- design a machine that includes mechanism+actuation+automation.

- build the mechanical parts and operate it manually.

Introduction

This week's assignment is a team work. and we uploded our overall team documentation in our FabLab Kochi page. here i documenting my individual contribution .Actually Machine Week is Splited two part ,One is Mechanical Design and machine design. in the Mechanical Design week we bulilded our Machine and operate it manually.

In Mechanical Design week my job is to cut the material based on the design and assembling the Machine Parts, and i am not the only who did this all are my friends invloved with the these process .

Machine Design

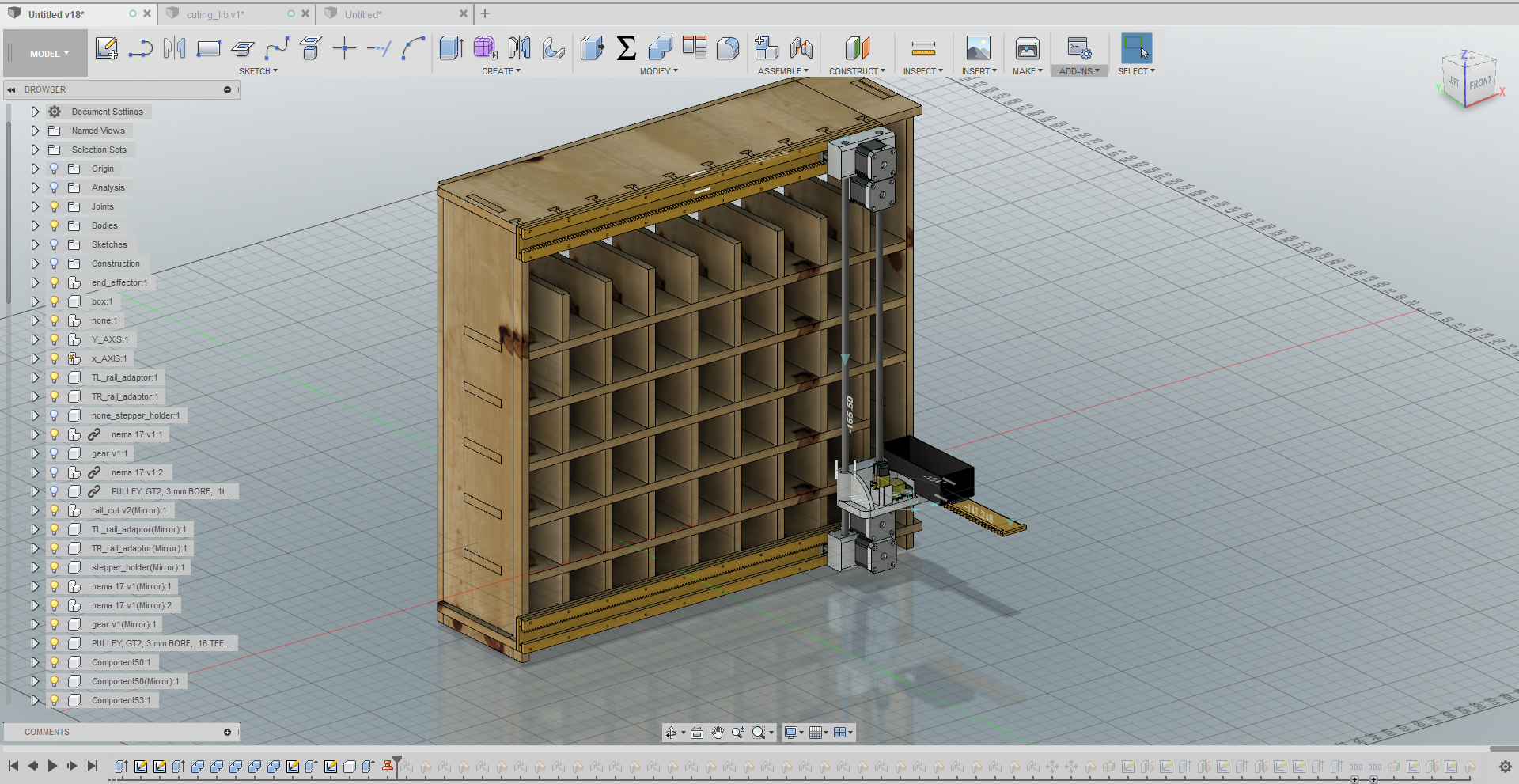

It's designed by Jogin Francis using Fusion360 I helped Jogin measure the rack size and box that we used in fablab . first we laser cuted the Prototype of linear rail in small size.

