Week 4

Vinyl cutting and laser cutting

In week 4 we are introduced in to the machines like vinyl cutter and laser cutter.As my fourth week assignment I have to make a parametric design and laser cut the design and also I should need to design a logo and use vinyl cutter to make a sticker. I used Rhino to design parametric designing and photoshop to design a logo for vinyl cutting.Unfortunately photoshop was not getting installed in my laptop so I used FAB laptop to do the assignment.

Vinyl cutting

Vinyl cutter is a computer controlled cutting machine.Its working is same as a printer.Like a printer controls a nozzle,the computer controlsthe movement of asharp blade over the surface of the material.This blade is used to cut out shapes and letters from sheets of thin self adhesive plastics.

To cut out the design a vector based image must be created in software programme.It is then sent to the cutter where it cuts along the vector path laid out in the design.The major limitations with vinyl cutter is that they can only cut shapes from solid colors of vinyl.

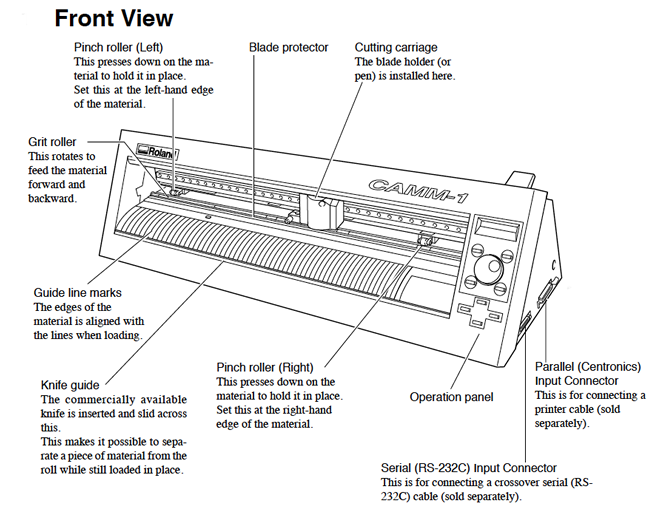

In our fab lab we use Roland vinyl cutter.It has a sharp blade to cut the materialsand it can move in X and Y axis.Tha commonly used materials in vinyl cutter is vinyl sheet ,paper etc

Our instructor gave us an introduction to the Roland vinyl cutter and information on how to set up the machine like setting the origin, changing the material types to roller or pieces, he even demonstrated a test cut to show us the procedures involved.We used the Fab module in ubuntu to set up the file and to adjust the cutting force and speed.

Our instructor also showed us how to transfer the pieces of vinyl to the required surface using a masking tape.

