Computer-Controlled Machining

So it's the 8th week since I begin my fab journey. In this week, I got following assignments,

- Test runout, alignment, speeds, feeds, and toolpaths for your machine

- Make something big

So this week we are leanrning about "Computer-controlled machining".Computerized Numerical Control(CNC) is a very helpfull tool in production of thing at large scale. It minimize human efforts in much effective way.

In our lab we are using "Shopbot" for this purpose. It allows to cut wood and other materials in a large scale. So let's meet shopbot...

Shopbot

A Shopbot is a computer-controlled cutting machine. A power tool router is affixed to the machine that directs its X and Y coordinates as it's cutting. ... CNC routers can be used to cut wood, foam, and plastics, but most hobbyists use it for carving wood.

Available in traditional shop-size and larger, all full size gantry tools are available with 8” or 14” Z travel. In addition to our standard size tools – 96 x 48, 96 x 60, 120 x 60, 144 x 60 – we can build your tool to any dimension up to 10’ by 30’ and with plunge depths up to 24 inches. Other customizable components are available, including dual Z options with two Z axes on the main gantry. You can download the details from Here

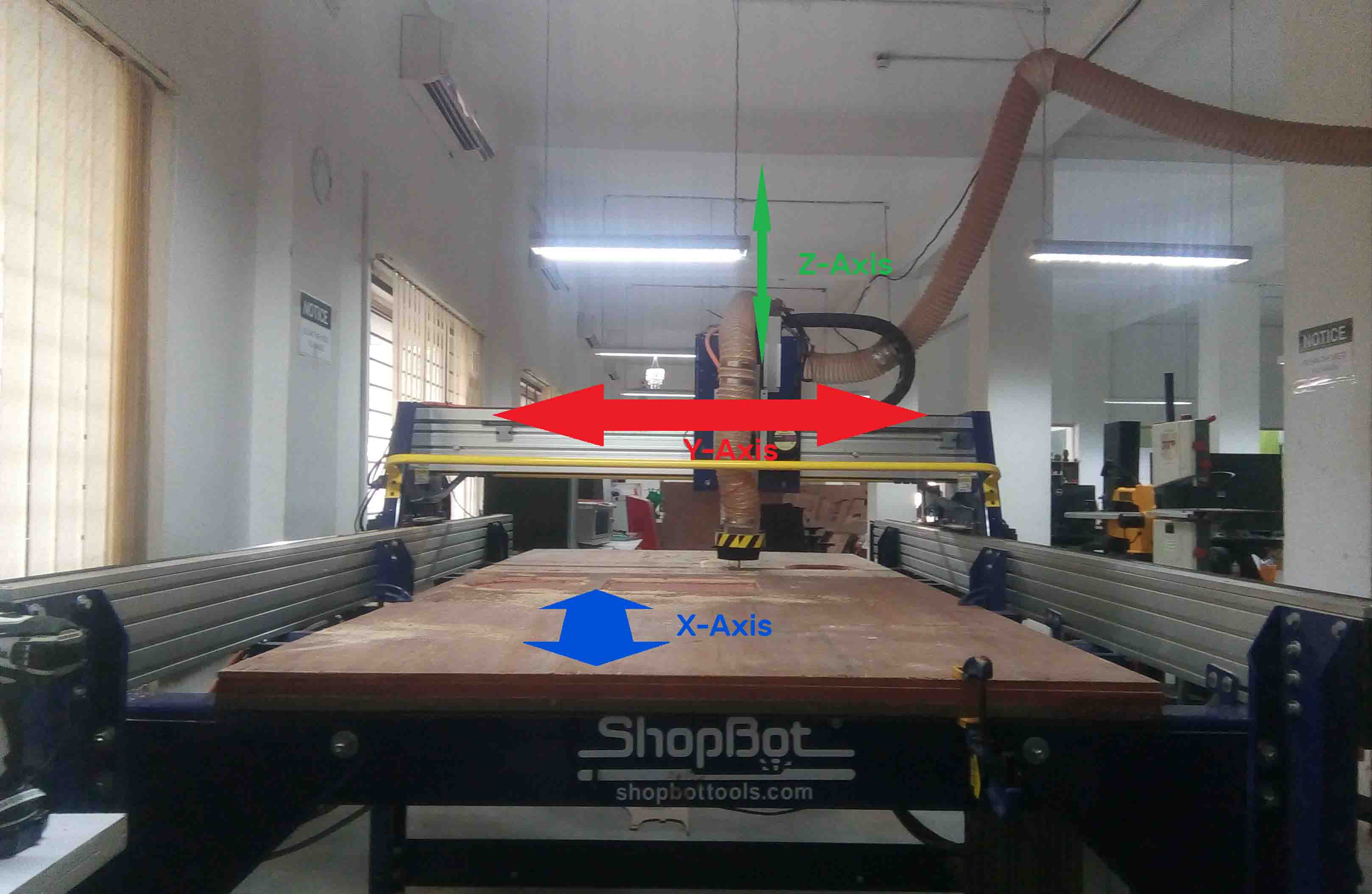

Shopbot consist of 3 Axis

- X-Axis(Horizontal movement)

- Y-Axis(Horizontal movement)

- Z-Axis(Vertical movement)

The X and Y axis are for Horizontalmovements. The vertical movement is covered by the Z-Axis. The Z-Axis contains "Spindle" and "Vaccum". Spindle contains the drill bit. Vaccum helps to clean the bed.

The end of the Vaccum is coonected to a suction vaccum cleaner which is given below

