3D printing (Final Project )

Most of the parts were 3D printed using 2 different types of printers one FDM which is Ultimaker 2+. and the other one is SLA which is Formlabs.2 . Using different types of filaments and resins.

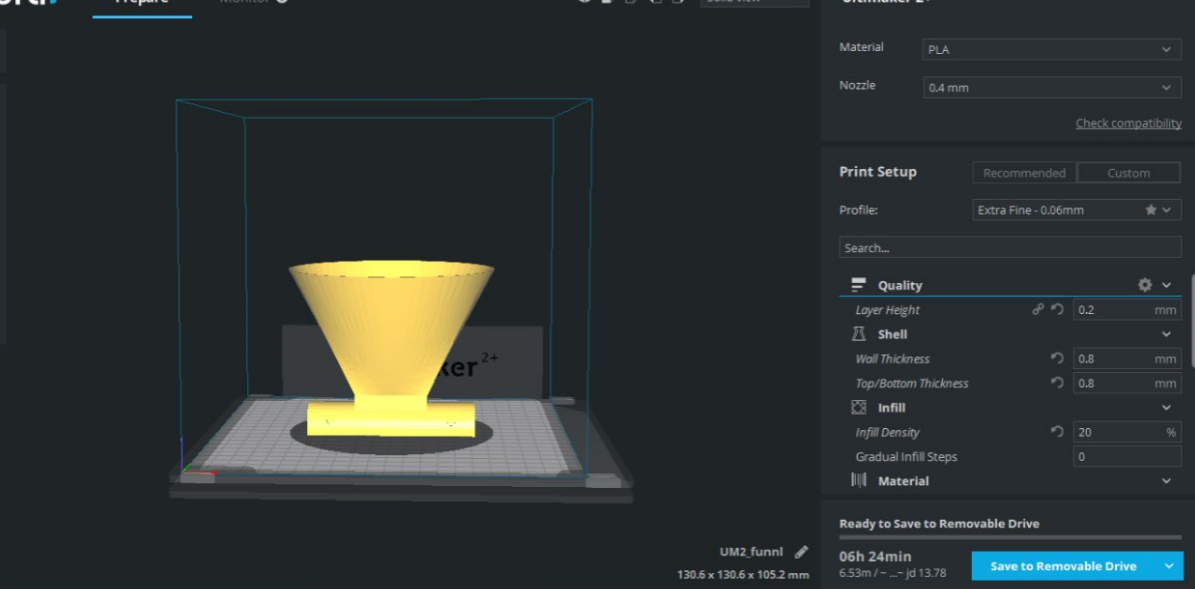

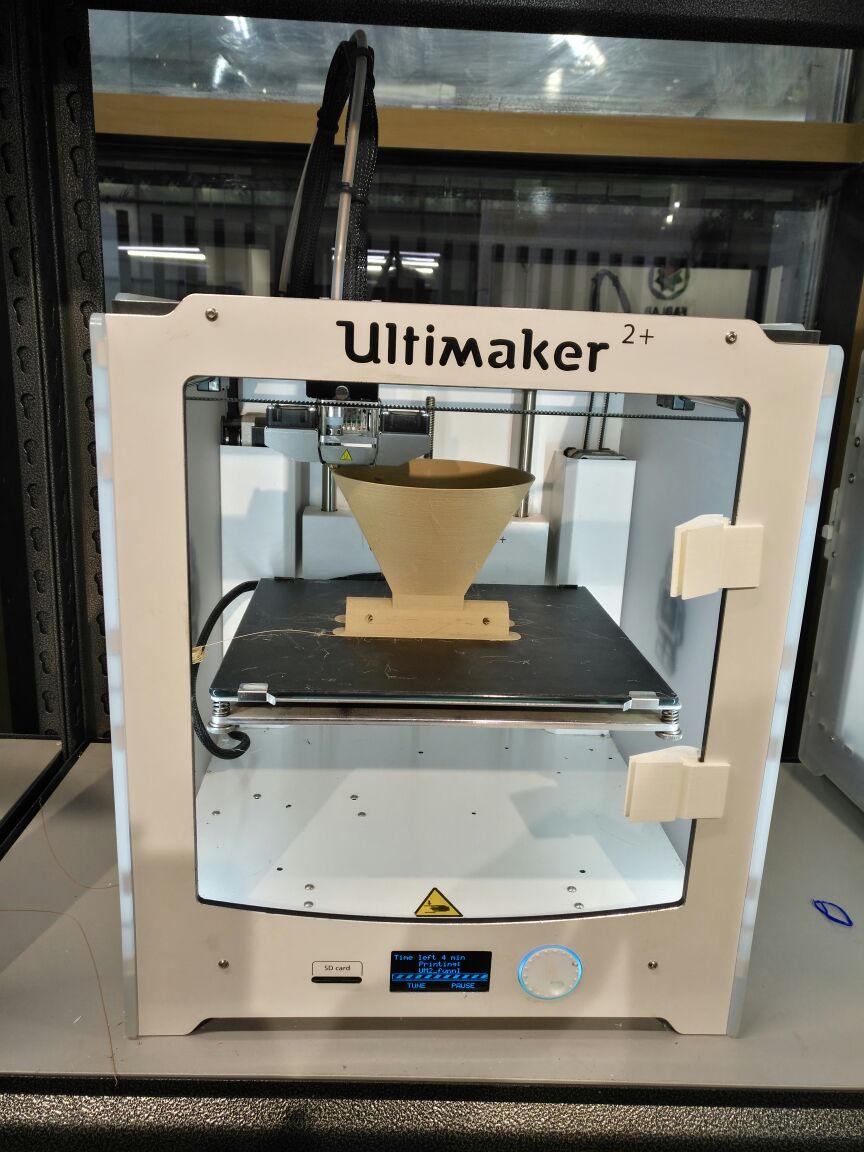

The funnel which I printed on Ultimaker using woodenfill materials and you need to adjust the temperature of the nozzle to 240 degrees instead of 210 degrees. I used a nozzle of 0.4 mm and layer height of 0.2 mm and the thickness of the top and bottom 0.8 mm and the infill was 20%

