WEEK-10

Molding and Casting

Lecture & Recitaton of a Week:

Lecture on 21st of March, 2018: Molding and Casting by Neil Gershenfeld

No Recitation on 2nd of April, 2018

Tasks for a Week

- group assignment: review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

- individual assignment: design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts

Molding & Casting

This week is full of learning new things. I never try molding and casting before so I planned to make something simple for this week assignment. Before modeling the designs of our individual assignments. First thing is to decide which materials are we going to use for Molding and Casting

Group Assignment

This week group assignment is to review the datasheets of the materials we are using in making mold and cast. Below we are sharing some important points after reviewing safety datasheets of Mold Max 60 for molding and Smooth-Cast 305 for casting materials

Mold Max 60 Safety DataSheet Review:

Mold Max 60

Product/Chemical Name: Mold Max 60 Part A:

- Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 300 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Product/Chemical Name: Mold Max 60 Part B:

- Hazards Identification

- Harmful if swallowed.

- Irritating to eyes, respiratory system and skin.

- Harmful to aquatic organisms may cause long term adverse effects in the aquatic environment.

- Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 150 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Smooth-Cast 300 Series Safety DataSheet Review:

Smooth-Cast 305

Product/Chemical Name: Smooth-Cast 305 Part A:

- Hazards Identification

- Harmful by inhalation.

- Irritating to eyes, respiratory system and skin.

- Limited evidence of a carcinogenic effect

- Harmful; danger of serious damage to health by prolonged exposure through inhalation environment.

- Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 262 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Hazardous Component: 4,4’ Methylene, bis(phenylisocyanate)

Product/Chemical Name: Smooth-Cast 305 Part B:

- Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 262 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Acute Inhalation Effects: None Established

- Acute Oral Effects: None Established

- Reproductive Toxicity: None Established

- Mutagenicity: None Established

- Teratogenicity: None Established

- Sensitization: None Established

Individual Assignment

For this week assignment I made a snowflake keychain which reminds me of beautiful winter season in these Khairpur high temperature days. I split my assignment documentation into 4 parts which are:

- Making 3D Model

- Milling a wax (to get regid mold)

- Making a flexible mold

- Casting the end result

3D Model

To make a snowflake First I download a suitable and simplified image of snowflake from Google, then I opened it in Adobe Photoshop CS2 to remove its background and save it as .png format.

Removing background from Picture in Adobe Photoshop CS2

Then I import photoshopped image in InkScape for making scalable vector file by using trace bitmap and save that as .svg format.

Making SVG file uisng Inkscape

To open an image in SolidWorks we need a DXF file, for that I export a file from .svg to .dxf format.

