Week - 04 Electronics Production

Assignment

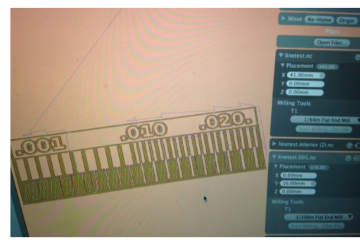

group assignment: characterize the specifications of your PCB production process

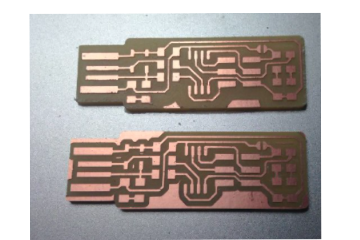

- In Germany everything is slightly different thus the PCB we were milling. It is called “FR2”, also a derivative of hard paper pcb and in a double sided version is very hard to come by, which is in this case not required anyway. (Img. 1)

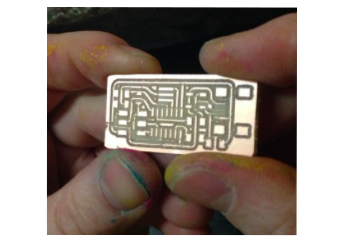

- Then we have to ensure that the PCB is straight, otherwise it will break the milling tool (Img. 2)

- With a double sided tape we tape it to the cnc machine at the lower left corner (Img. 3, 4). If we were about to make double sided PCBs, there would be a L-shaped bracket, so we can flip the pcb after it was successfully milled on the one side.

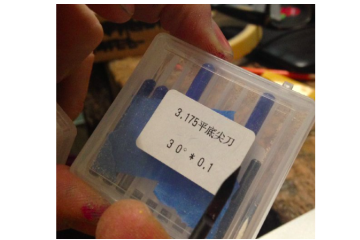

- (Img. 5) shows the milling tool imported from China, which is in fact quite usable.

- After the tool is inserted and secured, the machine homes the z-axis because the height of every tool can vary. It is important to start this process on a surface without the pcb, because this process heavily depends on electrical conductivity of the moving platform.

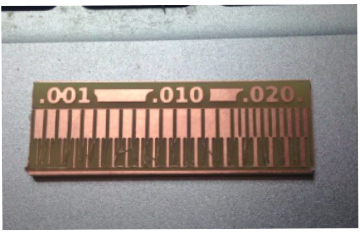

- Img. 7 shows how the final cut of the calibration PCB-pattern looks like. After some observersion it turned out to be not that precise.

- At Img. 8 we tried out 1/32th bit and it turned out to be quite desastrous. Img. 9 Shows a successful version with 1/64th.

- While we tried to figure out how to do it, we dropped accidentaly 3 milling bits and destroyed them… Although it is cheap, the working and waiting hours for them are quite obnoxious.

Individual assignment:

Make an in-circuit programmer by milling the PCB

For the basic design I used the ones by Brian with an ATtiny45

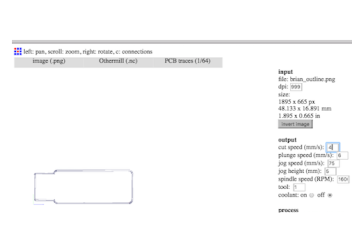

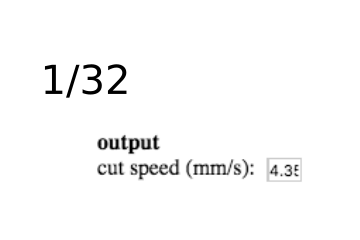

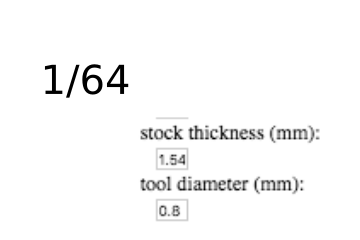

Img. 10 shows the configuration we used at the fabmodules, which turned out to be quite usable, hence Bantam-Tool-Software does not work with png formats.

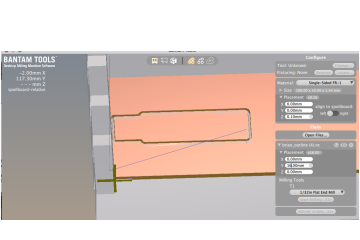

Img. 11 shows a screeshot from Bantam Tools to which we imported the generated gcode.

Img. 12 shows the milled pcb. For the final soldering we used the upper one which as a offset factor of 13. I could have made less but in the end, it helped out quite a bit, because I had to replace some components and they would not fit in size.

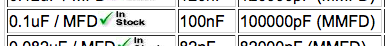

Img. 14 shows some components we had around in our fablab. But the Zener-Diode was missing, so I used the ones from Img. 22 which should work just fine.

For those all the capacitor metrics are not familiar with here is a small help:

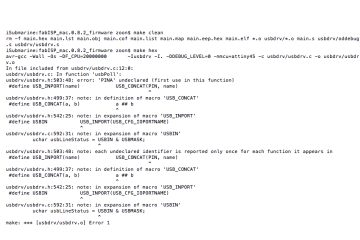

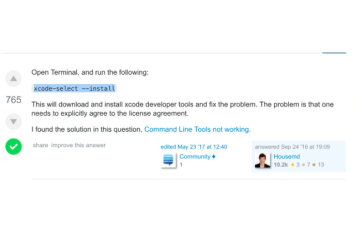

After soldering the components in place, also the solder-bridge based jumper for programming the programmer, and the right orientation fo the programming head, I could finally try to program it. Well, As you can see on image 18, with mac I ran into compiling error, which with the help of my friendly instructor we could resolve it (Img. 19).

Well, as to the part “then optionally trying other processes” was quite difficult because we did not have the copper-vinyl paper. So it has to be executed in another time.