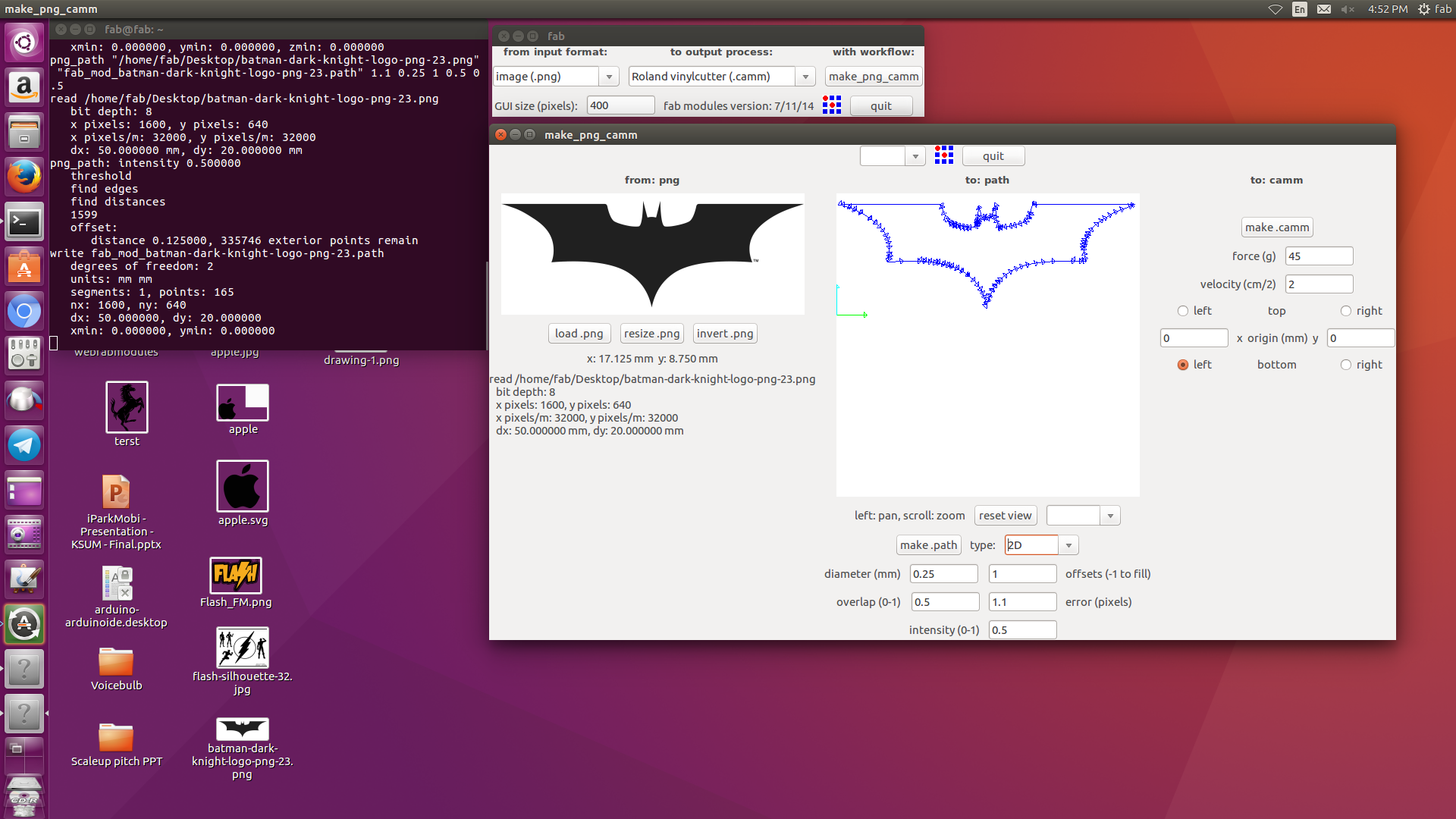

I like super heros very much.So I decided to try for batman for

vinyl cutting and make a sticker.After making the sticker I remove unwanted parts from the sticker.

for vinyl cutting I followed these steps

First I downloaded the image of batman which I wanted to print.

this is the link which I used for downloading the picture.

:- https://www.google.com/search?q=batman-dark-knight-logo-png-23&client=ubuntu&hs=wIj&channel=fs&source=lnms&tbm=isch&sa=X&ved=0ahUKEwjO9JbEq4jeAhUE3Y8KHRikBoUQ_AUIDigB&biw=932&bih=933#imgrc=Mx3Uxko_4PtMHM:

Then I put the image in fabmodules.

I clicked make.path.

Then I pressed make.camm.

After that I pressed send it.

for setting the michine

First we load the vinyl paper into the machine,for that:-

release the knob on the left back side.Then put the paper and tighten the knob.

Then we should selesct edge,piece or roll and then press enter.

Then you select the origin to print.

After that you can give the command to print your design.

After completing the vinyl cutting I got the picture of batman and I pasted it on a glass surface.

laser cutter

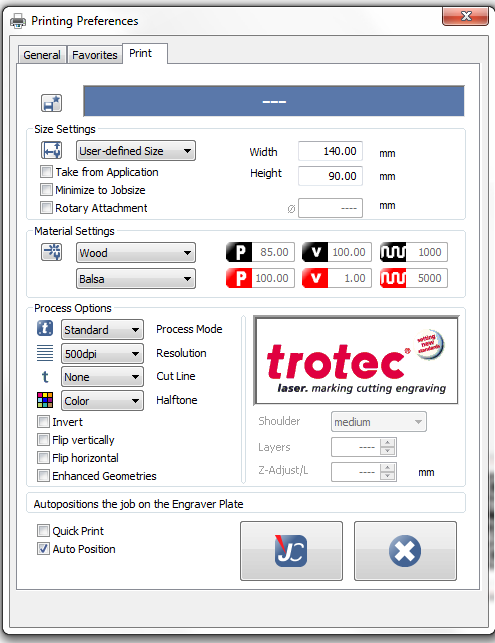

In this week we have to make laser cut of a parametric design and make a laser cut of it. Laser cutter is not as simple as vinyl cutter.Its laser beam ,its fumes smokes etc have bad effects also. But the filter used here will take out all the gases and fumes. Here in fab lab we used Trotec speedy 100 laser cutter.This laser cutter uses carbon dioxide laser for generatinghigh energy beam. The Speedy is the ideal laser engraving machine - whether you start your business or want to speed up production. Speedy laser engraving machines come with the JobControl® laser software. It is easy to learn - a 15minute tutorial is sufficient to start laser engraving and cutting.

