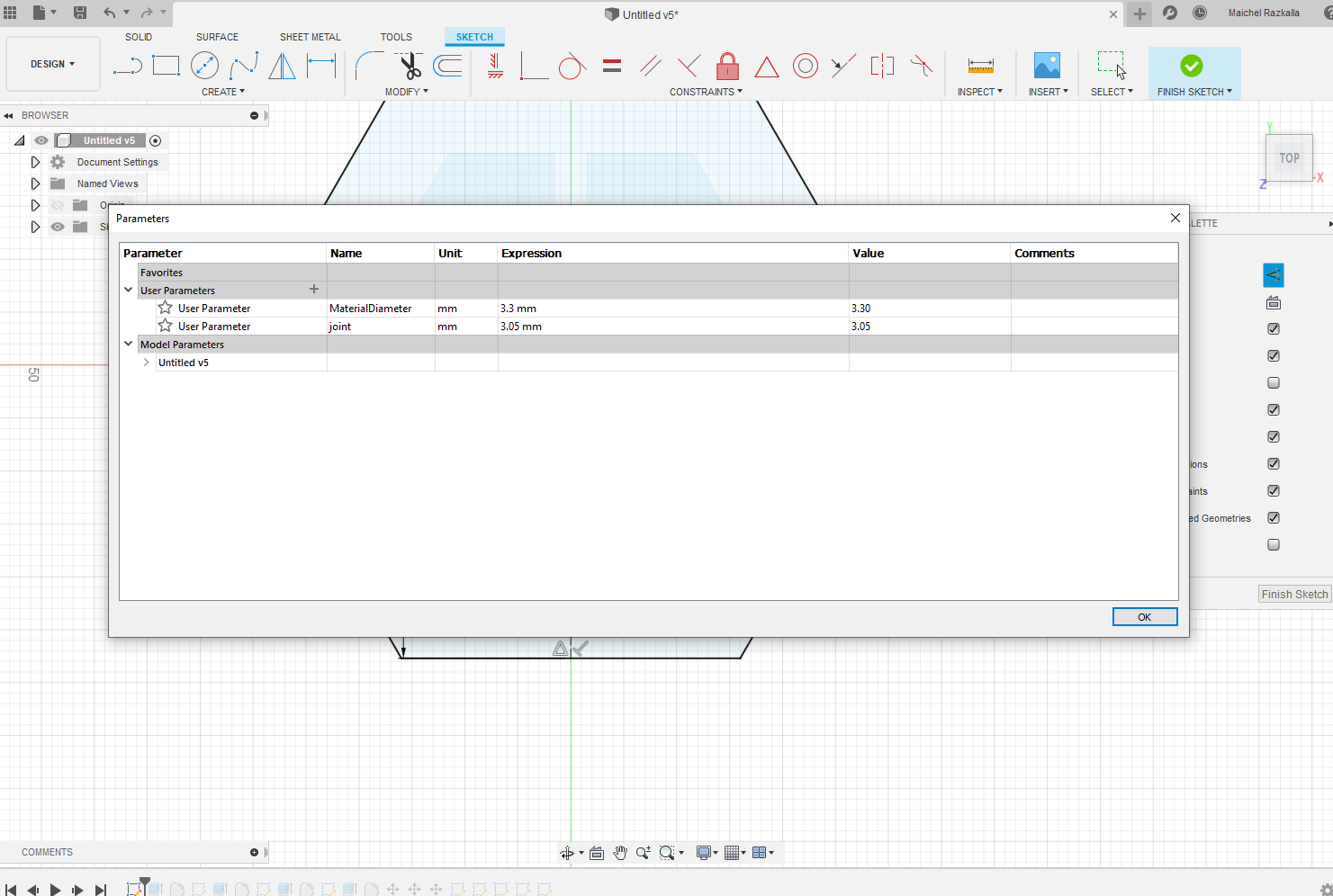

- Next to add a parameter for the joints and the material thickness