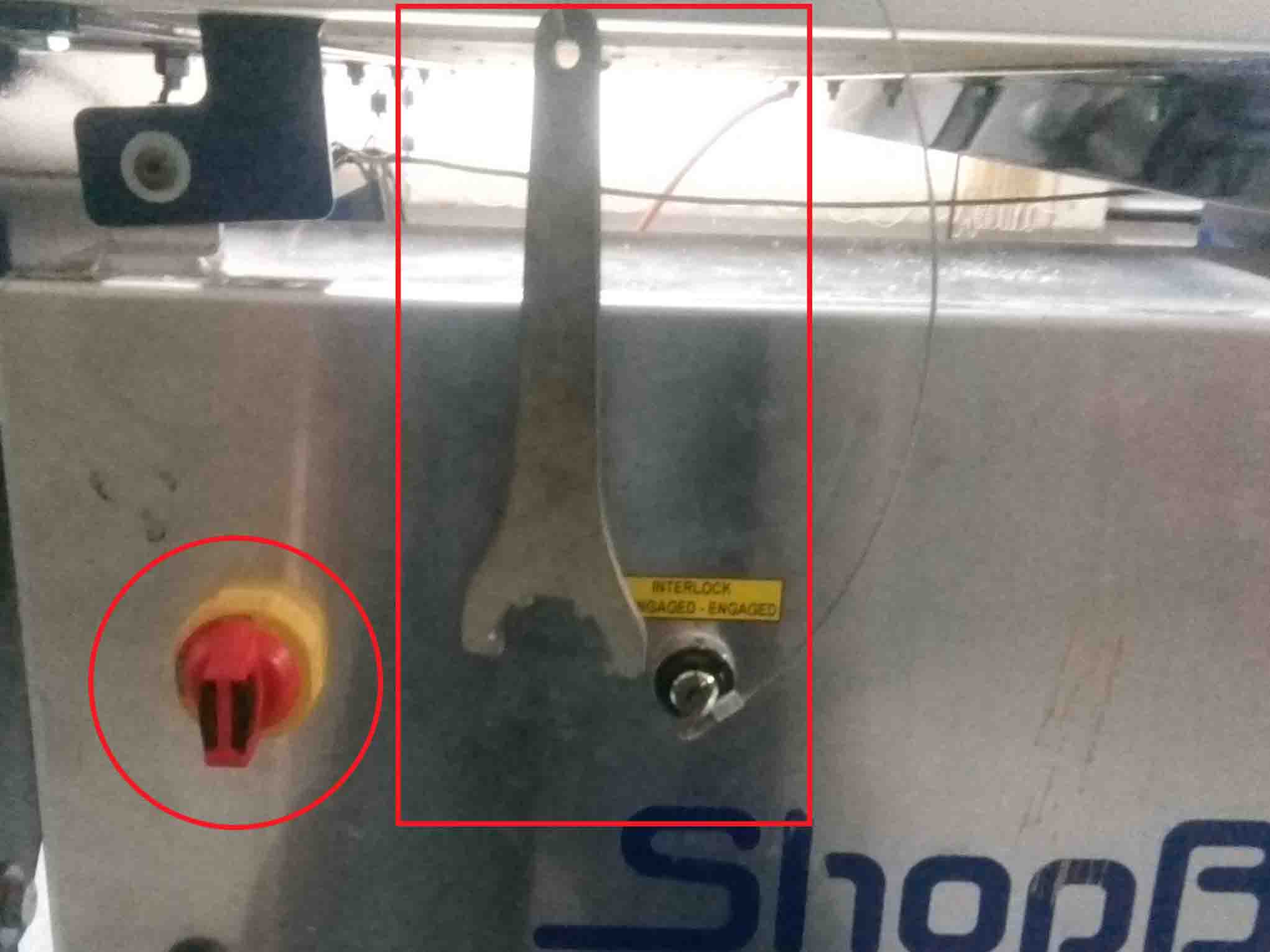

The shopbothave few safty mechanisms that is provided for the saftyof the users.

As you can see in the image, there are two emergency pause switches in case there is some problems occure. Also the "Power On/Off" knob is also given. There is a wrench given in order to change the bit from the spindle.

Before we get started we need to know bit about the drilling/milling bits...

Different Bits

Drill Bits vs End Mills

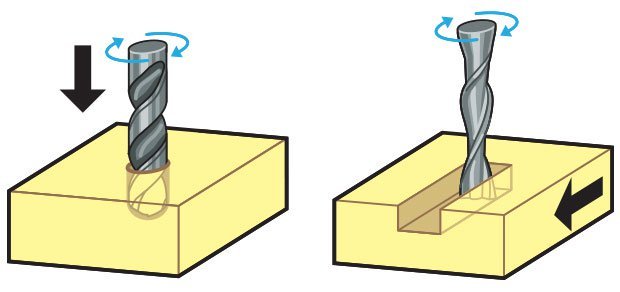

CNC machining is a subtractive process that uses rotational cutting tools called “end mills” to remove material. An end mill, while similar in appearance to a drill bit, is far more versatile. However, in practice the terms “bit” and “end mill” are often used interchangeably.

Here’s the key difference. Drill bits are designed to plunge directly into material, cutting axially and creating cylindrical holes. End mills are typically used for horizontal carving and cut laterally. Additionally, most mills are “center-cutting,” meaning they are able to cut both axially and laterally. This is due to cutting flutes that extend to — and protrude from — the end face and enable plunge cutting. To minimize tool breakage and stress on the material being cut, most CNC software will “ramp” the end mill slowly into lateral cuts.

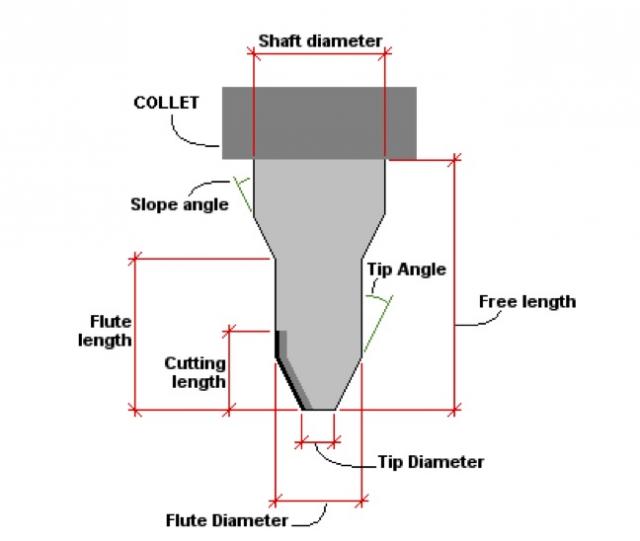

Tip Shapes and Applications

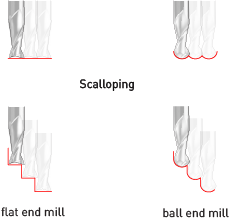

Choosing flat end mill vs. a ball end mill will determine the characteristics of the tooling marks

(or lack thereof) on your model. Most jobs will benefit from strategic use of multiple size and

shape tools for milling different features. End Mills are often used for roughing and 2D cutting

and V-Bit and Ball Nose cutters are often used for finishing operations.

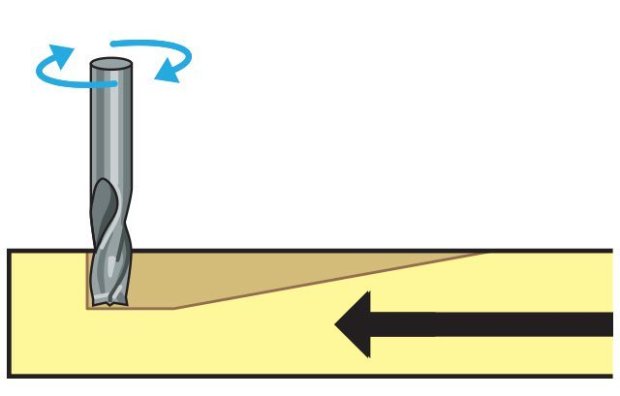

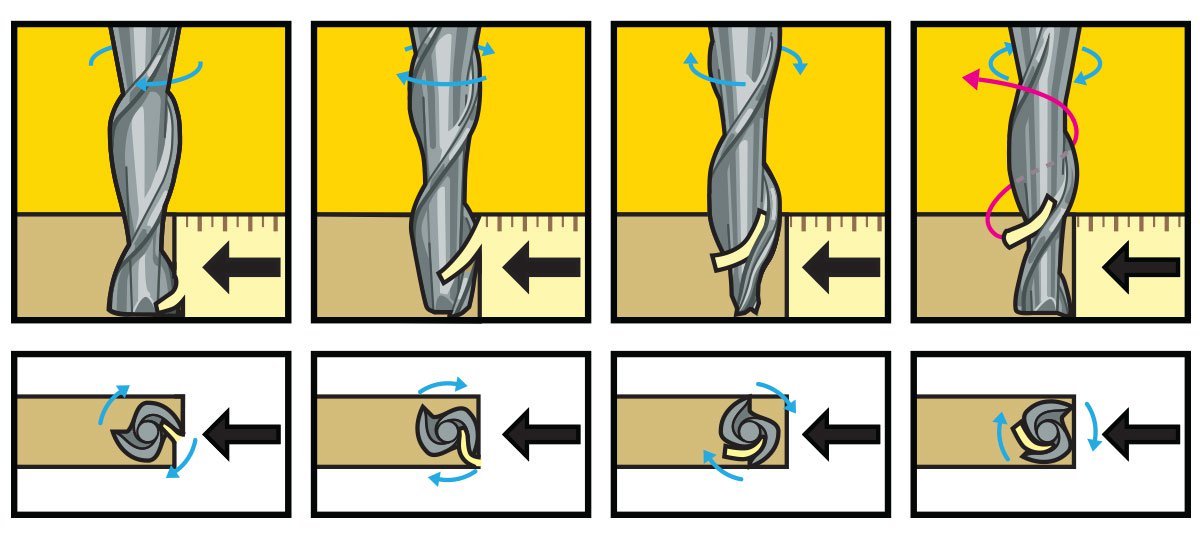

Up-cut, down-cut and compression cut determine the way the chips (cut material) are ejected and

the smoothness of the surface. With an up-cut end mill, the chips will be ejected upward and the

bottom of the material will be smooth. The down-cut end mill is the reverse by puching the chips

downward and the top of the material is smooth. The compression end mill creates a smooth surface

on top and bottom, which is perfect for pre-laminated woods.