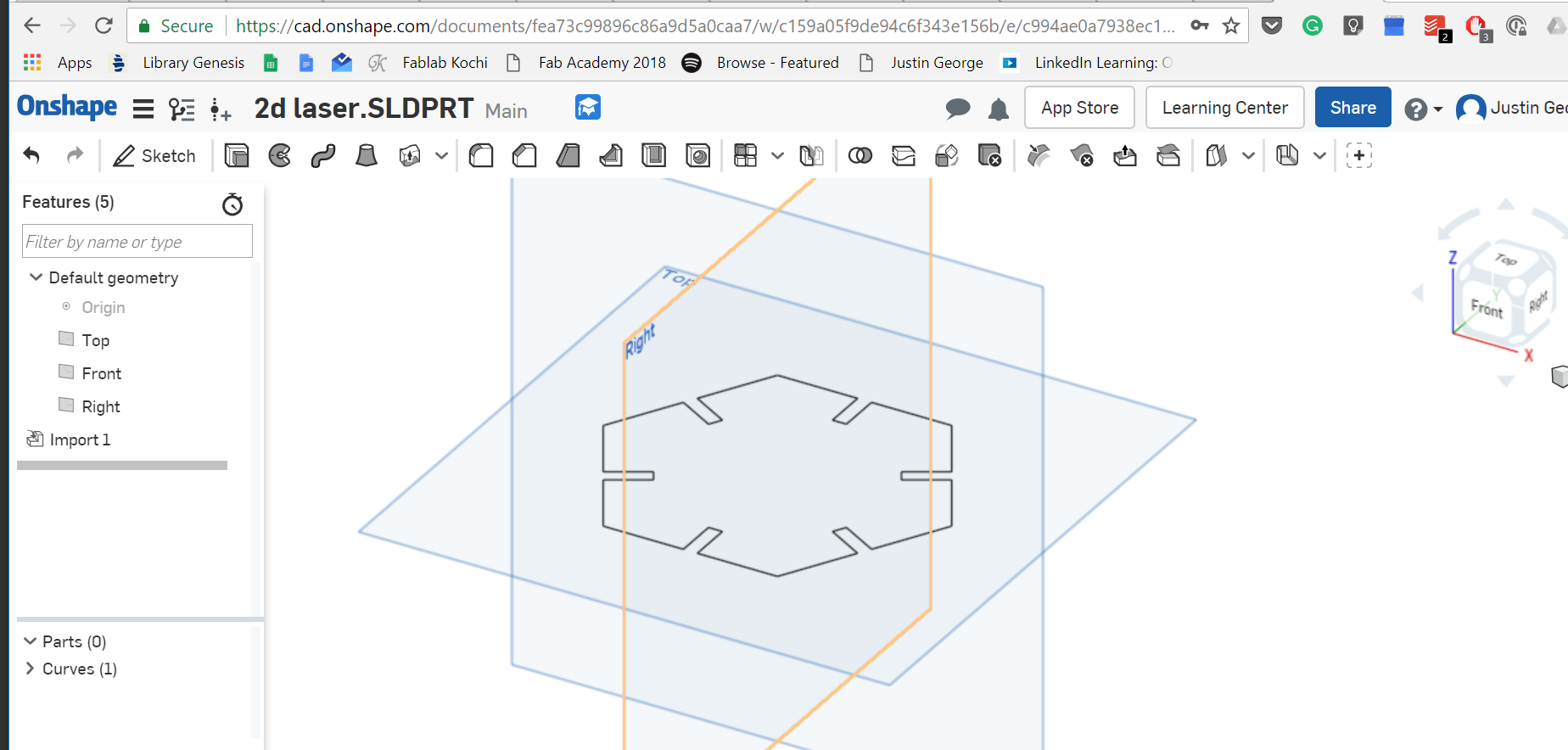

For this week assignment I decided to make press fit .