Making 3D from 2D in SolidWorks

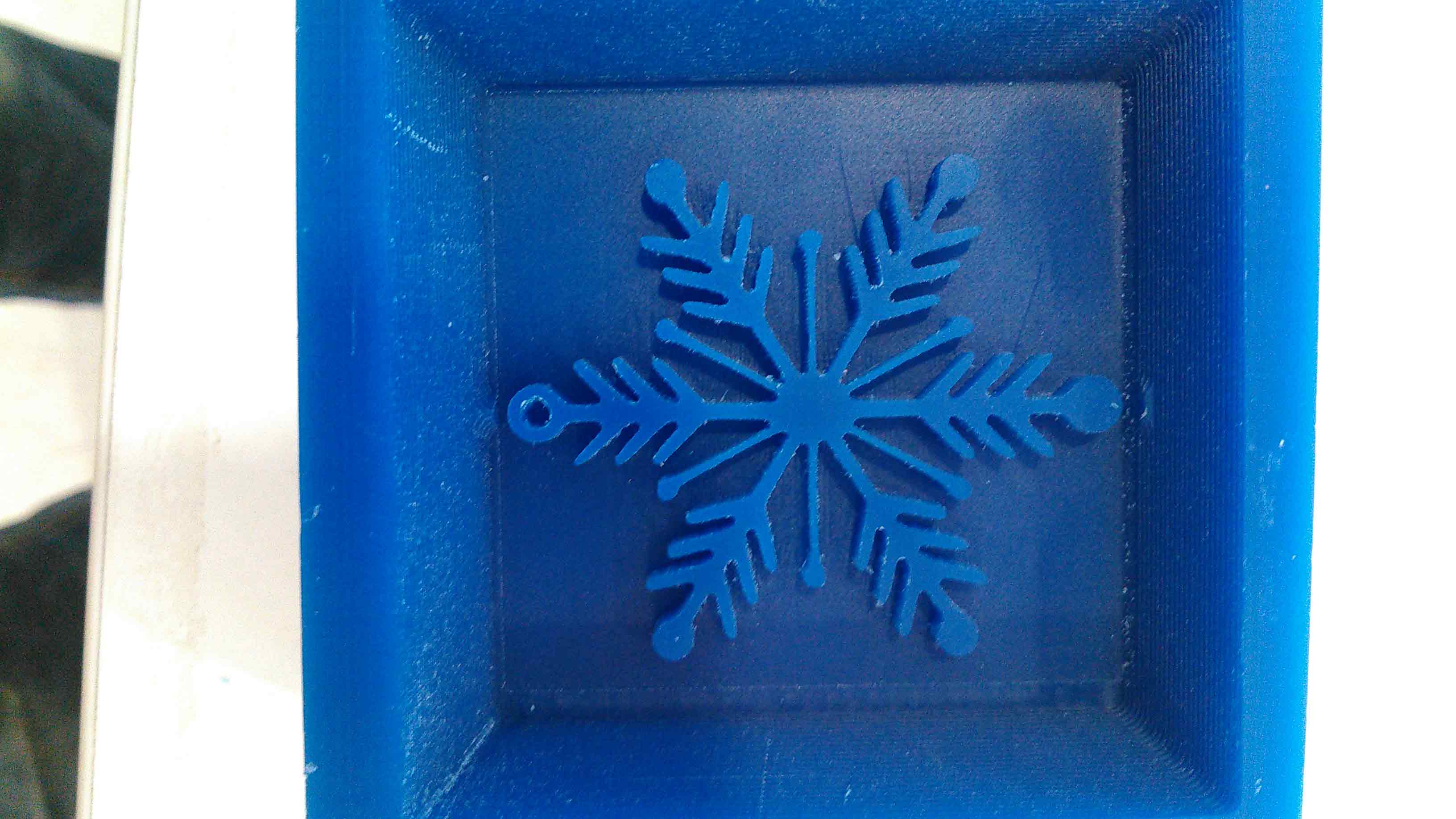

after extruding original design I make a square, extrude-cut it, and join it with original model and save as .stl format for furthur process

completing design with boundaries and save it as .stl

Milling

For milling I am using Rolnad SRM-20 machine and the material to mill is Machinable wax which is used as Rigid Mold here. SRM-20 is worked on .prn format and to generate that I am using MODELA Player 4 a software which came with SRM-20 for making molds.

Process in Modela Player 4

To generate .prn for SRM-20. I followed these steps which I mention below:

- After opening Modela Player 4, click on file and then select machine

selecting machine in MODELA Player 4

- Click on "File> Open" to open .stl file, then click on Solid sphere for Rendering View. Select Material type on right top to Modeling Wax

Opening .stl, selecting material and setting up a view

- Now to set parameters like origin and boundaries.Click "Set> Model" for selecting origin and "Set> Modeling Form..." to set boundaries and set as Manual (which we change later)

setting origin and boundary size settings

- For milling a wax in Roland SRM-20 we follow two process Roughing and Finishing. For Roughing goto "Set>New Process", choose the type of process by selecting "Roughing", select the tool for milling (in my case I select 3mm Square bit) then Set the cutting area depth by clicking on partial then change the red square on image as per requirement, select contour lines as "up cut" and in last set XY and Z speeds. Click Finish to see Preview.

Pictures of settings for Roughing Process

- Finishing Process is same as Roughing, I select finishing in new process, the tool I am using in finishing is 1mm square bit. Instead of contour lines I select both X+Y for Scan line in this process. Click Finish to see preview of Finishing settings

Pictures of Settings for Finishing Process

- After clicking on "Finish" two files are generated which is used to mill the wax. Next step is to set the cutting position by clicking on a button shown in right bottom corner. The file is sent to SRM-20 for milling process.

Cut Position Setting and Preview

- The milling Result:

Rigid Mold

Making Flexible Mold

After making Rigid Mold its time to make flexible mold from it. I am using Mold Max 60 which is used to cast both metal and plastic. The procedure to make mold is define below:

- First I need to measure the quantity that how much material is needed. For this I poured water in my mold, and weight an empty glass. Then I put water into glass from mold and measured it.

Measuring required weight

- Both part A and B are mixed in a ratio which is described in datasheet to get the same gram value measured in water.

Mixing part A and B

- The result was not good because the material is thick and when I pour it into mold it doesn't cover whole surface specially small areas.

Undesired result

- The problem in 1st try is that I forgot to stir part A before mixing with part B which makes it thicker while mixing both. So this time I first stir Part A, shake bottle of Part B and then mix them with 100:3 ratio. The result was good this time

Desired Result

Mold Max 60 is able to cast both metal and plastic. So we try both casting in our Lab.

Metal Casting

The material we are using in metal casting is Bismuth. It has low melting point which is 271.4C so it is less harmful to work on.

- First we heat the material till it reaches 350C

Heating Bismuth

- Then we set all the mold together and pour a melted bismuth in it.

