Weekly_Assignments :

- For this assignment we need to answer some relevant questions about our final project.

What will it do?

Twister is a wifi controlled small lego rotating cube with integrated application, it can connecting each other physically to create a control 3/4/5/6/7 axes robot arm, it can also be used to automate original lego pieces !

It can rotate on one face, change color,connect phisically by a lego original block, wifi connect automatically with other twister cube. Each twister cube can be a Server or client by click a button. You can control via smartphone, PC, tablet simply connect to his wifi network.

Who’s done what beforehand?

RERO - Cube Servo - Modular type robotic servo

Developing Novel Extensions to Support Prototyping for Interactive Social Robots

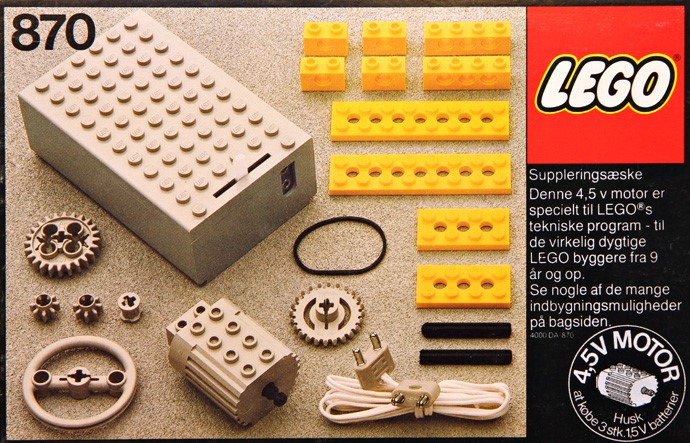

LEGO 1977 Technical Motor 4.5 v

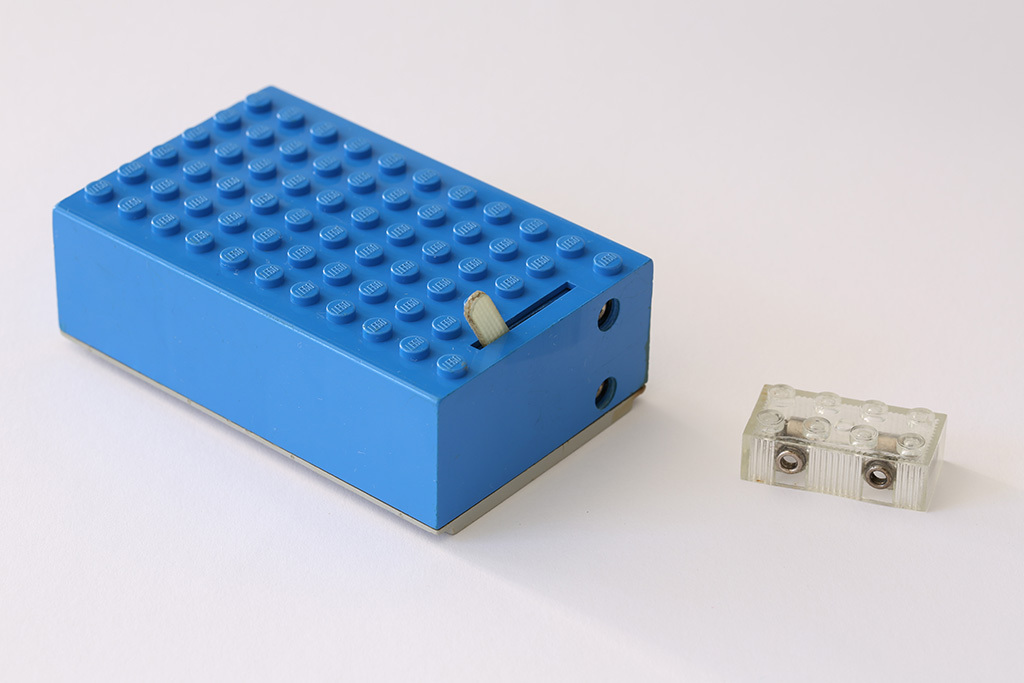

LEGO 1960 Technical Motor

What materials and components will be required?

- PLA Rolls blue, green, yellow and red

- white acrilic

- one micro-servo motors

- one ESP8266 rev A

- one (Esp8266 breakout board) RGB3.3-Servo5 pcb built with the experience of Output device week.

- one RGB led common catode

- one battery 3.3v

Where will they come from?

All electronics for RGB3.3-Servo5 pcb came from the fablab inventory (except LM3940 1-A )

I find a very good Pla rolls by ColorFabb

acrilic sheet and battery buyed from local store

ESP 8266 rev A by Olimex

How much will it cost?

- Printed parts ~3 Euros

- Servo motors HXT900 9g- 2.37 Euros

- white acrilic A4 format (sufficent for 2 cube)- 6 euros

- ESP8266 rev A - 5.50 Euros

- Esp8266 breakout board components - 4 Euros

- RGB led common catode - 0.20 euros

- Vinyl stikers - 2 euros

Total 23,07 euros

What parts and systems will be made?

Physical parts:

Lasercut - material: acrilyc case

Solidworks + Autocad (offset kerf)

3d Printed - material: PLA

Solidworks

- cube angle

- mechanism for cube rotation

- Laser cut acrilic external case

- RGB3.3-Servo5 pcb

Molding:

Solidworks

- Lego faces

Milling PCB:

Eagle

- breakout Esp8266 board

Software:

javascript - LUA - #C - HTML

- Web app interface integrated inside the memory of eaech ESP8266 - javascript

- LuaMcu firmware, with servo + RGB library call + Client SERVER switch.

- Wifi trasmission.

What processes will be used?

Lasercut - for external cube skeleton

3d printing - for cube angle,mechanism for cube rotation,Lego faces

PCB Production - breakout Esp8266 board

Vynil cutting - stickers for customizing the Companion looks and branding the box

Molding and Casting - For Lego Faces

What tasks need to be completed?

1 - improve the visual quality fo the web app

2 - Test : rotation movment

3 - Test : server-client connection between cubes

4 - Build at least 3 twister cube for perform Demostration

What is the schedule?

May 20-22 Modify Servo+RGB pcb for integrate 9v battery and switch button

May 22-26 Complete the App and add some beauty icons on web interface

May 26-30 To build 3 or 4 twister cube for create a demo test

May 31-June 10

How will it be evaluated?

The evaluation will be carried by making a demo test to demostrate the easy connection with server and client connection, set the color of each cube for undestand the movment and build some things with cubes and perform a demo test. A further tests will be showing during the fab11 for the amusing children and adults alike.