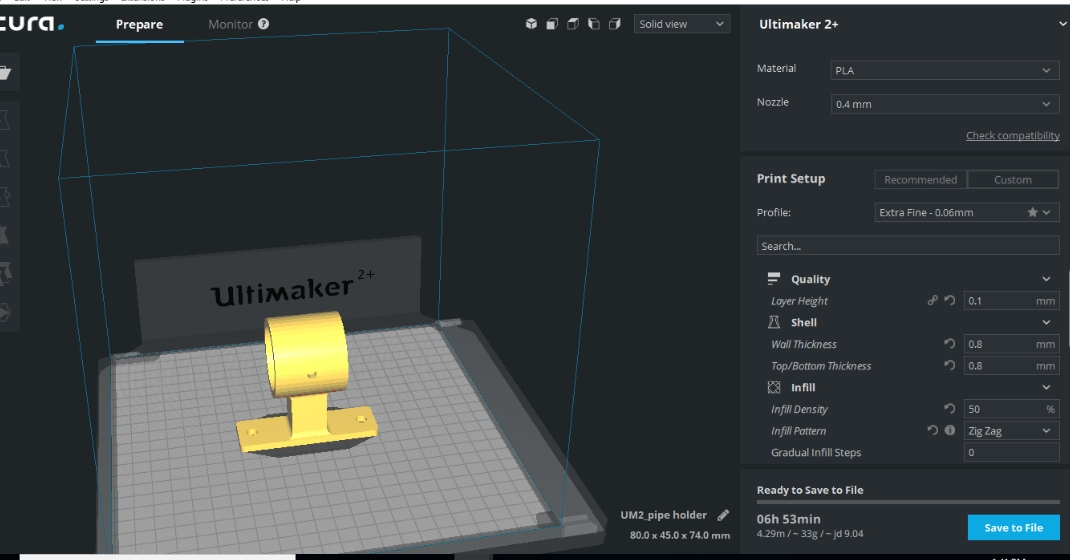

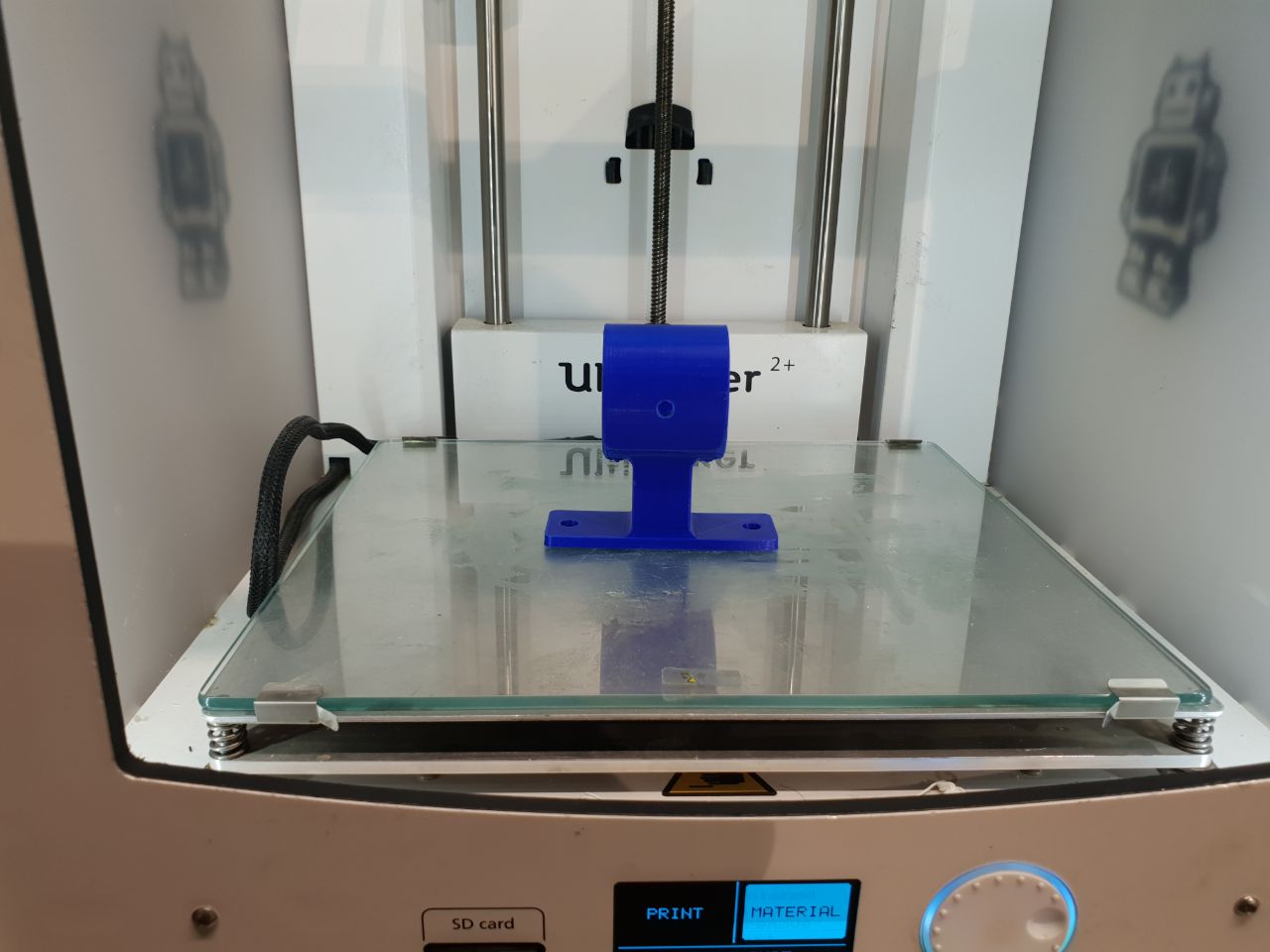

The motor holder I printed with PLA nozzle was 0.4 mm and layer height was 0.1 mm (I chose this to give better resolution as it will hold the motor). Top & bottom thickness 0.8 mm and infill 50% as I need it to be more solid.