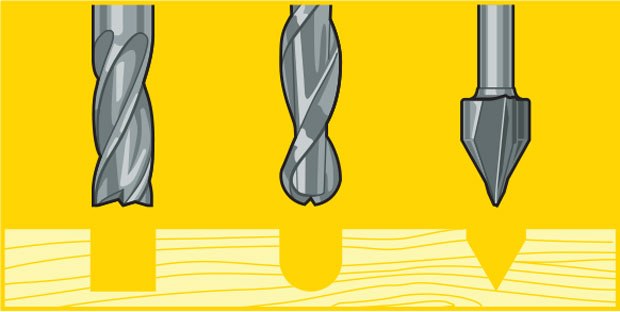

There are up-cut, down-cut, compression cut end mills with varying numbers of flutes. End mills are intended to cut horizontally. Up-cut, down-cut and compression cut determine the way the chips (cut material) are ejected and the smoothness of the surface. With an up-cut end mill, the chips will be ejected upward and the bottom of the material will be smooth. The down-cut end mill is the reverse by puching the chips downward and the top of the material is smooth. The compression end mill creates a smooth surface on top and bottom, which is perfect for pre-laminated woods. End mills come in a variety of shapes. The most common are flat end mills and ball end mills. Flat end mills will cut flat areas with no scallops. However, they leave a terrace-like scallop on non-flat surfaces. Ball end mills will leave smaller scallops for the same stepover value on sloped surfaces, but they will also leave scallops on flat areas. Flat end mills can be Center Cutting and Non Center Cutting: Center cutting square endmills are essential for plunge milling.

Each end mill tip shape is designed for a particular purpose. Some common cutter shapes are ballnose, fish tail, surface planing, v-carving, and straight.Ballnose mills produce a rounded pass and are ideal for 3D contour work, while fish tail cutters will produce a flat surface. V-bits produce a “V” shaped pass and are used for engraving, particularly for making signs.

The diagram above shows the difference in clearing path shape between a fish tail, ball nose and V tools. Ball nose mills are often selected when doing 3D contouring because their rounded edge reduces jagged steps when cutting several stepped layers. Ball nose mills can also be used to cut wide paths with rounded edges by reducing the step over amount (overlapping distance between) between passes. By overlapping steps, the central scallop shown in the diagram is eliminated.

Flutes and Chipload

Flutes are the helical grooves that wrap around the sides of the end mill. Each flute has a single tooth with a sharp cutting edge (although there can be more than one) that runs along the edge of the flute.

As the tooth cuts into the wood, each flute whisks away a small section or “chip”. The fewer the flutes, the more material that is ejected with each tool rotation. The overall cutting depth should never exceed the length of the flutes on an end mill. If cutting deeper than the length of the flutes, the tops of the flutes will be blocked and chips won’t clear, building up heat and reducing tool life

Chipload is the thickness of a machined chip as cut by a specific tool type. More flutes create a smoother surface finish, while fewer flutes remove material fastest, but make rougher cuts.Chipload is the thickness of a machined chip as cut by a specific tool type. More flutes create a smoother surface finish, while fewer flutes remove material fastest, but make rougher cuts.(Source:https://makezine.com/2014/09/10/endmills/, https://wiki.imal.org/howto/cnc-milling-introduction-cutting-tools)