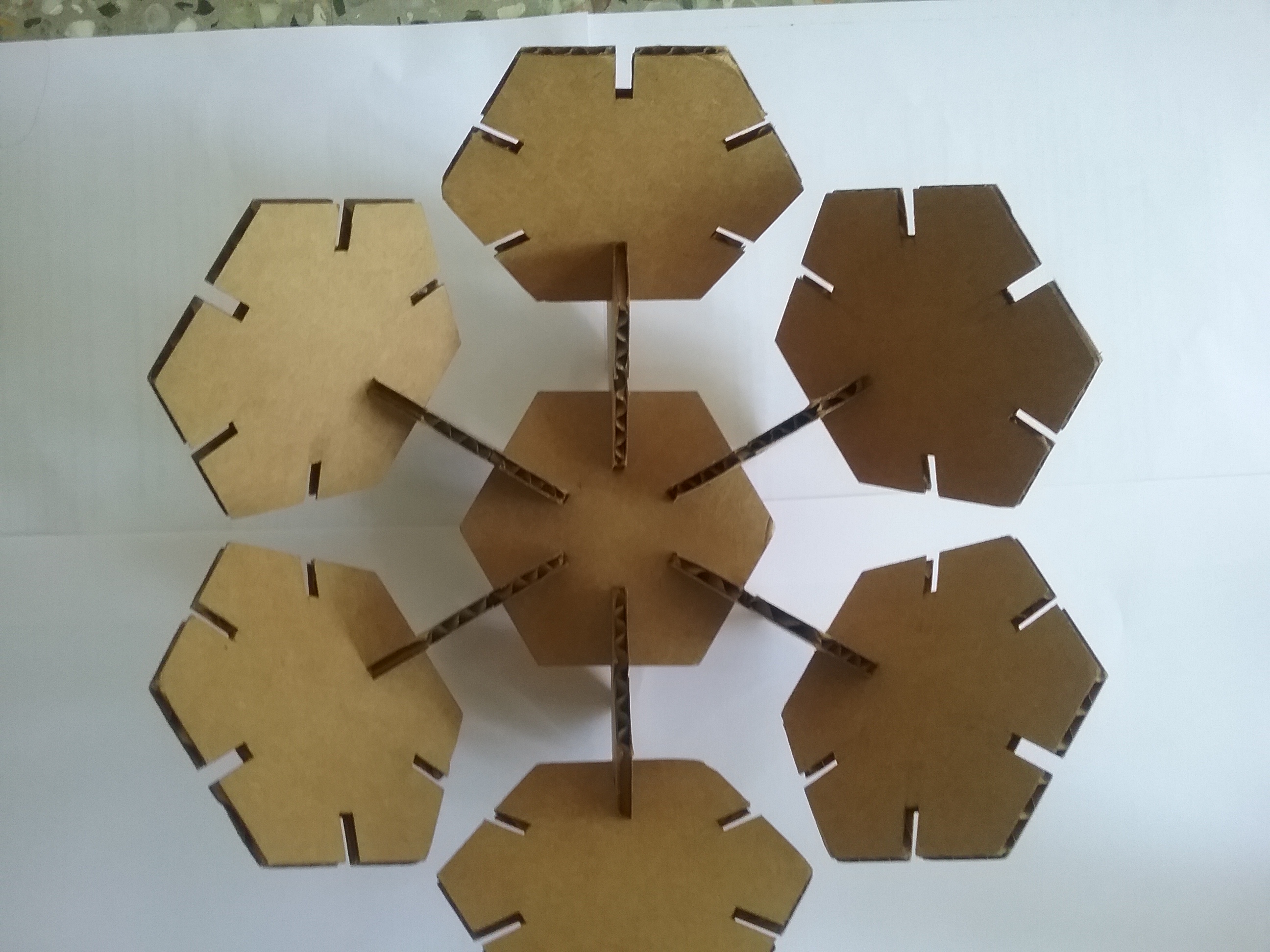

PRESS-FIT CONSTRUCTION KIT

A Press-fit must fit together without using glue, nails, screws or other fasteners,we need to adjust your joints to fit together in a precise way. A Prametric Press-fit like a template , when we design something for matrial we set the parameters based on the printing or cuting material , but in a Parametric way we can use the design with any Material like wood,Plastic,Paper.