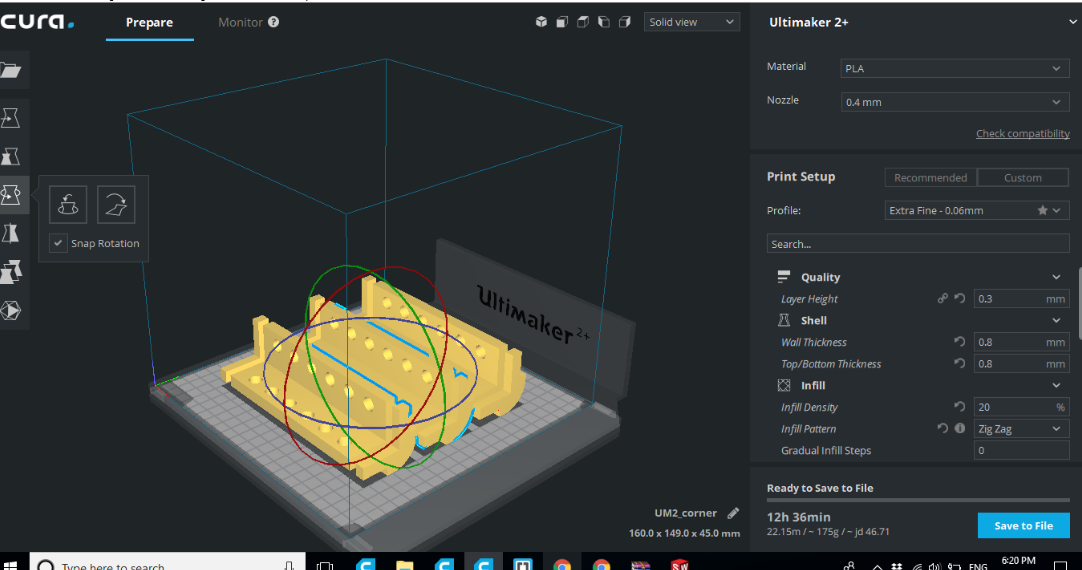

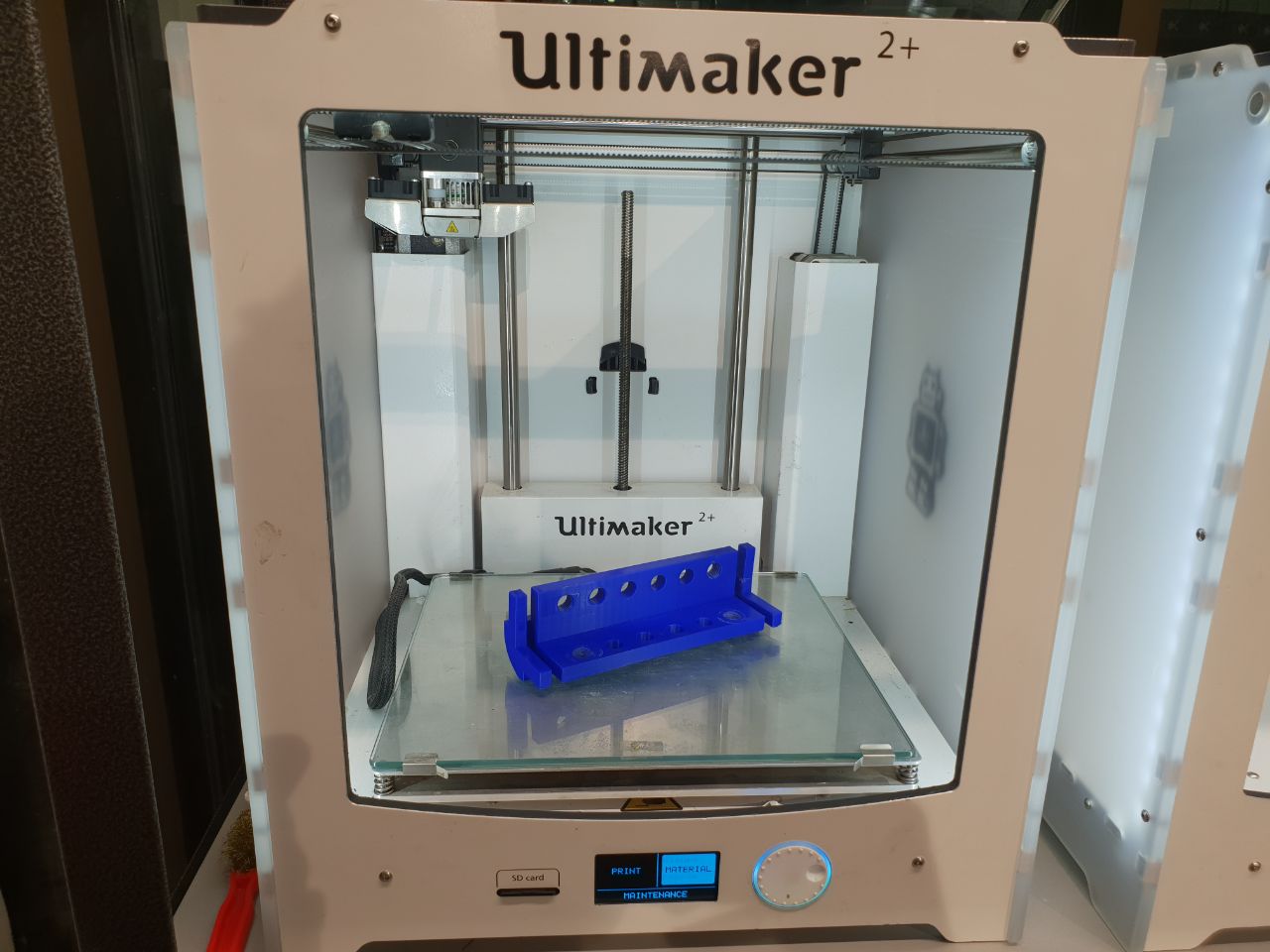

The corner joints I printed them with PLA material nozzle 0.4 mm and layer height 0.3 mm to save time as it is not to be of high resolution as I will be using screws on them. Also I added touch the plate support ZigZag shape to be removed easily.

