This assignment was to 3d print a model with our riprap 3d printer and 3d scan using one of the free software available on the web and a camera.

3d scanning

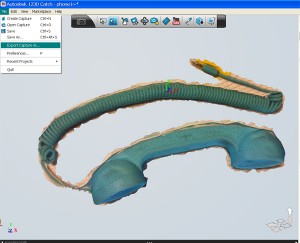

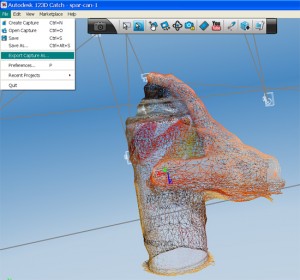

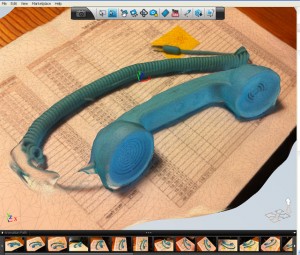

For scanning i use 123d catch by autodesk. it is very easy to install and there is an app for the i phone.

I took pictures with my i phone and loaded them into tje software for calculation. it is very important to have a good light from all over the object and he has to be in focus. if not, the mesh will be deformed and will have holes in it. i found that natural lighting, especially in the early morning or in the evening gives the best result. it is also important to have a noisy back ground which helps the program to stich the photos together.

I took about 40 pictures of the object from different angles and loaded then.

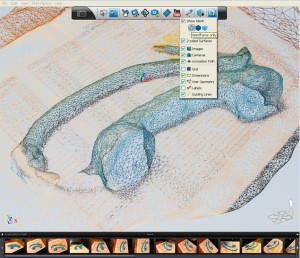

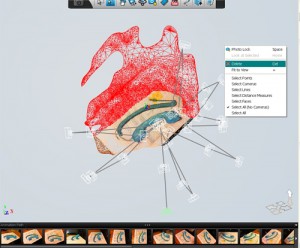

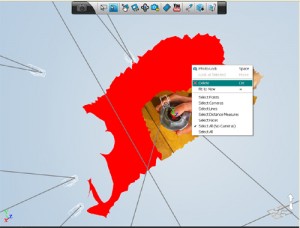

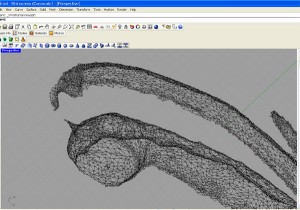

after a short time i got an e-mail with a link to the model. i changed to mesh view so i can clean the model from unnecessary parts.

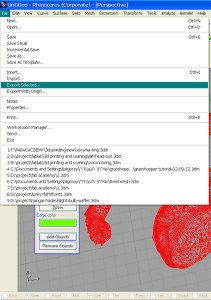

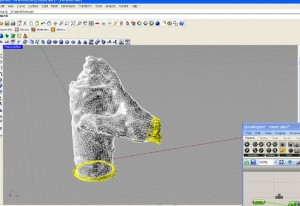

After i finished cleaning the mesh, i exported it as an .obj file so i can import it into rhino.

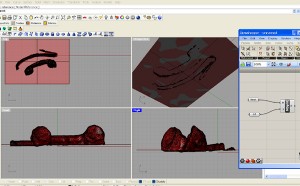

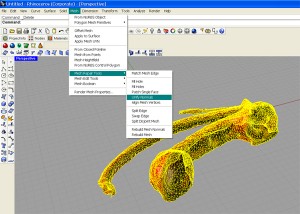

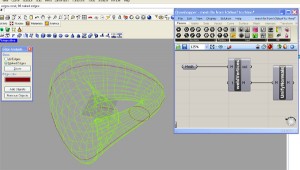

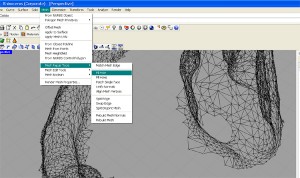

In rhino i continued to clean the mesh from small attachments and close the hole with “close hole” command from the “mesh” menu.

I want to try and print this model so i continue on playing with it. i split the mesh with some planes so i can get get a clean cut in the “ends” of the model.

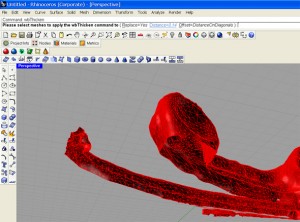

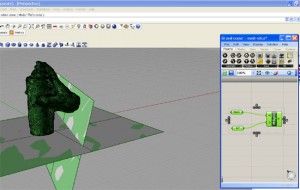

I used “unify normals” and “weaver bird thicken” ( a free plugin for rhino) to finish the modeling.

I check the mesh for naked edges.

Then i exported it as an .stl file.

That was the part that went by the plans…

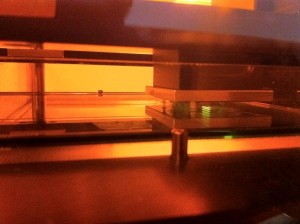

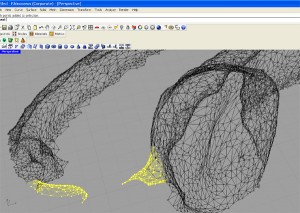

To print the model i have to get a gcode of it. I used slic3r for that. the first time i open the software i had to define the values for the printing process depending on the printer i use.

when i loaded the file into slic3r, i got a message that i have holes in the mesh. I checked the .stl file for naked egdes but didn’t find any. Again to slic3r and again that message…

I uploaded the .stl file to netfabb.com and got the file fixed. when i loaded it into slic3r it was working properly. Now i have a gcode and the file is ready for printing.

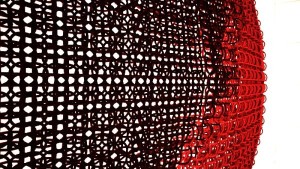

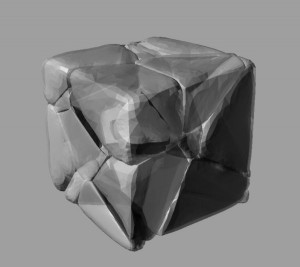

I played with the 123d catch for some time and got also this model:

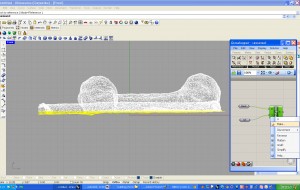

and also loaded into rhino for preparing to 3d print.

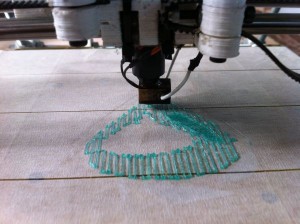

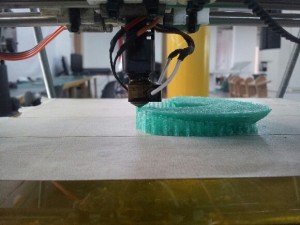

Then i 3d print it

3d printing.

The question is: what to print in 3d ???

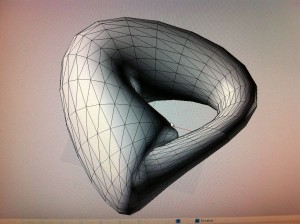

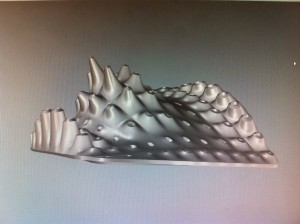

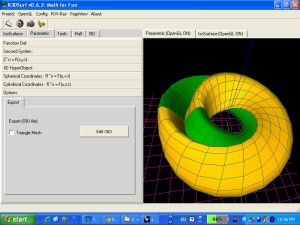

1. I down loaded a free software called k3dsurf. It generates 3d models based on mathematical equation. I played with the parameters and saved the models as.obj file.

I played with the parameters and saved the models as.obj file.

the problem is that the models generate with a naked egde that has to be fixed. If not, you don’t know what the the 3d printer will do with it. It doesn’t read correctly the file’ don’t know if the face is facing inside or outside…it will be a mess…My “klein bottle” broke during the printing process.

I fixed this issue with a simple code in grasshopper

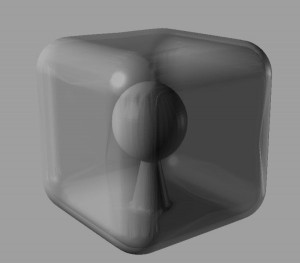

2. hollow models with something inside

something inside

3. complicated surfaces

I didn’t manage to 3d print any of the above. I hope i will do that tomorrow.

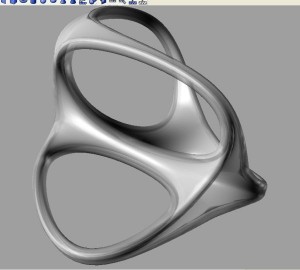

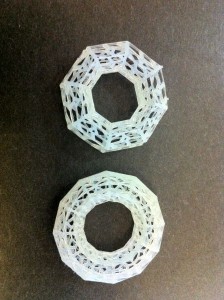

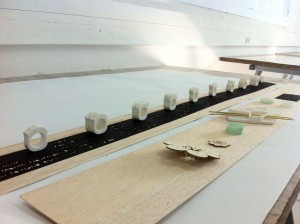

Last year i attended a short course in generative jewelry design. We used ” I-ring” and “paracloud gem”, two parametric softwares designed by architect Eyal Nir. The I-ring software is an application for Ipad that helps you to design a ring from scratch and send it to be 3d printed. Paracloud gem is a software that helps you mount 3d element on a parmetric surface.

In that course we used a 3d printer making wax models for casting. The resolution is high and the product is very accurate.

we also used a 3d plaster printer for less accurate models