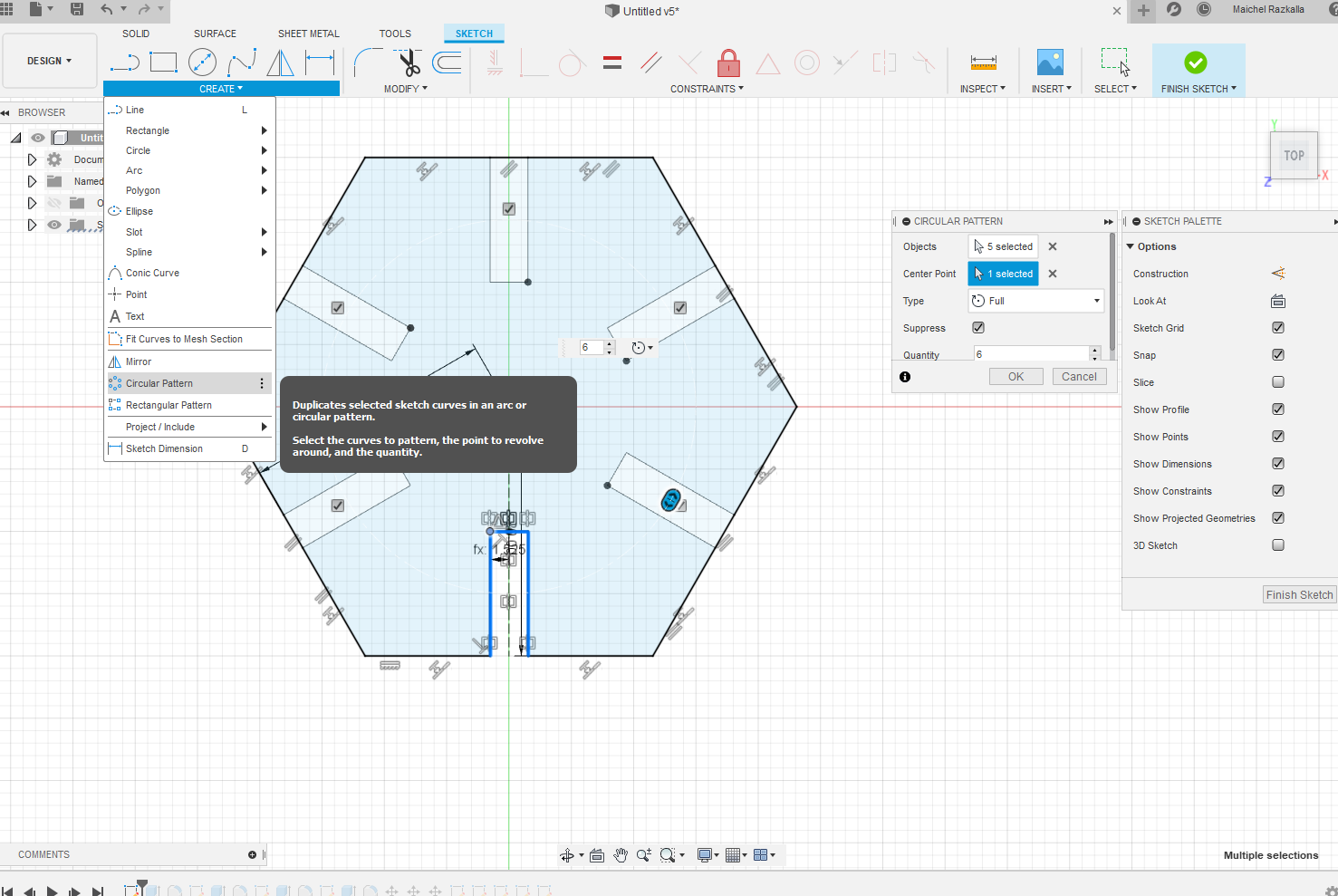

- After drawing the joint it’s time to make “curricular pattern”

