Weekly Assignments

Final Project

About Me

Weekly Assignments

Final Project

About Me

Weekly Assignments

Final Project

About Me

Weekly Assignments

Final Project

About Me

Gamified Manufacturing Cell for Industrial Engineering Education

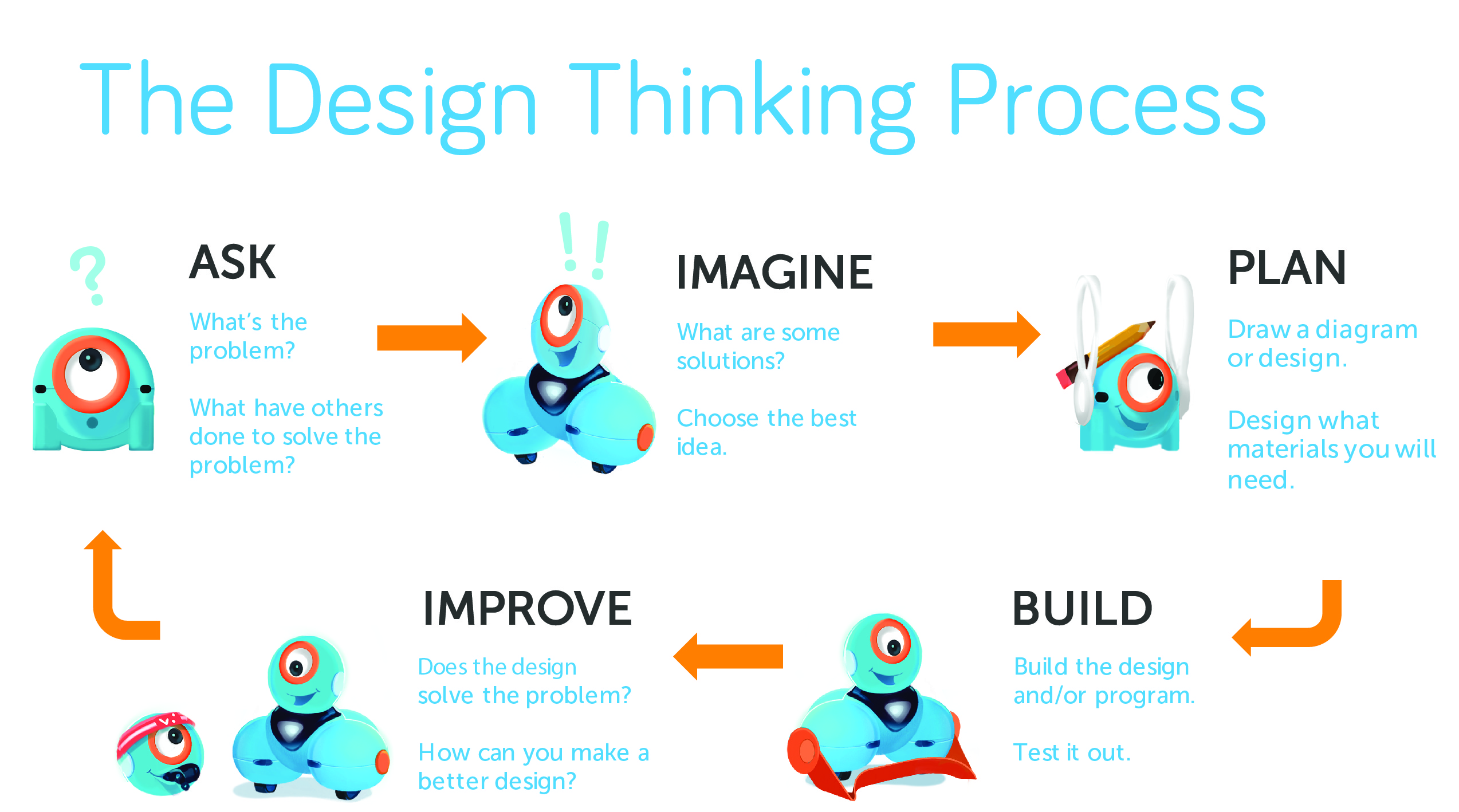

This project originates from the need to make abstract engineering concepts tangible for a diverse audience. Traditional teaching of Lean Manufacturing is often limited to theoretical tools such as spreadsheets, diagrams, and static simulations. This creates a disconnect between product design decisions and their real impact on production speed, efficiency, and system performance.

