Week 15

Machine Design

assignment

Group Assignment

1- actuate and automate your machine

2- document the group project and your individual contribution

Build a CNC

Machine Design group page

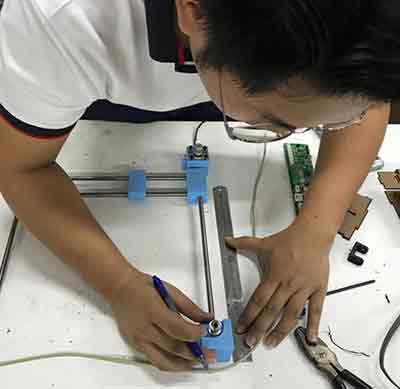

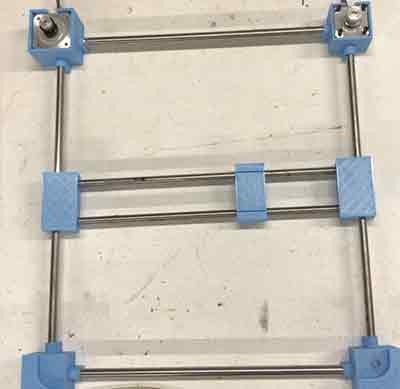

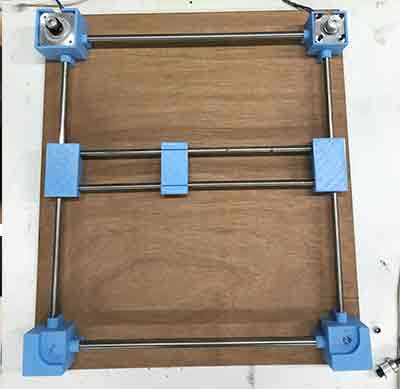

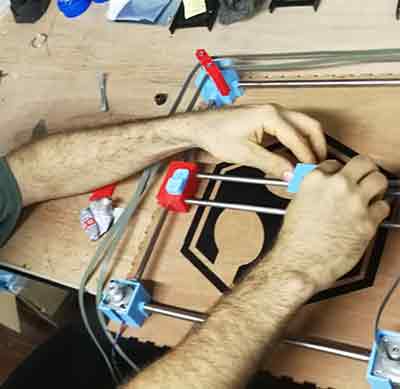

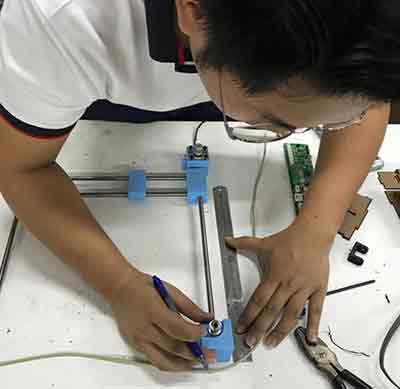

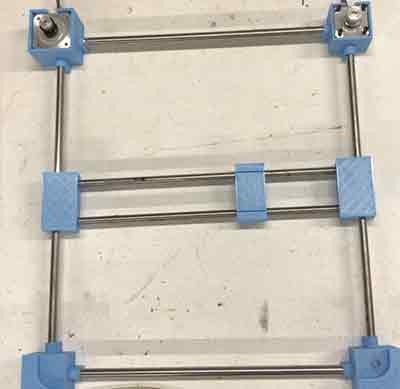

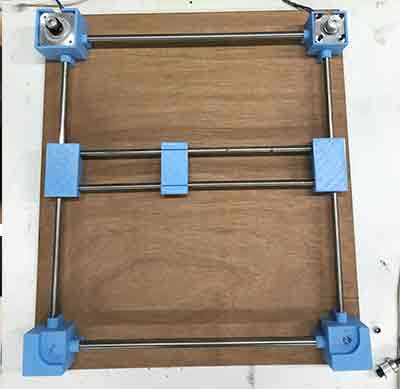

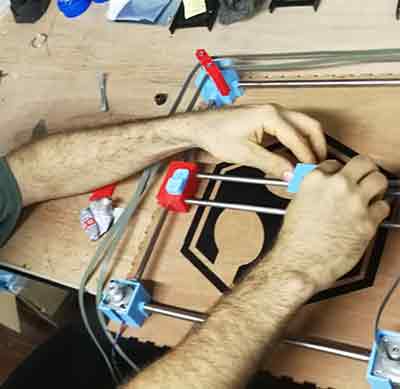

With most of the components acquired we began assembling our core xy sand printer.

We attached the magnet to the center slider and fastened the corners in place.

Using sand from a local beach, we strained it using a chicken wire mesh. Additionally we passed a magnet over the sand behind a coffee filter to attract any magnetic particles and remove them.

We filled the transparent box with 1mm of sand and the machine was now ready to program.

VIDEOS AND PROJECT PROGRESS

MANUAL LABOR

FIRST TEST MANUALLY OPERATING 3D PRINTED SLIDERS WITH MAGNET AND BALL.

Test on acrilic box with no sand and manually moving motors:

Test #2 identifying directions moving motors manually:

Test #3 moving motors manually using milk powder as a medium:

DIGITAL CONTROL

SUCCESSFUL GCODE PERFORMED BY THE CORE XY PLOTTER

Clicking 'start' for the first time with our core xy plotter:

First test uploading a gcode file, a squiggle:

Test #3 creating files to test the machine

1- actuate and automate your machine

2- document the group project and your individual contribution

Software Used

SketchUp,Fusion 360, RD Works V6, AutoCAD, Adobe Illustrator, Google Chrome, Sublime Text, Photoshop, Git

Tutorial Used

Fab Academy Week 15 - Machine Design CoreXY CNC PlotterBuild a CNC

Machine Design group page

Walkthrough

Using our MakerBots we printed out some of the motor housings.

With most of the components acquired we began assembling our core xy sand printer.

We attached the magnet to the center slider and fastened the corners in place.

Using sand from a local beach, we strained it using a chicken wire mesh. Additionally we passed a magnet over the sand behind a coffee filter to attract any magnetic particles and remove them.

We filled the transparent box with 1mm of sand and the machine was now ready to program.

VIDEOS AND PROJECT PROGRESS

MANUAL LABOR

FIRST TEST MANUALLY OPERATING 3D PRINTED SLIDERS WITH MAGNET AND BALL.

Test on acrilic box with no sand and manually moving motors:

Test #2 identifying directions moving motors manually:

Test #3 moving motors manually using milk powder as a medium:

DIGITAL CONTROL

SUCCESSFUL GCODE PERFORMED BY THE CORE XY PLOTTER

Clicking 'start' for the first time with our core xy plotter:

First test uploading a gcode file, a squiggle:

Test #3 creating files to test the machine