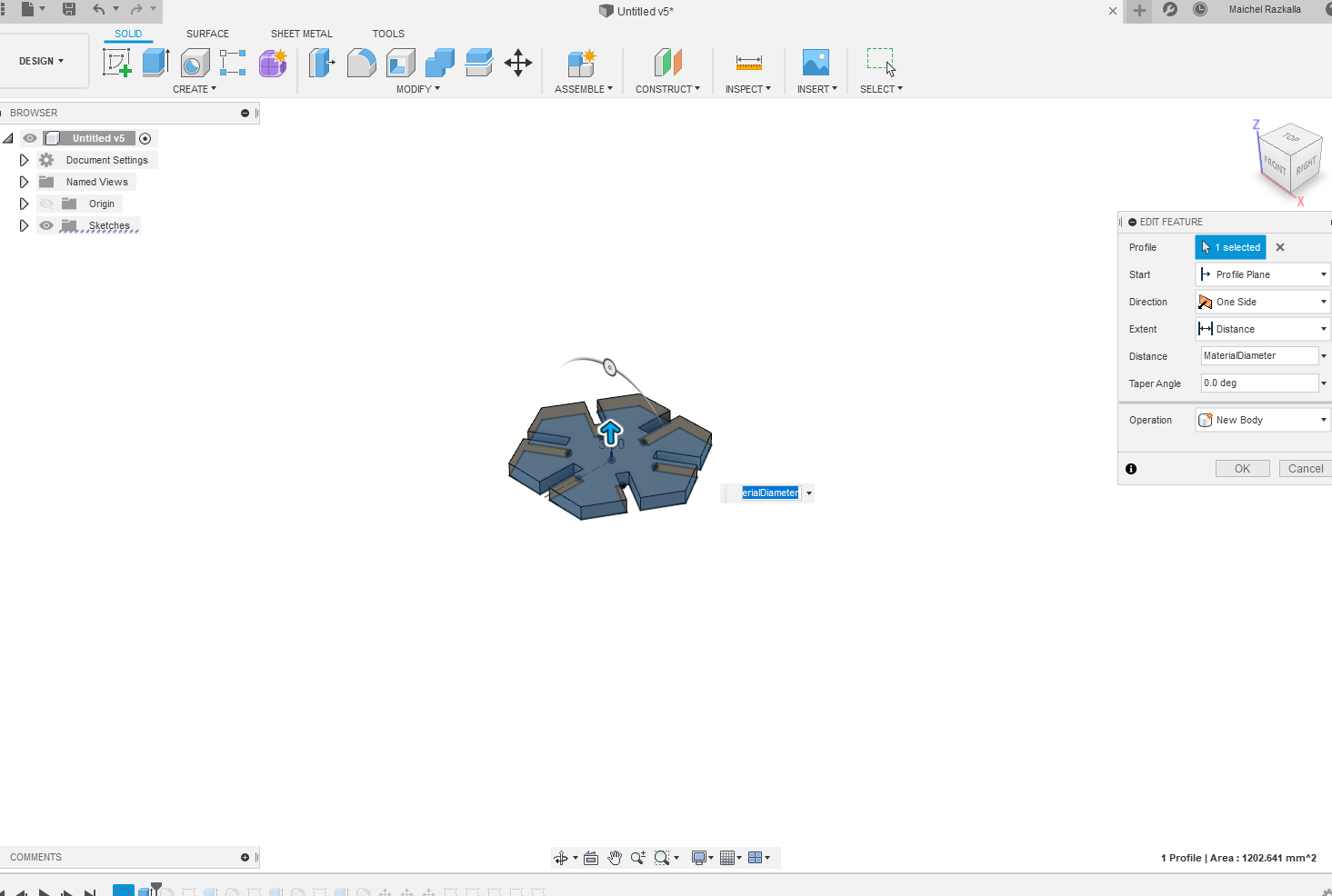

- Next step is to “extrude”

