Metal and wood work (Final Project )

I didn't have a lot of experience in the metal shop, but I definitely wanted to be more well rounded using the machines available there since they call metal work the mother of manufacturing.

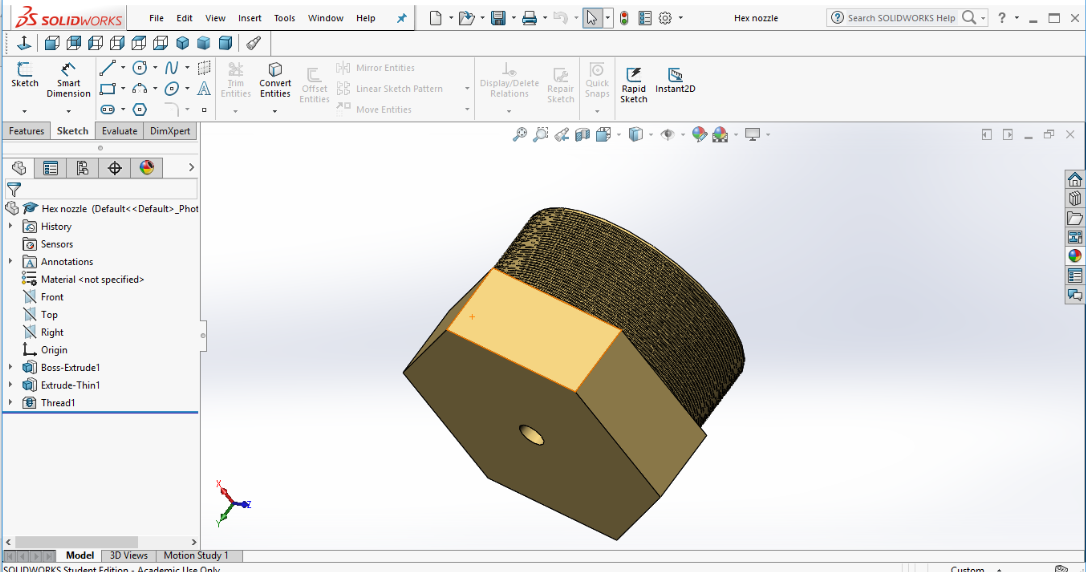

Using the lathe machine I reduced the thickness of a metal rod and threaded it using a special knife on the lathe machine to make my hex nozzle.

Also using the lathe machine, I changed the tool and inserted a drillbit to make my nozzle hollow.

The above video shows part of the process of making my hex nozzle.

After I was finished and satidfied with my nozzle, I used a circular saw to cut my nozzle out. The reason why I shaped my nozzle while it was a rod rather than cutting it first because it is easier to fixture a rod than a small metal piece.

Using the tormach metal CNC, I punched a hole inside my nozzle. I created two nozzles, one 1.75mm and the other 2.85mm. The reason why I used the tormach is because I wanted it to be as accurate as possible.

The above photo shows the nozzles I created! It is ready to make beautifully recycled 3D Printing filament now!

Manual Wood Work

I cut the base for my extruder using the Makita saw with the dimensions of 16cm x 60cm. I also drilled the holes manually.