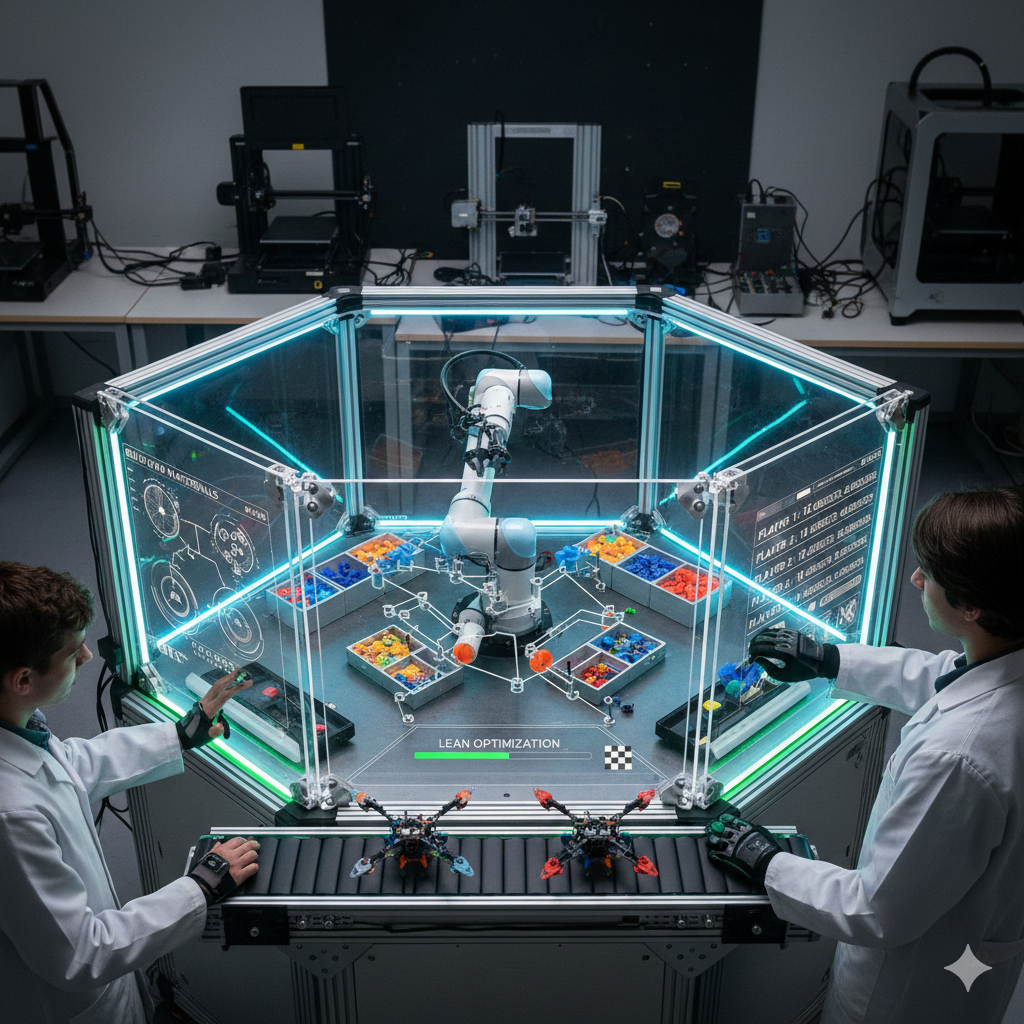

Fab Labs typically focus on the fabrication of individual objects. This project intentionally shifts the focus toward designing and fabricating the system that manufactures objects, allowing learners to experience industrial engineering concepts through direct interaction with a functional manufacturing environment.