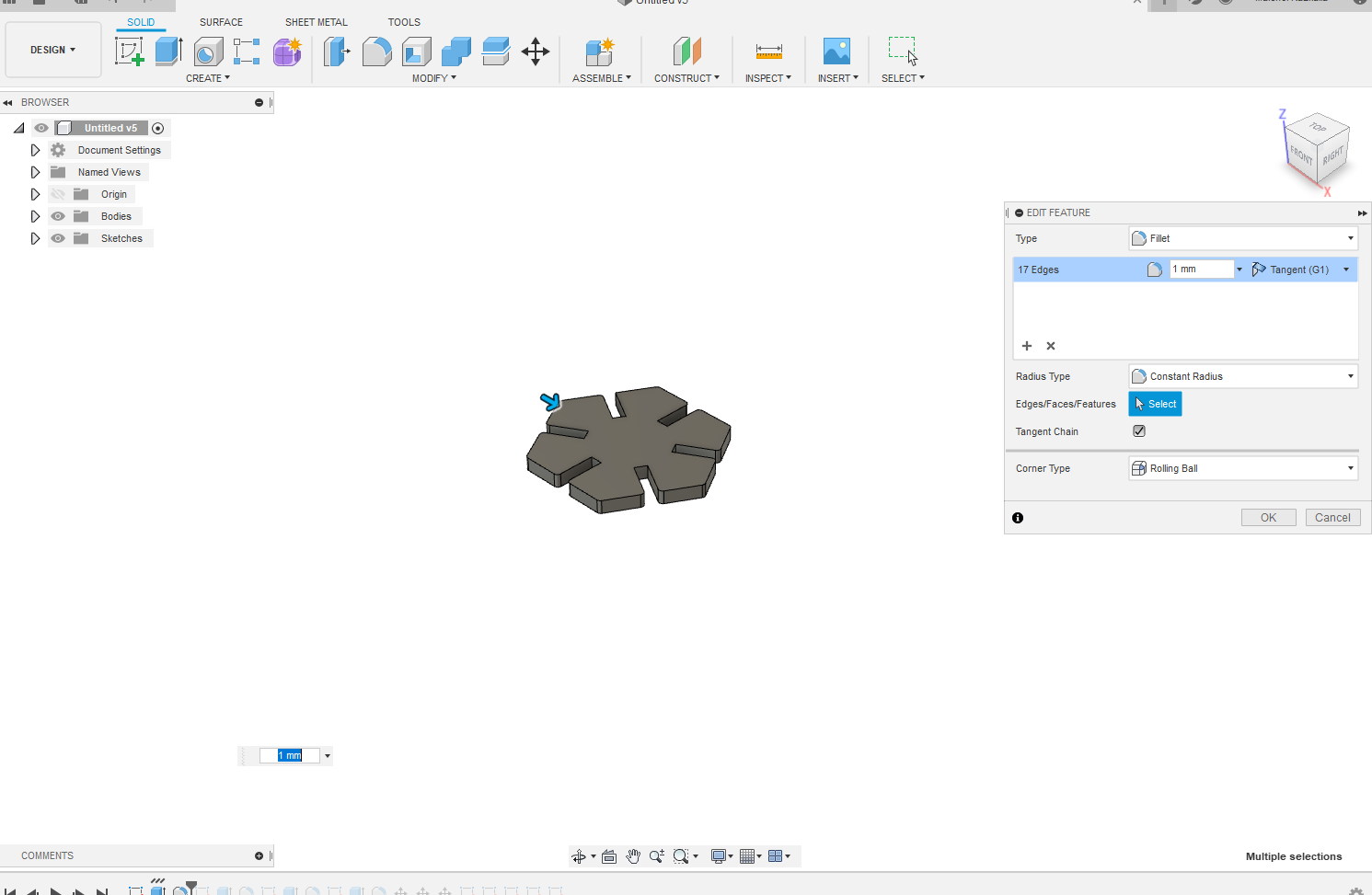

- After I extrude the part I used "Fillet" to make it more easy when I interlock the parts together

- Now I have the parts but it's a bodys not sketches so i used tool called "Interseact" to use it you have to creat sketch on the face of the body you need and interseact tool will outline all the body faces to a new sketch

Next, I trayed to cut the shapes with a 3mm joint width without adding any laser kerf to see if it will fit.

as expected it wasn’t press-fit it was more like hammer-fit X”D

Now the only modification I have to do is to adjust the “joint parameter “ and now I have my construction kit.

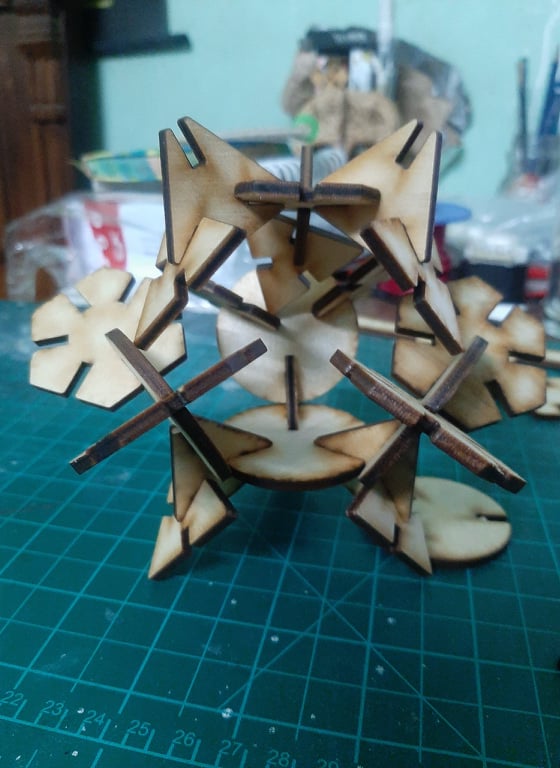

Imagination Time

The result of assembling my kit.

I will start with my orange juice cup holder

Mobile holder

Last but not least my try to make an artistic shape X"D .

Vinyl cutter

What is Vinyl cutter?

A vinyl cutter is a type of computer-controlled machine. Small vinyl cutters look like a desktop printer. Like a printer controls a nozzle, the computer controls the movement of a sharp blade over the surface of the material. This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic.

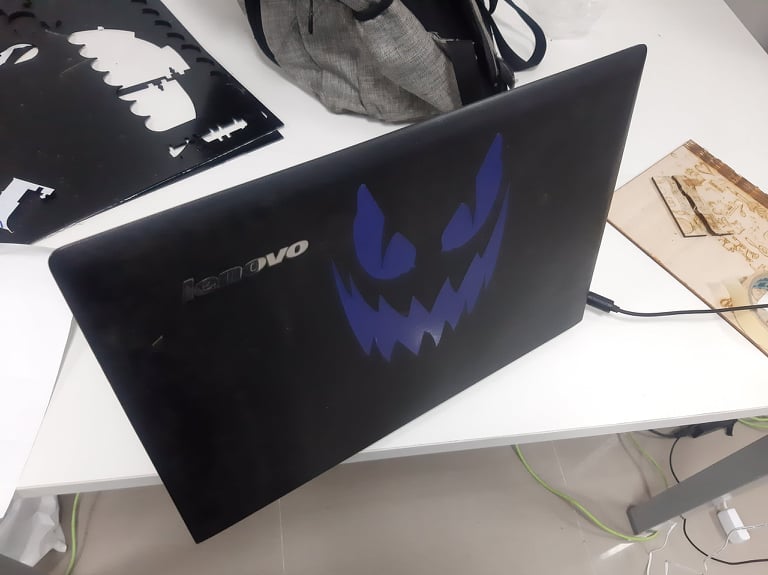

I decided to use this machine to make a Halloween sticker for my laptop, and I found this great pic.

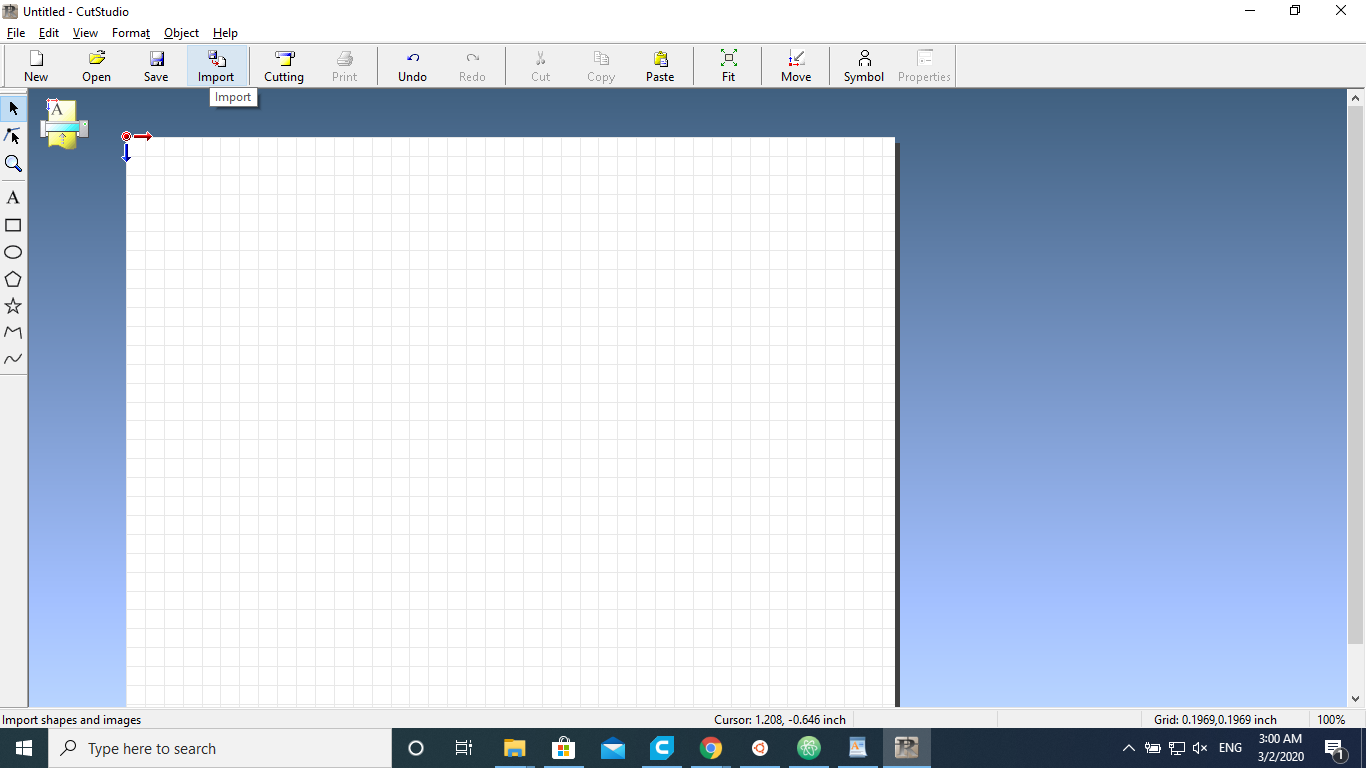

To cut the vinal frist i have to covert the img to format the vinal cutter can understand , so i will use "Roland cut studio".

First is to import the img

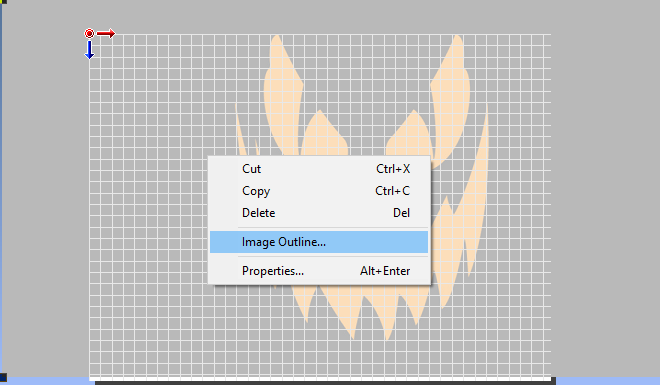

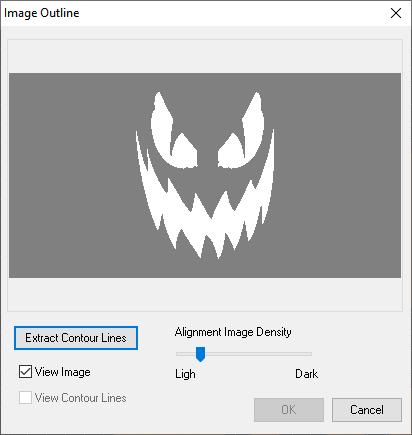

Now we need to generate the "image outline", so to do that we need to right-click to the image we select and click image outline.

Now we need to adjust the image density, next we will click on "Extract contour lines" and last will click ok .