Now we can confirm the big part

Next we did the Shopbot Machining

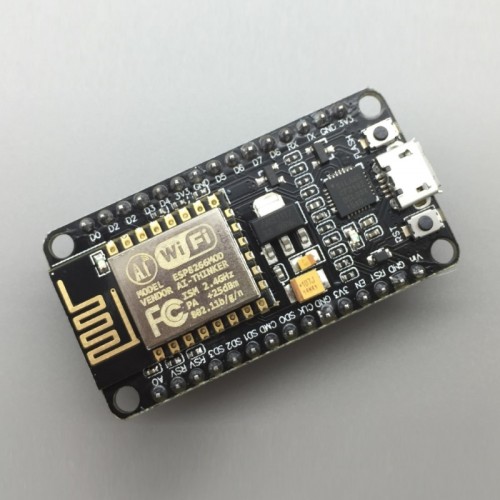

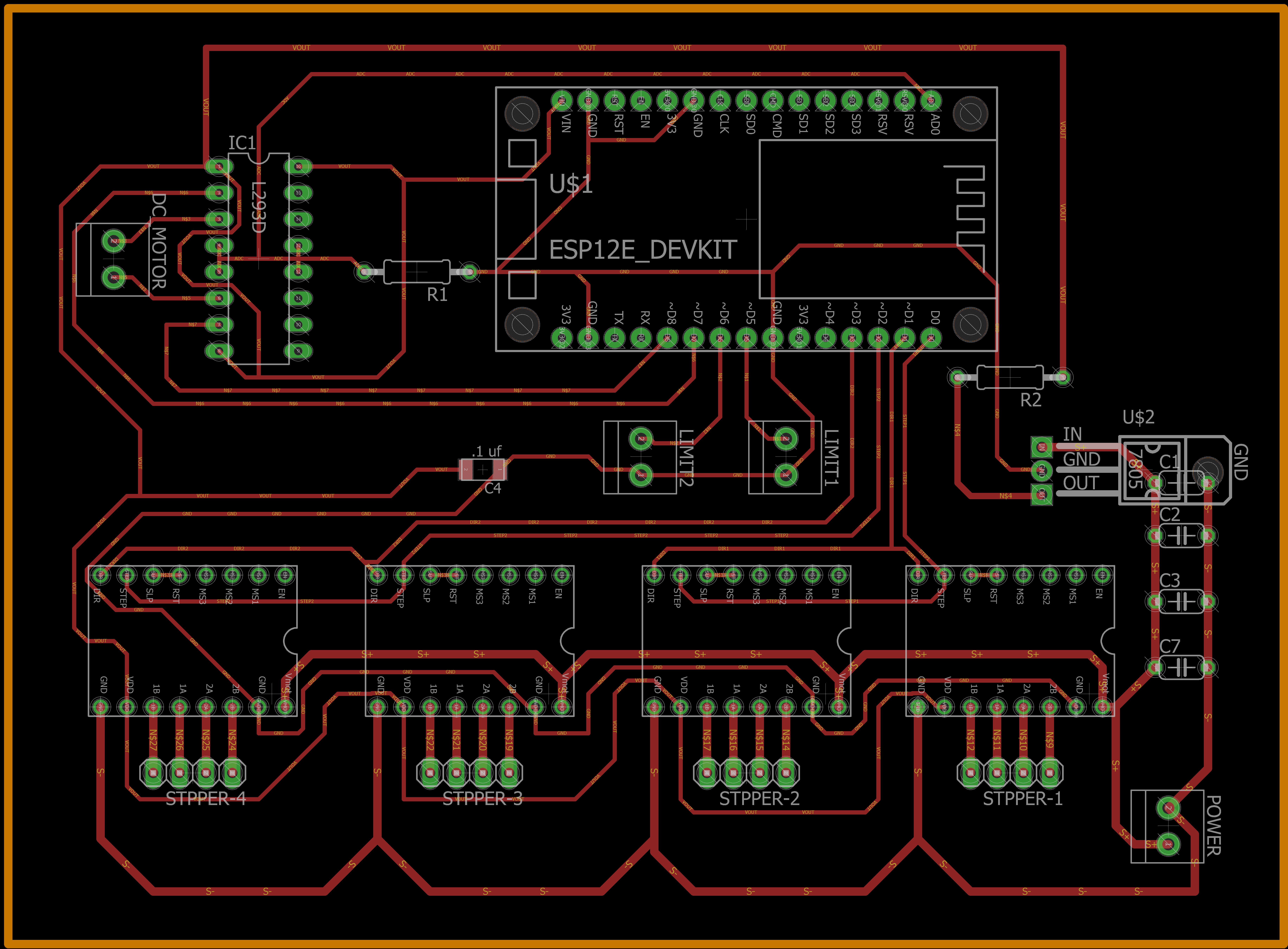

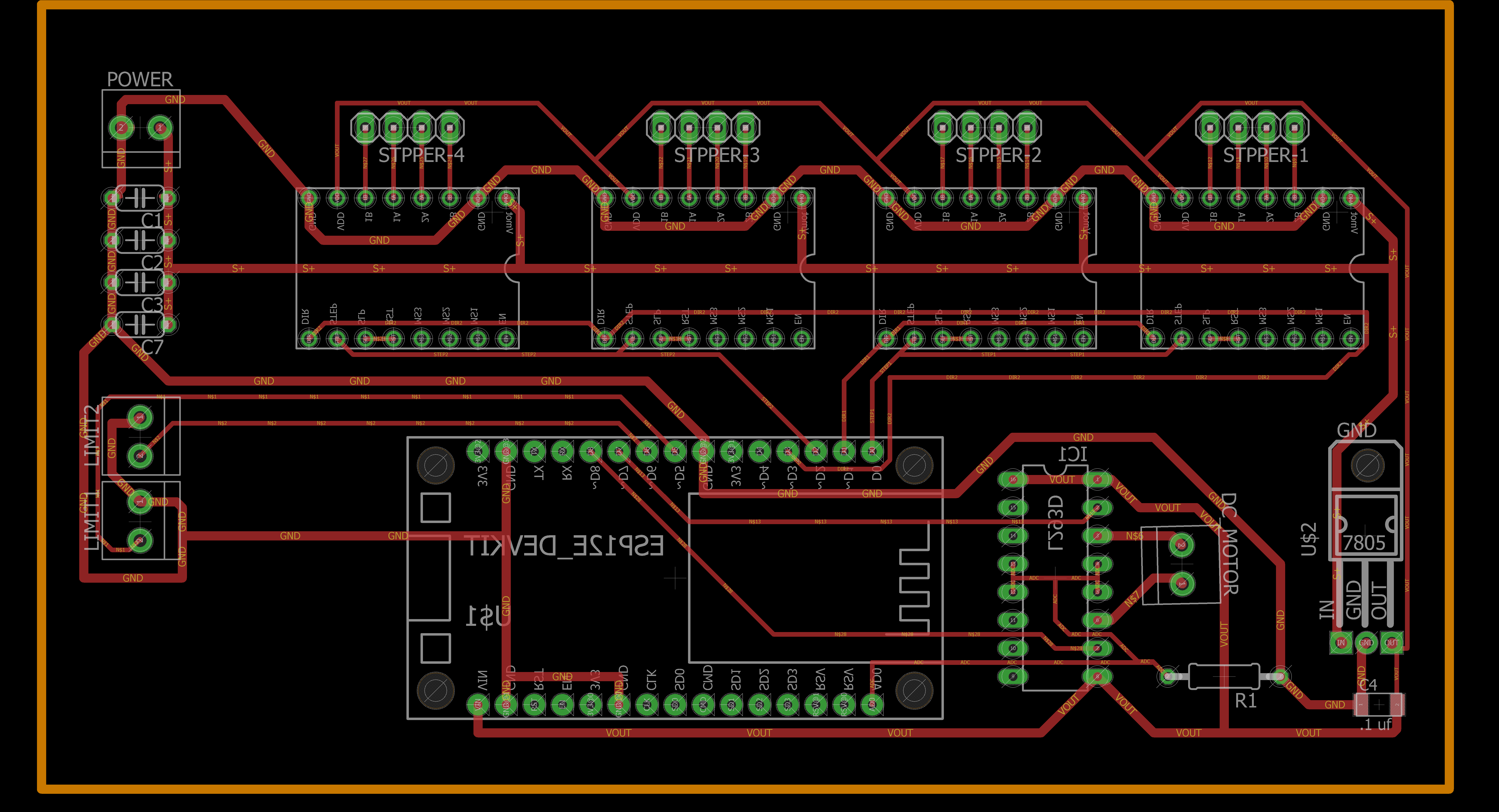