Group Assignment

Test runout, alignment, speeds, feeds, and toolpaths

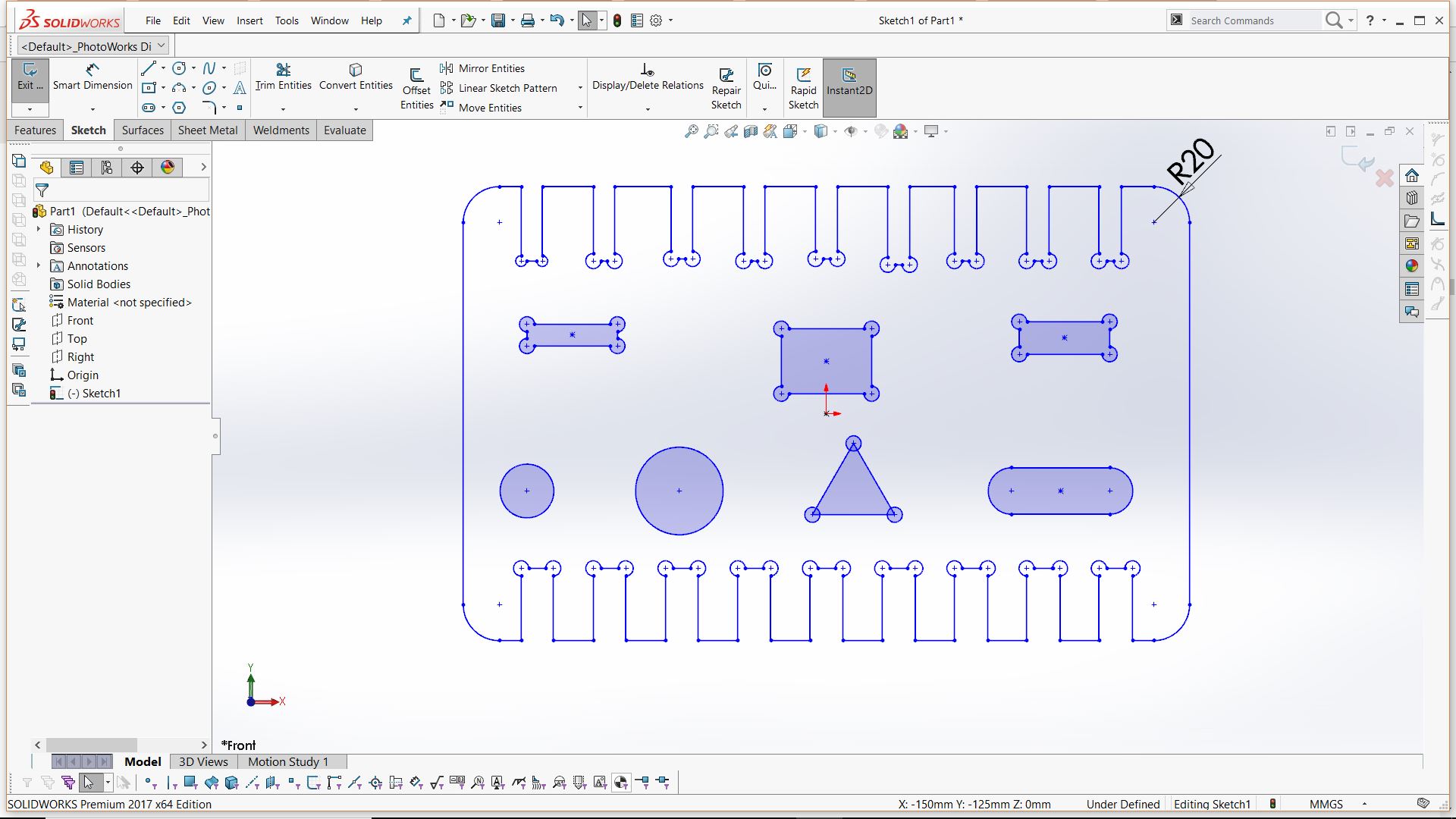

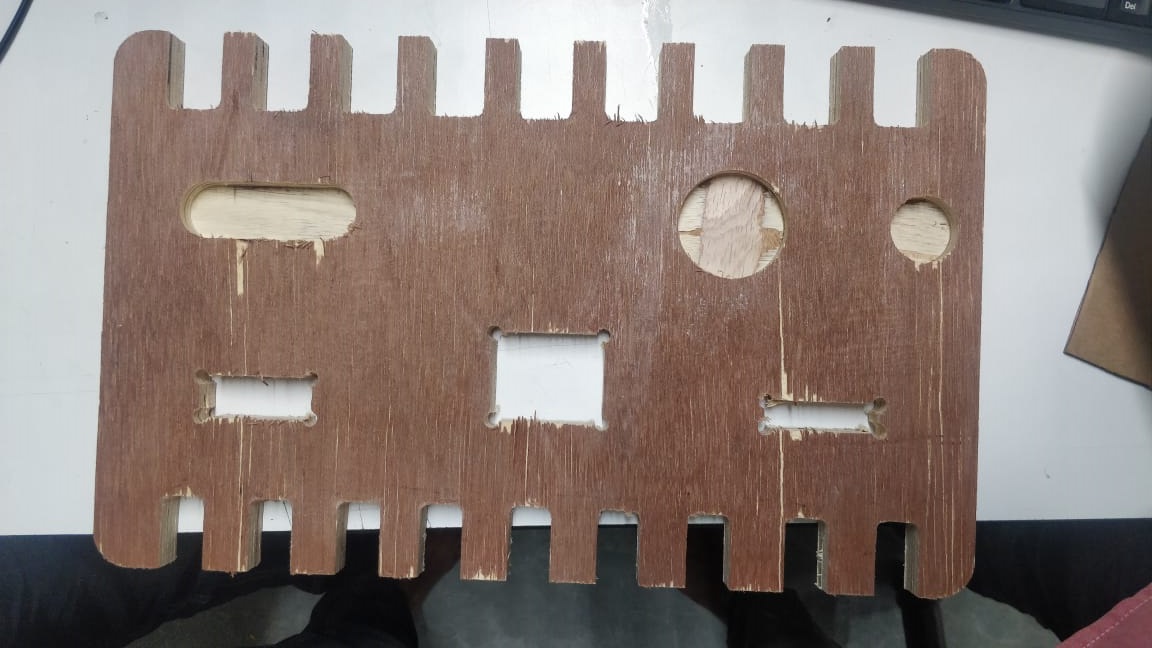

So for testing some parameters in shopbot, we have designed a structure in Solidworks.

after cutting

Make Something Big

3D-design

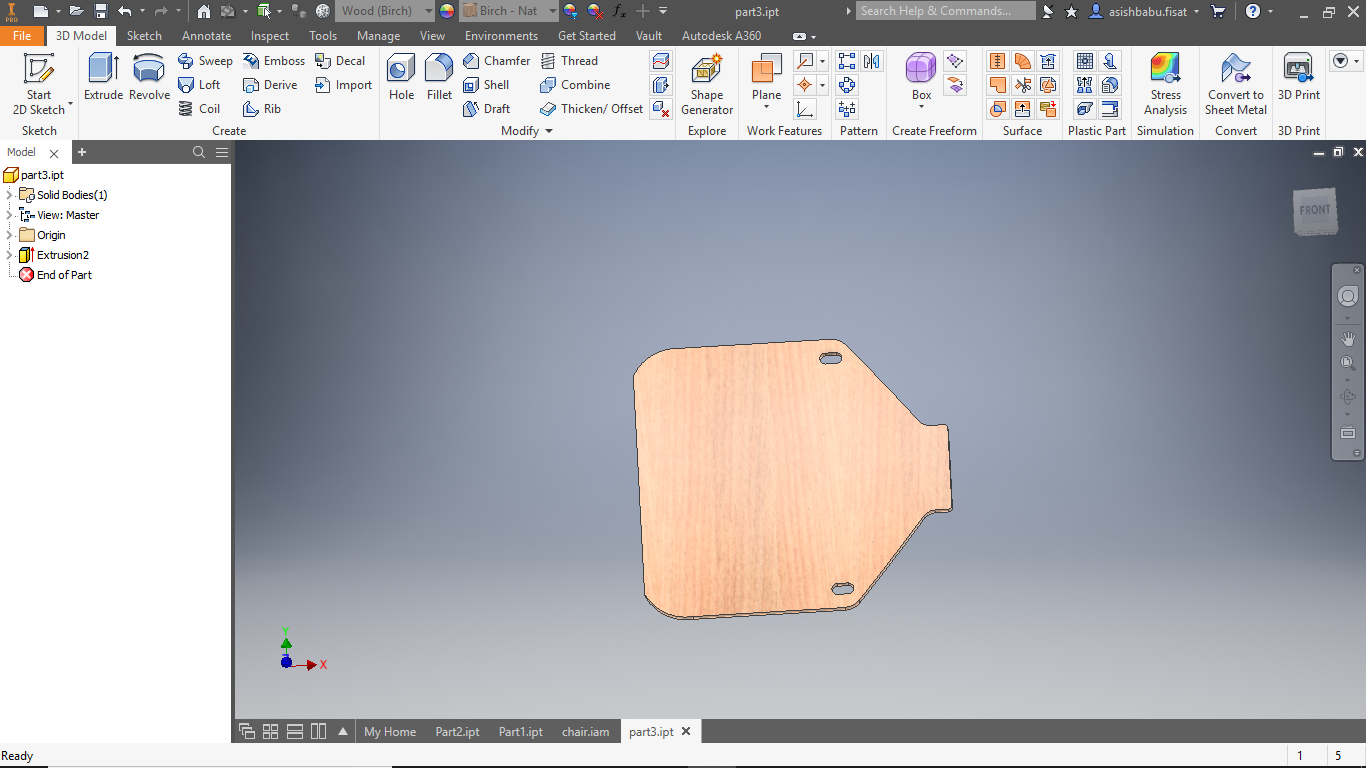

Heare i deside to design a foldable chair. i use inventor to design this.

i have some plans in my mind, i take some measurments from some chairs.With plans in my mind i

start

designing. To learn Inventor from base please reafer my CAD

design week. I attach full assembly files in below. This is very base design, you can

download and edit it as you wish.

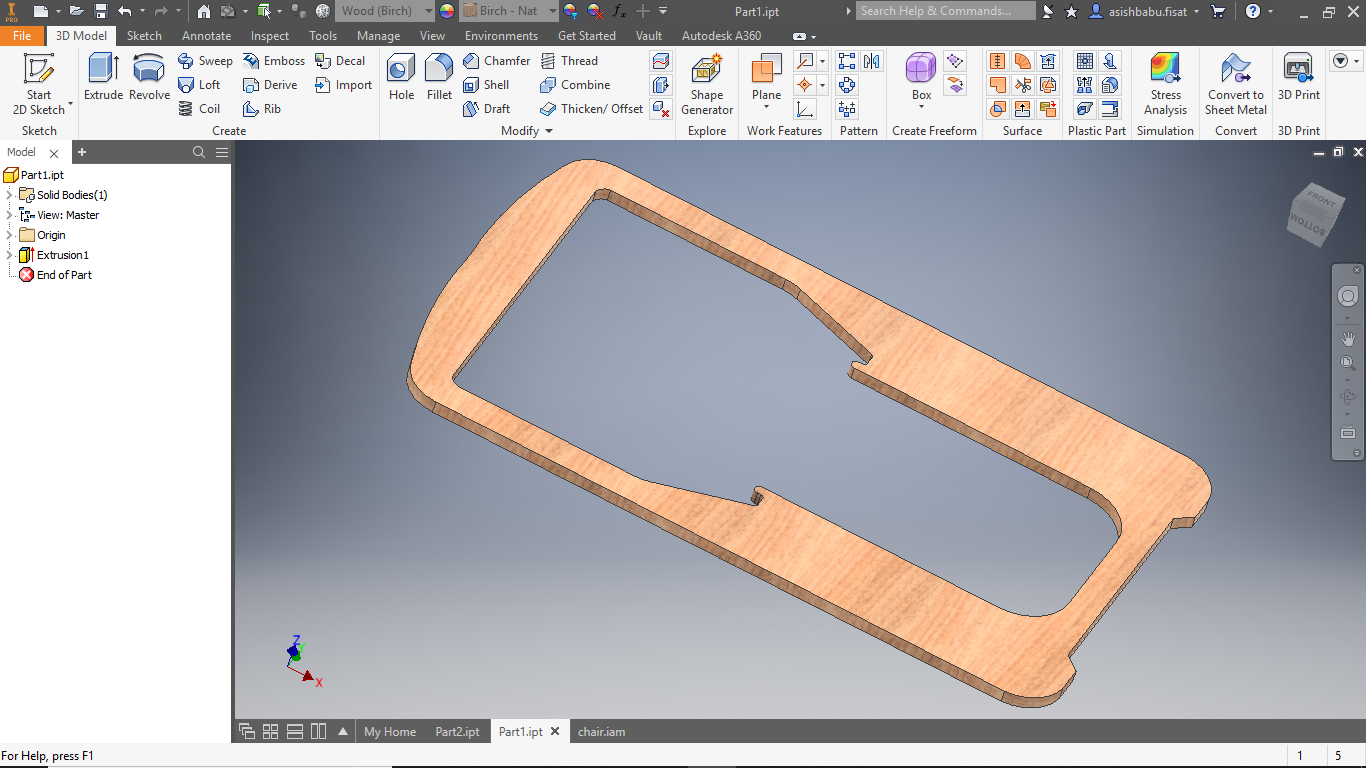

1st i make an base to sit.

