Previous experience cutting with laser machine.

We have worked with different assembly techniques, programs and materials.

One key finding is that you can experiment with cheaper materials in order to assure fitting. The chair and table are designed in real scale but we decided to cut them in MDF before and found out there were gaps. That saved us money and router time.

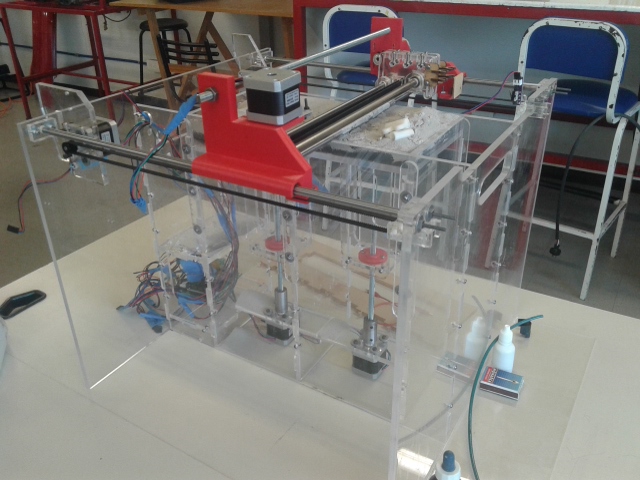

In the case of the pwdr printer we cutted the structure first in carton board out of open source files. We found that it was poorly designed and fitting was impossible, that saved us a lot of money from the 8mm acrilic.

Build a Press Construction Kit

This week's assignment is to build a press construction kit. I decided to investigate different patterns to look for a shape that could be flexible in more than one axis.

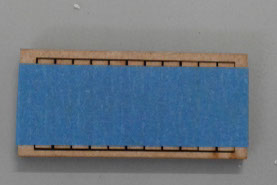

The first thing I researched is our machine's kerf size (The machine is a CAM Five CMA 1200) . To find this out I made a square with 12 vertical cuts, then I took them out to clean the parts a little bit and re joined the parts to see how much material was vaporized. You can find the Kerf file HERE

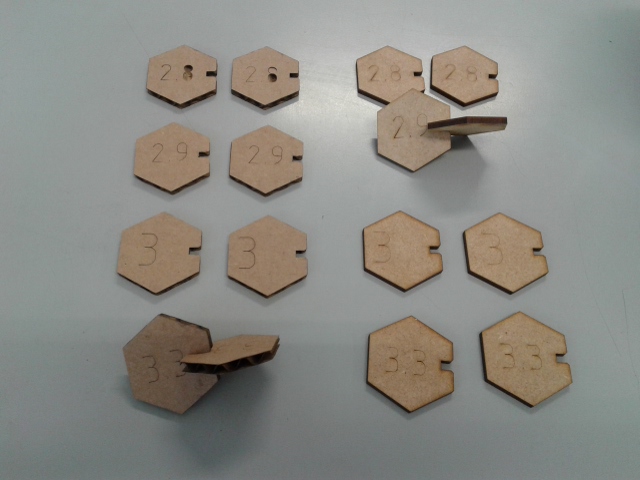

The total kerf of the twelve cuts is 1.5 mm so 1.5 / 12 = 0.125 mm per cut. This means that for every joint there will be 0.25 mm of vaporized material. With this in mind I tested different joint sizes in different material, cardboard and MDF.

As shown in the picture the best joint size for MDF was 2.9 mm because accounting the kerf it leaves a joint of 3.15 mm (2.9 +0.125+0.125) getting a very precise fitting.

For carton board the best fit was 3.3 since the material thickness is greater.

You can find the file by clicking HERE.

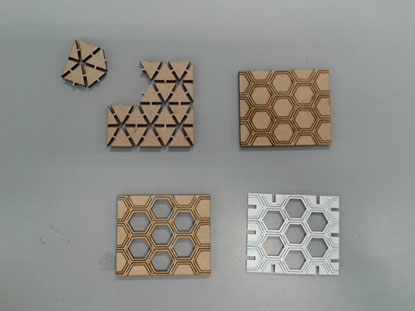

My next experiment was to find a shape that allow material to bend in two axis, I made several experiments, with different materials. It was not possible to achieve this bending properties, I think further investigation on the behavior of material with the hexagon form cutted with a TSP line ( a pattern produced with a single continuous path) probably will bring better results in a multi - axis bending part. You can find the file by clicking HERE and HERE.

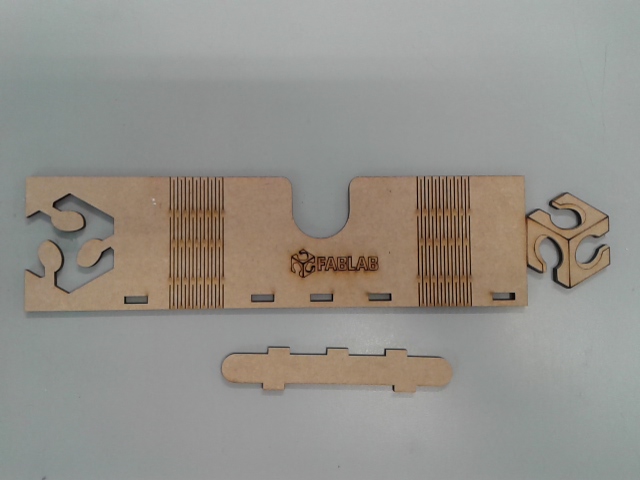

At the end I decided to built a single assembled object, with regular one axis bending and special joint. I thought the object should be useful so I made a card holder with Fab Lab Puebla's logo as assembly joint. I decided to make it in MDF since is a much more resistant material than cardboard. You can find the DXF files by clicking HERE.

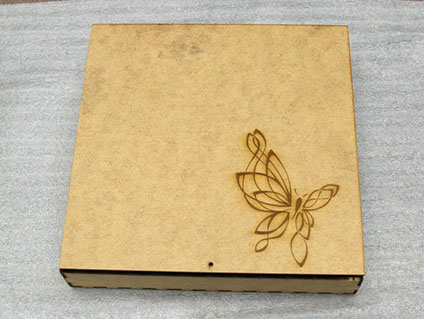

At the Computer - Aided design assignment I made an special box for my sister's obsidian set you can view the assignment by clicking HERE.

I made the box with Inkscape and then I finished it with Librecad. You can find the Librecad Archive by clicking HERE.

The box is tabbed to press fit and the protective foam was also cut in the laser cutter.

Since the lesson was computer controlled cutting, I decided to use Fab Lab Puebla Waterjet to experiment cutting an object.

I did some vinyl cutting for my computer with the Roland program. The interesting part was that Isabel, another member of Fab Lab Puebla showed us how to cut paper with the vinyl cutter. This is important since in Mexico we could not find copper to cut circuits. With the base used for paper and found a supplier for laminated copper. We will test the material.