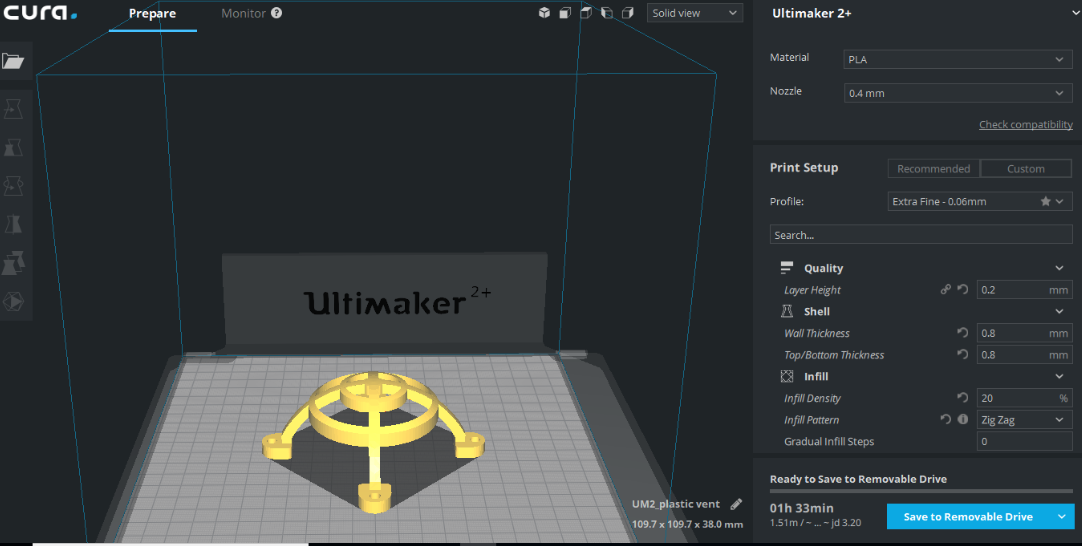

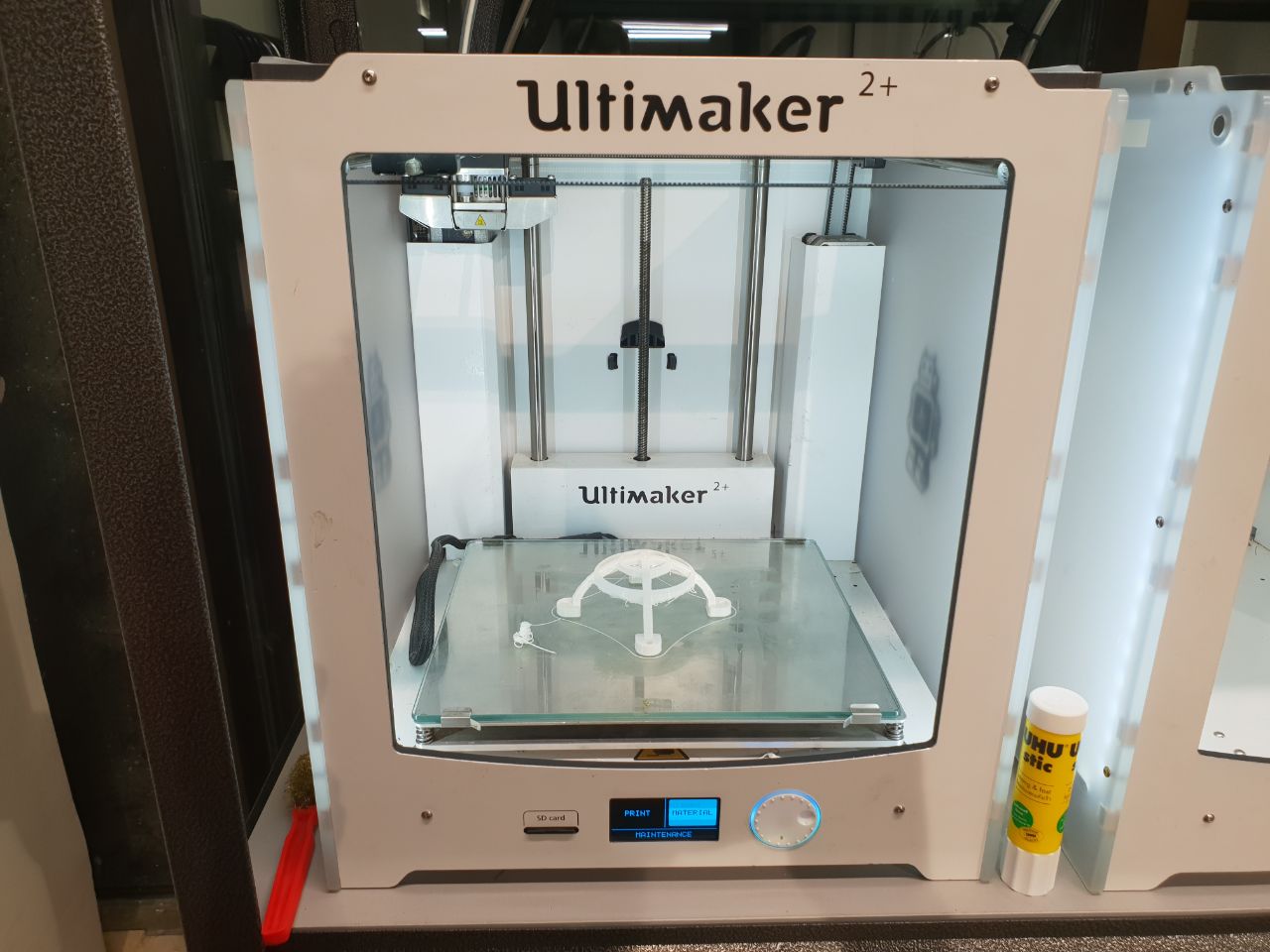

This is the plastic vent which I printed with PLA materials nozzle 0.4 mm and layer height 0.2 mm top & bottom thickness 0.8 mm; with a design of self support so no need to add a support to it.

