| Seonghee Kim | |

| 6. 3D Scanning And Printing | |

| HOME | ABOUT | ASSIGNMENTS | FINAL PROJECT| CONTACT | |

Week6

AssignmentS

-group assignment

test the design rules for your 3D printer(s)-individual assignment

design and 3D print an object (small, few cm) that could not be made subtractively

3D scan an object (and optionally print it)

Hardware and Softwares used

-Fusion 360

-Cura Creatable

-Creatable D2

-Kinect scanner

-Maker Bot

Outcome

I have tried 3D printing and 3D scanner before. This time We tried various types of printing value togeter such as length of T branches, slopes, bridges, joints. After some expriment, I got to know which value is good for 3D printing.

3D Printing

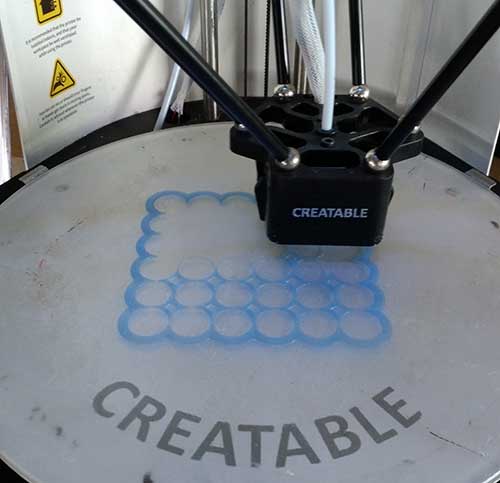

I tested the length of T branches and circle joints. For 3D printing, I have to do 3 steps; to design on Fusion 360, import to cura to make G-code, print on a creatable D2. Seoul Fab Lab use PLA 1.75mm

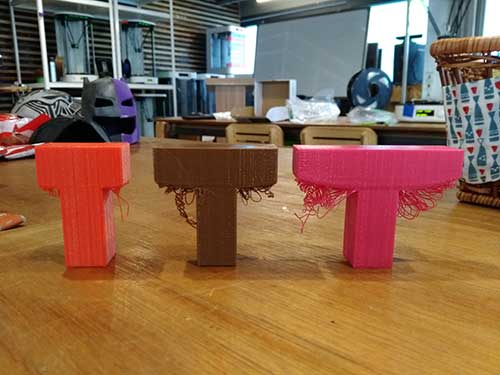

Tolerance Test: 3Ts on Creatable D2

To see how long T branch could be printed caccurate without support. T needs support even only 10mm. -3 Types of Ts without a support. The branch lengths are 10mm, 20mm, 30mm. Even 10mm has run down. Compare to bridges JinHyeok Nam made, T definatley needs the support. Taking time is 53min to 1h 50min.

-3 Types of Ts without a support. The branch lengths are 10mm, 20mm, 30mm. Even 10mm has run down. Compare to bridges JinHyeok Nam made, T definatley needs the support. Taking time is 53min to 1h 50min. -Import to cura, and change rotation of T.

-Import to cura, and change rotation of T. -Values form cura: Layer length 0.3, shell 0.8, infill 0.8, no support, no platform.

-Values form cura: Layer length 0.3, shell 0.8, infill 0.8, no support, no platform.Test 3 Circle Joints

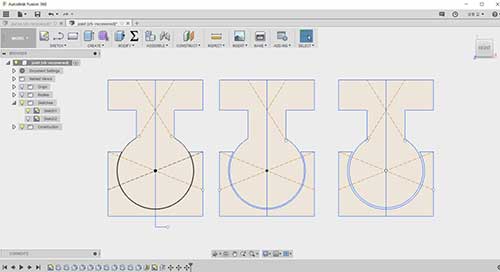

I want to make the firm circle joint, not loose one. So I tested 3 diffrent gap values. The hole of joint is smaller than the circle joint, it can not make substractively.

-From left 0.3mm gap, 0.6mm gap, 0.9mm gap

-I tried printing 3 at the same time, but one fall down and I failed all 3 at once, so next time I printed one by one.

-I tried printing 3 at the same time, but one fall down and I failed all 3 at once, so next time I printed one by one.-Too many run downs I can see, I need a support.

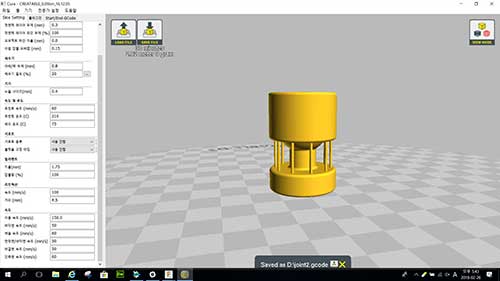

-Import only 1 joint this time. And because I don't want to make support in the gap, I designed a support where I want to be at fusion360 and select without support at cura.

-Import only 1 joint this time. And because I don't want to make support in the gap, I designed a support where I want to be at fusion360 and select without support at cura.

-Gap 0.3mm, 0.6mm joints are to tight so that it broken when I tried to turn it. Gap 0.9mm joint is nice to turn, but was not firm enough to stay.

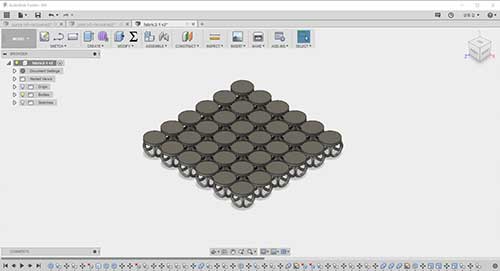

Modeling and print object suitable for additive design.

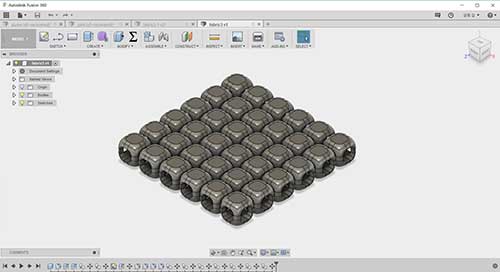

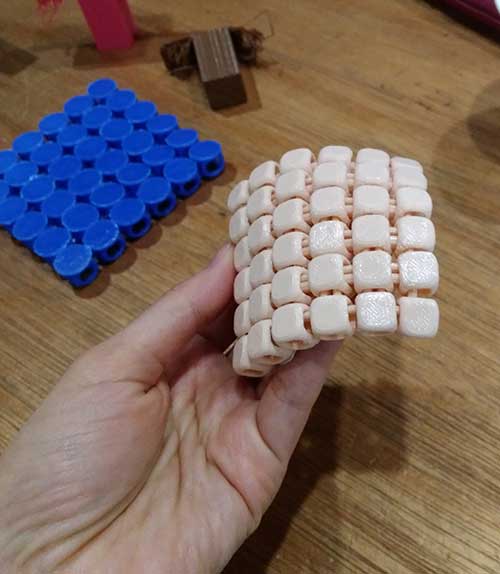

I design the flexible fabric-like 3d print. I printed 2 types of design and tried to make a small purse. Those are consited with elements linked together with rings before it manufautred. so it is strong and flexible.

Fabric type 1.

-Modeling on fusion 360.

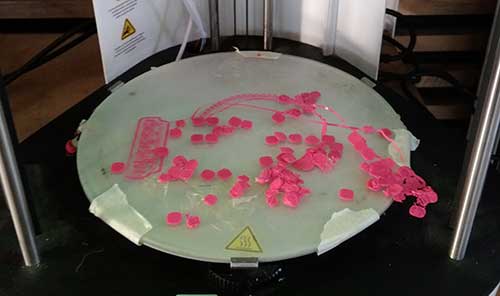

-Modeling on fusion 360.  -Brim platform is printing.

-Brim platform is printing.

-Printig rings for flexbilty.

-After taking off the brims.

Fabric type 2.

-Modeling on fusion 360.

-Modeling on fusion 360.  -Printing.

-Printing. -After taking off the raft.

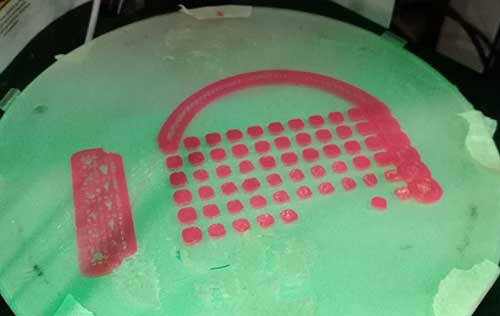

-After taking off the raft.Print small purse

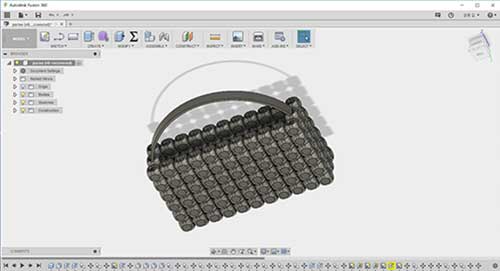

-I designed small purse with second fablic-like design. File size was too big so it slows the computer speed.

-I designed small purse with second fablic-like design. File size was too big so it slows the computer speed.

-Without any platform, it failed.

-Without any platform, it failed.

-With brim, without raft was also failed.

-Fail agian and also becuse of the support everywhere, it is not flexible.

3D Scanning: Kinect

check this video before start.

-Scan Euny with Kinect scanner. It's interface was easy to understand, but scanning was not easy at all. I tried 3 types of posture, but only 1 sucessed.

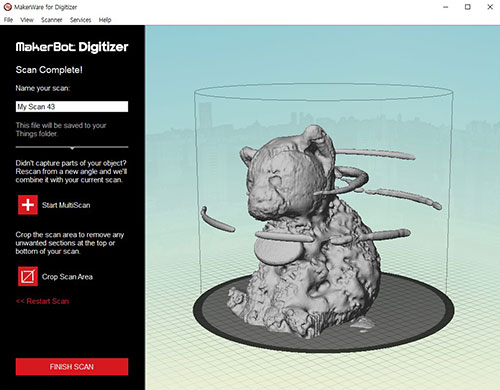

3D Scanning: Maker Bot

-I want to see how the fur comes out with the scanning. The result looks messy and creepy.

downloads

-click here to download fabric file.-click here to download the 3d scanning.

Date: 2018-02-27 Author: Seong Hee Kim @ Fablab Seoul