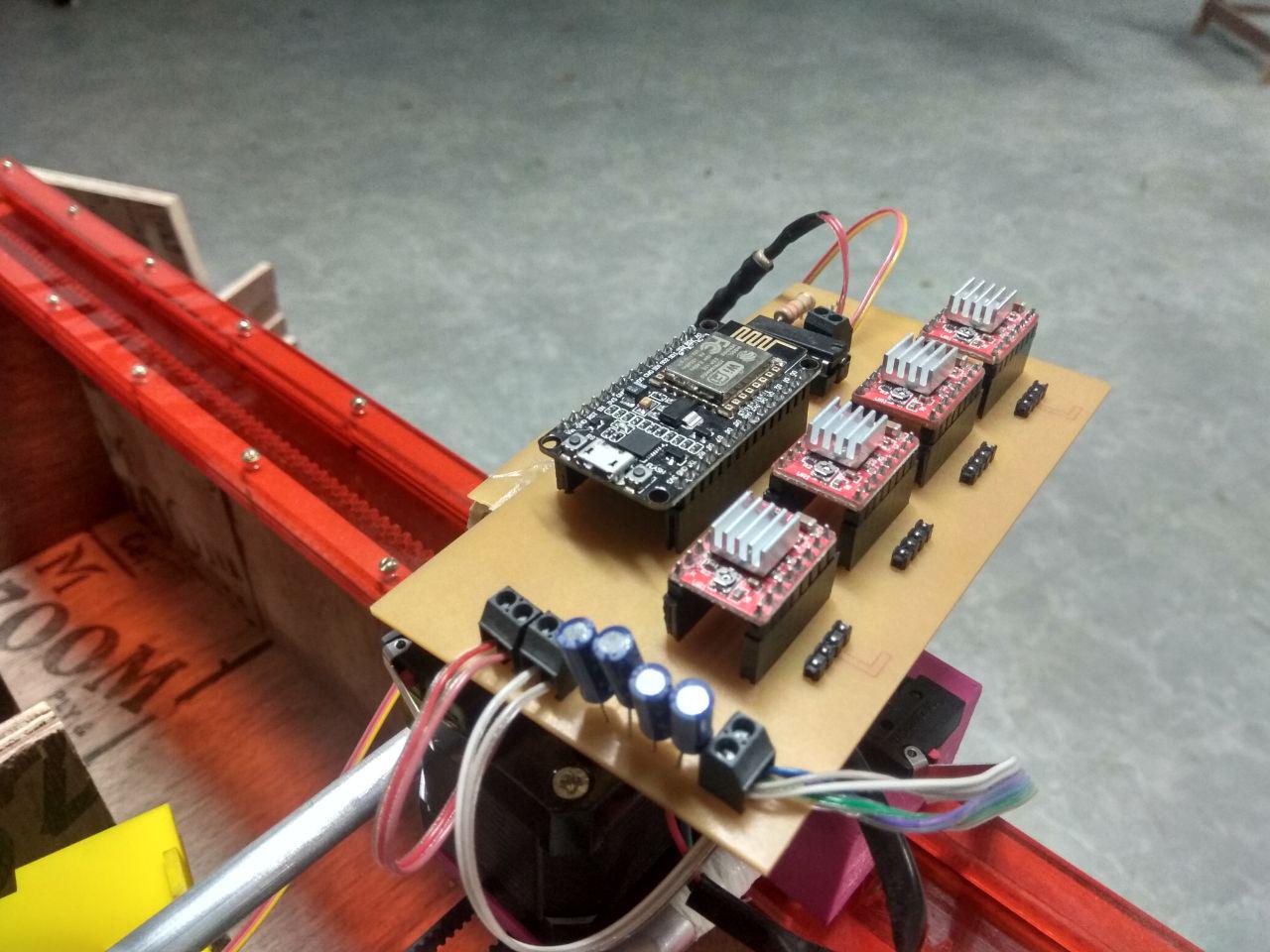

In Machine Design week my job is to Design PCB of main board and also develop Firmware.we choosed NodeMCU wifi Devlopment board as the main brain of our project , it's embedded with wifi so can simply contorl and monitor our machine remotly .and we used polulu stepper motor contoller.

