Week 8

Computer Numeric Control

In this week assignment, we need to learn to use a CNC machine. First we need to do a group assignment to understand some parameters of CNC machinie.

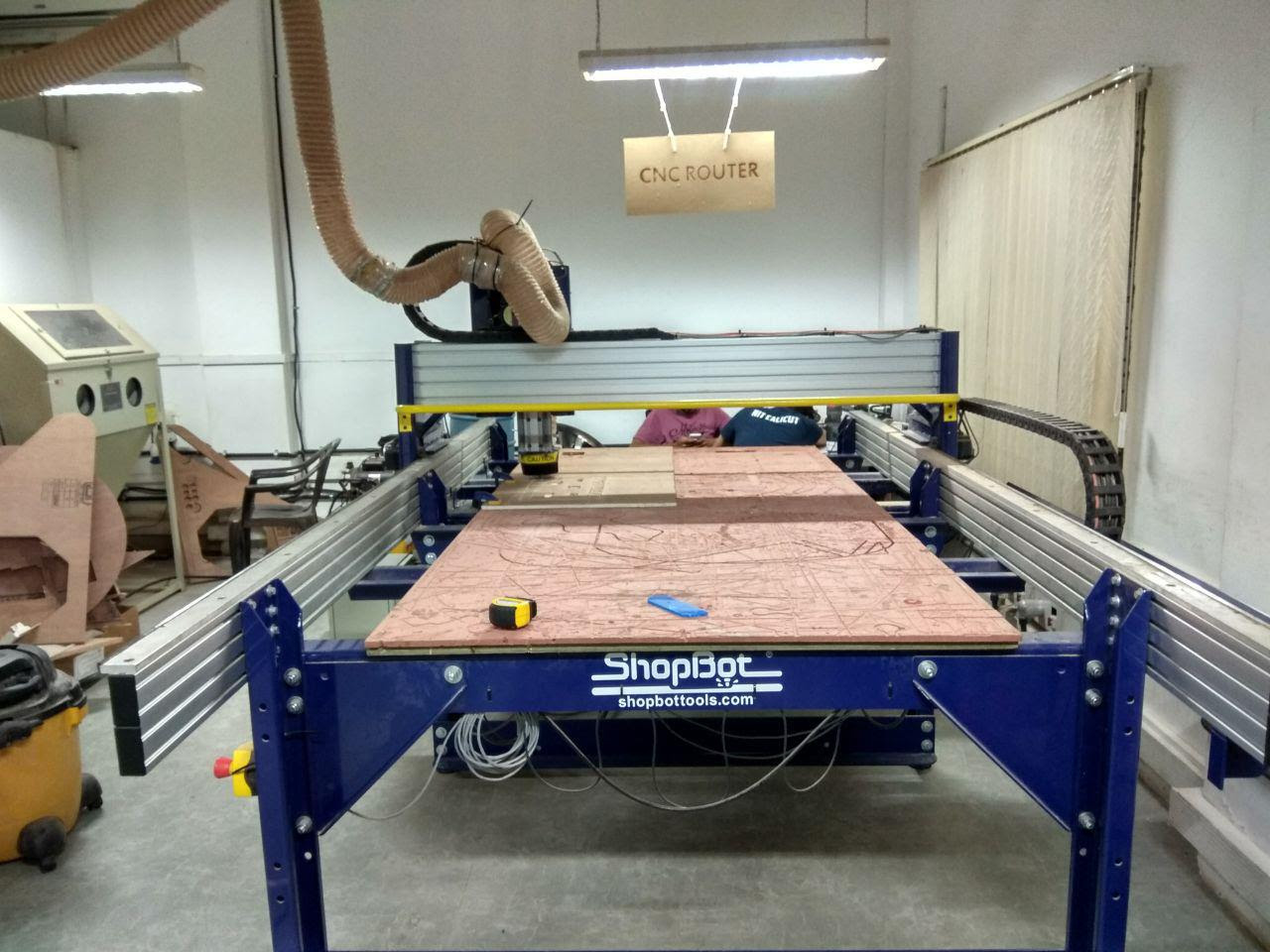

CNC stands for Computer Numeric Control it is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders.The process involves creating a CAD(Computer Aided Design) file of the desired object. Then a specialized CAM (computer aided Manufacturing) software is required to convert the 3D CAD file into a set of codes which the machines can understand. CNC machining language, called G-code essentially controls all features like feed rate, coordination, location and speeds.In our Fablab kochi we have full Size PRSalpha CNC.

Safety Precautions

Safety is always comes first when you are gonna use CNC machines or other big machines anywhere.We always double check the safety gears when using CNC machines in Fablab kochi. Here is the Safety Gears we use in our Fablab.

I have got a great idea to make a table.I started thinking about the table and how should the table look like.

Steps for making the table

1.First I Designed the 2D image with the help of Rhino

exporting the design

Seting up the machine

2.We need to setup the machine before Cutting, so first clean the sacrificial layer and load a new Plywood of 18mm.3.Then I used ShopBot Control Software to set the X and Y axis.

4.I set the Z axis using a steel plate.

5.I used F-clamb to secure the wood in the scarificial layer.

6.Also we need to fix it with screw , so first i designed the screw in my design so i can make sure that the Spindle will not hit the screw.

7.I added Dogbone for fitting the Pressfit.

8.Then I need to make the cutting settings. I used Profile cuttings, Drilling and pockets to complete my designs.

9.After setting all I need to click on the start button.Now the machine starts to do it's job.

parts of CNC

1.control box

2.spindle key and spanner

3.power distribution box

4.vacuum system

tools used in CNC

The concept of computer numerical control (CNC) incorporates a wide range of machines that perform various functions. These CNC machines are designed with precisely crafted tools to aid in the production process. Here is a basic overview of some common tools that are involved in CNC machining:

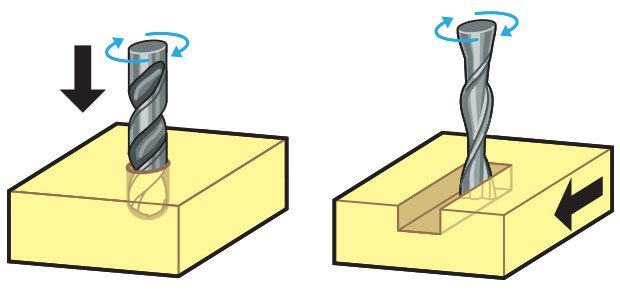

CNC Cutting Tools

The majority of CNC machines utilize some types of cutting tools. These tools perform precise cuts on metal, wood, steel, aluminum, and a variety of other materials. Multi-axis cutting tools can move in many directions, enabling the most precise cuts possible on the materials at-hand. Plasma cutting tools and water jet cutting tools offer unique ways to cut materials that are different from the traditional sharp-ended cutter. These tools use plasma and water to cut through a desired material, which can be extremely effective in certain cases.CNC Drilling Tools

Drill bits and other drilling tools allow CNC machines to drill through any type of material that a user wants to manipulate. Drilling tools can be very high-powered, which allows a machine to drill through most materials of any size and thickness. For instance, if you’re looking to drill 4 holes in a slab of metal, this can be done quite easily with CNC drilling tools.CNC Router Bits

CNC router bits are the cutting implement that are found at the end of a spindle on a CNC router. CNC router bits have the capability to cut materials like aluminum, brass, copper, and a variety of non-ferrous metals. They can also cut fiberglass, plastic, PVC, tiles, and wood.ball and flat points of bit

final output