Target Users: Industrial engineering students and curious learners aged 10 years and above.

Lean Manufacturing is frequently taught in a theoretical manner, making it difficult for students to understand how design, layout, and process decisions directly affect mass production efficiency. This project addresses that gap by combining physical fabrication, automation, and real-time performance feedback.

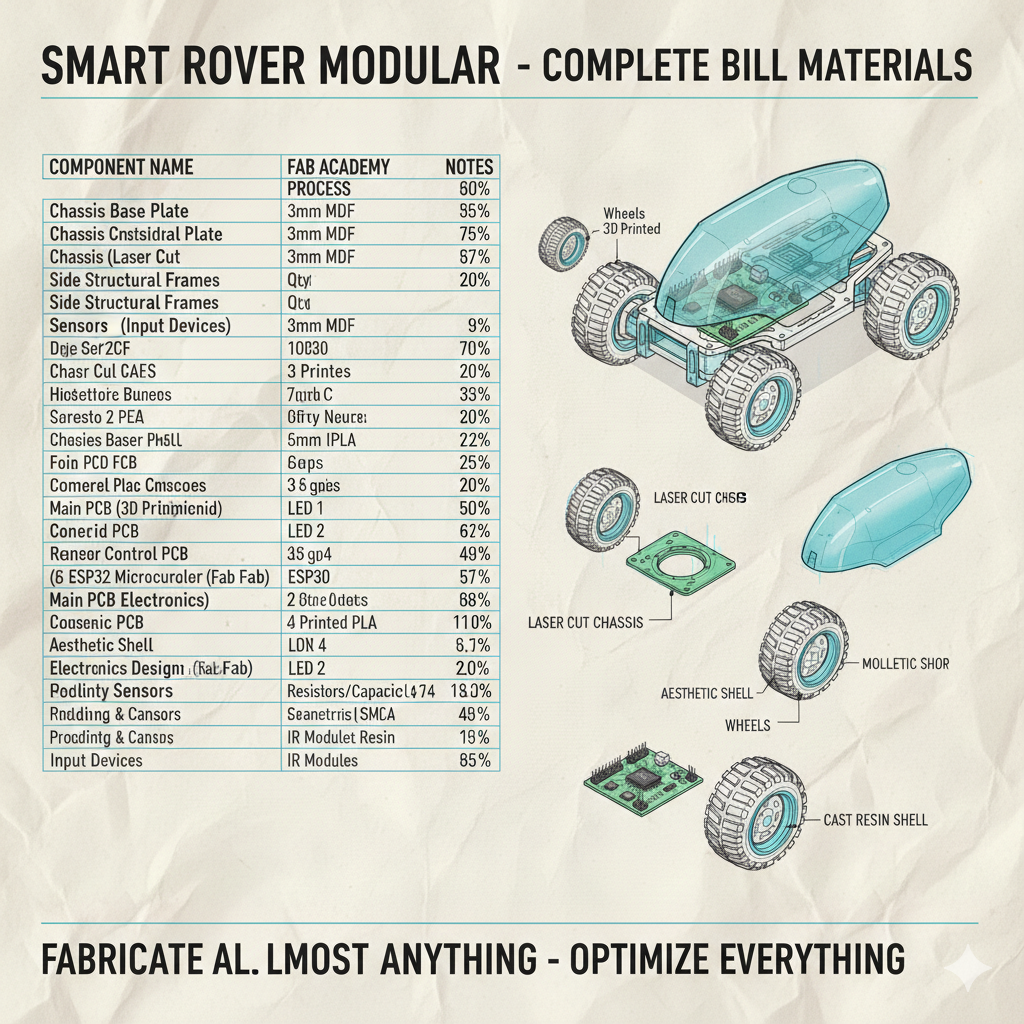

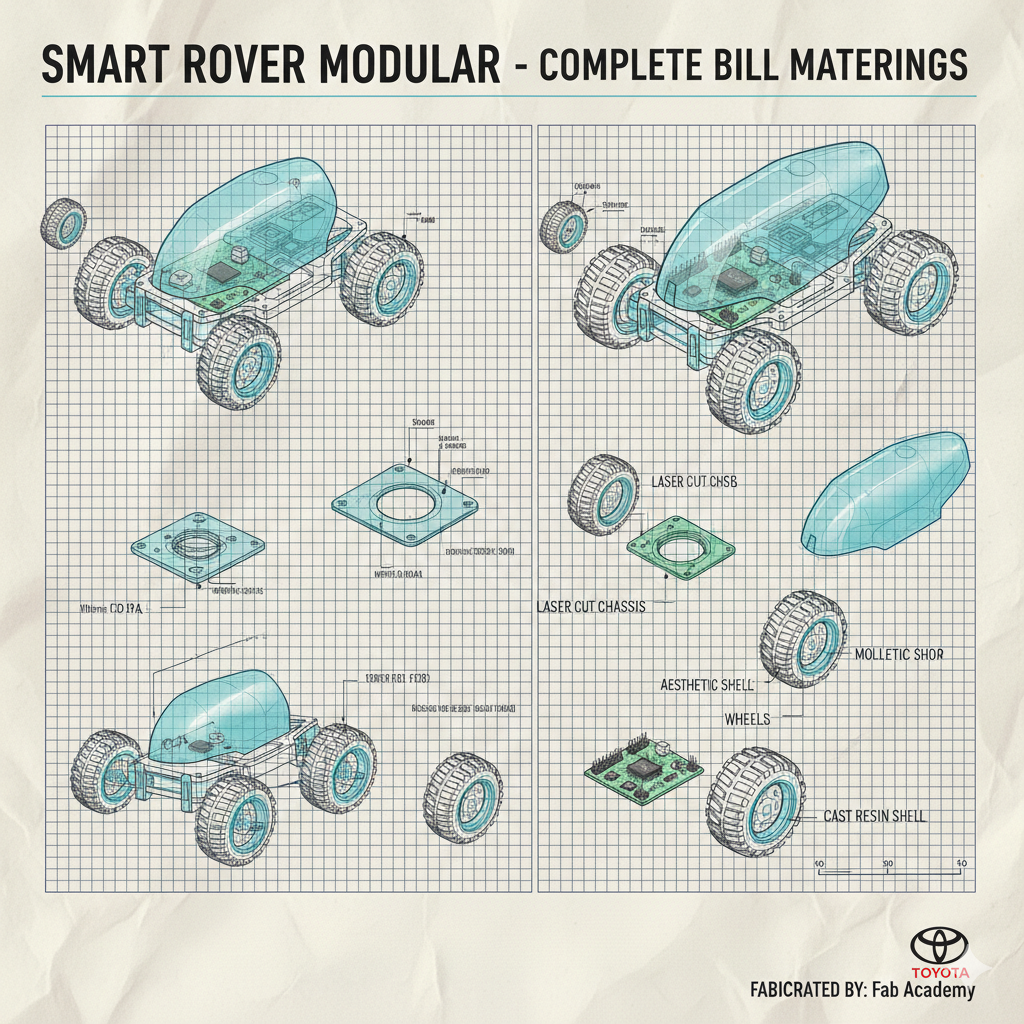

The core insight guiding the project is that efficiency is not about going faster, but about eliminating what does not add value. Based on this insight, the project aims to design a manufacturing workstation that uses gamification and real-time data to teach optimization of assembly times for a modular technological product.