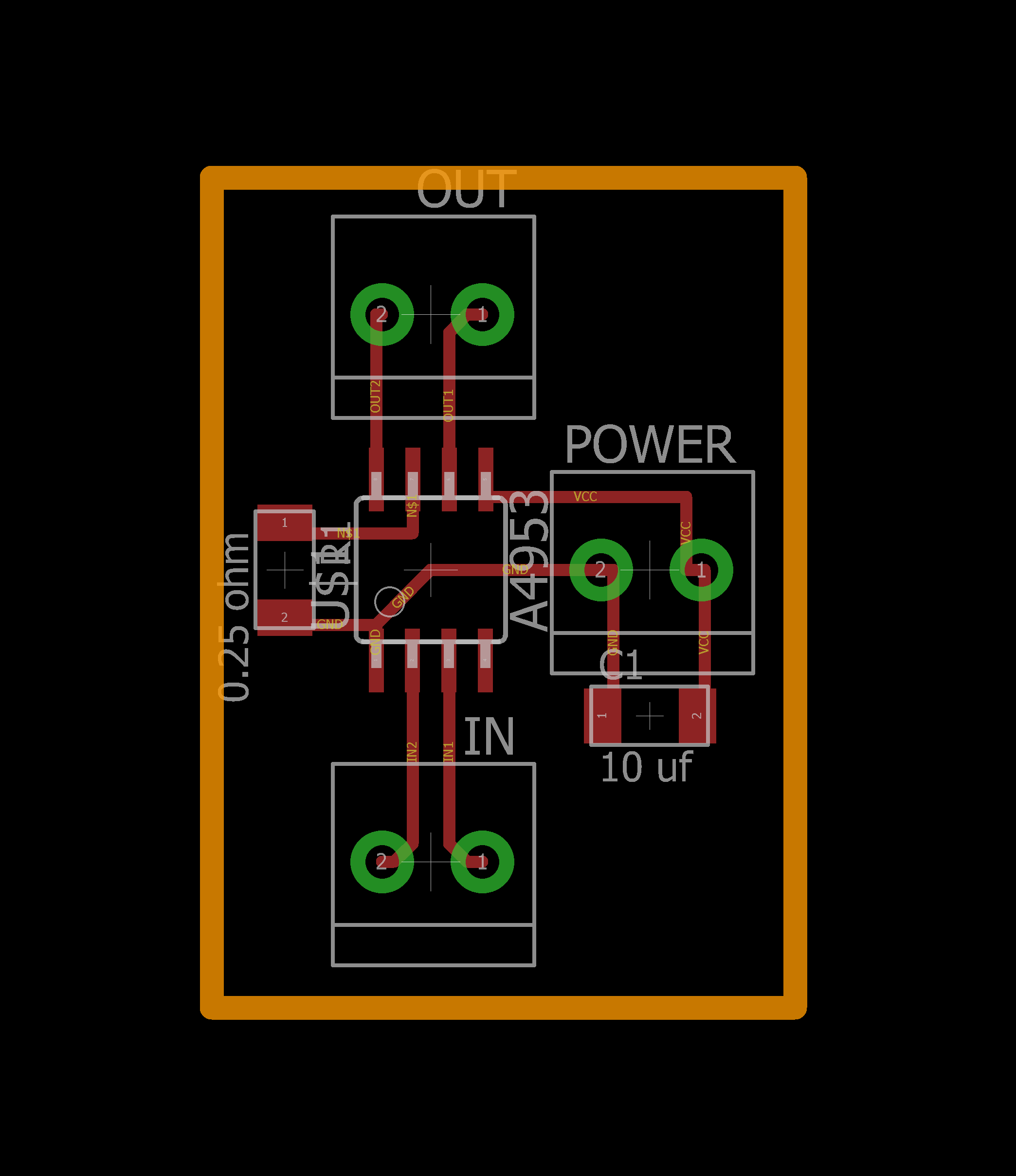

PCB Design

First all members come togther and we discussed about the hardware and it's feature , finally come with ESP8266 SOC(System On a Chip) , and it's not a good idea to use the barebone SOC so we picked the NodeMCU board it's a ESP8266-12E development kit

we can also flash Arduino bootloader in order to compatable with Arduino IDE and progarmmes.

