Assignment #17

Mechanic design

The 17th assignment of the Fab Academy it’s Mechanical Design. Due to CoVid emergency it’s really though to work together, however, I ganged up with some sudents from Open Dot Fablab in Milan to work on this assignment. The machine we’ll build it’s going to be a soap bubbles shooters.

1 – the idea

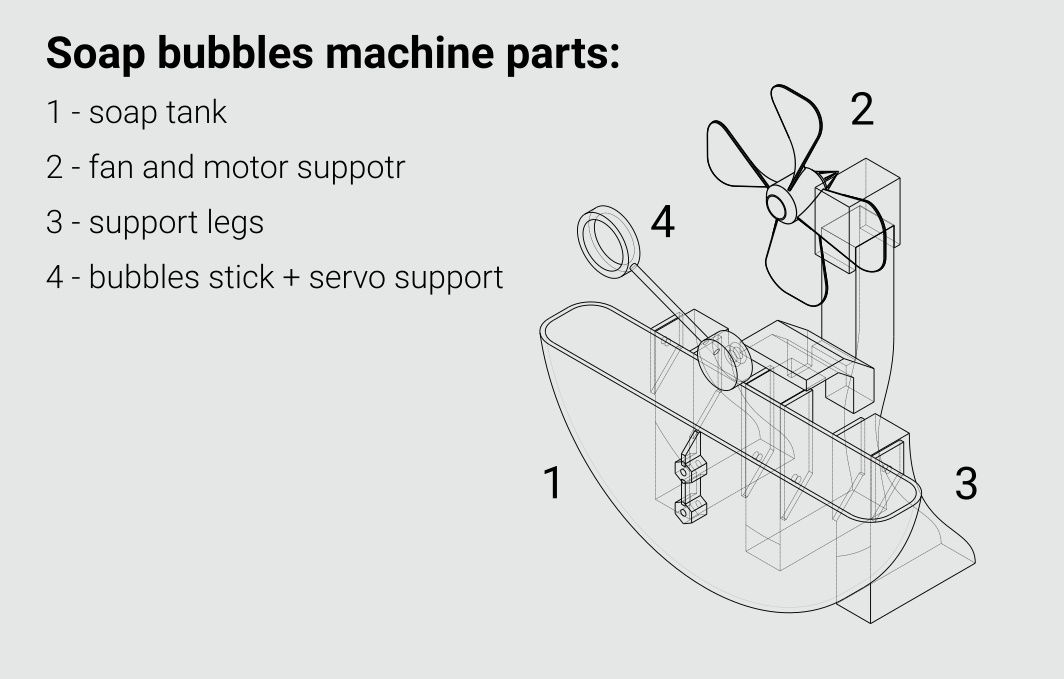

The machine will be made out of a semi circular tank, a DC motor, a servo motor and an ultrasound sensor.

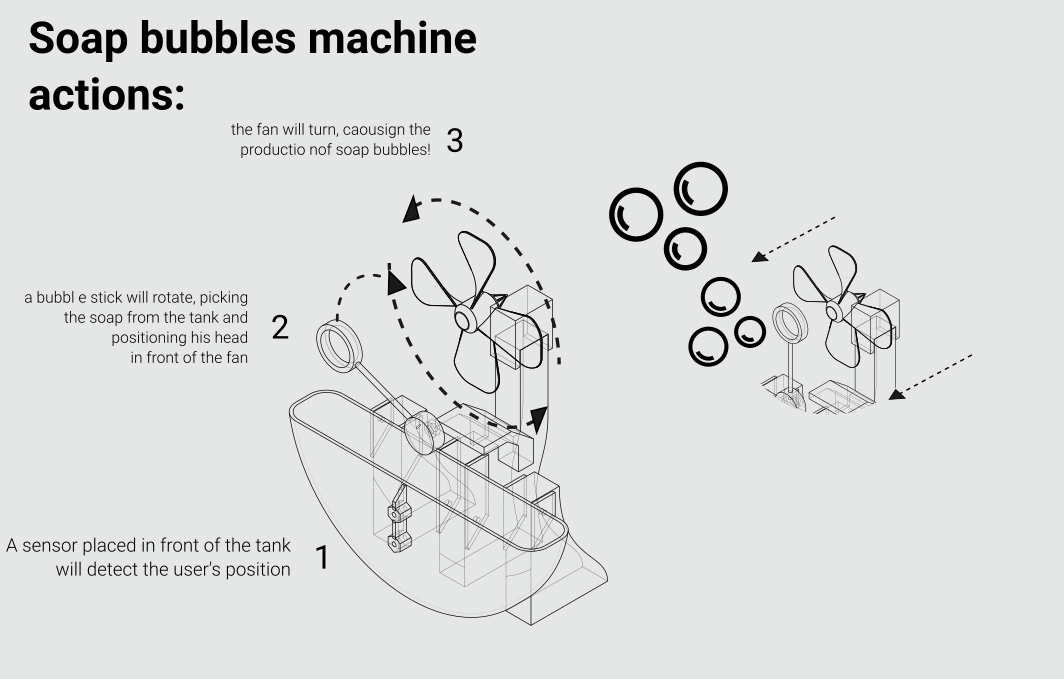

The mechanism will be very straight forward: a motor will rotate around the Y axis of the machine, moving a bubble stick(s) that will move his head inside the tank, and then in front of a fan situated in the upper part of the machine, causing the production of soap bubbles!. The mechanical design will therefore see the deisgn of 4 main parts:

- 1 - a soap tank that will keep the soap and the proximity sensor

- 2 - a support to keep the motor that will move the fan

- 3 - support legs to keep the machine standing and to host the circuit

- 4 - a support to keep the servo motor and an element to stick the bubbles stick to the head of the motor

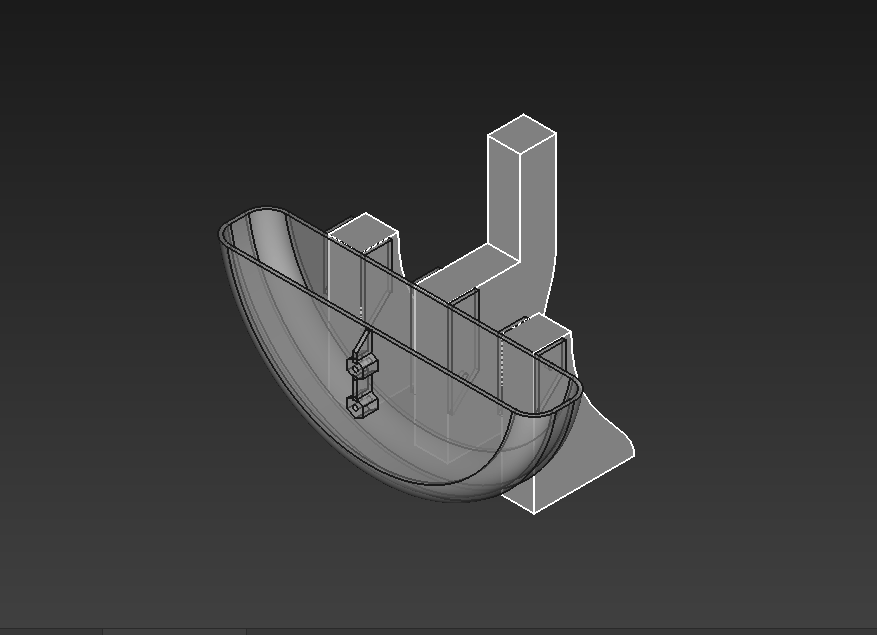

2 – 3D modeling

To proceed with the research I 3d modeled the semicircular tank and the supports that will keep the motors. On the front side of the tank we’ll place the sensor, but that’s something that we will explore in the next assignment

3 – manufacturing the basic parts

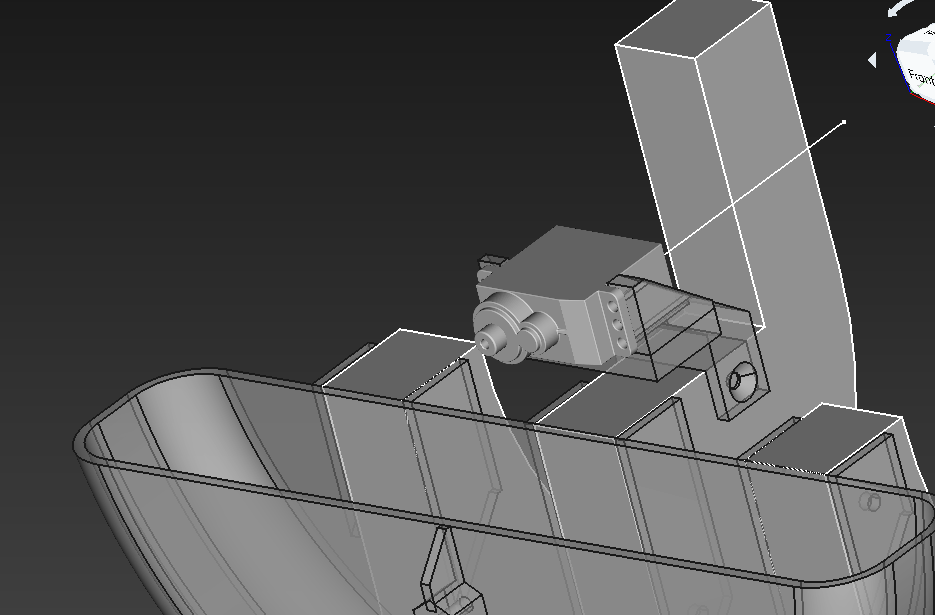

After the 3d model was done I moved to digital fabrication to fabricate the first parts. I used a 3d printer to produce the tank, and the CNC milling machine to mill the wooden elements that will hold the motors. Once the parte were done We placed them together to see if everything fits

4 – preliminary assembly of the mechanism

Once I had in my hands the pieces was time to make a further exploration to make sure that the rotation of the bubble stick matches the reach of the fan, so that the bubbles production is really effective. To do that we just used Plasticine and some basic elements like iron string, In this way we could figure uot more of the properties that are needed to make the machine works, such as how long the stick needs to be in order to sink well in the soap and

5 – further 3d modeling and assembly

Once I was reasonably happy with the results of that phase, I moved back to FreeCAD and modeled more elements to hold the motors and the bubble stick Once also this phase was done I 3D printed the parts and assembled the parts. I used some 3d models downloaded from the web to help the process

And so, we assembled everything and manually moved our parts to make sure everything works (it look like it does...). Next step will be to add the circuit and code it so that our machine will finally start to make some bubbles!

source files

Here are all the source files for the Wildcard assignment:

1 - freecad file for parts

2 - stl file for tank

3 - stl file for servo support

4 - stl file for bubble stick support

5 - stl file for bubble stick support

6 - stl file for DC support

7 - stl file for ultrasound sensor