Introduction:

Object 1: Flower pot design in CAD(Designed in CAD)

Object 2: Process of Flower pot Machining on shopbot

Object 3: Actual maching on shopbot

Step 1: Using Windows XP,I have already installed Partwork 3D, for step 1: see the Modeling flowerpot in the CATIA then export .stl file open that .stl file in the Partwork 3D.Click on start-->3D Partwork

Figure.1

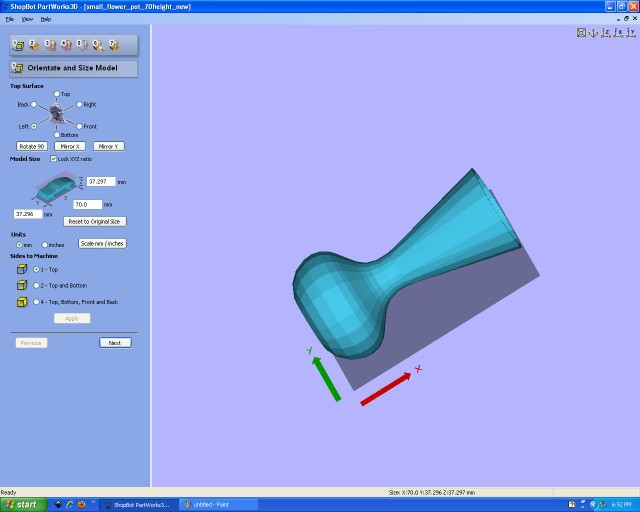

Step 2: set the Orientation and size of the model.Here Orientation is Left so according to that i will set the wooden block on the shopbot bed. x=70,y=37.29,z=37.29,I want all diamention unit in mm with TOP view.

Figure.2

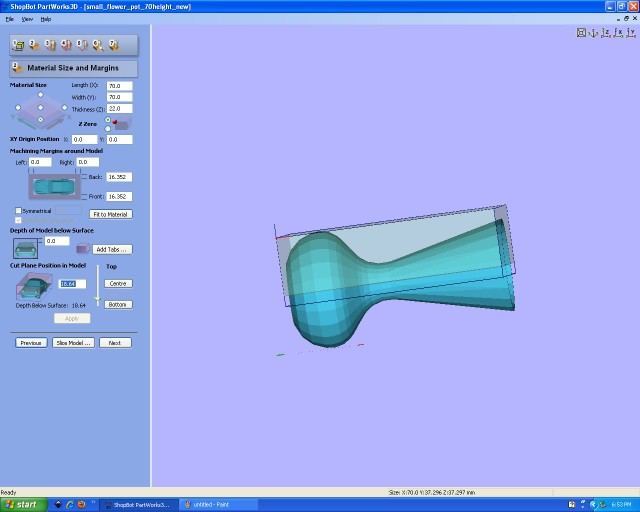

Step 3: Here we can set the material specification that i am going to clamp on the shopbot.I entered all diamention and margins with proper depth of cut because I am machining only half portion of the flower pot for mold and cast.

Figure.3

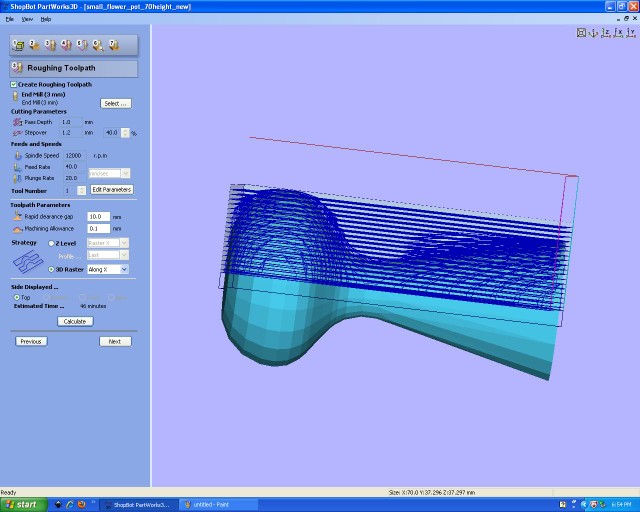

Step 4: Here step 4. Shows the actual object machining with roughing toolpath

Figure.4

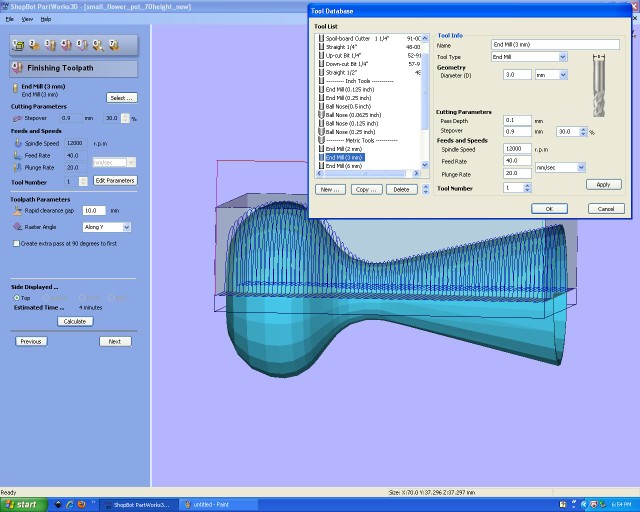

Step 5: Select the milling tool that we are using here for milling and set its parameter like passdepth, stepover,Speedrate,feedrate,Plungerate

Figure.5

Step 6: Then assign the finishing toolpath, and set finishing parameter as shown in following image.

Figure.7

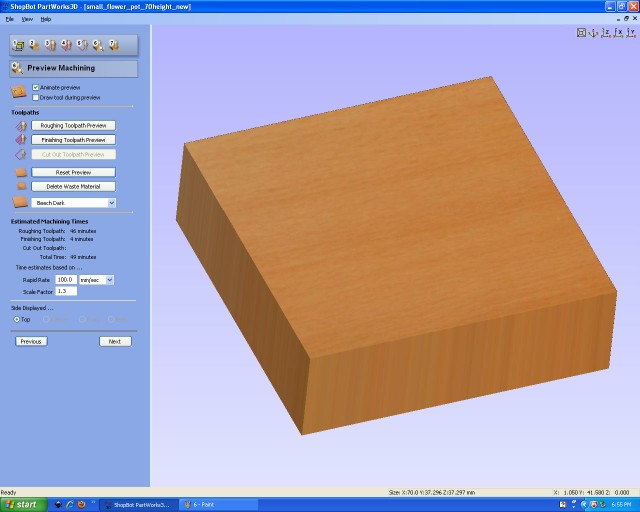

Step 7:At this stage we can preview the machining processes.click on Reset preview.

Figure.8

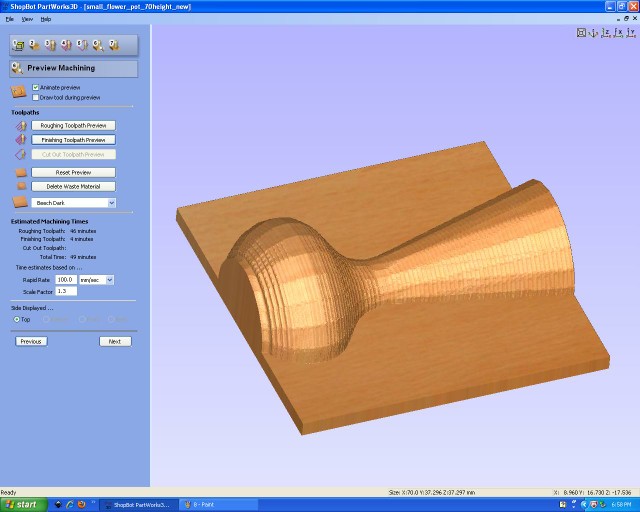

Step 8:Following image shows the Roughing process of flowerpot.

Figure.9

Step 9:then finishing process on shopbot to give finishing to rough object.

Figure.10

Step 5: Then we can save this roughing and finishing processes in shopbot acceptable file format.

Figure.11

Figure.12

Figure.13

Figure.14

Step 7:

Figure.15

Figure.16

Figure.17

Figure.18

Figure.19

Cutting file

.stl Flower pot file

Partwork 3D mold

Shopbot file