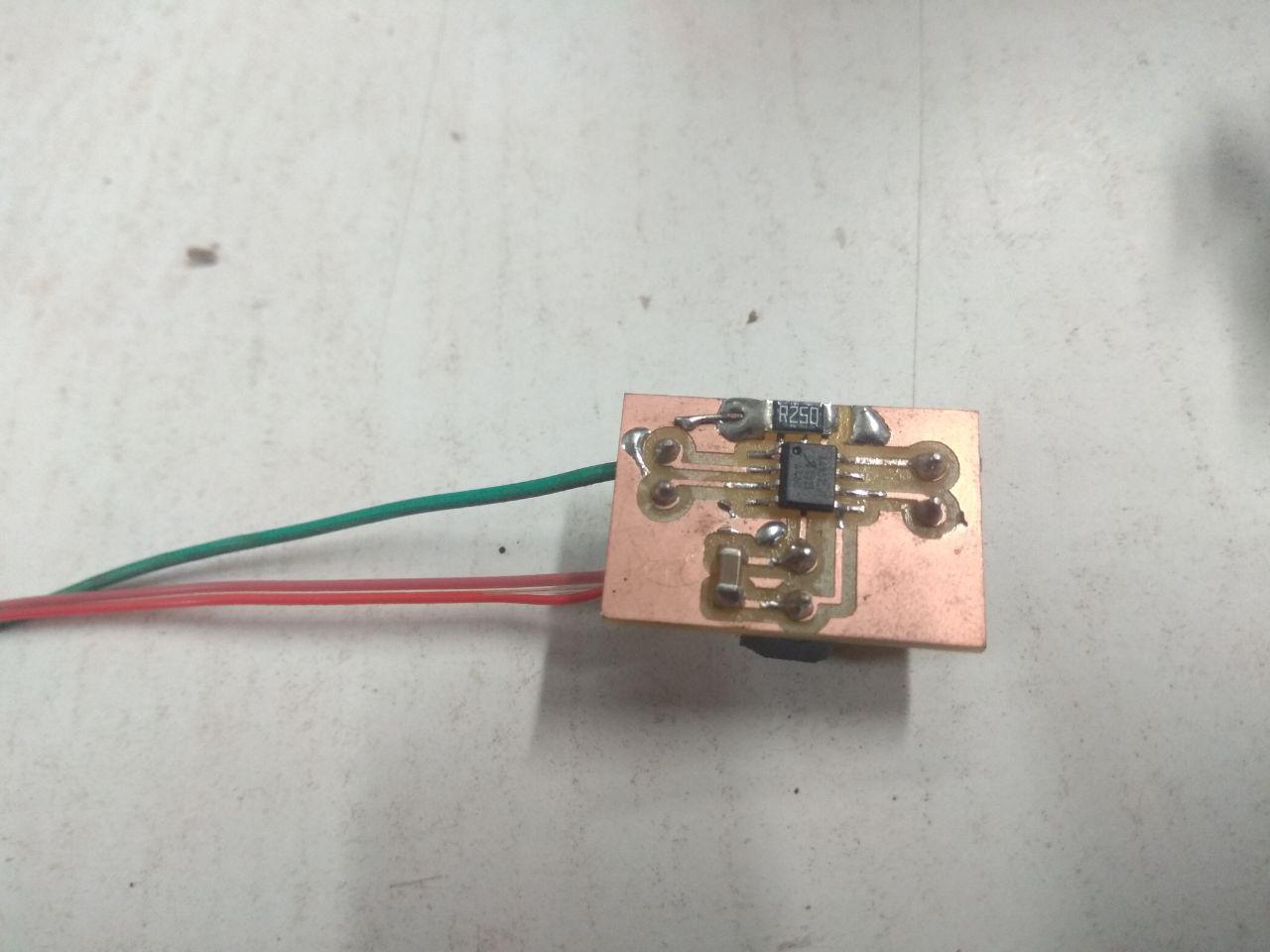

Started to dedsign in eagle , before that we tested each componets independely to enusre that will work as we expected . first i designed a motor driver based on the A4953 .

It's not worked as we expectd(some times it's stucked ) , so we choosed L293D, it's worked great so .

So after that we tested the stepper motor and other parts , then i staretd design main board .

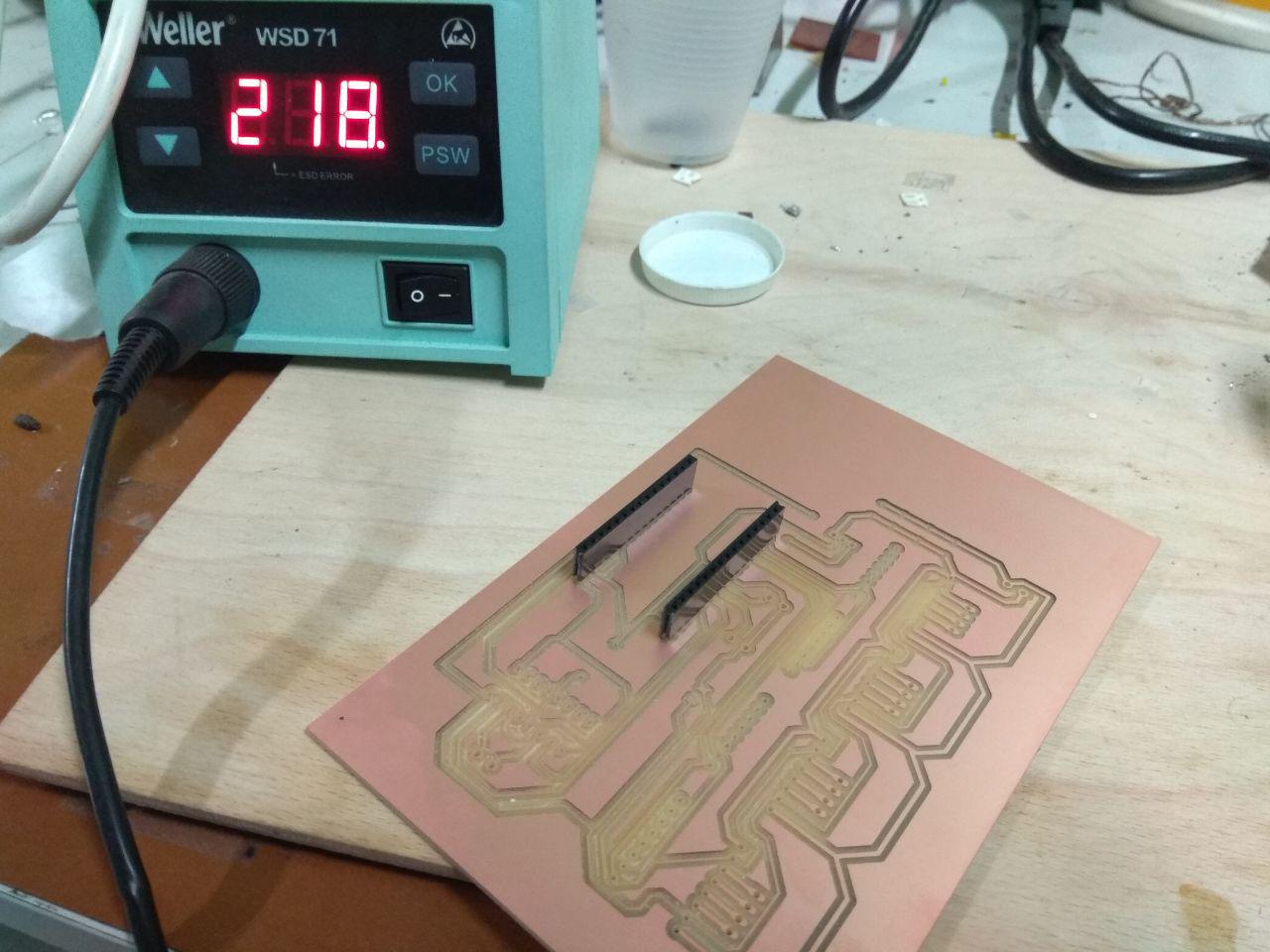

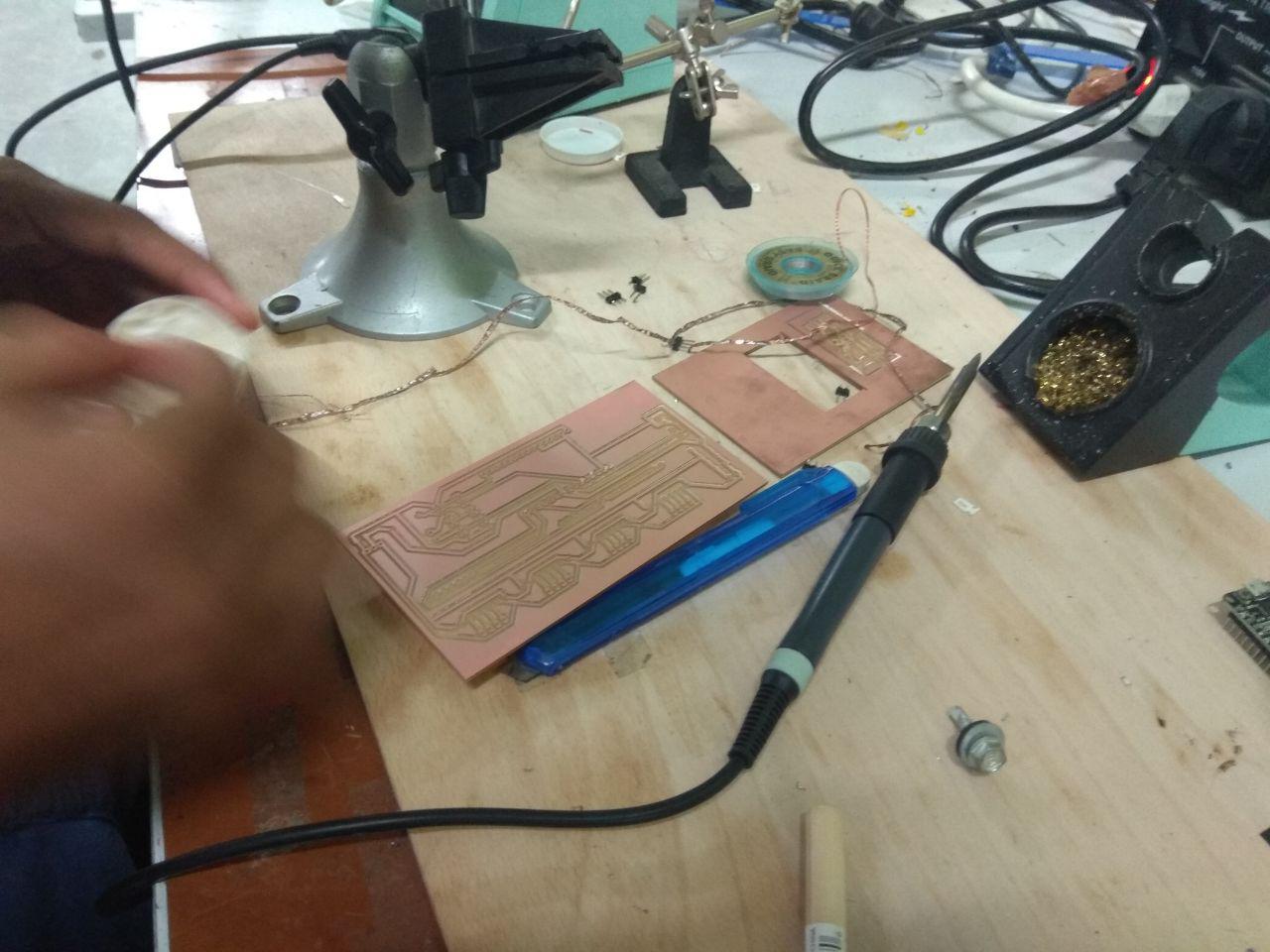

PCB Milling and Soldering

One of the biggest problem is we can't solder it very well, because in design i did't mirrored throgh-hole componets ,so it become a mess . i re-designed it fully.

in this new design i can reduce the size of the pdf, it's actually a plus point.

