Week 1 – Plan and sketch a final project

We start at the end, by sketching ideas for a final project. I didn’t start Fab Academy with a project in mind, so I’ve tried to come up with something that I’m interested in now; maybe I’ll change course later on …

Approach

I don’t know exactly what criteria make a good or just ‘valid’ final project, but I’m working on the basis that it should incorporate as much of the course material as possible. That is:

- some electronics design

- working with some inputs and outputs

- making circuit boards

- programming a microprocessor

- 3D design for a product casing or components

- cutting, printing or casting those parts

- integrating the parts into something resembling a product

Ideally, I’m looking for a project that relates to something else I’m working on, but failing that, just something that’s fun, useful or might have a life beyond the academy. And I’m looking for a balance between challenge and achievability – I could be cursing this choice a few months from now.

I’m not so concerned about originality, or whether it would make a compelling product; though those would both be nice goals.

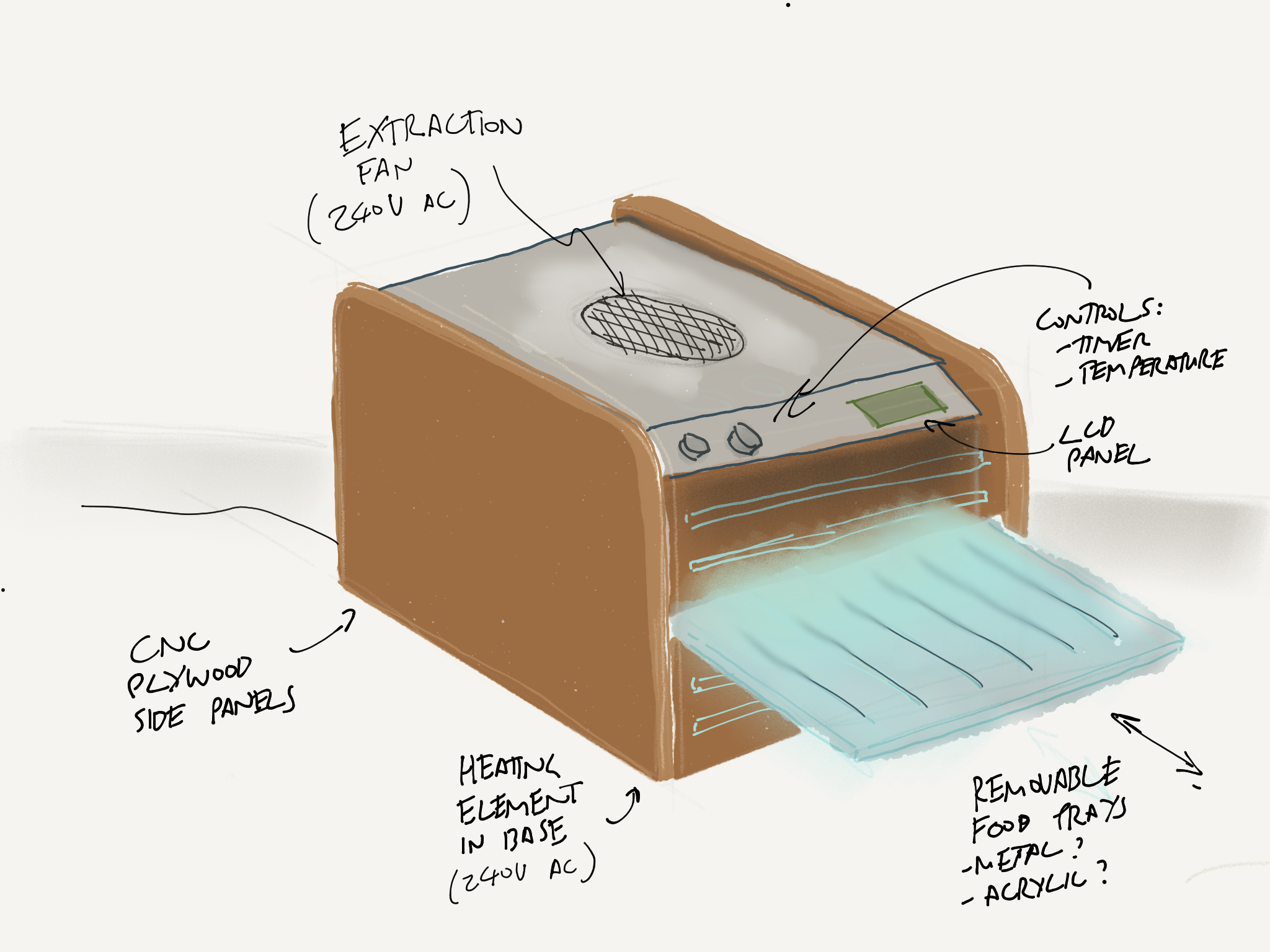

Food dehydrator

Why make it?

I do a lot of backpacking, so I need to carry food over long distances. Food is very heavy, and contains lots of water, which is often freely available in the wild. So, like lots of backpackers, I prefer to carry dry food, and then rehydrate it with water I find as I go. Cooking and dehydrating food yourself at home gives you many more options for trail meals than just pasta, rice and couscous. So I’d like to make a food dehydrator.

What would it a good project?

This is not a novel idea. There are many food dehydrators available commercially, and several design on Instructables. But there might be way to do it differently:

- A high quality design - commercial units are designed to a price point.

- Documented and open source, so others could make and improve it.

- Using readily available materials and Fablab tools, so it’s not contingent on having access to special materials (or in the case of many of the Instructables, repurposing something existing).

The electronics could be quite simple, but I’d need to control a fan and a heater, possible using a timer or temperature/humidity sensor. It might need relays to switch 240V circuits on and off, and an LCD display to show settings or current status.

Issues to consider

Food safety:

- What conditions do foods need to dehydrate safely while retaining flavour and nutrients?

- How do you manage wet foods within the dehydrator? (e.g. liquids dripping down from the upper trays)

Materials:

- Which materials are food-safe?

- How would they respond to moisture or heat?

- Is it possible to use materials that are readily available ot other DIY makers?

- Could I fabricate the unit by assembling flat panels, or would I have to use cast 3D elements (which would be much harder for others to replicate)?

Power supply:

- Could all the parts be run from a low voltage DC supply, or would I need to include a transformer in the box?

Automation:

- Can I use sensors in the unit to detect, say, humidity?

- Would these give me useful information about the state of the food, and allow me to automate the process?

- Or would I be better off with more basic time and temperature controls?