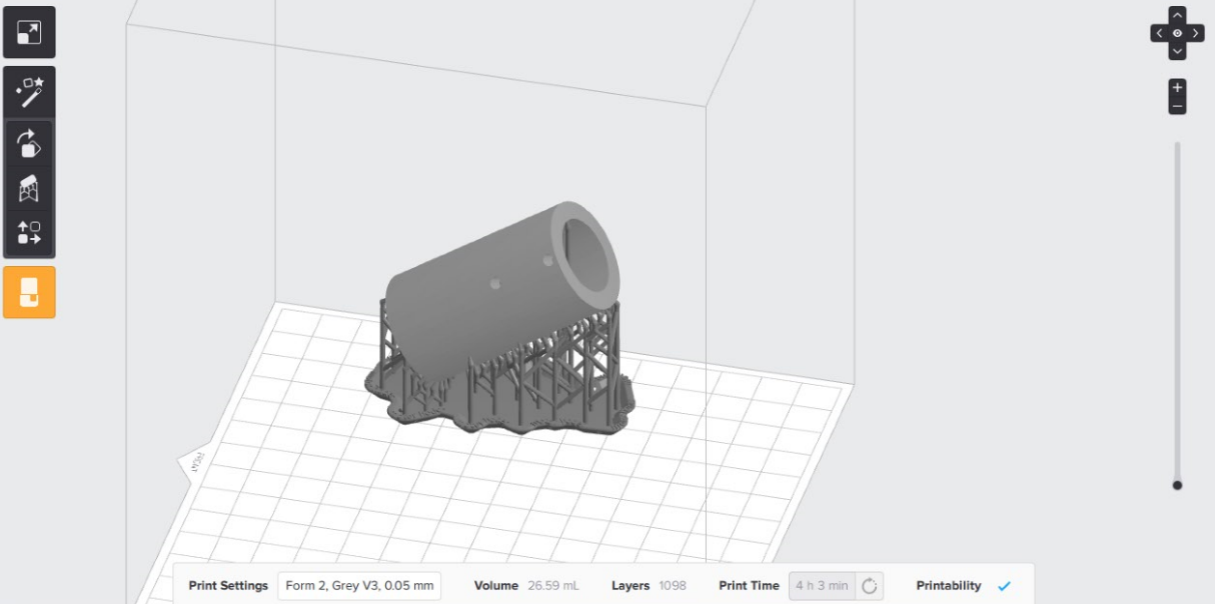

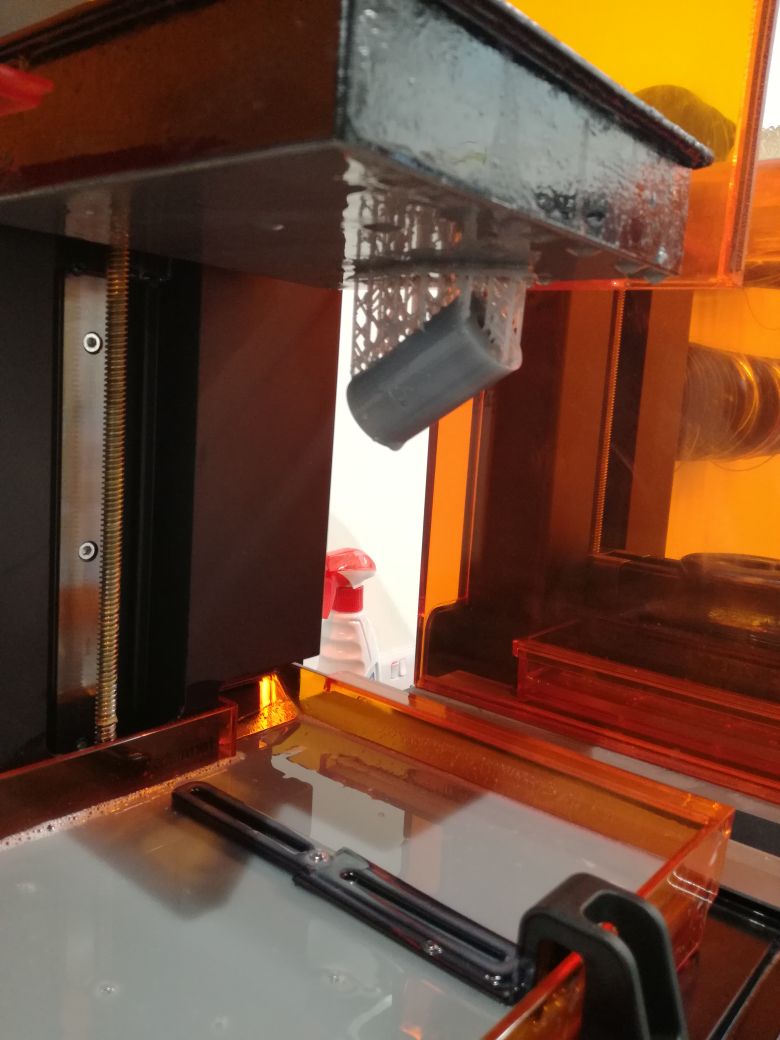

This is the motor holder I printed with SLA printer because I need to have it with high accuracy and it gives you accuracy 0.05 mm. This part is very sensitive as the feeding screw and motor will be fitted on it.