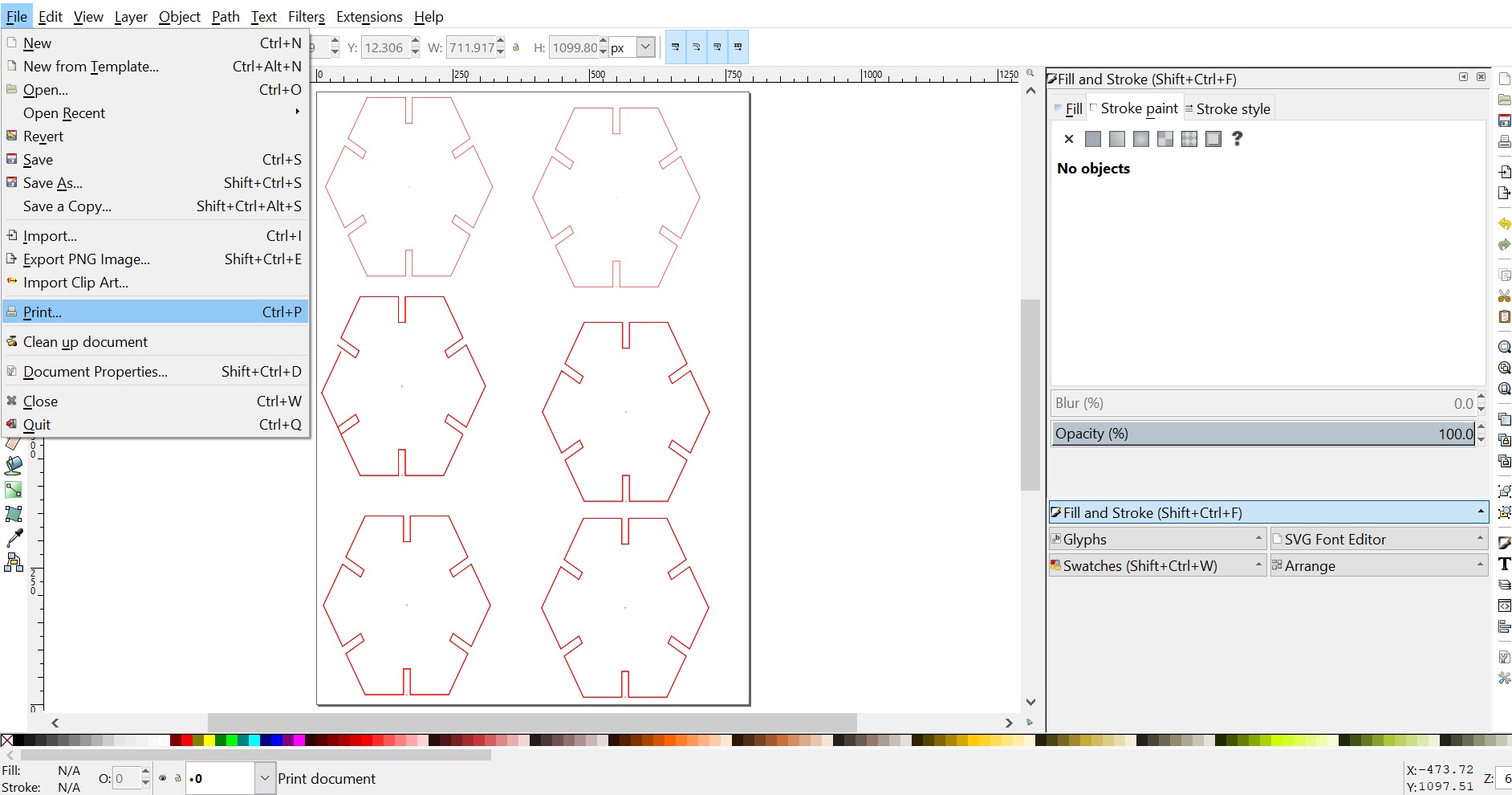

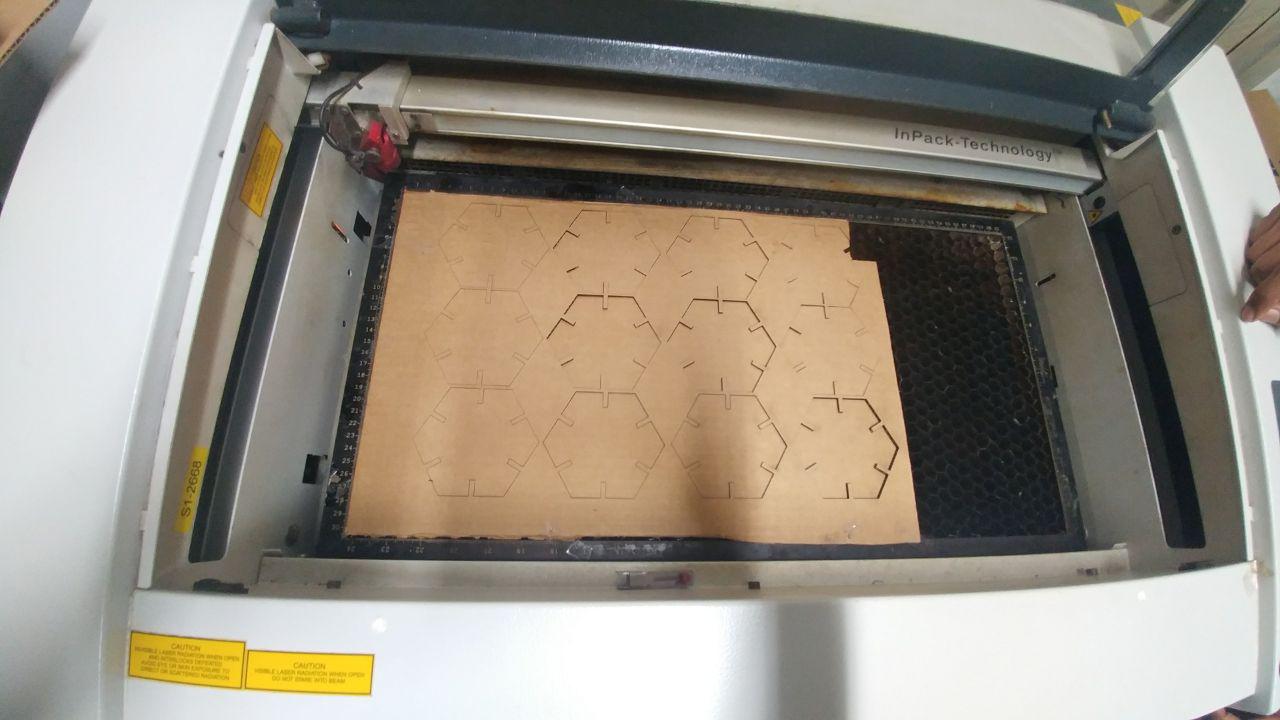

For doing the laser cutting first I design the parametric design in Rhino and then the instructors taught me all the steps.First I clicked print in Rhino then I copied my design to jobcontrol and I clicked ready so I know where the laser pointer is.Then I drag the window to the laser pointer shown in the computer.After