The Pressure Sensor:

Bend / Load / Flex sensors are quite expensive, and we needed one for each end unit so we decided to make them ourselves. I made the sensors and Ida wrote the code for them.

I followed again some instructables:

DIY Bend Sensor (Using only Conductive Bags and Masking Tape) How to Make Bi-Directional Flex Sensors

But after some tests I finally came up with my own method wich is very simple to make and has very nice results (reliable and consistent sensors).

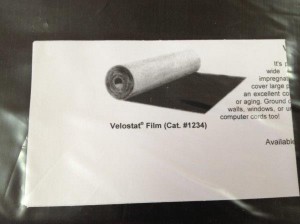

The “secret ingredient” in the sensor recipe is an inexpensive conductive material: velostat!

Velostat is a very low cost, extra-wide conductive sheet for electric field shielding.

So – The materials I used:

- Velostat

- Copper foil (we had some in the lab)

- Wires

- Masking Tape

The making:

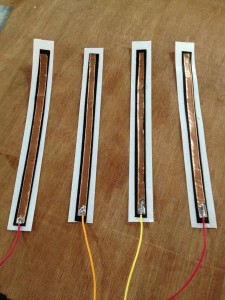

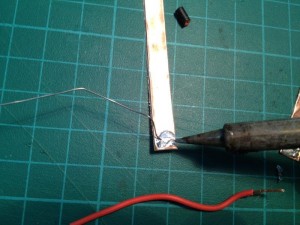

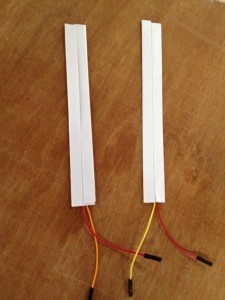

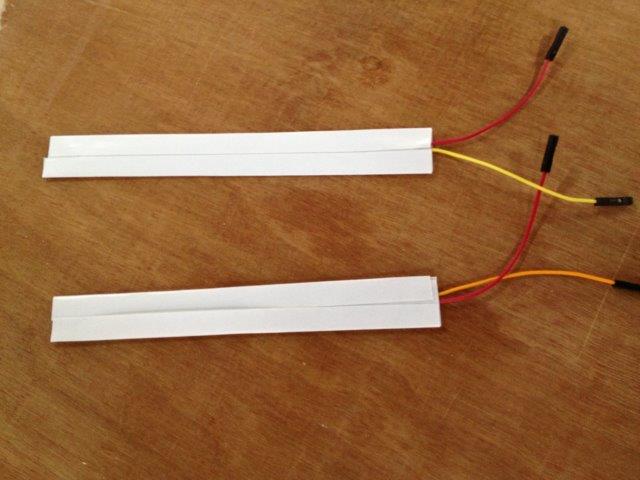

- First I cut 10 copper foil strips, I exposed 10 wires ends and soldered each wire to an end of a copper foil stripe.

- I cut 10 velostat stripes (a bit wider then the copper foil) and 5 more stripes that are two times wider from the first ones. I attached the 10 cooper foile stripes to the 10 velostat stripes (the copper foil has a copper on one side and the other side is sticky)

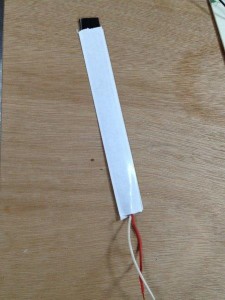

- I cut 10 stripes of masking tape (a bit wider then the velostat stripes) and attached the velostat and copper stripes to it (the velostat part is facing the masking tape)

- I folded the wide velostat stripes in two and put two stripes from stage 3 on each side of it (like a sandwitch) with the copper side facing the folded velostat.

- I wrapped this sandwitch with some more tape. and that’s it!

See it in action (with some versions of the sensor I was playing with: