Electronics Production

Testing the CNC Machine

So the idea was to understand the different settings of the CNC milling process that could affect the output products.

There are many variables in the Milling process setting that could be changed and respectively affect the output of the machine.

The settings are:

- RPM of Milling Bit is the variable that controls the rotating speed of the milling bit.

- Mrilling Bit Diameter is the variable that is directy related to the bit diameter. The bigger the diameter, the less we can achieve thin connecting lines.

- Feed Rate is the variable that controls the rate the milling bit moves on the surface of the copper board. Milling the inner lines requires a normal feed rate. However, milling the outer parameter of the pcb required very slow feed rate.

- Offset Number is the variable that controls the number of passes the milling bit does over the same path. This setting majorely affects the final product. Paths that are not cut in the first pass post probably will be cut during the other passes.

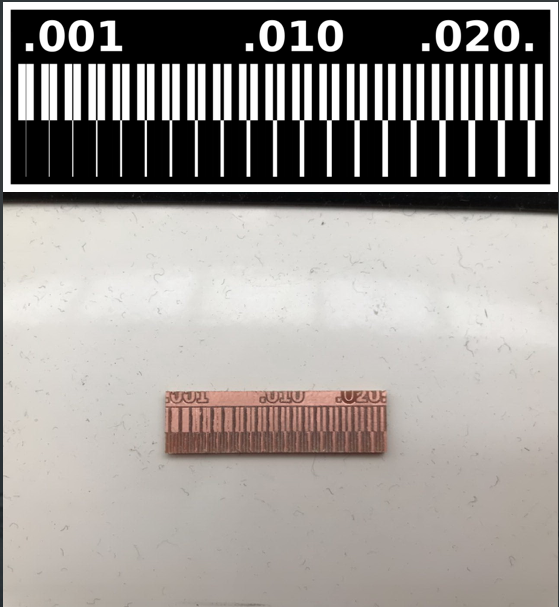

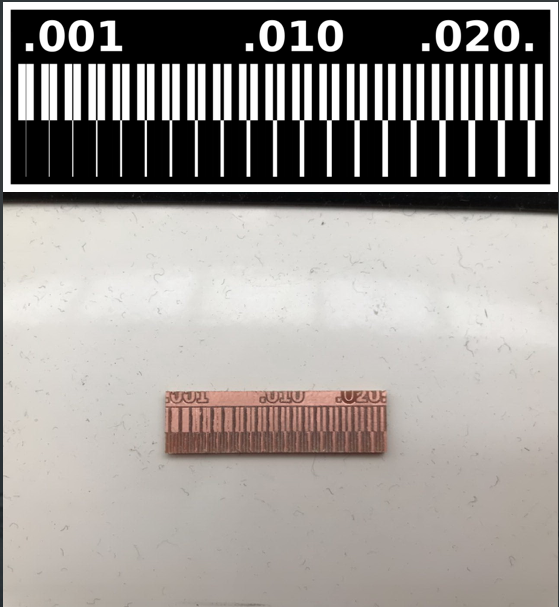

Saying that, we started by a Test File we got from the internet, that has different paths of vairious thicknesses. We tested milling this image using the milling bit of diameter 0.2mm.

The test file was downloaded from the following Link

After that, we noticed that not all paths stayed, and the thin paths (less than 0.005mm) were missing. Thus we deduced that our limitation is that the milling bit cannot mill paths less than 0.005 mm.