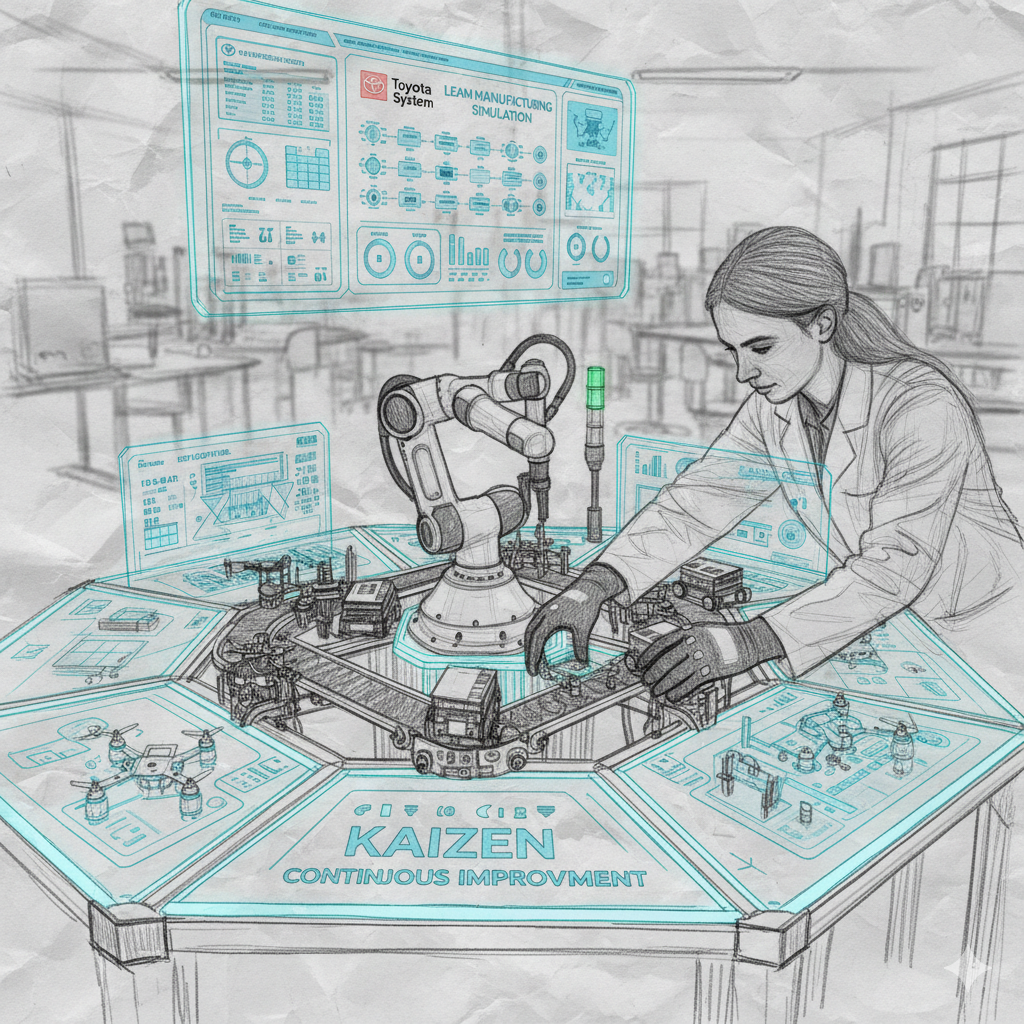

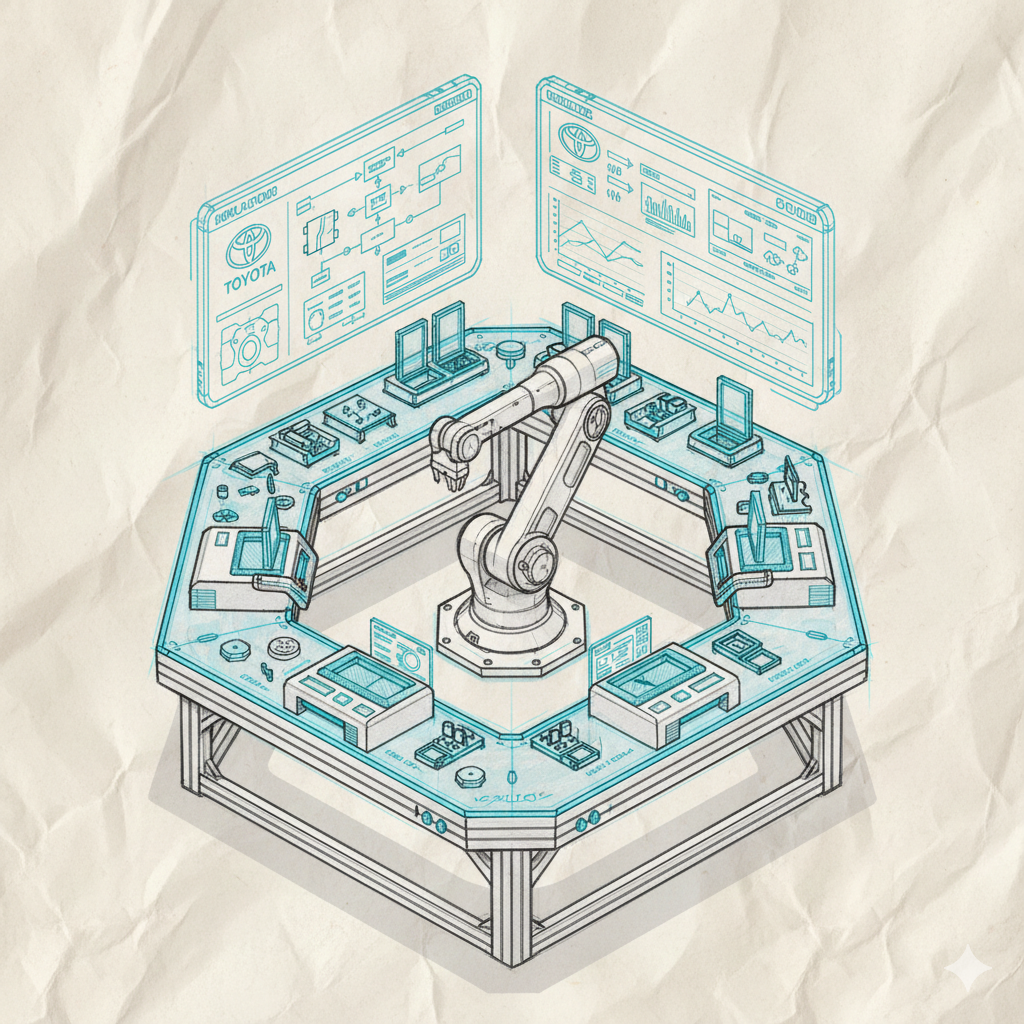

The hexagonal manufacturing cell forms the physical and conceptual foundation of the project. It functions as a STEAM learning module that integrates digital fabrication, electronics, automation, and industrial engineering principles.

The hexagonal geometry was selected for functional reasons: it enables 360-degree ergonomics, clear visualization of material flow, and reduction of unnecessary operator movement. Each face of the cell supports a specific function such as assembly, material input, inspection, automation, or interface interaction.

The structure is fabricated using CNC machining with 15 mm plywood and press-fit joints. The lower level houses power supplies, controllers, and cable management, while the working surface includes laser-engraved Kanban areas that enforce Lean organization and visual management.

An integrated Andon system provides immediate visual feedback to the user. Green indicates normal operation, yellow indicates transition or waiting states, and red signals errors or production stoppages. This reinforces industrial best practices and connects time performance with visual cues.

The robotic arm is the core automation component of the Smart Lean Cell. Its role is not to replace the human operator, but to regulate production flow by acting as the pacemaker of the system. From a Lean perspective, the arm enforces Just-In-Time delivery of components.

The arm is designed as a serial articulated mechanism with three to four degrees of freedom, fabricated primarily through 3D printing. It is mounted at the geometric center of the hexagonal cell to ensure equal reach to material containers, assembly area, and conveyor interface.

