5. Electronics production¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Group Assignment¶

We ran the cailbration picture milling using the Othermill & found out that our machine need to be week adjusted on milling depth.

I still have to do the same using the ShopBot :)

Making the mini fabISP¶

File preparation¶

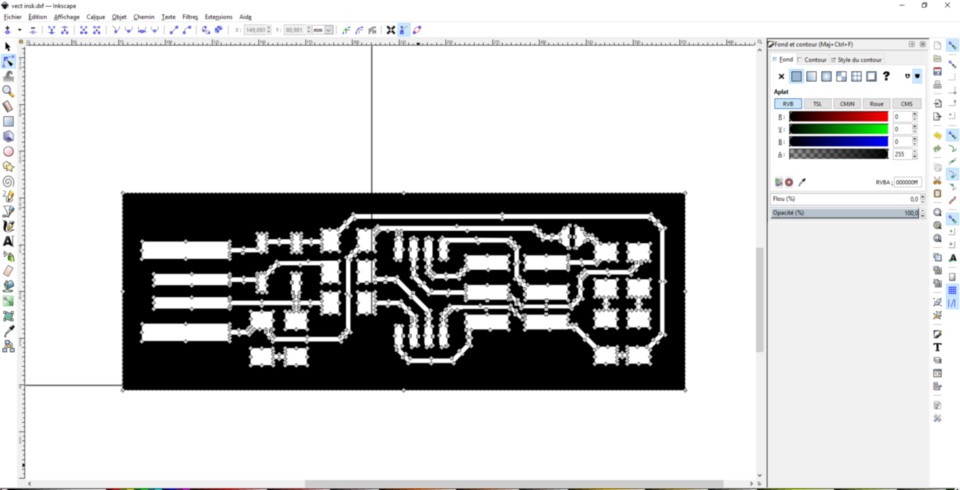

I has to vetorize the png to import it in the VcarvePro software

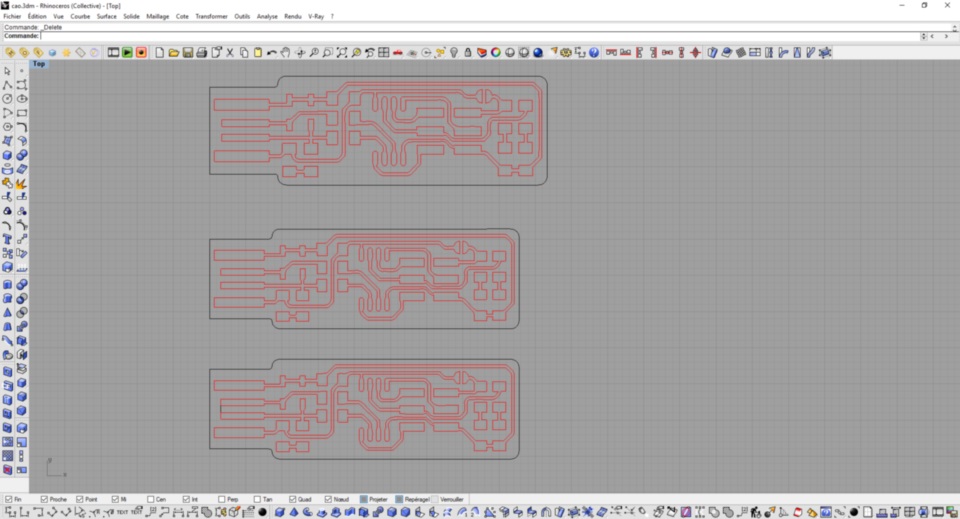

I had to check the dimensions maually, and did it using my favorite software: Rhino

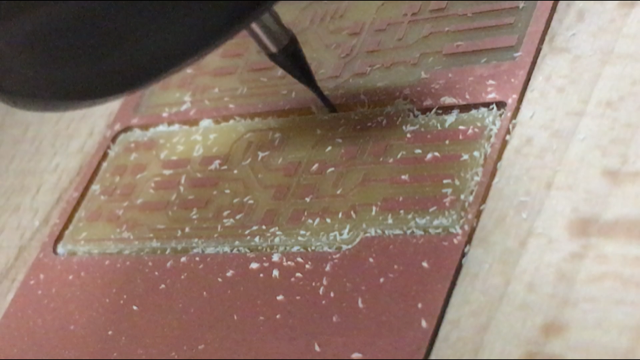

Machining a PCB using the Shopbot¶

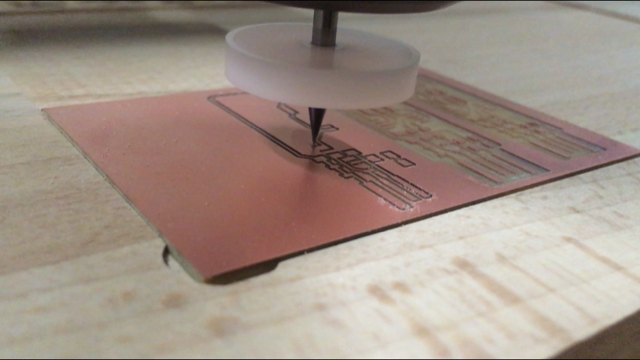

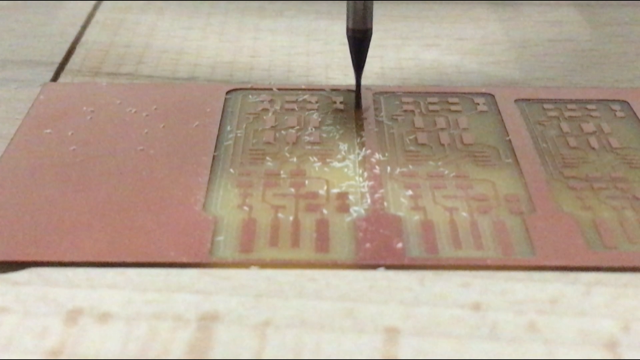

For testing purpose (and for fun), I decided to make my first PCB using the machine I know the best. I had t find out the machine parameters. I began by surfacing a piece of wood that became the support for PCB milling

