Group Assignment:

This week group assignment was more of the same as what we did in laser cutting week because in this week also we had to measure the kerf but this time it was of the tool rather than laser. Follwoing attached picture is a very compact and basic example to test the kerf with pocketing and cutting on shopbot. We can see different size female-teeths, and the one that fits in perfectly with male-teeth would give us the error margin. In this figure also we tested engraving tool and did pocketing also as shown.

Individual Assignment: Make something big!

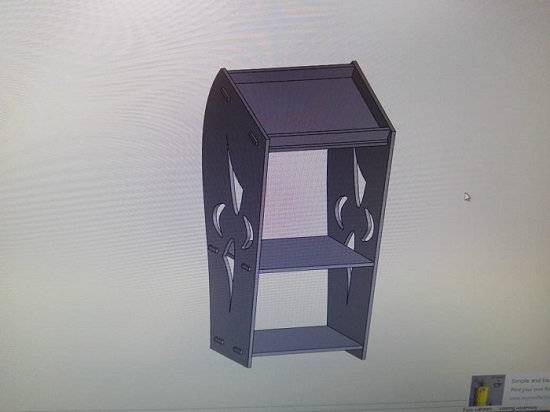

Idea of this assignment was to use shopbot primarily to cut a parametric press fit kit. To do so i had many ideas but none qualified for cutting so after searching for 3 long days i found this idea of making a podium from fab academy previous student. I sketched all of the following designs out of simple rectangles with average dimensions from google. I sketched main part of my design and that was side part. To cut evrything i made another assembly with top view of every part placed side by side.

To cut evrything i made another assembly with top view of every part placed side by side.

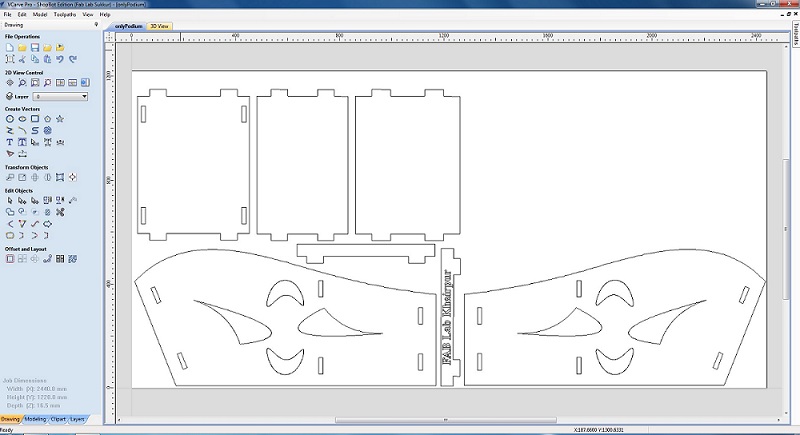

open Vcarve. Here first thing is to adjust the parts and make copies if needed using tool bar on the left side. I simply used move, rotate, copy-paste, etc tools to get following adjustment for an 4x8 sheet.

open Vcarve. Here first thing is to adjust the parts and make copies if needed using tool bar on the left side. I simply used move, rotate, copy-paste, etc tools to get following adjustment for an 4x8 sheet.

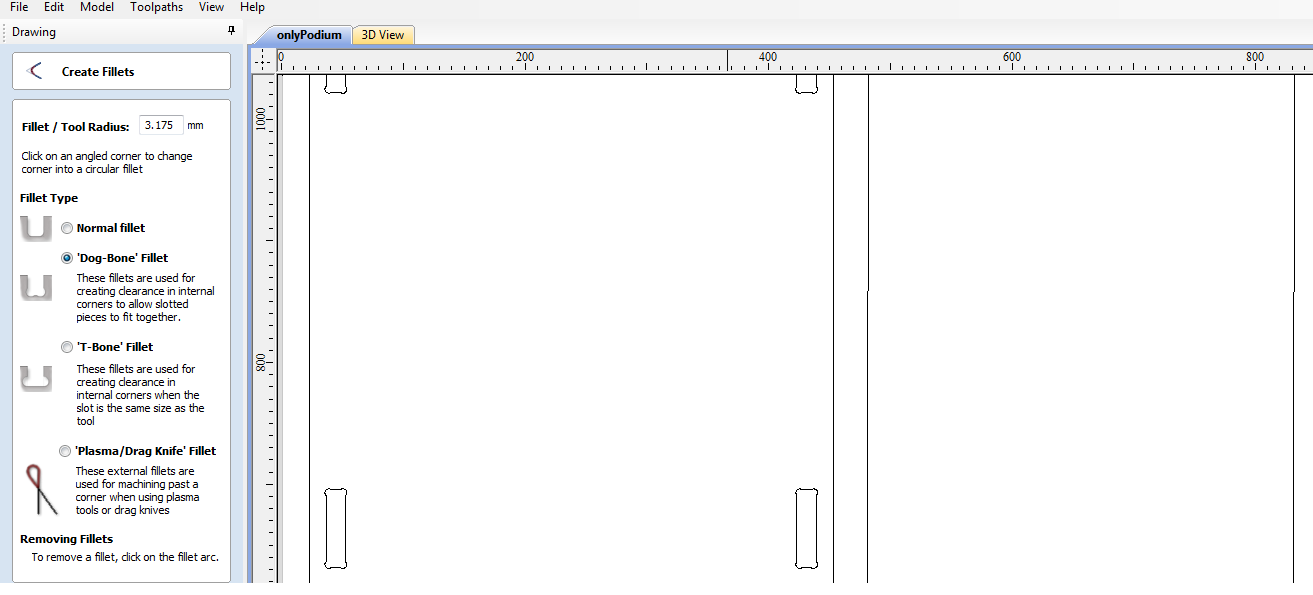

Next we make the dog bones as shown.

Next we make the dog bones as shown.

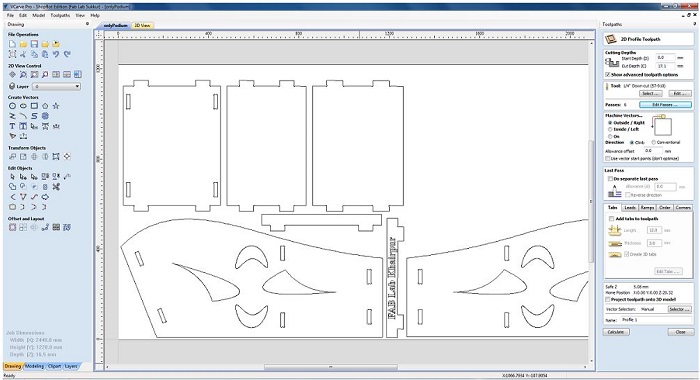

Now let's generate toolpaths..

Now let's generate toolpaths..

We need to specify the passes. Passes means number of turns machine should take to cut the part. To define passess we will devide our material thickness to the thickness per pass/turn, (e.g we need 3mm per pass/turn) so 18mm/3mm will let machine to take 6 turns to cut our design.

We need to specify the passes. Passes means number of turns machine should take to cut the part. To define passess we will devide our material thickness to the thickness per pass/turn, (e.g we need 3mm per pass/turn) so 18mm/3mm will let machine to take 6 turns to cut our design.

and Nothing more.. We have our podium ready.

and Nothing more.. We have our podium ready.

Click here to get design files.. Cut/assemble the podium and enjoy!

Click here to get design files.. Cut/assemble the podium and enjoy!

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License

Copyright © 2019 Azmat Hussain