Principles and Practices

Wednesday January 17, 2018

Preamble

Today I landed in Shenzhen City, China. Incredible! It's a super young city with an industrial and trade focus being strategically placed on the border with Hong Kong.

Due to the Great Firewall of China, I was unable to tune into the classes so Wendy (my instructor) snuck me a message in a bottle to start thinking about my final project. It was opportune that I was in Shenzhen at the time since any useful parts I may need in the future I would be able to source at the Huaqiangbei Markets. Some items I found, others I found but didn't want to carry around a 1000 quantity of.

I visited the Shezhen Open Innovation Lab (an affiliated FabLab), Lab Zero and Troublemaker Labs while I was there. That was super cool, but an experience more appropriate for a blog post!

However if you're working on something cool I'd love to hear about it. Perhaps there's a place for you there to develop it. Let me know!

What's it all about?

Basically this week was an administrative week but also time for us to get enthused about what we would build by the end of the course.The task that was asked of us was to plan and sketch a potential final project. Since I came late and didn't know much about the capacity of the lab I would be settled into, I didn't want to have a single project to set my heart on.

I joined FabAcademy to meet people and visit labs, however from a technical content point of view I had also wanted to solve a few recurring problems for me through technology. Other projects that were contenders for a final project included:

- Raspbuino

- A RaspberryPi and Arduino powered electronics diagnostics tool. Portable oscilloscope, logic analyser, programmable function generator and signal intercept and playback device.

- The idea is that you could plug the device into a range of equipment to debug controllers, serial commands and signal voltage anomalies. For example, you could record a signal from a working motor controller on a CNC machine and play it back on an erroneous motor controller (I have needed to do this previously, and a similar test was required between two motors on an electric vehicle). This type of device would also be quite useful for intermittent problems, for example a misfiring engine due to a sensor under intermittent thermal failure.

-

This project would focus a lot on

- GUI programming

- Data processing (python preferred)

- Circuit board design and manufacture

- 3D printing

- Laser machining

- Airspenders and Smartwear

- A suite of digital wear that can help the wearer. The main system would be an air cooling system mounted on suspenders (as in, hipster fashion suspenders) and would be powered off a battery (probably a USB battery like for charging mobile telephones). Having a power system onboard, it would open up to a bunch of wearable uses via a RaspberryPi Zero.

- The idea is that you could wear this all the time (especially useful in uniform or work gear) and it would assist the user to maintain comfortable temperature. This has particular usefulness for example with mining workers in desert environments like Australia or UAE due to the dry temperatures and requirement to wear sun protection and other protective equipment.

- Some examples of further enhancements available through data processing could include monitoring and profiling vital signs throughout the day (heart rate, temperature, etc.), activating a hands-free flashlight (or even using an ir camera for low-light vision assistance), and potentially using a machine learning dictation and translate service (at this point Google is the best option) to upload dialogue from the wearer and display it in another language in near-realtime. This would greatly increase the vocabulary of anyone in the process of learning another language.

-

This project would focus a lot on:

- 3D printing

- Textiles

- A bit of embedded programming

- A bit of networking

- Circuit board design and manufacture

- Potentially limitless functional programming and data processing (python)

- Luggage Rack

- A folding luggage rack that allows me to contain all my luggage in one package and add wheels - I brought a selection of my own tools with me on my adventure and it would be great to have a rack that allows it to be highly portable. Potential improvements were to add a dock which would make it a functional but limited workstation in a mobile environment (say, an airport, or on site), including a power board for laptops, USB power, a 3-20V power supply and maybe some other nerdy gadgets. But mainly, I just wanted to machine and mold some awesome wheels for my setup.

-

The idea is that I have two items of luggage - a hardcase and a softcase. The hardcase is for tools and although slightly smaller is a lot heavier, and the softcase is for papers, my two laptops and any associated computing peripherals.

-

This project would focus a lot on:

- 3D scanning

- 3D printing

- CNC machining

- Comprehensive CAD and CAM

- Moulding and casting

- Potentially composites work

- Potentially textiles work

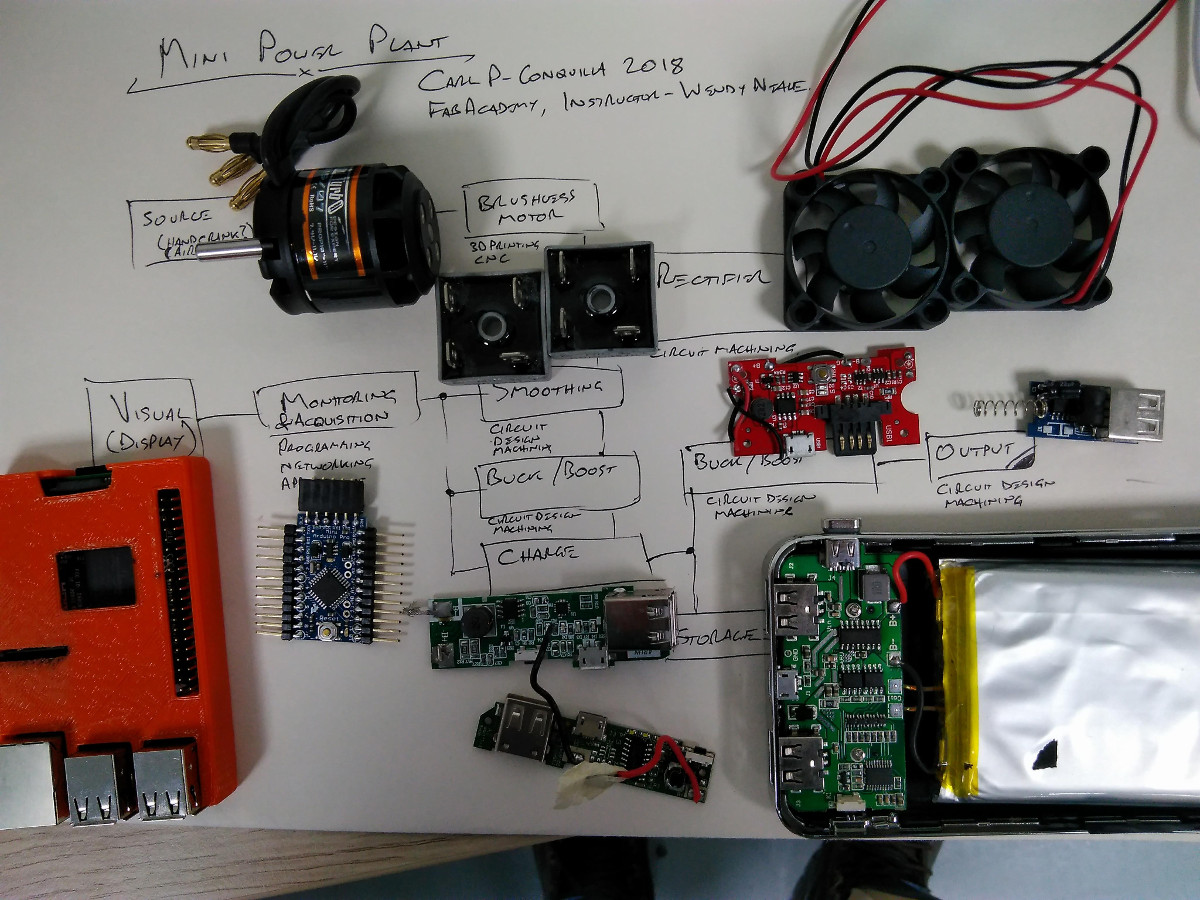

- Mini Power Plant

-

A power conversion device designed to convert rotating power into battery energy. More specifically, I'd like to couple a small engine with lithium batteries, theoretically producing a portable battery supply that can provide power for more than 24 hours.

You could also potentially use this in an 'eco-friendly' power source like a wind turbine or hand crank or something. That would be cool and all, but for now I'm focused on ridiculously high-powered applications. -

The idea is to have a rotating supply attached to a brushless motor, then rectifying the output to be usable. In lieu of an engine that I may not be able to get my hands on, a gearbox would be required to use another rotating source, probably a hand crank but also potenitally for the purposes of demonstration another brushless motor could be used.

The next step involves a serious amount of power conditioning in order to make that power usable, and I also imagine charging a lithium battery is going to take an amount of time to get stable. One of the major innovation elements with this project will be packaging in a clever way, and also making the entire assembly as light and portable as possible.

The final step involves data acquisition using an Fabduino sending data to a RaspberryPi to display the waveform of the rectified power to monitor efficiencies and understand how to improve the project in future. -

This project would focus a lot on:

- Circuit board design and manufacture

- 3D printing

- CNC machining

- CAD and CAM

- Laser machining

- Embedded programming

- GUI programming

- Functional programming

So Carl, what'd you end up picking?

Oh boy. In a rush, what I ended up deciding was the Mini Power Plant simply because it seems like the most innovative and most aligned with the skills I'd like to master.The other projects I'll still likely explore during my time here, but in a simplified embodiment. The skills I'm looking forward to picking up in the coming semester are CNC machining, circuit board design and manufacture and GUI programming.

In my time at university I found that the best way to learn is to be motivated by application, so I am intent on having a final project that exercises the skills I would like to master. This device is aimed at a future technology that will allow people to use their electronic devices for longer duration, and opens up opportunities for devices to use high amounts of power without the worries of running out of battery. It's not quite 'infinite power', but it's a practically tenfold increase in energy capacity for the many people growing up in an electronic world.