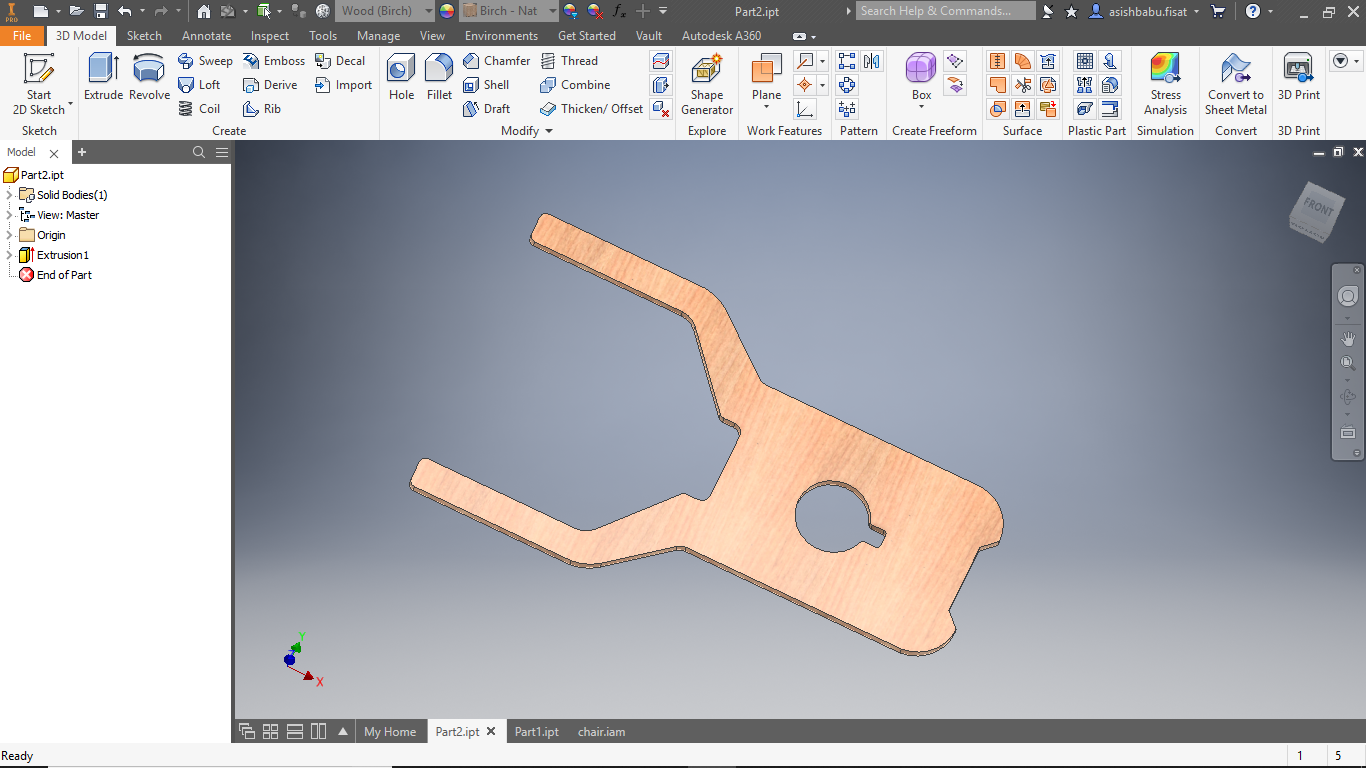

Then i make a stand

Then i make an outer base to connect each things

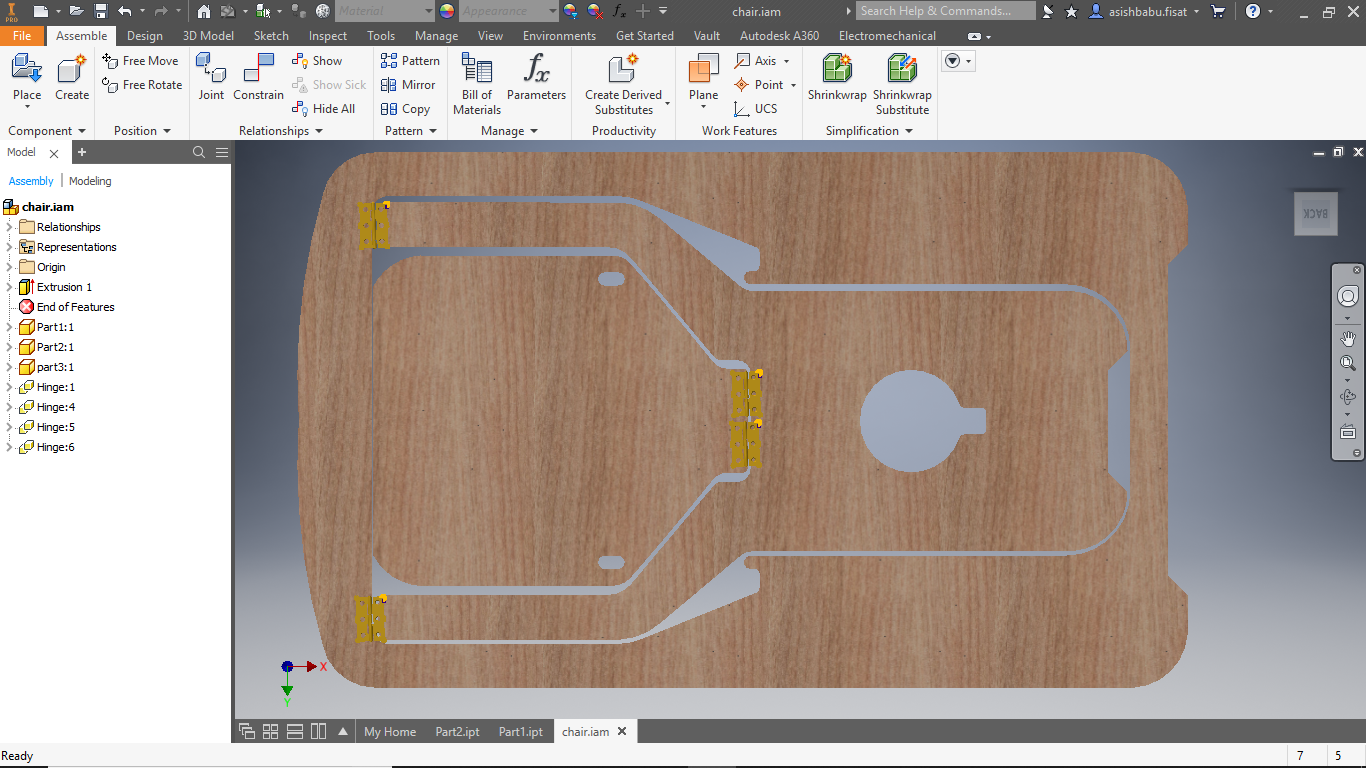

Finaly i made a base model. Next task is to cut this with shopbot

Preparing CNC

To cut wood in CNC, we need to follow steps below....