that I pressed Start. I used 4mm cardboard for making the parametric design.

the design

then i exported to job control

setting the machine

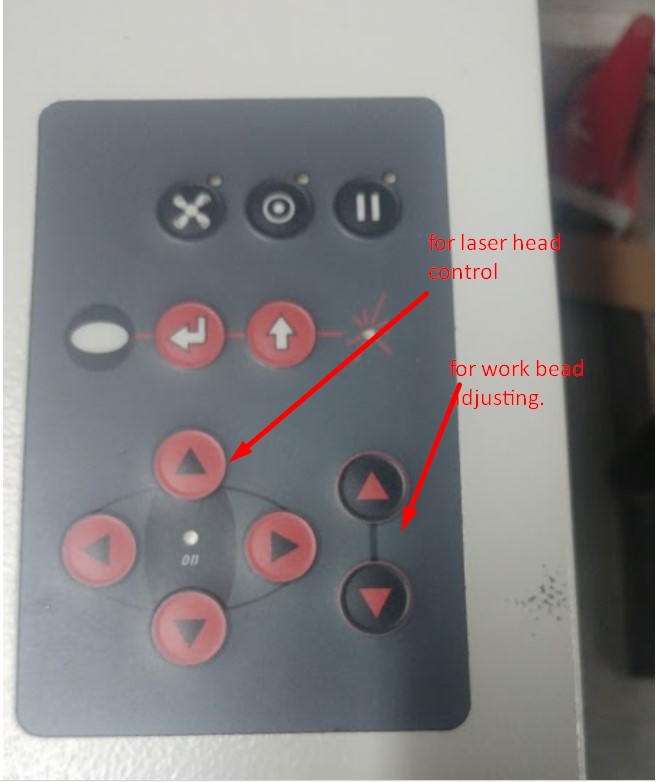

We used a probe and Z axis button for focussing the laser.We use the X and Y axis for setting the origin.Once the origin is set ,we can give the command to cut and cutting starts.

then I gave it to cut

finally i got this