Pouring bismuth into molds

- The resut was noot good because the design has very narrow structure and for this type of designs we need a mold which has two parts that helps material to transfer in a place only where needed

Cast made with Bismuth

Plastic Casting

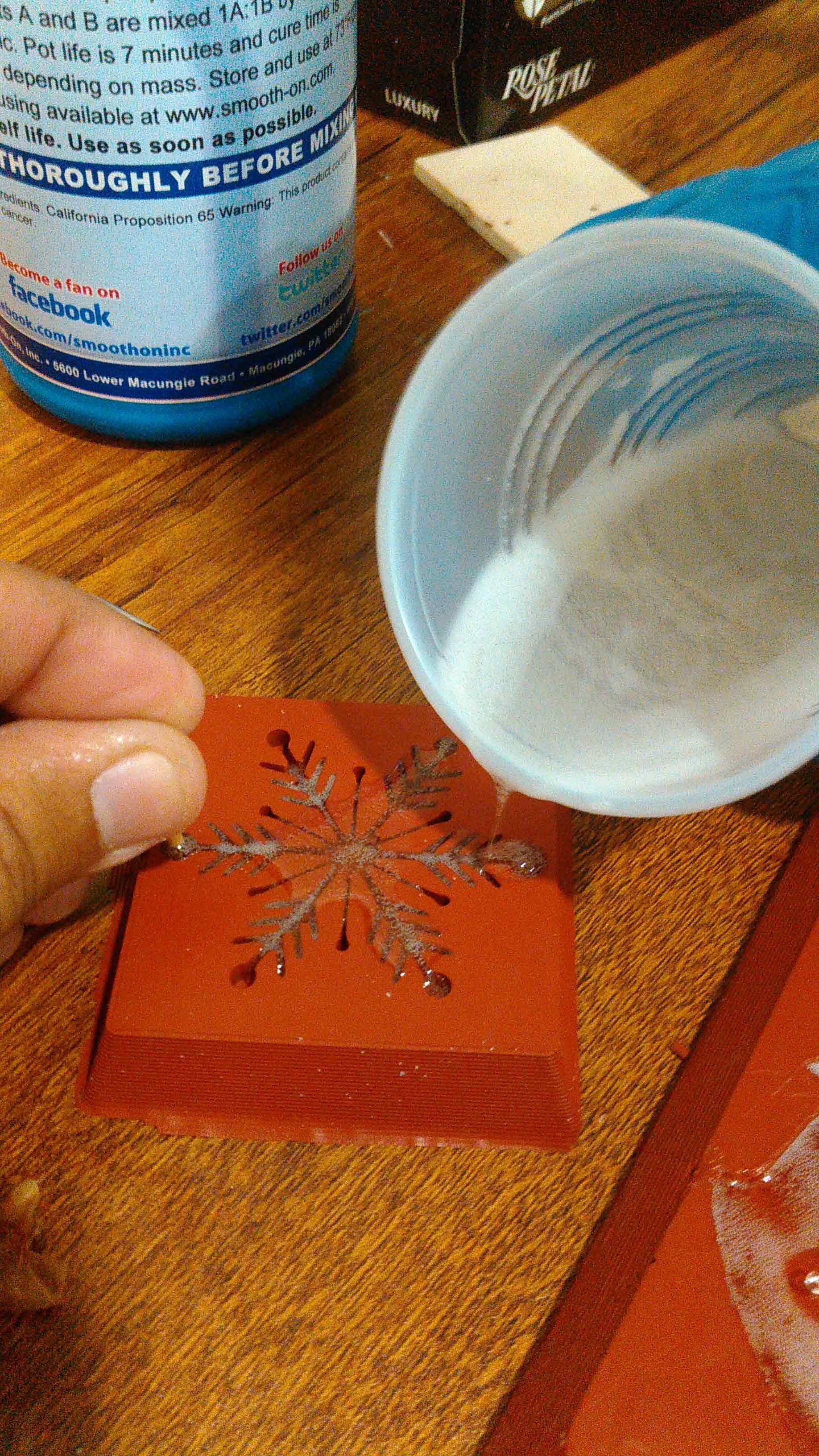

For plastic casting we used Smooth-Cast 300. The ratio of part A and B is 1:1. I miscalculate the time and when I poured it in mold it freezes between pouring.

another bad result

- In 2nd turn I stir it till 1 minute then poured it in mold and then waited for 10 minutes for mixture to dry

Pouring Smooth cast 300 mixture into mold

- After 10 minutes the results was quite good. It just need little finishing to be perfect

Plastic Cast removed from Mold

- Unwanted plastic are very thin, they easily removed with pointed tuiser.

Removing unwanted plastic from Cast

- After clearing unwanted plastic the sample was looking beautiful and perfect

Hero Shot of Final result

All process Rigit Mold > Flexible Mold > Cast in one picture

"Click here"to download all files of this week

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License