This weeks assignment was to make a mold and cast something.

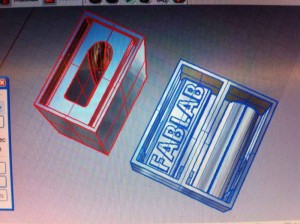

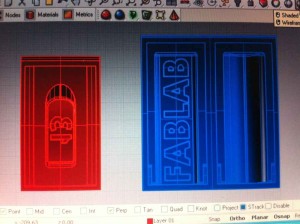

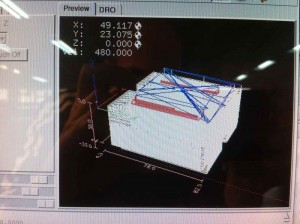

I decided to cast a shot glass from ice. for that i had to make a three part mold.I started with rhino and modeled the mold

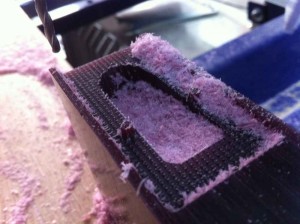

I milled the mold from casting wax using the Shereline 5410 for the first two parts and the Shopbot for the third part generating the .png files and g-code with the fabmoduls. I used 0.5 overlap of the milling bit. To get a better resolution and a smooth surface it is recomanded to use 0.5 overlap.

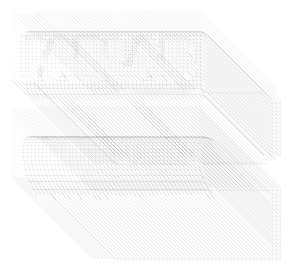

.png files

g-code

Milling with the Shereline 5410

Milling with the shopbot

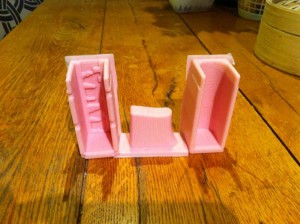

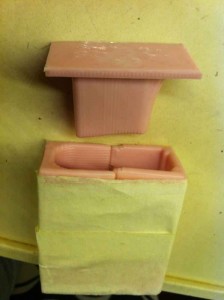

After cleaning the part of the mold with Aceton i mixed silicon and poured it into the mold to create the mold for the shot glass. It take 24 hours until the silicon is completely dry and the i put it in the oven for two hours in 80 deg. C and another hour in 100 deg. C.

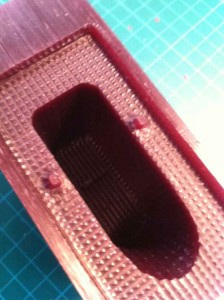

The mold look a little bit to flabby-the “walls” should be thicker. i did them 5 m”m thick and i think they should be 10 m”m thick.

The design of the mold was two delicate. I thought the bit i used ( 1/32 inch v mill) will do the job…

I tried to place bits in the mold to close the parts together but they were to small ( 1 m”m radius is not enough).

After i took the mold out of the oven and tried to assemble it together i saw that the two sides of the mold don’t connect together very well and the water i try to put in spill out.

my conclusion is that the way i designed the mold isn’t good for casting water. I should have made the main part from one piece. Assembling it together doesn’t hold water.

After one hour in the freezer