A custom PCB controls the robotic arm, integrating a microcontroller, motor drivers, power regulation, and expansion connectors. The control logic follows a state-based model, ensuring the arm operates only when the workstation requires a new component.

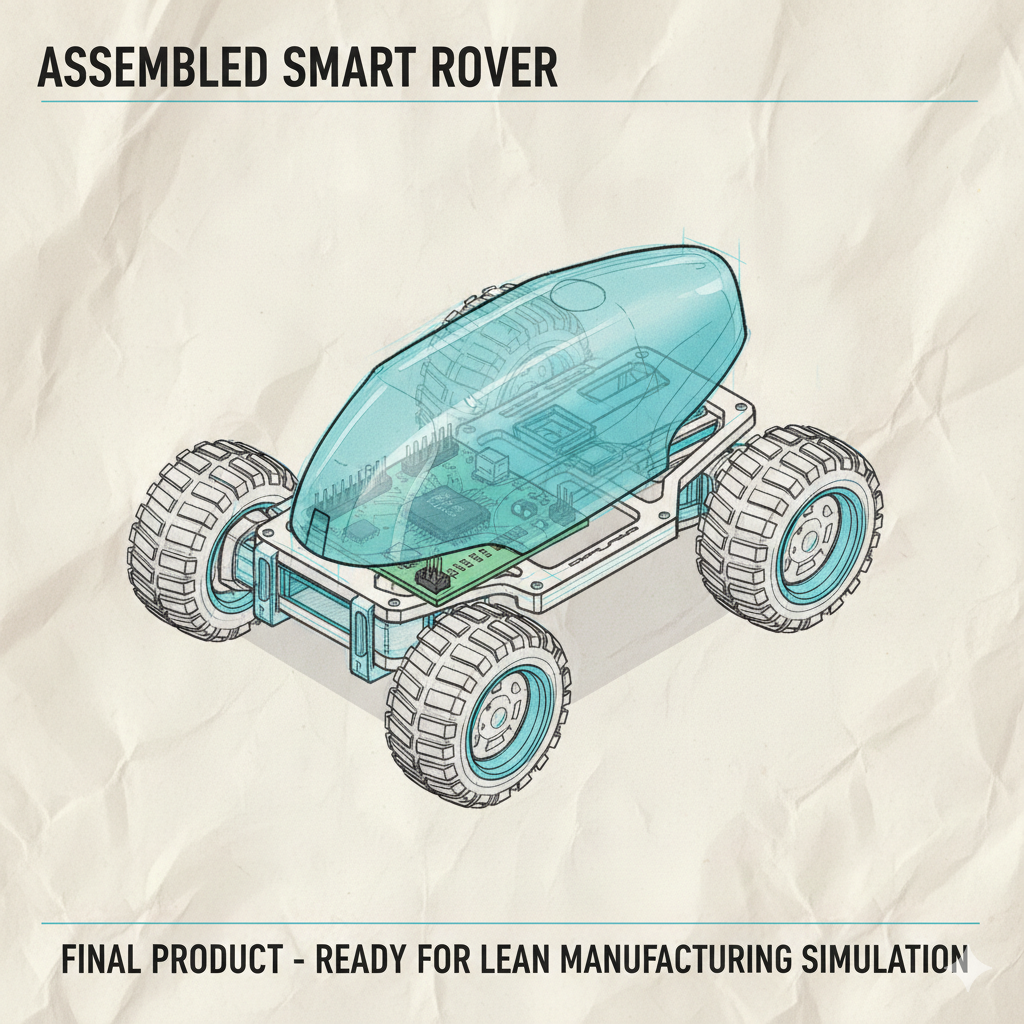

Upon completion of these phases, the project results in a fully fabricated manufacturing cell with an integrated robotic arm. Together, these systems create a coordinated machine capable of teaching Lean Manufacturing through direct interaction, measurement, and iterative improvement.

These phases establish the physical and functional foundation required for subsequent integration of the conveyor system, performance dashboard, and full gamified learning experience.