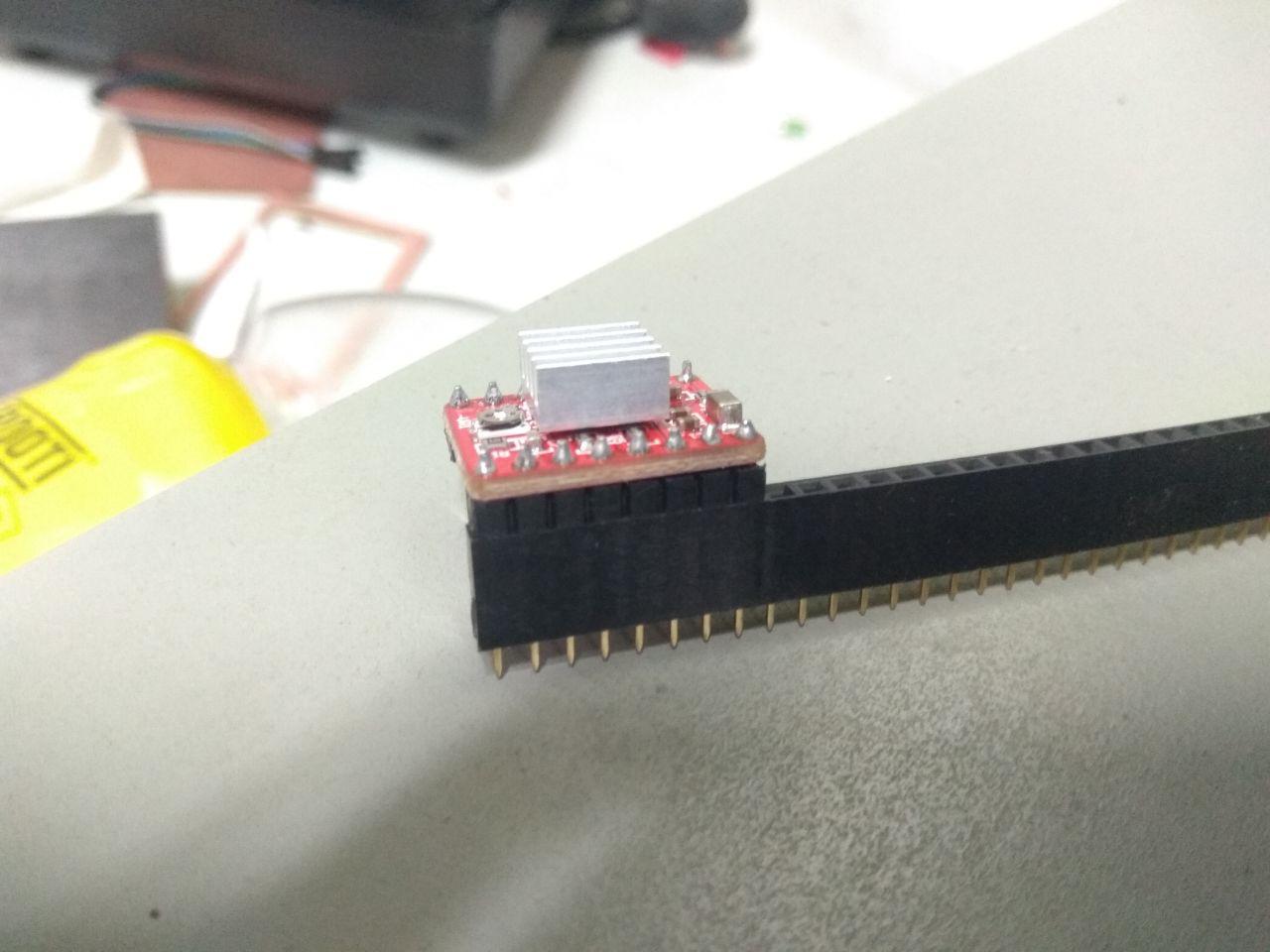

I used Female pin's for attching Polulu Stepper Driver

Demo Video Samples

=> Endeffctor prototype

=> Vertical Rail model.

This is my contribution to Machine Week .

Group Assignment Page

Click here to view group Assignmnet