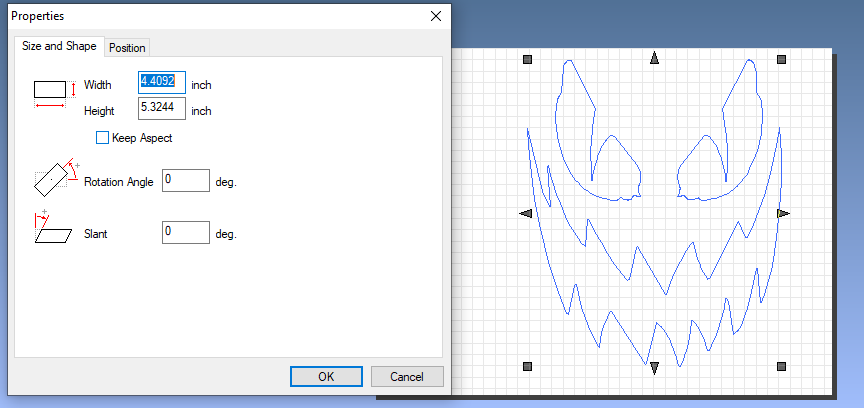

After I rid of the image now I have the image outline now I need to scale the lines down to fit my laptop size, so t scale the image we need to right-click the lines and select "properties" .

Last step after scaleing the image is to click "Ctrl+p" and select the vinal cutter and print .

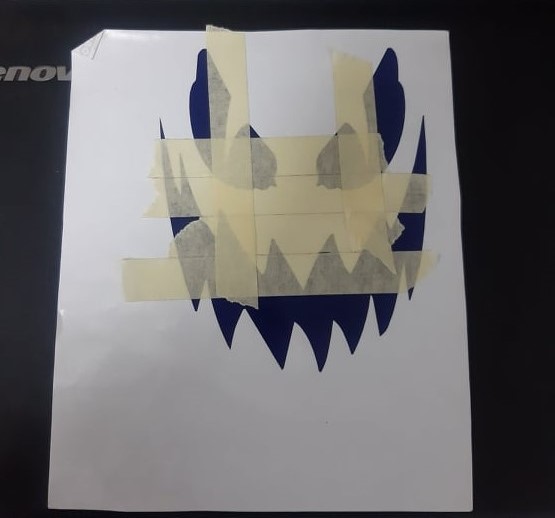

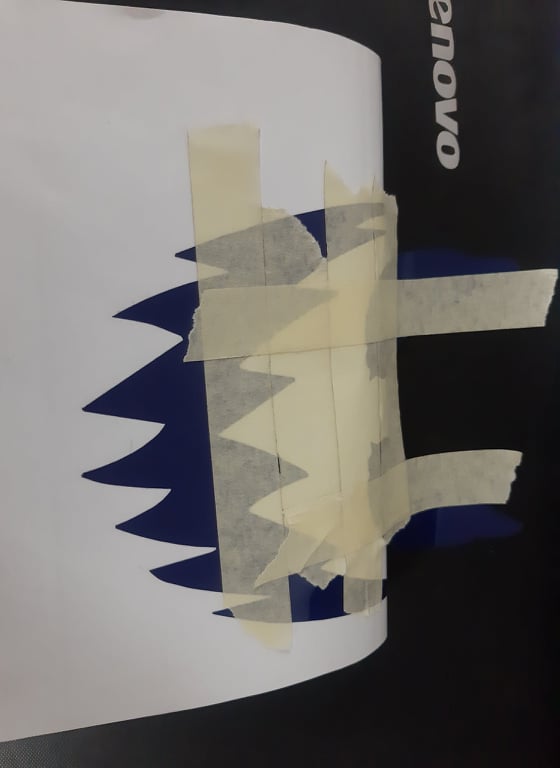

After cutting the vinyl it's time to transfer the vinyl to my laptop but I don't have vinyl transfer paper any problem I'm a maker so I used paper tape to make the vinyl like a one-piece to be easier to transfer.

to transfer the vinyl it could be a little tricky you need to pull the back of the vinyl slowly with fixing it to the laptop.

And this is the final result after cleaning a lot of paper tape X"D