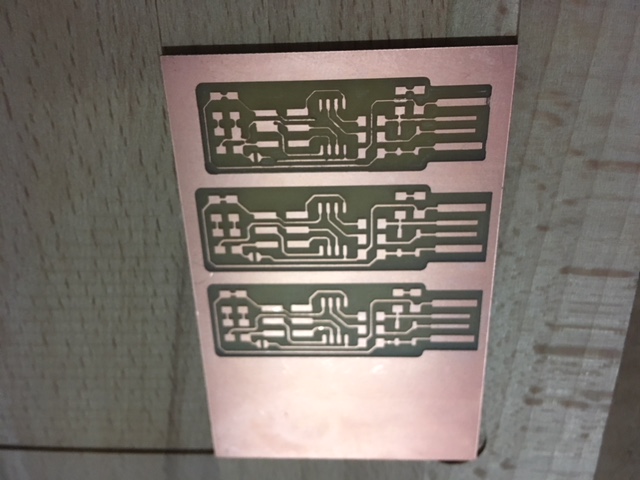

I milled using the 1/63 bir and cut with the 1/32.

I made three tests and the result was quite good to me.

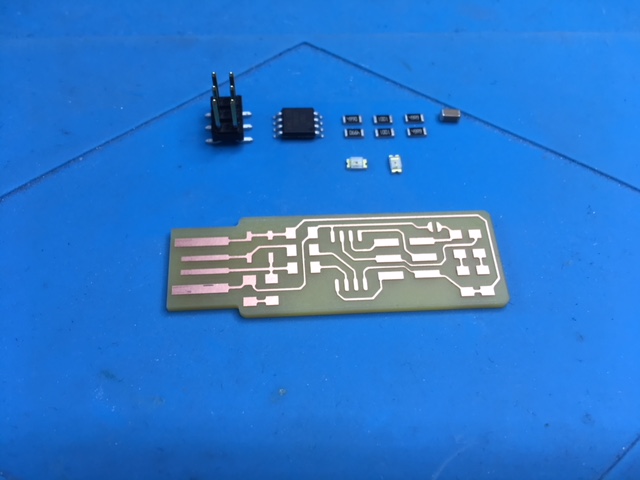

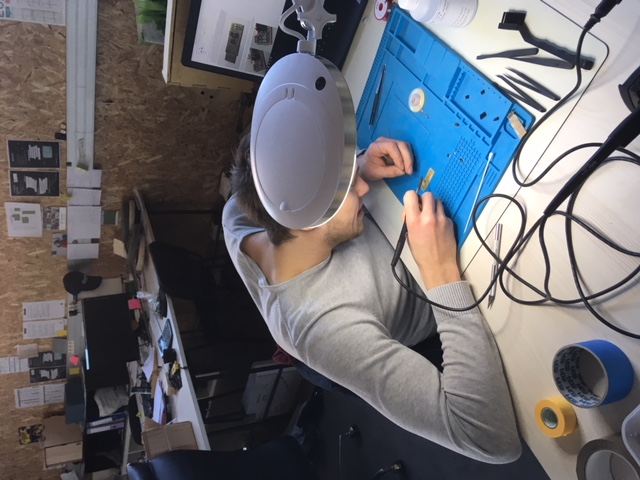

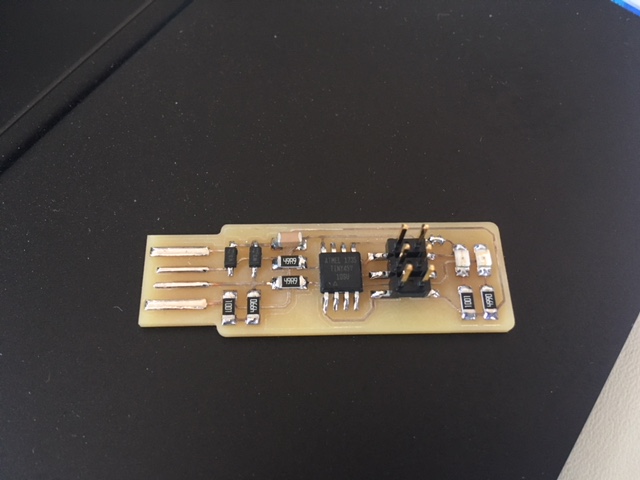

Soldering and testing¶

This was the first time I soldered components, but I am used to work on very accurate things.

flashing¶

I did flash the board on OSX I still have to make it work, using atom and platformIO :-( .

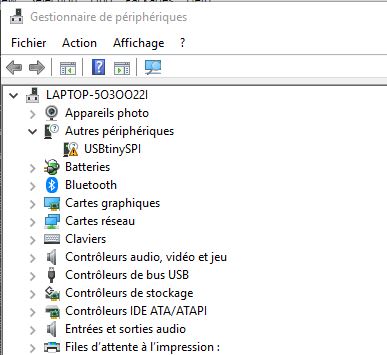

result¶

The board is recognized by Windows

Wood & PCB¶

I tried to make a PCB using my personal skills in wood working. The idea is to mill a precious part of wood and dill the spaces with stain.

This is still not finished but I Think it will work. I may also try with copper wire