This is the 12th week of fab lab related to aplication and implications. Prof Neil gave us a detailed lecture on the 10th of April 2019 on all these.

Task of the Week.

Propose a final project masterpiece that integrates the range of units covered.

answering the questions highlighted in the documentation:

What will it do?

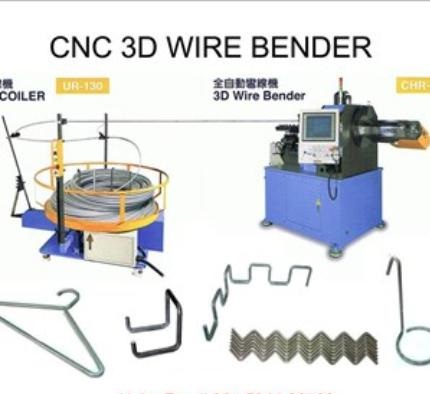

For my final project I want to make a Wire Bending Machine. It is not easy to make exact shape from wire with exact dimensions manually, So its better to make a machine for theis purpose, In market there are large

machines for the bending the wire for industry level. I will make a simple Wire bending Machine for my desktop in Fab lab.

large wire bending machine

Who's done what beforehand?

In market there are some brands that are manufacturing wire bending machines

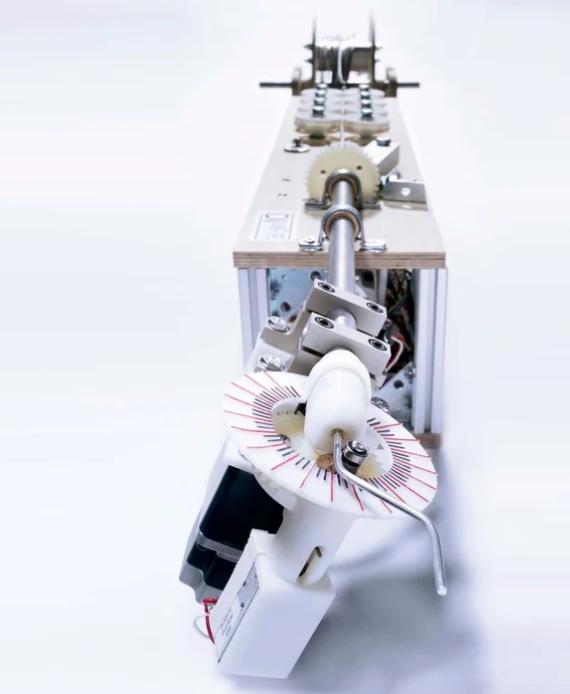

D.I wire is one of those brands(

Pensa labs). They are making wire bending machine for the table top.

Some refrences:

[01] [02] [03]

What will you design?

As discussed above, I want to make a wire bending machine, since it is really an important tool for our lab and its not avialable here. I will make a small bending machine

as in above picture that machine is too large and for industry level I will make it for small scale so we can make the small wire products.

This project will include all the necessary skills learnt so far; 3D printing, Laser Cut, Electronics Production, Embedded Programming, Input

and Output Devices.The Wire cutter will be capable of cutting the specified number of wires of the given length and diameter.

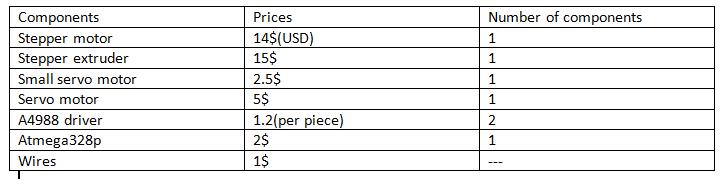

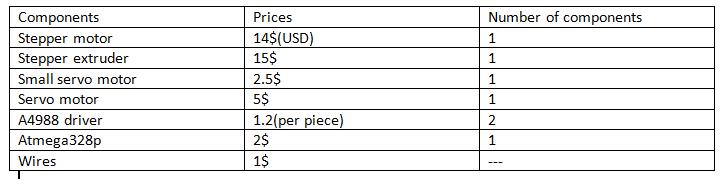

What materials and components will be used?

• Acrylic sheet-3mm as Base plate for placing the motors and bearings onto it

• Stepper motors and Servo motor

• A4988 Stepper driver

• Atmega328 microcontroller Board

• Push button

• 3D printed parts for motors and bearing

• 3D printed base Box

• Wires

How much will they cost?

Where will come from?

I took some of the components from the inventory of our FabLab. Including Acrylic sheet. I used milky acrylic sheet of 3mm width. Atmega328 Microcontroller,

in our FabLab's inventory, so I took them from my university's lab incharge, and some components like motors ,drivers I ordered Online from

Hallroad.

What parts and systems will be made?

• Electronics: The PCBs- mainboard of Atmega328 and the circuit for input and output.

• Laser Cut: The White Acrylic motor and bearing base for Project.

• 3D Prinitng: The 3D printed parts for holding motor , bearing case and main body.

• Input DEvices: For giving the data required for shape and the length of wire.

• Output Devices: Motors for bending.

• Programming: All the programming required for motors.

What processes will be used?

o Electronics: Eagle PCB Designing and interfacing of Atmega328 board, and input+output board.

o Electronics production:Fab modules, Milling, and Soldering.

o 3D designing:3D Casing designing, and Acrylic sheet, body designing using SolidWorks.

o 3D printing:3D Case printing on Ultimaker 2+.

o Laser cutting: Laser cut front panel for case on 3mm milky acrylic sheet.

o Vinyl cutter machine:stickers for labeling the input and output tagging on front sheet of acrylic.

o Programming:Writing firmware in Arduino IDE.

How will it be evaluated?

My project will be evaluated on the following parts:

• Video demo.

• Its designing on CAD softwares (SolidWorks).

• Showing that the Input and Output works fine.

• The wire cuts as per the given length and number of pieces to be cut.