- fix sheet in CNC bed

- Set X,Y,Z axis minimum positions(origin)

- set toolpath

- fix required bit in spindile

Before we begin, wee need to take some safty precausions. Also we need some tools. Here is a list of tools and safty we equipments we need:

- Hand-Drill

- Screws

- Gloves

- Safty google

- Mask

- Noise cancelling headphones

Fix sheet in bed

Preparing the Jobs

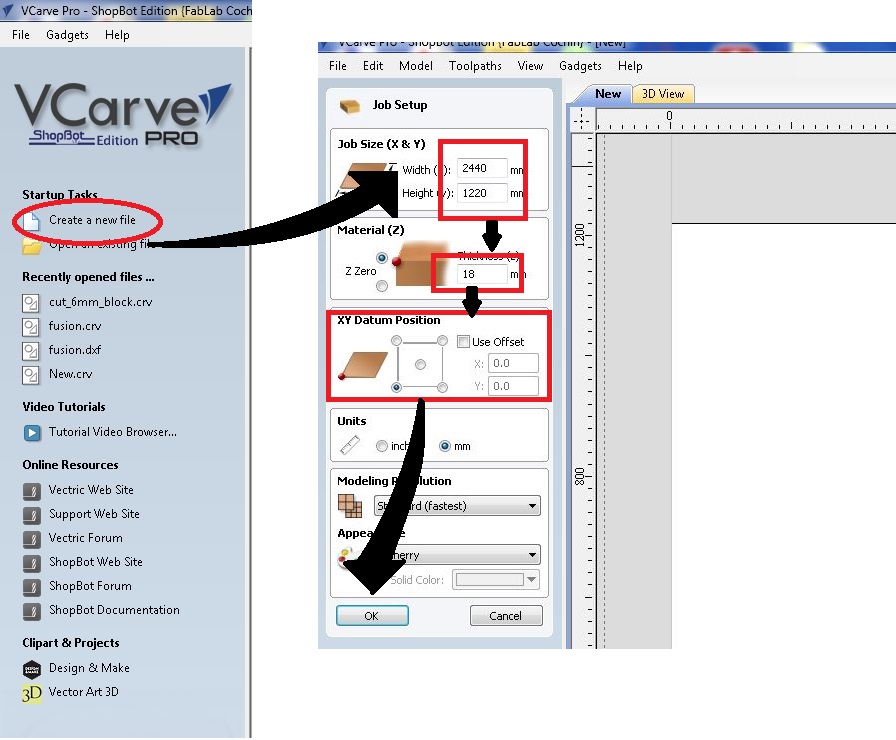

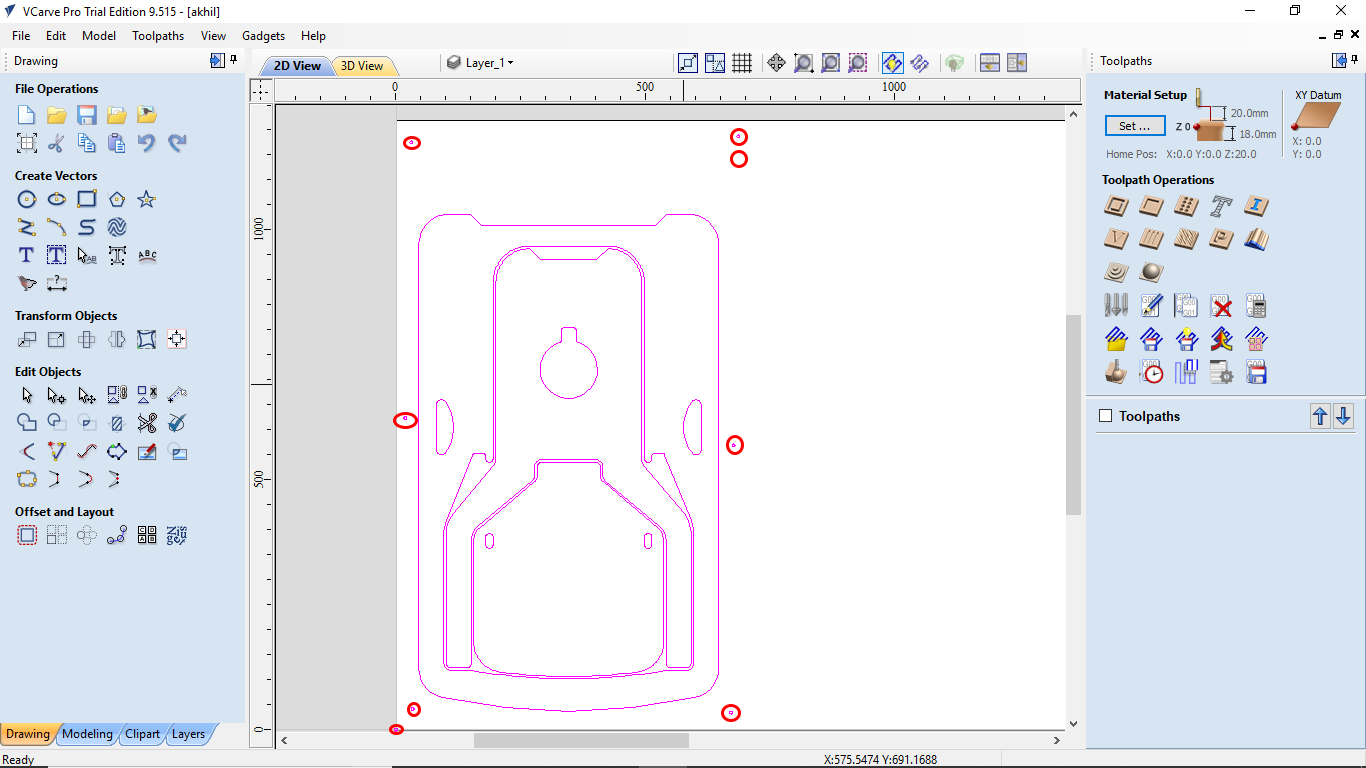

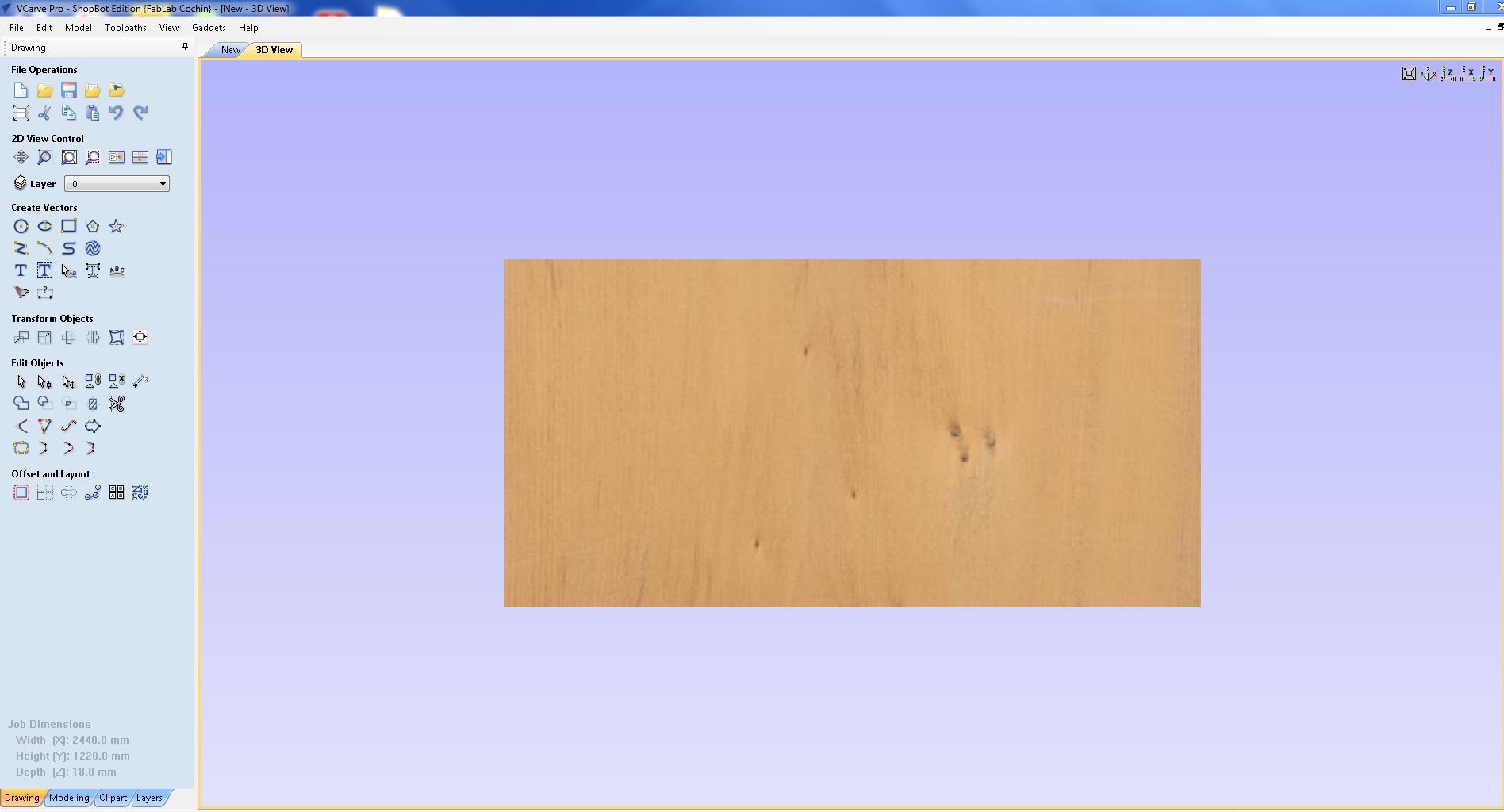

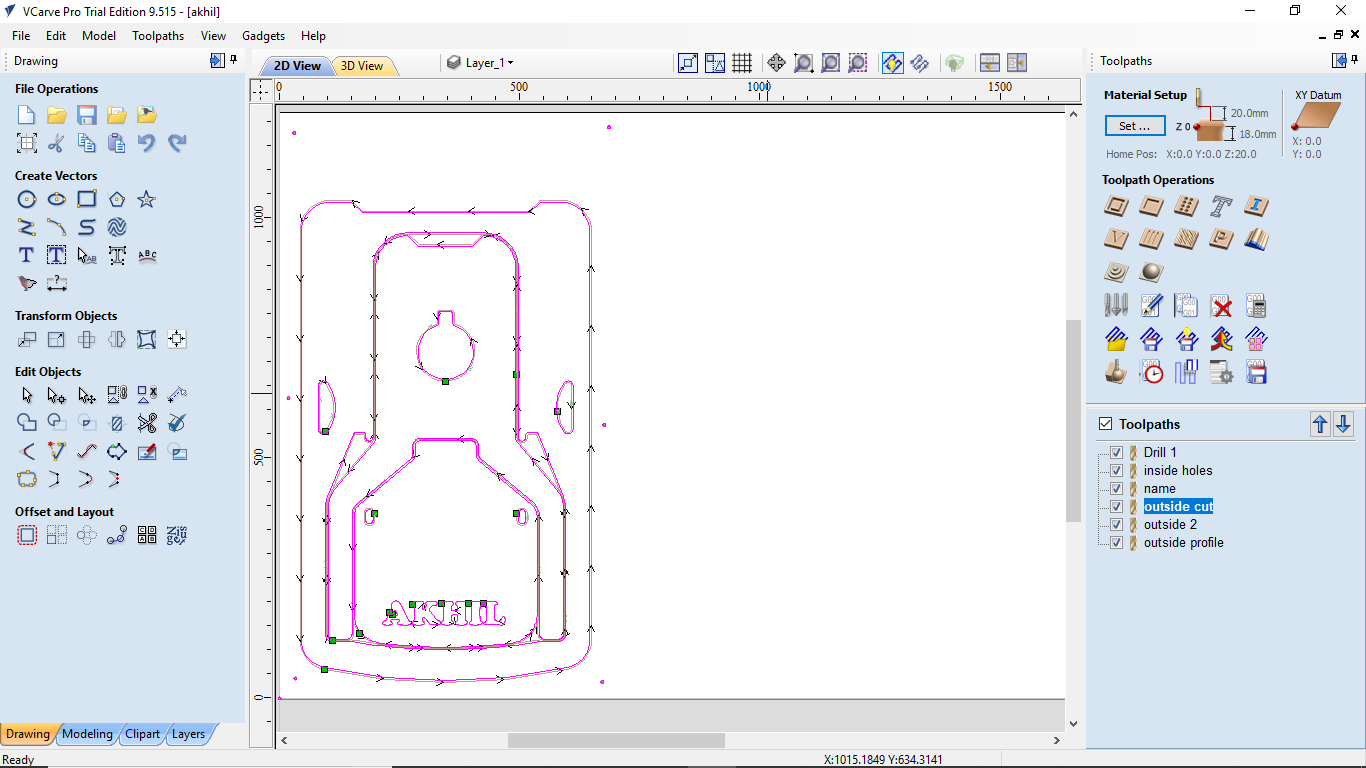

So we have designed a foldable chair. Now we have to make G-Code that understandable to Shopbot. For that I opened "V-Carve on the system linked to shopbot."

Now click "Create new file" and fill following:

- Width=2440mm

- Height=1220mm

- Thickness=18mm

Now set origin point and click "Ok". Then open our design DXF file in VCARVE. which we take from inventor

Now we need to to add some drill holes fot fixing the wood to the bed. For that, I selected a "circle tool" and draw few circles away from cut pieces. Always remember to set offset distance of the drill bits diameter between work piece and holes.

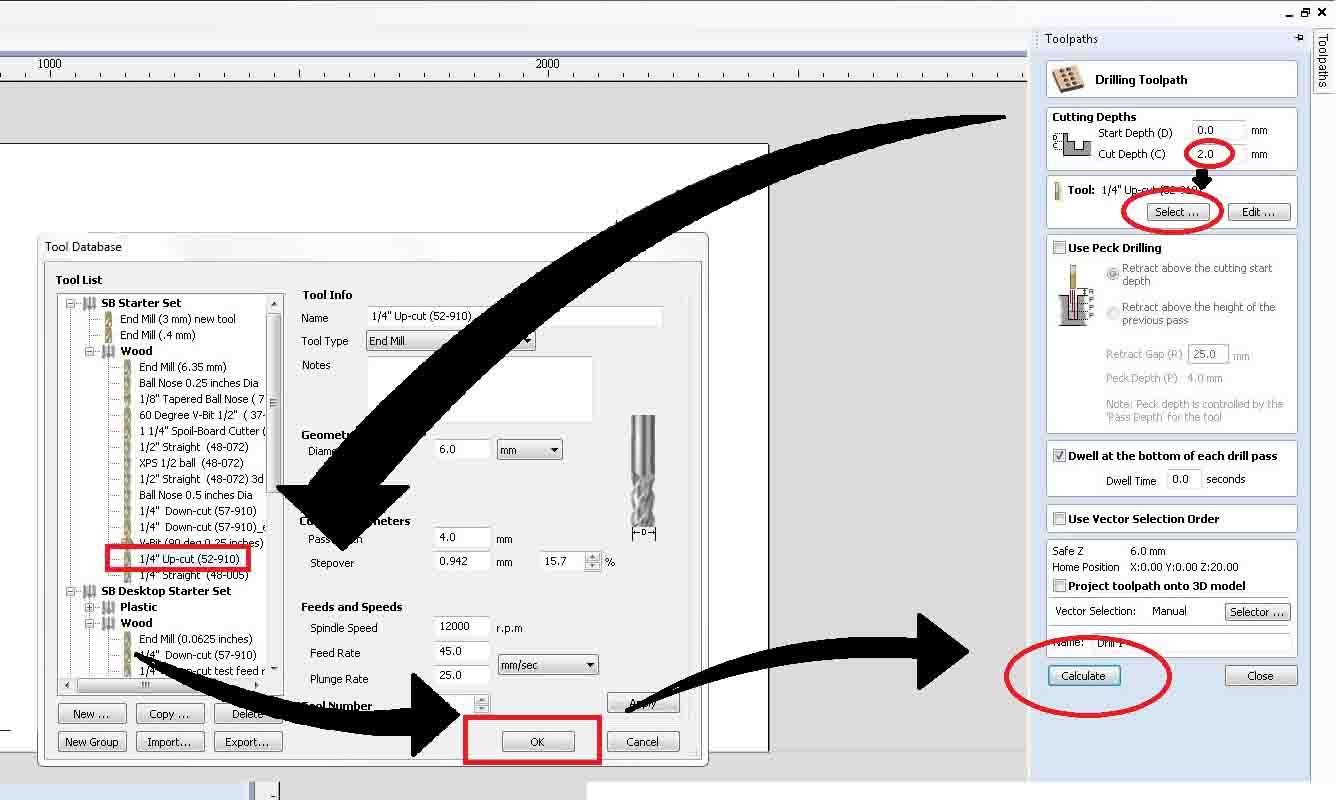

Here I have set a radious of "6.0mm" to the holes and set depth as "2.0mm". Next we need to create tool paths for each operations. For that select tool path from top right corner of the window. Click "Drillling Toolpath".

Now select each holes and group them. Set cut depth 2.0 and click "Select". We have to select the right tool for this operation. I am using and end mill with diameter of "1/4 inch".Select the end mill and click "Ok".

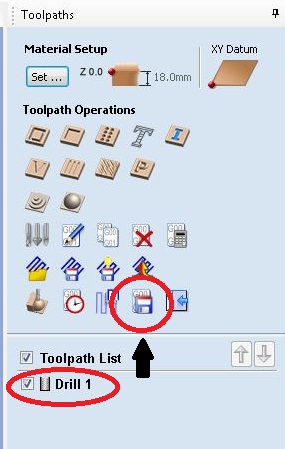

Now click "Calculate" to view the 3D pathway.

Now close it and it will take you to the main window. Now select drill 1 and click "Save" icon. It will save to required folder.

Now we need to cut the profile. For that click "Profile cut" from toolpath tab

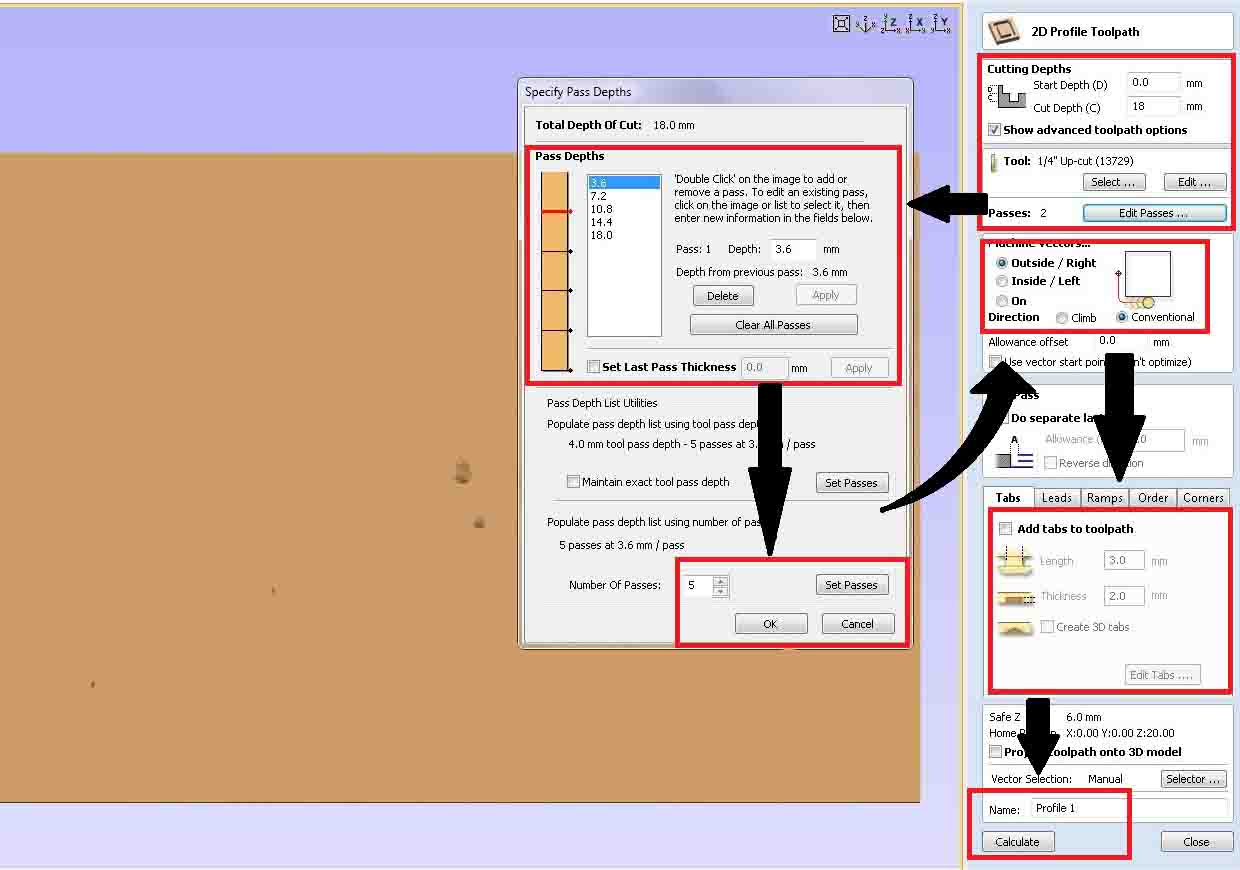

Set the following Parameters

- Depth=18 mm

- No. of passes=5

Now click "Ok". Now select "Macchine vectors" as "Outside". and add tab of following parameters:

- Thickness=2.0mm

- Length=3.0mm

Now give a name and save as we did in the Previous work. Finaly we got following window in screen

Now Let's start machining

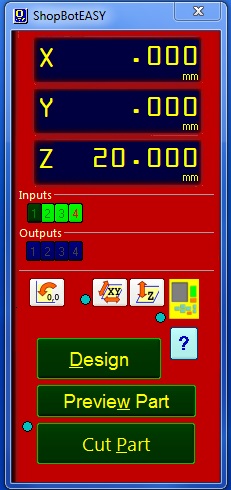

So we have prepared the toolpath. Now we need to cut it. for that open CNC controller.

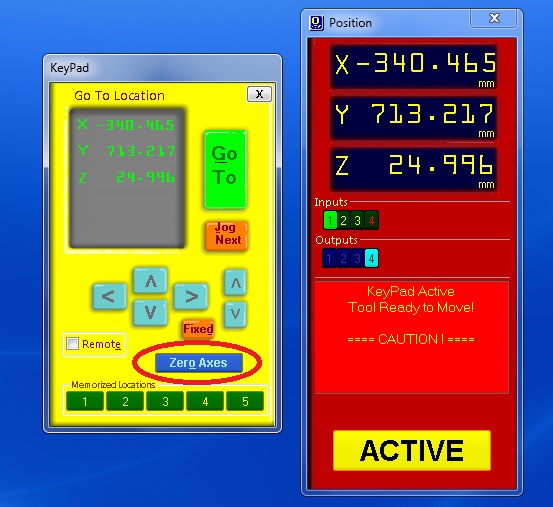

Now we need to reset the axes from the previous work. For that twist the controller in the control box and push Reset button.

Now open position control box and set X,Y and Z axes. Click on zero axis and tik all the boxes.

Now we need to add the file needed to be cut. For that click on "Cut Part". Open the Drill.sbp file and follow these steps.

- Click start

- Click "start" button to start the spindle.(Make sure to turn the key on.)

- Click "ok" on the screen

- The process will start immediatly.

I added the drill holes first to fix the work piece to the bed. After the milling I drill some holes and screw the work piece to the bed.

After fixing them to the bed, I started milling the rest of the pieces. After that, i bought 4 door fitings and some screws from hardware shop. its cost around Rs.130. Then i fit all things together.

Finally!!!!